The Experimental Advanced Superconducting Tokamak

Jiangang Li, Yuanxi Wan; the EAST team

Institute of Plasma Physics, Chinese Academy of Sciences, Hefei 230031, China

1. Introduction

New sustainable energy is urgently needed to meet the fastgrowing requirement for clean energy in this century. Nearly 80%of the world’s energy is still generated by burning fossil fuels,resulting in pollution and climate change.To realize long-term sustainable development, it is necessary to explore large-scale new energy sources that do not produce carbon dioxide (CO2), within the next few decades.

Fusion energy is a promising source of clean energy that could solve the issues associated with conventional energy generation,such as energy shortages and environmental pollution. Fusion has proved to be a potential candidate for safe, inexhaustible,and environmentally friendly energy. Fusion research started 60 years ago,and significant progress has been made.In the 20th century, the best fusion plasma performance was obtained using the tokamak approach [1], in comparison with other methods such as laser fusion and zeta (Z)-pinch. More than 16 MW of fusion power has been produced in the Joint European Torus (JET) tokamak [2], and the Japan-Torus-60 (JT-60U) tokamak achieved a fusion output-input ratio of Q >1 and a fusion triple product approaching burn-through conditions[3].Thus,the scientific feasibility of fusion has been clearly demonstrated by the global tokamak fusion community.

A fusion plasma temperature of about 100 million degrees Celsius is required for an efficient fusion reaction rate.High-intensity magnetic fields are applied to confine the hot plasma. To achieve real steady-state confinement, superconducting magnets are the most effective way to validate the engineering feasibility of a tokamak for fusion energy application. The design, construction, and successful operation of a fully superconducting tokamak was one of most engineering challenging tasks in the 20th century. Such a fully superconducting tokamak is urgently needed for the development of a future tokamak fusion reactor. The Experimental Advanced Superconducting Tokamak (EAST) was proposed in 1996 by the Institute of Plasma Physics, Chinese Academy of Sciences (ASIPP), and was approved as a major national science and engineering project by the central government in 1998. Construction of EAST began in October 2000 and finished in early 2006, with the first plasma in EAST being obtained in October 2006.This paper introduces the development and key technologies of EAST.

2. Project overview

EAST is the first fully superconducting tokamak in the world[4].The mission of the EAST project is to develop an advanced fully superconducting tokamak so as to establish solid scientific and technological bases for the future continuous operation of tokamak fusion devices. The main objectives of EAST are to ①demonstrate long-pulse divertor operation over 1000 s; ②realize high-performance high-confinement (H-mode) operation over hundreds of seconds; and ③address key physics and engineering issues for future fusion devices.

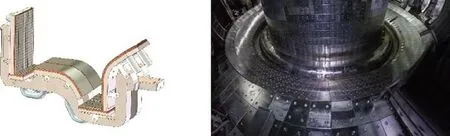

The major and minor radii of EAST are R=1.8-1.9 m and a=0.4-0.45 m, respectively. The toroidal field (TF) and maximum plasma current that are currently being achieved are Bt=3.5 T and Ip=1 MA, respectively. EAST can operate in lower single null,double null, and upper single null divertor configurations with a flexible poloidal field (PF) control system. The successful design and construction of EAST (Fig. 1), with its unique features, has led to the achievement of valuable scientific advances and technological developments during the past 20 years.

Fig. 1. The EAST device.

Superconducting magnets provide a very strong electromagnetic field in a tokamak,which is necessary to achieve high-performance plasma discharge. Nevertheless, the first attempts at these techniques affected the safe operation of the superconducting magnets, with very fast current ramping rates. This problem was solved by optimizing the plasma performance through effective control of the plasma parameters via the superconducting magnets, by means of advanced plasma shaping and flexible real-time feedback control. This scheme was significant for tokamak operation, which challenged the operation limits of superconducting magnets.

Advanced auxiliary systems are applied to effectively heat the plasma and control the plasma performance. EAST is the only device with four different major key heating and current drive(H&CD) methods, which provide continuous heating at a multimegawatt level. The successful technological development of continuous wave (CW)auxiliary systems represented a crucial transition from pulsed operating modes to steady-state operating modes,which are needed for a future reactor.

Active control of plasma-wall interaction, real-time wall processing, and heat- and particle-flux exhaustion under steady-state conditions are further crucial issues for future fusion reactors.The first actively cooled divertor, together with a built-in cryo-pump and real-time wall conditioning systems, has been developed in EAST, providing a unique platform to control plasma-wall interactions under very high heat and particle fluxes.

Through the integration of all these newly developed technologies,EAST has successfully extended its H-mode operation to highperformance and real steady-state operation regimes [5]. The utilization of a non-inductive current drive, current profile control,strong shaping of plasma configuration, and effective exhaust of heat and particle fluxes has brought current research to a high level, with technological developments that are indispensable for next-generation steady-state tokamak devices.

During the past 20 years,the EAST project has made significant contributions to the global fusion research and development program. Efforts continue to be made to bridge the gap between the steady-state operation regime of existing short-pulse tokamaks and that of the world’s largest tokomak,ITER(Latin for‘‘the way”),which is currently being developed through cooperation among 35 nations and regions, including China, the United States, the European Union (EU), and Japan [6]. EAST could convince the scientific community(other than the fusion community itself)that a tokamak reactor can operate continuously in the near future.

3. Key technologies developed from EAST

Many important technologies have been developed from EAST.Three crucial technologies are introduced below:superconducting magnets,H&CD systems,and the actively cooled divertor.All these technologies play essential roles in the EAST project.

3.1. Superconducting magnets

EAST is the first tokamak that uses superconducting coils for all magnets[7],which provides the TF and plasma control through PF coils. The EAST superconducting magnet system consists of 16 TF coils, six PF coils, and six central solenoid (CS) coils. A niobiumtitanium alloy (NbTi) was chosen as the superconducting material for all of EAST’s magnets. Cable-in-conduit conductor (CICC) technology was applied to all coils to provide a very high operation current and sufficient anti-alternating current (AC) loss capacity.

The key challenges of TF magnets are the precise coil winding,a low resistant conductor joint of 3 nΩ, a high insulation of up to 10 kV, and quench protection. TF magnets consist of 16 D-shaped coils, which weigh about 16 tonnes each, as shown in Fig. 2(a).The total energy storage is about 200 MJ.The TF system conductor exceeds 20 km in length and weighs 210 tonnes. The TF magnet shown in Fig. 2(b) can provide a maximum magnetic field of 4 T in the center of the plasma. Each TF coil was fully tested before installation at 120%over current operation.More specifically,insulation and quench tests have been thoroughly carried out to qualify each TF coil.

Fig.2. Superconducting magnets in EAST.(a)A D-shaped TF coil;(b)the TF magnet system during installation.

The major challenge for the PF and CS coils is that a fast current ramping rate is required for plasma control and operation. This induces AC losses and a temperature rise inside the coils, which may cause quenching during operation.The solution is to specially design the PF and CS cables. The PF and CS coil strand diameter is 0.85 mm, and the ratio of copper (Cu) to NbTi is 1.38. There are 8910 filaments, each with a diameter of 6 μm. The twist pitch is 10 mm, and the critical current at 5 T and 4.2 K is about 550 A.In order to increase the stability of the conductor, oxygen-free high-conductance copper strands are added in the conductor. The test results showed a sufficient margin for anti-AC losses and temperature rise.The CS coils with the highest ramping rate have been fully tested at up to 100 kA·s-1and 120% over current operation.

Simultaneous high current in all coils during tokamak operation is another challenge for superconducting magnets, due to the fast ramping rate in each coil and the very strong magnetic interference in between the coils. This can easily induce high electromagnetic noise in the magnet quench protection system. After the installation of the magnets, extensive commissioning was done to test all the magnets. All coils were energized with different currents and ramping rates; tests of 20 kA·s-1for 60 ms, 10 kA·s-1for 160 ms, and 5 kA·s-1and lower rates for the steady state with a sufficient safety margin were carried out. A large amount of data has been obtained from the quench detection and magnetic diagnostics, which provide a reliable quench protection database for machine operation.

During the 15 years of EAST operation, all superconducting magnets have gone through different tokamak operation scenarios without any failure, demonstrating the quality and robustness of the first tokomak to use fully superconducting magnets.

3.2. Heating and current drive systems

The effective heating of plasma and a controlled plasma current profile are essential for fusion application. Four major H&CD systems have been widely used in tokamak research during the past decades:ion cyclotron resonant heating(ICRH),electron cyclotron resonant heating (ECRH), neutral beam injector (NBI), and lower hybrid current drive (LHCD). Most of these H&CD systems were developed on short-pulse modes, which last for a few seconds.To achieve EAST’s mission, a new generation of H&CD systems is necessary, with long-pulse (100-1000 s) capacity. The major challenge for steady-state technology is to remove the high heat flux on each component of each system,especially on antennas,which suffer from very strong plasma interaction and high power microwaves on the limited surfaces inside the vacuum chamber of the tokamak.The high heat flux is a major reason for the production of impurities and hot spots that can terminate discharge, which are very harmful.

After nearly 20 years of technological development, 34 MW long-pulse H&CD systems have been developed. A 12 MW CW ICRH system [8], an 8 MW NBI system of 50-80 keV [9], a 4 MW ECRH system of 140 GHz [10], a 4 MW CW of 2.45 GHz, and a 6 MW LHCD systems of 4.6 GHz [11] have been built, which provide a very flexible H&CD for EAST and play a key role in exploring various physics-related issues.

Based on the short-pulse NBI system of the DIII-D tokamak in the United States, through cooperation with General Atomics(GA), long-pulse positive NBI systems have been developed. The ion source is actively cooled by filament structures,providing currents of up to 26 A. A series of ion sources have been made, and a beam operation of 4 MW was achieved for each of the NBI systems.Using this type of ion source, stable 60 kV, 100 s beam pulse operation and 50 kV, 80 s modulated beam pulse operation were achieved for the first time.This was a crucial step toward the goal of high beam power and a long-beam pulse. These 10-60 s pulsed deuterium beams from each ion source are now routinely used during EAST plasma experiments.

The CW ICRH is one of the most important heating systems in major tokamaks,such as the US tokamak fusion test reactor(TFTR)[12]and JET,as the ICRH plays a key role in heating ions effectively.Experiences learned from the CW ion cyclotron range of frequencies (ICRF) in Tore Supra [13] facilitated the rapid development of the EAST ICRF system. A 12 MW CW ICRF system with a wideband frequency of 20-70 MHz was constructed,consisting of eight radio frequency(RF) generators and related transmission systems.Actively cooled transmission lines, ceramic feedthroughs, antennas, and liquid double-T matching systems have been successfully developed and used for EAST experiments.

The 4 MW ECRH system consists of four gyrotrons(1 MW,140 GHz), transmission lines, power supplies, and an antenna. The most difficult part of the ECRH system is the antenna, which is located on a mid-plane port. Due to the physics requirements,ECRH is used not only for the H&CD, but also for other purposes,such as neoclassic tearing mode (NTM) suppression and plasma current profile control. A steering mirror is needed, which can rotate rapidly in both the poloidal and toroidal directions, and must be actively cooled to handle the high heat flux from the plasma.A shutter is also needed to protect the mirror surface from dust coating. All these technical problems have been overcome,and very good results have been obtained using ECRH, such as a high electron temperature of up to 16 keV for several tens of seconds during long-pulse H-mode discharges.

The most important H&CD system on EAST is the LHCD system,which has the highest current drive efficiency and is critical for driving the plasma current in a real steady state. Two kinds of LHCD systems are used on EAST. A 4 MW CW system of 2.45 GHz has been chosen for the edge current drive. The antenna is a passive actively cooled module (PAM) type, which has the advantage of coupling the wave at a very low edge plasma density. The 6 MW LHCD system of 4.6 GHz[14]is the most reliable H&CD system on EAST, as shown in Fig. 3. The antenna is a multi-junction structure with sandwich-type cooling channels, which provides a stable mechanical and thermal performance. The 24 modules in the multi-junction grill antenna are arranged in an array of four rows and six columns.Each module is divided into three sub-rows in the poloidal direction,and each sub-row consists of eight active sub-waveguides with a 90°phase difference in between,generated by a built-in phase shifter. In each sub-row of the launcher, seven passive waveguides are inserted between the adjacent main waveguides. Therefore, the whole launcher is composed of 660 sub-waveguides (576 active and 84 passive sub-waveguides). The EAST 4.6 GHz LHCD system showed excellent performance during the past 15 years of operation, achieving the longest tokamak plasma discharge of over 411 s, fully driven by the LHCD system alone, and an H-mode operation of 100 s.

Fig. 3. The 6 MW CW 4.6 GHz LHCD system of EAST.

The EAST H&CD systems play a key role in developing technologies for ITER and other large steady-state tokamaks. In particular,the experiences gained from tokamak experiments can provide an integrated way for testing all H&CD systems. Table 1 is a summary of the H&CD systems in the world’s major tokamaks.In comparison with other tokamaks,EAST is the only long-pulse tokamak with all major H&CD systems,which can provide a flexible combination of different ways to heat and control the plasma to promote high-performance steady-state operation.

3.3. The actively cooled divertor

The strong interactions that occur between the plasma and the wall, with high heat and particle fluxes under long-pulse conditions, present a critical challenge for a future fusion reactor. This is particularly the case for divertor targets,where the highest heat and particle fluxes are above the material limits.Three generations of divertors have been used in EAST to meet its objectives.

In the initial campaign of EAST,fully actively cooled doped graphite plasma-facing components (PFCs) and a graphite divertor were used,as shown in Fig.4.The doped graphite,which had thick silicon carbide(SiC)coatings,exhibited a good performance with a continuous heat load-removing capacity of 2 MW·m-2, which was tested prior to installation. For economic and technical considerations, doped graphite with active water cooling was employed for both the main vacuum chamber wall and the divertor target plates in the EAST campaigns from 2008 to 2014. A doped graphite named GBST1308 (1% B4C, 2.5% Si, and 7.5% Ti) was developed and exhibited the good characteristics of high density, low open porosity, high strength, and high thermal conductivity. The doped graphite tiles were coated with a layer of SiC about 100 μm thick using the chemical vapor reaction technique, which provides gradient SiC coating by the infiltration of reaction gas through open pores.This process yielded sufficient resistance against exfoliation.The SiC coatings had much lower chemical and physical sputtering yields compared with the graphite materials from experiments in other tokamaks for long-pulse plasma discharges [15]. The graphite tiles were bolted to a copper alloy (CuCrZr) heat sink and restrained through spring washers that allowed limited deformation during thermal expansion. Up to 2 MW·m-2of heat flux can be tolerated under steady-state conditions. The full graphite PFCs resulted in significant improvements of the plasma performance in EAST; 411 s plasma discharges were achieved, which is the longest high-performance plasma discharge in tokamak operation.The fully actively cooled graphite PFCs played a key role in this world record.

By gradually increasing the H&CD power, EAST can produce ITER-like long-pulse H-mode plasmas with a divertor heat load of over 10 MW·m-2under steady-state conditions. Therefore, graphite PFCs with 2 MW·m-2of heat-flux removal capacity cannotmeet the physics requirements.Furthermore,ITER PFCs were changed from carbon/beryllium(C/Be)to a full metal wall with a tungsten(W)divertor target.To investigate plasma performance with a full metal wall, a full W divertor was adopted for EAST.

Table 1 Parameters of tokamak H&CD systems across the world.

Fig. 4. Graphite PFCs and divertor in EAST.

The second generation of the EAST divertor utilized ITER-like W mono-blocks as divertor targets with a heat-flux handling capacity of up to 10 MW·m-2[16]. In order to provide valuable experience for ITER before its operation, similar materials, structures, and technologies were used in EAST; for example, ITER-grade W [17]was used for the PFCs.The conjunction of W and CuCrZr was difficult, due to the mismatch in their thermal expansion coefficients and Young’s moduli. The W mono-block PFCs were manufactured in two steps: First, W mono-blocks were cladded and joined with a pure copper interlayer by means of hot isostatic pressing (HIP);next, the W mono-blocks were welded to a CuCrZr tube by means of hot radial pressing (HRP). The seal welding of the pure copper tube and the W blocks was performed by brazing and e-beam welding under a vacuum environment before the HIP process.After the HIP process, the W blocks were machined into the designed size of 26 mm×26 mm×12 mm,which is similar to the designed size in the ITER design. A good quality of bonding was achieved between W and Cu, with a bonding strength of over 150 MPa.Ultrasonic nondestructive testing(NDT)indicated that the bonding of the W mono-blocks and copper met the technical requirements.Thermal fatigue testing was also performed.A W/Cu mockup with five mono-blocks manufactured by means of HIP and HRP was loaded for 1000 cycles at about 10 MW·m-2. Each cycle consisted of a 15 s heating phase and a 15 s cooling phase. Active cooling was performed with water at room temperature. The temperature difference of the cooling water between the inlet and outlet was as high as 18°C.The surface temperature was observed using infrared(IR) scanners. The mockup resisted 1000 cycles, with surface temperatures of up to 1150°C [18]. No surface overheating was observed, and the W/Cu mockup exhibited good performance and quality. After one year of efforts, EAST’s carbon upper limiter was replaced with an ITER-like W mono-block divertor, which is shown in Fig. 5. With these newly augmented capabilities, different types of steady-state H-modes (vp= 0) have been obtained through a combination of NBI, LHCD, ECRH, and ICRH, lasting up to 100 s.

Due to the rapid development of EAST experiments, the heat load on the EAST divertor targets is exceeding 10 MW·m-2and will soon reach 20 MW·m-2.After nearly six years of operation with the ITER-like mono-block divertor,some slow degradation of the target tiles has been found. New-generation divertor targets are needed to provide a fast and robust solution for a future reactor.A flat-tile W/Cu divertor with a hypervapotron structure for 20 MW·m-2was selected to meet future needs. The W flat tiles were first joined to the pure copper interlayers by means of vacuum hot pressing(VHP) at a temperature of about 900°C; next, the interface of Cu and CuCrZr was bonded by HIP at a lower temperature of 500-600°C.NDT results showed the good quality of the W/Cu interface.High heat-flux testing was performed with up to 1000 cycles and a heat load of up to 20 MW·m-2.The surface temperature was about 900°C, which is much less than that of the ITER mono-block configuration [19]. A quarter of the EAST divertor has been replaced by flat-tile W/Cu targets, as shown in Fig. 6. The new W divertor was installed in EAST early in 2021.Long-pulse and high heat-flux experiments have been carried out over the past half year, and no failure has occurred. The performance of this new type of divertor is better than that of the ITER-like mono-block divertor,especially in terms of heat- and particle-flux handling capacity. Further experiments and a comparison between the two generations of W/Cu divertors will provide solid experience for a future fusion reactor.

Fig. 5. The ITER-like W mono-block divertor in EAST.

Fig. 6. Current divertor design in EAST. (a) Design of the W flat-tile divertor; (b) the new W divertor in EAST.

4. Closing remarks

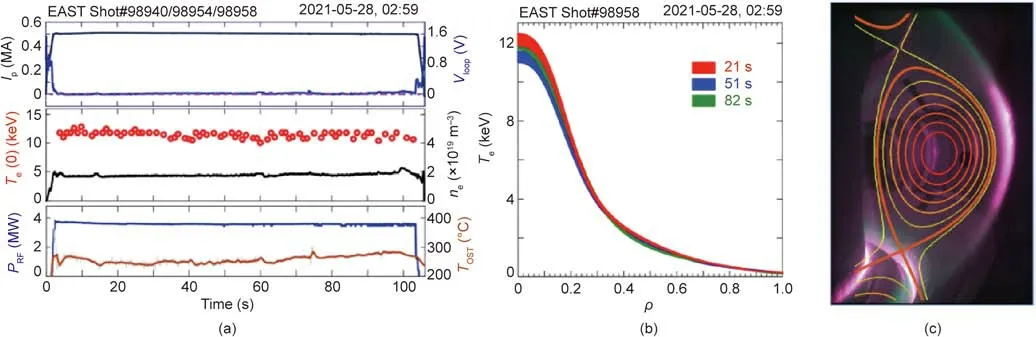

On 28 May 2021 in EAST, repeatable 100 s high-performance plasma discharges were obtained with an electron temperature of 12 keV (Fig. 7) by means of a combination of ECRH and LHCD with the newly installed W ITER-like mono-block and flat-tile divertor, setting a new record in tokamak research for such longpulse durations. During the past 15 years of operation, significant progress has been achieved with EAST.Wide-ranging international cooperation has been carried out from the beginning of its operation, and extensive joint experiments have been conducted in order to plan for and benefit ITER. The design, construction, and operation of EAST have yielded valuable experiences, resulting in the training of personnel for the construction and operation of ITER—or, more generally, for fusion energy systems in the future.

EAST positions China at the frontier of steady-state advancedperformance tokamak operation, with all the technical prerequisites (i.e., a divertor, H&CD systems, and long-pulse capability)for tokamak fusion research.Lessons have been learned from EAST prior to the start of operation of ITER in the area of superconducting systems and the steady-state operation of tokamaks.

In the next one or two years,H-mode discharges of up to 400 s,which are required for ITER, will be the target of EAST. In its ten-year long-term schedule, with further upgrading of H&CD and advanced diagnostics, EAST will extend its advanced-performance operating modes into the steady-state regime with the aim of investigating the conditions for future fusion reactors, such as operation for hours under reactor-relevant operation conditions.Further efforts with EAST will continue to be made as EAST serves as a valuable platform for new operating scenarios and technologies—not only for ITER and the Chinese Fusion Engineering Testing Reactor(CFETR),but also for the training of next-generation scientists and engineers around the world.

Fig.7. The EAST 100 s high-performance discharge with an electron temperature of 12 keV.(a)Main plasma parameters;(b)electron temperature profiles at 21 s(red),51 s(blue), and 82 s (green); (c) magnetic surface during plasma discharge. Ip: plasma current; Vloop: loop voltage; Te(0): central electron temperature; ne: central line average electron density; PRF: total RF power; TOST: out target surface temperature;ρ: normalized plasma minor radius.

- Engineering的其它文章

- PVC Formulation of Anastrepha suspensa Pheromones Suitable for Field Studies

- Handheld Ultrasound Advances Diagnosis

- Nuclear Energy Seeks Revival with Advanced Fuel Options

- Mars Helicopter Exceeds Expectations

- Toward Systemic Thinking in Managing Environmental Risks

- Modified Therapeutic Antibodies: Improving Efficacy