Effect of xanthan gum on the quality of low sodium salted beef and property of myofibril proteins

Zirui Zho,Shujie Wng,Dyu Li,Yjun Zhou,∗College of Biologicl nd Agriculturl Engineering,Jilin University,Chngchun,130025,Chin

bDepartment of Food Science and Engineering,Jilin University,Changchun,130062,China

Keywords:

Low sodium

Myofibril proteins

Salted beef

Xanthan gum

ABSTRACT

The effects of xanthan gum(0% and 0.3%)on the quality of low sodium(2.0%,2.4%,2.8%,3.2%,3.6% and 4.0%)salted beef and property of myofibril proteins(MP)extracted from salted beef were researched.Changes in the salting absorptivity,cooking loss,shear force,color and sensory analysis showed that xanthan gum had a positive effect on the quality of salted beef with low salinity(2.0%,2.4% and 2.8%).MP of salted beef treated with xanthan gum had higher solubility,lower hydrogen bond than that without it(P<0.05).The decrease of surface hydrophobicity and intrinsic fluorescence intensity indicated that the chromophore of protein was brought into a hydrophobic environment in the presence of xanthan gum.The electrophoresis showed that xanthan gum could improve the concentration of myosin heavy chain,paramyosin and actin after tumble-salting.The data suggested that salted beef and its MP treated with xanthan gum and 2.8% salt(XS3)had the best properties.Together,xanthan gum could be considered as a sodium salt substitute for the development of low sodium meat products.

1.Introduction

Meat industries increase the salt content in order to obtain better quality and maximize profitability[1–3].Beef is commonly salted because sodium chloride has a number of various functions,such as increasing the shelf life,providing the characteristic flavor,and creating the desired texture. Previous studies have pointed that the action of salt is likely due to the contribution of negative charges from the chloride ions to the myofibril proteins[1,4].Myofibril proteins are the most important function protein related to the meat quality.Various researchers have reported that the conformational change of MP has been associated with meat protein functionality[5,6].Furthermore,changes in solubility of MP in turn influence water-binding capacity and texture that is generally improved with salt[3].Although salt has several excellent functions in meat products,many organizations advocate to reduce the addition of salt in meat.This is because the hypertension and cardiovascular diseases are attracting more and more attention,and approximately a quarter of adults are suffering from these diseases[7].The direct relationship between excessive sodium intake and increased incidence of hypertension has been proven.Meanwhile,a great deal of studies shown that sodium,which emerges from salt,not only affects blood pressure but also poses an effect on body weight and other nutrient levels[8].Consequently,there is a significantly growing demand of the diet with reduced salt levels,while low sodium treatment still effectually balanced many factors such as producing juicy and tender meat.

In order to reduce the content of salt in meat products,previous researchers have studied several methods, such as reducing the salt content directly,replacing sodium chloride with chloride salts,adding flavor enhancers, changing the physical structure of sodium chloride and so on[3].Xanthan gum,a kind of anionic polysaccharide,can improve the water holding capacity and elasticity and reduce the cooking loss and hardness of meat products.These characteristics have attracted the attention of researchers,and it was used in recombinant meat products[9].In addition,the interaction between proteins and polysaccharides has been proved by several researchers,which is closely related to the gel and protein characteristics[10].However,there are few studies concerned about the effect of xanthan gum on the salted beef,and the combination effect of xanthan gum with various low sodium salting solutions needs to be observed to determine the threshold of low sodium salting solution,so that the salted beef has the same good yield,color and sensory acceptability as low sodium salted beef.Therefore,the main purpose of this study was to determine the effect of xanthan gum in combination with various low sodium salting solution on the salting absorption,cooking loss,shear force,color,sensory acceptability of low sodium salted beef and the solubility,hydrogen bond,surface hydrophobicity,intrinsic fluorescence intensity,electrophoresis of MP,and to determine the minimum amount of low sodium salt that could be used to produce salted beef without affecting the quality.

2.Materials and methods

2.1.Sample preparation and salting

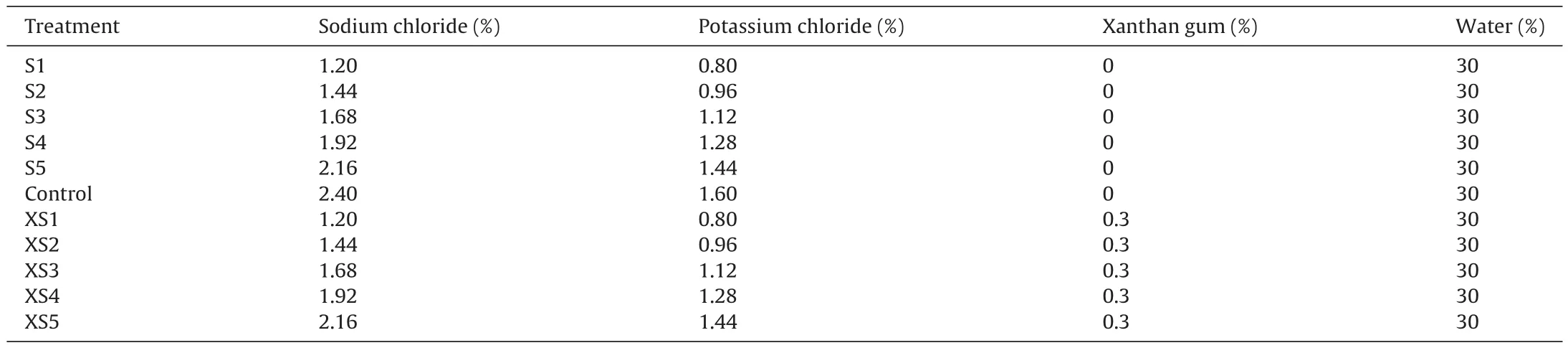

Beef buttock meat(hindquarter)was produced by a local company(in Changchun,Jilin,China)for all investigations.The frozen meat was thawed overnight at 4◦C before use.All visible fat and connective tissues were carefully removed,and each muscle was cut into slices approximately same as weight and size(100g and 80mm×40mm×20mm by length, width and thickness).Samples were then stored at 4◦C and marinated within 3h.The average pH value of meat samples was 5.8–6.0.Salting treatments included different concentrations of NaCl(China Salt,China,Beijing),KCl(Tianyu Shihua Corp.,China,Henan),xanthan gum(Qianzhi Food Corp.,China,Henan)and water.All products’salting solution was shown in Table 1.The control treatment was prepared with 2.4%(m/m)sodium chloride,1.6%(m/m)potassium chloride,30%(V/m)water and 100g beef.The S groups(S1-S5)contain various levels of sodium chloride and potassium chloride.The other 5 salted meat(XS1-XS5)were salted with 0.3%(m/m)xanthan gum and various levels of sodium chloride and potassium chloride.Sixty-six chunks of 80mm length×40mm width × 20 mm thick were obtained from 20 buttock muscles(right and left muscles were selected at random).Eleven kinds of salting solution treatments were injected into beef chunks,and they were vacuum-tumbled(GR-30,Zhucheng Ruiyang machinery corporation, Shandong,China)clockwise for 3h(tumbled for 10min,intermittent for 20min)at11r/min,0.04MPa,4◦C individually.The experiments were performed in 3 batches(6 beef treatments per batch).Between each treatment,the vacuum tumbler was cleaned and cooled to 2◦C.The samples were vacuum packaged and stored at 4◦C after treatment,then analyzed within 48h.

2.2.Quality of salted beef

2.2.1.Salting absorptivity

After vacuum tumbling,beef was taken out from the tumbler and gently blotted out excess brine prior to weighting.The weight difference of beef before and after tumbling was recorded as the salting absorptivity.

2.2.2.Cooking loss

The beef samples were removed from tumbler and cut into approximately same weight and size (5g,20mm×20mm×20mm).Each sample was wrapped in cooking bags,cooked at 98◦C for 10min,cooled off with running water and stored at 4◦C for 120min.The residual moisture was wiped off with filter paper before reweighing.Cooking loss was calculated as a percentage based on the raw beef weight,with 6 replicates from different pieces.

2.2.3.Shear force

Tenderness was determined using a RH-N50 Meat Tenderness Tester(Guangzhou Runhu instrument Corporation,China).The core of each treatment(12.7mm×20mm,by diameter and height)was cut out parallel to the muscle fibers direction.Samples were sheared off using a 5 N load transducer, with a speed of 50mm/min.The force was perpendicular to the muscle fibers.Each strip was sheared off once.Shear force(N)was recorded as the maximum peak force of each sample.The measurements were carried out in sextuple to guarantee the accuracy of results.

2.2.4.Color

Color was measured by Spectrophotometer(WSF,Wuguang,Shanghai,China)with a 10◦standard observer and a D65 illuminant,after exposing the muscle surface for 15min blooming time.The cylindrical slices(about 2mm height)were taken from each beef and determined immediately.Each sample was rotated 120◦in one direction to get 3 sets of data(0◦,120◦and 240◦).CIE-LABL*,a*andb* values were determined as indicators of lightness,redness and yellowness.The treatment was performed 3 replicates.

2.2.5.Sensory analysis

Sensory characteristic of beef treated by various salting solution were evaluated by 10 panelists.All panelists had 3–6 years of experience majoring in food science.After cooking,meat samples were cut into 15mm×15mm×15mm cubes and assessed by panelists.A9-point hedonic scale(1=dislike extremely,5=neither like nor dislike,9=liked extremely)was used to evaluate the overall acceptability of the samples by considering appearance,aroma,texture and flavor[1].To avoid biasing responses, each panelist was provided with water and plain crackers for palate cleansing before tasting samples.

2.3.Preparation of myofibril proteins

MP was prepared according to a method with some modifications[11].Eighty grams bovine buttock meat samples within each treatment were minced,mixed with 4 volumes(m/V)of rigor buffer(0.1mol/L KCl,2mmol/L MgCl2,1mmol/L EGTA,and 10mmol/L Na2HPO4/NaH2PO4,pH 7.0)and homogenized twice by a FJ200-5H blender(Shanghai Specimen and Model Factory,Shanghai,China)at 7000r/min for 30s each with an interval of 1min in ice bath.Then the myofibril suspension was passed through a piece of gauze,and centrifuged(TGL-16GR,Anting,Shanghai,China)at 4◦C,9800r/min for 10min.After discarding the supernatant,pellets were resuspended under the same conditions above.The last step(homogenization after centrifugation)was repeated 3 more times.The supernatant was discarded and the pellet was mixed with 4 volumes of 0.1mol/L NaCl,homogenized for 1 min,centrifuged at 4◦C,9500r/min for 10min.This step was repeated twice to collect the protein pellet.Myofibril pellets were kept on ice and analyzed within 48h.

2.4.Physicochemical property and structural change of MP

2.4.1.Solubility

Desired amounts of MP were weighted and added with 0.6mol/L NaCl,50mmol/L phosphate buffer at pH 6.25,and the protein concentration was adjusted to 2.5mg/mL by the Biuret method[12].Then MP salt suspensions were incubated at 4◦C for 1h.After that,all samples were centrifuged at 4◦C,8000r/min for 15min,and the protein liberated in the supernatant was measured.Protein solubility was defined as the protein concentration in the supernatant divided by the protein concentration of the original myofibril suspension.

Table 1Beef salting treatments.

2.4.2.Surface hydrophobicity

Surface hydrophobicity of myofibril was measured using bromophenol blue(BPB)[13].Specifically,MP was homogenized(2800r/min,30s)in 0.02mol/L phosphate buffer at pH 7.0,and the protein concentration was adjusted to 5mg/mL.Then 1mL protein solution was added with 200μL BPB(1mg/mL)and mixed well.Samples and control were incubated in a shaking bath at room temperature for 10min and then centrifuged at 8000r/min 10min.The absorbance of the supernatant(diluted 1/10)was measured at 595nm with UV-8000 spectrophotometer(Shanghai Techcomp Instrument Co.,ltd.,China)using phosphate buffer as blank control.The amount of BPB bound is calculated by the following formula(1):

whereA1means the absorbance at 595 nm of control;A2means the absorbance at 595nm of each sample.

2.4.3.Hydrogen bond

The hydrogen bond content was determined according to Wu et al.[14]with some modifications.The protein solution(3mL)of 5mg/mL was added with 0.5mL S1 solution(20mmol Tris,1% sodium dodecyl sulfate SDS,pH 8.0),0.5mL S2 solution(0.5mol/L NaOH)and mixed well.Samples and control were incubated calmly at room temperature for 1h,and then centrifuged for 30min at 8000r/min.After adding 50% trichloroacetic acid(TCA)to the supernatant(0.6mL),TCA concentration of supernatant reached 10%.Prior to final centrifugation(2500r/min for 10min),the sample was placed at 4◦C for 15min.The precipitation was resuspended in a small volume of S2 solution,and the protein concentration was determinated.Hydrogen bond content was expressed as a percentage of the soluble protein concentration in the S1 divided by the protein concentration in the S2 solution.The corresponding phosphate buffer was used as blank control.

2.4.4.Intrinsic fluorescence

The determination of intrinsic fluorescence spectra was conducted according to Xu et al.[15]with slight modifications.A Shimadzu RF-5301 spectrometer with 5nm emission and excitation slit was used to scan MP(0.5mg/mL)which were suspended in 0.6mol/L NaCl solution.Emission spectra were set up between 300 and 400nm with an excitation wavelength of 295nm and a scanning speed of 1500nm/min.

2.4.5.Sodium dodecyl sulfate-polyacrylamide gel electrophoresis(SDS-PAGE)

The change of myosin dissociation was pretty important for meat quality.To measure if different salting treatments influence myosin dissociation in beef after salting,MP was analyzed by SDSPAGE.Each MP was diluted to(3.0±0.5)mg/mL with 0.6mol/LNaCl solution.The protein samples were mixed with 5×buffer(containing 2mL distilled water,300μL 1mol/L Tris-HCl(pH 6.8),0.005g bromophenol blue,0.1g SDS,2.5mL glycerol,and 250μL DTT)at a volume ratio of 4:1.These mixtures were heated at boiling water for 5min and then 10μL of each sample was loaded onto a polyacrylamide gel including a 10.5% separating gel and a 5% stacking gel.After electrophoresis with a mini-vertical apparatus(Beijing Liuyi,Inc.,China),the gels were stained,decolored and photographed.

2.5.Statistical analysis

The determinant was performed at least 3 replicates,and the results were expressed as the mean±standard errors(SE).The differences between means of values among the 11 different treatments were assessed by ANOVA one-way using the SPSS Statistics program 21.0(SPSS Inc.,Chicago,Illinois,USA).Significant differences(P< 0.05)between means were identified using Duncan’s multiple range test.

3.Results and discussion

3.1.Salted beef quality

The effect of salting solution composition on the quality of salted beef was shown in Table 2.When the salinity was within the range of 2%–4%,with increasing salinity(from S1 to control),the salting absorptivity of beef gradually increased from(17.11%±0.89)% to(29.69%±1.76)%(P<0.05).However,in another salting solutions with xanthan gum,the salting absorptivity of beef increased with increase in salinity up to 2.8%(XS3)but with further increase in its salinity lower salting absorptivity was observed.The salting absorptivity of XS1,XS2,XS3 treatments was elevated remarkably compared to S1,S2,S3 treatments,respectively(P<0.05).This probably because xanthan gum interacted with free water through anionic sulfate groups[16].According to Bak and Yoo[17],intrinsic viscosity of xanthan gum solution decreased with the increase of NaCl concentration,which is conducive to diffusion absorption.Whereas no significant difference was found when comparing XS4 treatment with the S4 treatment,and XS5 treatment was decreased significantly compared to S5 treatment(P<0.05).This decrease might be associated with a low diffusion of salting solution into beef at the highest salinity(3.6% and 4%).

As salinity increased from S1 to control,cooking loss and shear force decreased as shown in Table 2.The values of cooking loss decreased from(37.62±3.84)% to(26.67±2.82)%,and the shear force of beef decreased from(38.72±3.94)N to(23.88±2.17)N.No significant differences of cooking loss were observed among the treatments with or without the addition of xanthan gum.A significant decrease(P<0.05)in shear force was observed in the XS1 and XS3 treatments when compared to the S1 and S3 treatments.The change in shear force was because xanthan gum entrapped a large amount of water by forming the network[18].

Salting with tumbling affects the meat color by changing the osmotic pressure and oxidizing the ferritin[19].The results ofcolor are presented in Table 2.TheL*value anda*value were significantly affected(P<0.05)by the addition of xanthan gum and different salinity.With the increase of salinity,theL*values of meat displayed a significantly decrease(P<0.05),which produced darker meat(from S1 to control).In addition,XS1 and XS2 treatments exhibited lowerL*values compared with the S1 and S2 treatments,respectively.While the other 3 treatments(XS3,XS4 and XS5)presented higherL*values compared with S3,S4 and S5 treatments,respectively.The higherL*values of XS3,XS4 and XS5 treatments probably due to the increasing light scattering of xanthan gum residue in the sample surface[20].For thea*value,it decreased gradually from 27.09±1.04 to 24.20±1.00 with the increase of salinity(from S1 to control).It decreased further when salting solution containing xanthan gum at lower salinity(XS1,XS2 and XS3)compared with S1,S2 and S3treatments,respectively.The decrease ina* value with xanthan gum treatment may be explained by the decrease in oxygen pressure,which inhabited the conversion of the myoglobin.Theb*value of XS2 and XS3 treatments was slightly higher(P<0.05)than S2 and S3 treatments.But no significant differences(P<0.05)were observed among the other treatments.

Table 2The instrumental properties of beef affected by salting treatments.

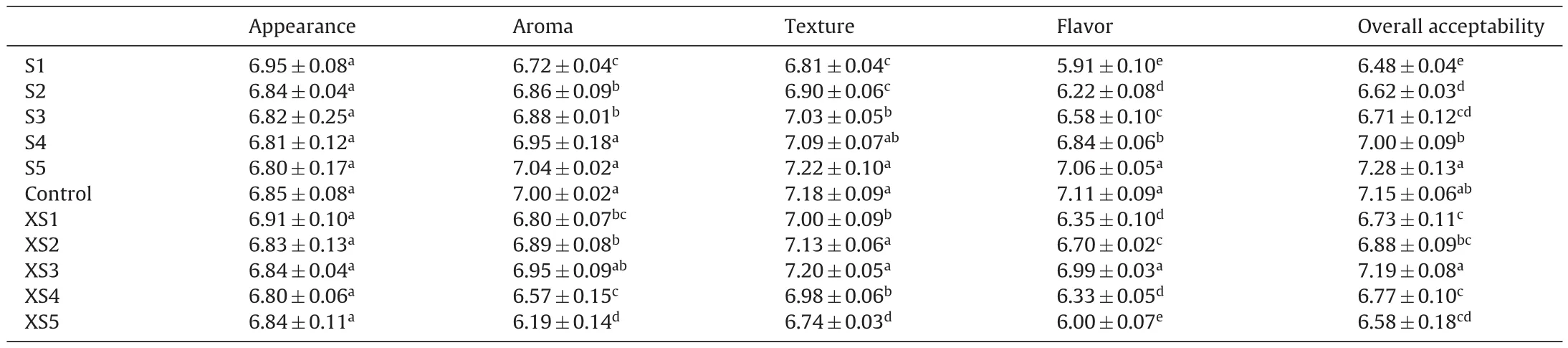

Table 3 showed the results of sensory evaluation in response to the different treatments.There was no significant difference about appearance among each treatment(P>0.05).When salinity was within the range of 2%–4% without the addition of xanthan gum, the scores of aroma,texture, flavor and overall acceptability gradually increased with increasing salinity(P<0.05).A significant difference(P<0.05)in texture, flavor and overall acceptability were observed in the xanthan gum treatments.Specially,xanthan gum at lower salinity(XS1,XS2 and XS3)improved the texture, flavor and overall acceptability of salted beef,suggesting that it was more tender and juicer than S1,S2 and S3 treatments.In addition,XS4 and XS5 treatments got a lower score for aroma,texture, flavor and overall acceptability than S4 and S5 treatments,which could be explained by the low salting absorptivity causing the higher chewiness and lower moisture content of XS4 and XS5 samples(Table 2).In contrast,no significant differences were found between the XS1,XS2,XS3 and S1,S2,S3 in aroma.The overall acceptance scores of XS3 treatment was similar to the control and S5 treatments.

3.2.MP property

3.2.1.Solubility

The solubility of protein firstly was measured to investigate the effect of prosperity of MP with the addition of xanthan gum.As shown in Table 4,with the increase of salt concentration,the solubility increased rapidly from S1 to control(P<0.05).Interestingly,the solubility of MP was significantly affected(P<0.05)by the addition of xanthan gum(XS2 and XS3),which reached to 42.66%.This may be due to the interaction between salt and xanthan gum under tumbling conditions,which destroyed the xanthan gumwater binding and formed a rigid anionic polysaccharides-proteins helical conformation in a non-electrostatic way[21,22].Villamonte et al.[6]also showed that xanthan gum significantly inhibited the loss of protein solubility under high pressure.For the XS1 and XS4 treatments,no significant differences in solubility were observed compared with S1 and S4 treatments,respectively.XS5 treatment exhibited lower solubility when compared to the S5 treatment,which could be explained by the reduction of salting absorptivity.These findings indicated that xanthan gum with moderate ionic intensity(2.4%–2.8%)could improve the MP solubility.3.2.2.Surface hydrophobicity

Earlier studies found that xanthan gum inhibited the increase of surface hydrophobicity under high pressure[6].The effect of xanthan gum on the surface hydrophobicity under different treatments needs to be further explored.As shown in Table 4,except for S5 treatment,the binding value of BPB increased significantly with the increase of salinity(P<0.05),which is an indicative of non-polar amino acids exposure.However,these results seem inconsistent with other study[23].This mainly related to the fact that the beef for protein extraction was fully tumbled in our study,which contributes to the hydrophobic interactions and denaturation of protein.It is worth noting that the surface hydrophobicity of MP with the addition of xanthan gum was reduced compared with S groups at same salinity,even though the difference of XS1 and XS2 did not reach statistical significance.This reason may be that the hydrophobic groups were embedded into the molecule cavities by the interaction between proteins and polysaccharides under the action of tumbling and salting. Our results suggested that the structural modifications by tumbling promoted the specific interaction between protein and xanthan gum.

3.2.3.Hydrogen bond

The hydrogen bond content was determined to verify whether xanthan gum had an effect on hydrogen bond of proteins.As shown in Table 4,there was significant difference(P<0.05)in hydrogen bond content of MP made with the addition of different salinity and xanthan gum.The content of hydrogen bond decreased with the increase of salinity(P<0.05)due to the destroying of the salt bridge and unwinding helical tail[24].Research had revealed that H-bond cooperativity played an important role in the stability of α-helix[25].Xia et al.[26]observed that the content of α-helices decreased at 0.3mol/L NaCl.Zhang et al.[24]also showed that the secondary structure distribution of the paramyosin molecule changed from 100%α-helical in 0.1mol/L KCl to 100% β-sheet in 0.5mol/L KCl,which indirectly re flected the reduction of hydrogen bond.In addition,the presence of xanthan gum to the salted beef treatments(XS2 and XS3)resulted in the lower(P<0.05)content of hydrogen bond when compared to the S2 and S3 treatments.Thepossible reason was the interaction between anionic polysaccharides and proteins.Villamonte et al.[6]reported the increase of α-helices contents in the presence of xanthan gum.On the other hand,the use of higher salinity together with xanthan gum(XS4 and XS5)increased the content of hydrogen bond when compared to the treatments S4 and S5,which was possibly due to the lower salting absorptivity.The minimum level of hydrogen bond content was observed in XS3 treatment among the XS groups.Since the control,S5 and XS3 treatments have high sensory scores and low hydrogen bond content at the same time,we could conclude that the lower the hydrogen bond content,the higher the sensory score.

Table 3The sensory evaluation of beef affected by salting treatments.

Table 4The physicochemical properties of MP affected by salting treatments.

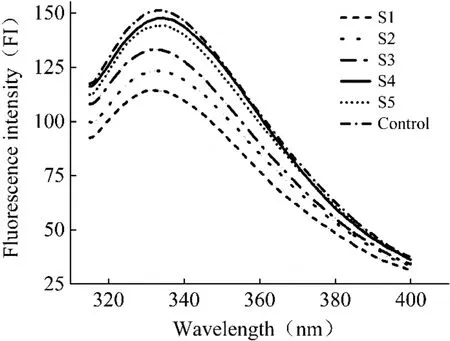

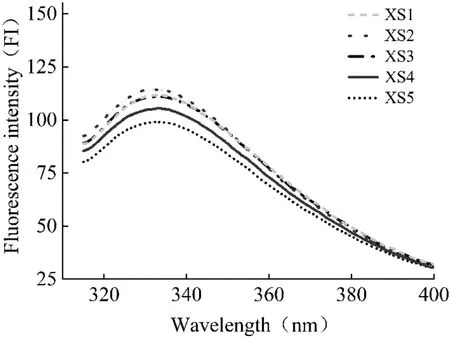

3.2.4.Intrinsic fluorescence

The fluorescence spectra of MP were shown in Figs.1 and 2.The excitation wavelength was set at 295nm(tryptophan only).The maximum magnitude of signal was observed at 333nm approximately,which was almost unchanged among all treatments.As illustrated in Fig.1,the fluorescence intensity of all samples showed a marked salt-dependent increase.The fluorescence intensity of MP declined in the presence of xanthan gum(Fig.2),demonstrating that the interaction between protein and xanthan gum changed the environment of tryptophan residues.At the same time,as the salinity increases,the fluorescence spectrum showed a small blue shift.It is likely that the MP and xanthan gum form aggregates with micelle characteristics,meaning the chromophore is faced inward of the aggregate.Villamonte et al.[6]assessed that the disruption of tertiary structure under pressure could be perturbed by xanthan gum.Perhaps the specific spatial structure from myosin rod tail or the myosin head of tertiary[27]was aggregated and folded in the presence of xanthan gum.

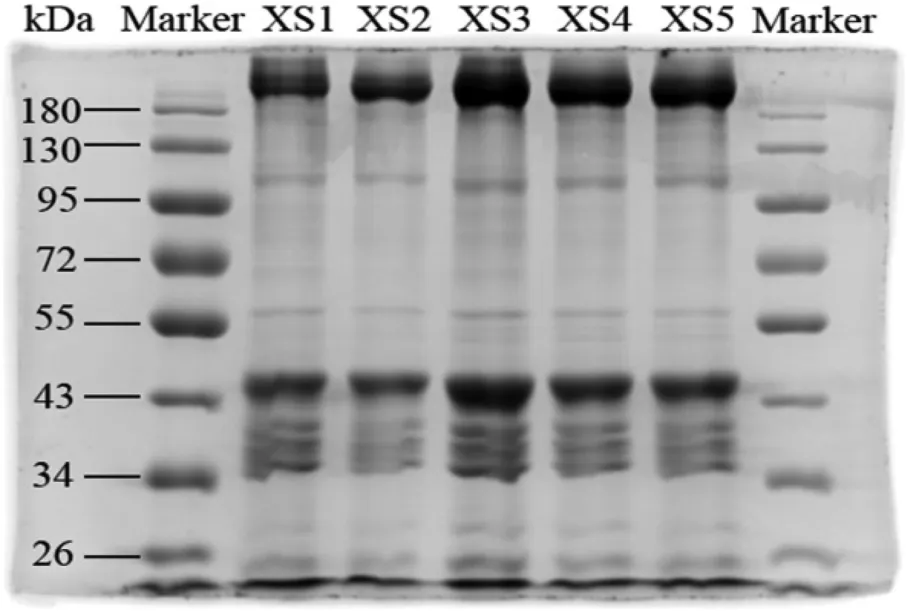

3.2.5.SDS-PAGE

Fig.1.The fluorescence spectra of MP at different levels of sodium chloride and potassium chloride.Control:2.4%NaCl,and 1.6%KCl;S1:1.2%NaCl,and 0.8%KCl;S2:1.44%NaCl,and 0.96%KCl;S3:1.68%NaCl,and 1.12%KCl;S4:1.92%NaCl,and 1.28%KCl;S5:2.16%NaCl,and 1.44%KCl.

The electrophoresis profiles of MP were shown in Figs.3 and 4.The characteristic fractions such as myosin heavy chain(MHC)(200kDa),paramyosin(100kDa)and actin(43kDa)were all detected in the MP.After tumble-salting by different salting solutions,the concentration of each protein was different.With the increase of salinity,the concentration of protein bands of the S2 and S3 treatments was decreased.In contrast to above-mentioned trends,the protein bands concentration was increased at S4,S5 and control.These results may be related to the dissolving-out amount of proteins from beef.Previous study reported that protein concentration in the supernatant increased more than fivefold at high ionic strengths(0.1–1.0mol/L NaCl)[28],which resulted in decreased protein concentration in beef after salting.However,the increase of protein concentration at S4,S5 and control most likely due to the cross-linking between protein molecules, which resulted in reduced dissolving-out amount of proteins from beef. In the presence of xanthan gum,no significant differences of electrophoresis profile between S groups and XS groups were observed,indicating that the addition of xanthan gum did not affect the composition of beef proteins after salting.Similar results were reported by other researchers[6,26].Compared with the gels without treatment with xanthan gum,the myosin components increased in the presence of xanthan gum,indicating that the cross-linking between xanthan gum and proteins prevented the diffusion of salt-soluble proteins into the salting solution.It is possible that the interaction between proteins and xanthan gum could improve the technological properties of beef after tumble-salting.

Fig.2.The fluorescence spectra of MP in the presence of xanthan gum at different levels of sodium chloride and potassium chloride.XS1:1.2%NaCl,0.8%KCl,and 0.3% xanthan gum;XS2:1.44%NaCl,0.96%KCl,and 0.3% xanthan gum;XS3:1.68%NaCl,1.12%KCl,and 0.3% xanthan gum;XS4:1.92%NaCl,1.28% KCl,and 0.3% xanthangum;XS5:2.16%NaCl,1.44% KCl,and0.3% xanthan gum.

Fig.3.The electrophoretogram of MP at different levels of sodium chloride and potassium chloride.Control:2.4%NaCl,and 1.6%KCl;S1:1.2%NaCl,and 0.8%KCl;S2:1.44%NaCl,and 0.96%KCl;S3:1.68%NaCl,and 1.12%KCl;S4:1.92%NaCl,and 1.28%KCl;S5:2.16%NaCl,and 1.44%KCl.

Fig.4.The electrophoretogram of MP in the presence of xanthan gum at different levels of sodium chloride and potassium chloride.XS1:1.2%NaCl,0.8% KCl,and 0.3% xanthan gum;XS2:1.44%NaCl,0.96% KCl,and 0.3% xanthan gum;XS3:1.68%NaCl,1.12% KCl,and 0.3% xanthan gum;XS4:1.92%NaCl,1.28% KCl,and0.3% xanthangum;XS5:2.16%NaCl,1.44% KCl,and0.3% xanthan gum.

4.Conclusions

The present results demonstrate that moderate salinity(2.8%)with xanthan gum can improve the salting absorption and sensory quality,and decrease the cooking loss,shear force anda*value of salted beef.For MP,xanthan gum reduced the surface hydrophobicity by decreasing the exposure of hydrophobic groups,and increased solubility with myosin concentration and decreased hydrogen bond.Thus,the amount of salt can be reduced while the quality of meat products can be improved by choosing moderate salinity with xanthan gum.Xanthan gum can be considered as a sodium salt substitute.Further research is required to evaluate the microbiological of meat products in the presence of xanthan gum to adapt the batch production of the food industry.

Declaration of Competing Interest

The authors report no declarations of interest.

Acknowledgment

This work was supported by the National Key Research Program of China(2016YFD0401501).

- 食品科学与人类健康(英文)的其它文章

- Peptide fraction from sturgeon muscle by pepsin hydrolysis exerts anti-inflammatory effects in LPS-stimulated RAW264.7 macrophages via MAPK and NF-κB pathways

- Chronic consumption of thermally processed palm oil or canola oil modified gut micro flora of rats

- Hypoglycemic polysaccharides from Auricularia auricula and Auricularia polytricha inhibit oxidative stress,NF-κB signaling and proinflammatory cytokine production in streptozotocin-induced diabetic mice

- Simultaneous determination of 15 pesticide residues in Chinese cabbage and cucumber by liquid chromatography-tandem mass spectrometry utilizing online turbulent flow chromatography

- Characterization of spoilage bacterial communities in chilled duck meat treated by kojic acid

- Purification,structural elucidation,and in vitro antitumor effects of novel polysaccharides from Bangia fuscopurpurea