Research on anti-loosening performance of arc screw thread and general purpose screw thread anchor bolts

Zhong-gui YANG,Jie BAI,Meng-han LI,Zi-qiang WANG

(Haiwei Zhengzhou High-tech Co.,Ltd.of CSIC,Zhengzhou 450015,China)

Abstract:In this paper,the difference of thread structure and looseningmechanism between arc thread and general thread anchor boltswas analyzed.Based on the finite elementmethod,the residual preload of arc thread anchor and general thread anchor was calculated under different preload and lateral displacement load conditions.The results show thatwhen the threaded coupling pair is loosened by the lateral displacement cyclic load nut,the residual preload force of the arc thread anchor can be divided into a rapid decline and a stationary phase,and the preloading force is extremely slow in the stationary phase.The variation trend of the residual preload force of the general thread anchor bolts changes linearly,there is no obvious step,and the residual preload force of the arc bolts is always lower than thatof the general thread anchors.Therefore,the comprehensive anti-loosening effect of the arc thread anchor is better than that of the general thread anchor.

Key words:Arc screw thread,General screw thread,Anchor bolts,Anti-loosening

1 Introduction

In 2018,the cumulative installed capacity of wind power in China is 184 million kw.The wind turbine foundation is used to support the wind turbine tower structure and blades,and to bear wind loads,vibration loads and fatigue loads during the operation of wind turbines.The domestic wind turbine foundation generally adopts the pre-stressing anchor wind turbine foundation.The anchor boltassembly consisting of anchor bolts and nuts is an important component of the wind turbine foundation.Because the wind turbine bears periodic vibration load in the actual use,itmay lead to the loosening of nuts,and the reduction of the pre-tightening force of the direct anchor bolt.In serious cases,itmay cause the anchor bolt to break and break teeth,resulting in serious accidents[1-2],and the collapse of the tower of the wind turbine.The looseness of the bolt of the anchor bolt assembly is a phenomenon in which the axial preload force of the anchor bolt is reduced due to various factors,and is mainly divided into loose looseness and non-rotation looseness[3-4].“Rotation looseness”refers to the looseness of internal and external threads when they rotate relative to the loosening direction,“non rotation looseness”refers to the looseness of internal and external threadswhen they do not rotate relative to each other.At present,there are two structural forms of anchor bolts in the wind power market,one is nonstandard large pitch arc thread,and the other is general thread(metric thread).

2 Thread connection loosening m echanism

2.1 Two kinds of thread structure

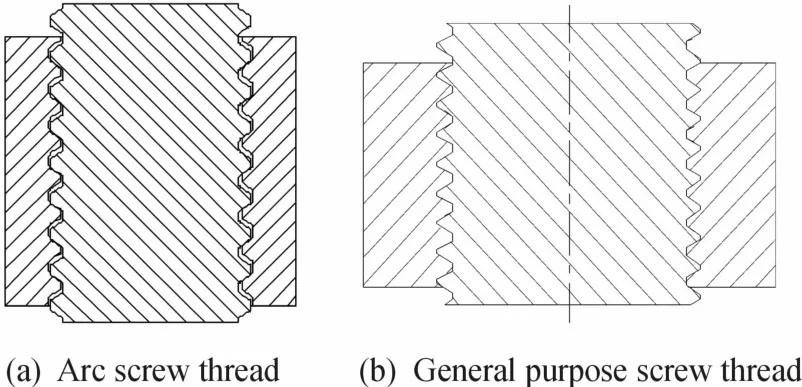

The anchor bolt assembly is the core component of the wind foundation of the pre-stressed anchor bolt.The anchor bolt cage is composed of anchor bolt,nut,washer and upper and lower anchor plates,and a PE pipe is used between the upper anchor plate and the lower anchor plate,isolating the anchor bolt from the concrete.The concrete foundation of wind turbine is always in the state of bearing pressure by the comprehensive utilization of the high strength and rigidity of metal components and the role of the whole concrete transferring stress.In this way,the stress concentration and damage of the concrete on both sides of the traditional annular wind foundation are avoided.The anchor bolt is a fastenerwith thread atboth ends,with length from 3m to 11m and specification from M36 to M48.The anchor bolt is used to apply pre-stress through a special tensioner.The thread form of the anchor bolt is divided into an arc thread and a general thread,as shown in Fig.1.The arc thread anchor bolt adopts a large pitch circular thread and a non-equal width tooth thick thread connection pair,and the connection between the anchor bolt and the nut is smooth,thereby avoiding the stress concentration phenomenon of the general thread.When the thread is rolled,the plastic deformation region of the metal material is small,which greatly reduces the difficulty inmanufacturing the rolling process.Table 1 compares the bolt parameters of the two threaded configurations.

Fig.1 Schem atic diagram of two kinds of thread struc tu re

2.2 Analysis on mechanism of rotational loosening

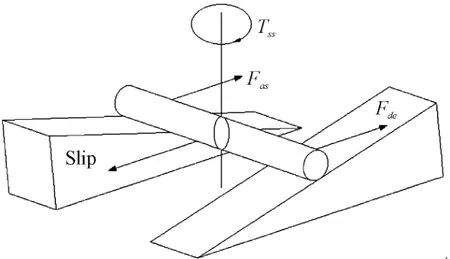

For the threaded coupling pair of anchor bolt and nut,the load causing the nut to loosen can be divided into three types:shear load,torsion load and tensile load.After a lot of studies by many scholars at home and abroad,it is generally believed that shear load is very sensitive,torsion load is sensitive,and tensile load is safe[5].Under the shear load,if the connector does not slip,then the anchor bolt and nut thread surface and support surface pressure or displacement will not change,so there will be no loose rotation.However,any slight slip between the jointed partswill also cause the axis of the anchor bolt to tiltand lead to pressure changes on the thread surface and support surface.However,when the sliding occurs on the thread surface,because the thread surface is a spiral bevel,the left side and the right side of the sliding center line become the rising side and the falling side of the bevel,and the forces acting on the rising side and the falling sidemust be differently.Fasis larger in the upward sideslip resistance,andFdeis smaller in the downward sideslip resistance,resulting in uneven forces on the left and right sides.As a result,the rotary torqueTSS,is generated tomake the anchor bolt rotate along the axial direction,causing the anchor bolt to become loose,as shown in Fig.2.The results show that the sliding of the fastened-piece is one of the important indexes to check the anti-loosening performance of the screw thread.

Tab Ie 1 Com parison of two kinds of thread structure parameters

Fig.2 Schem atic diagram of rotary torque

3 Finite elem en t sim u lation

3.1 Finite elementmodeling

In order to study the thread anti-loosening performance of anchor bolt,the finite elementmodel of anchor bolt is established,which ismainly composed of anchor bolt,nut and support plate.Take the anchor boltwith a major diameter of 48 mm as an example,the length of the anchor bolt with arc thread is 290 mm,the height of the nut is64mm,the length of the anchor bolt with general thread is 250 mm,and the height of the nut is 38 mm.The structural parameters of the two kinds of thread are shown in table 1,and the thickness of the support plate is 10mm.The anchor boltmaterial is 42CrMo,the strength grade is 8.8,the nutmaterial is35CrMo,and the strength grade is 8.This paper only studies the influence of the screw thread structure of anchor bolton the anti-looseness performance.In order to simplify the calculation,the elastic model is adopted,so the plasticity of the material is not considered.Thematerial properties are shown in Table 2.

Tab Ie 2 Materia I p roperties of ancho r bo It com ponen ts

3.2 Set boundary conditions

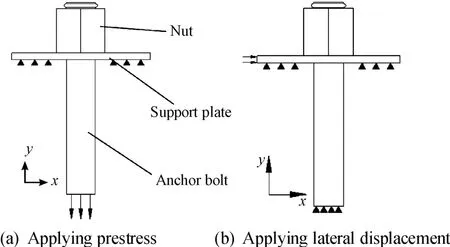

Anchor bolt anti-loosening calculation boundary condition setting is divided into two steps:first,the initial axial preload is applied,and then the lateral displacement load is applied.As shown in Fig.3,when the initial preload is applied,thex,yandzdirections of the bottom of support plate are restrained to ensure that the anchor bolt does not tilt during the loading process,and a downward axial preload is applied at the lower end of the anchor bolt.When applying lateral displacement load,remove the support ofxdirection constraints,so that the support plate can be moved in thexdirection,and the initial preload force is cancelled and thex,yandzdirections of the lower end of the bolt are restrained to ensure that the elongation of the lower end of the anchor is constantwhile ensuring that the lower end of the anchor does not move when the lateral displacement load is applied,and then the lateral displacement load in thexdirection is applied to the left side of the support plate.

According to 60%,70%,and 80%of the nominal yield strength of the anchor boltmaterial,the initial preload force is divided into three working conditions:396 MPa,462 MPa,and 528 MPa.The lateral displacement loads are:2mm and 2.5mm.In the simulation calculation process,a total of two contact pairs are provided,one is the contact between the anchor and the inner and outer threads of the nut,and the second is the contactof the nutwith the support plate.According to the actual contact situation,the“hard contact”is adopted in the normal direction of the contact surface,and the contact pressure that can be transmitted between the contact faces is not limited,and the penalty function Coulomb friction model is adopted in the tangential direction,and the friction coefficient is 0.2.

Fig.3 Setting of boundary conditions for Ioosening of anchor bo Its

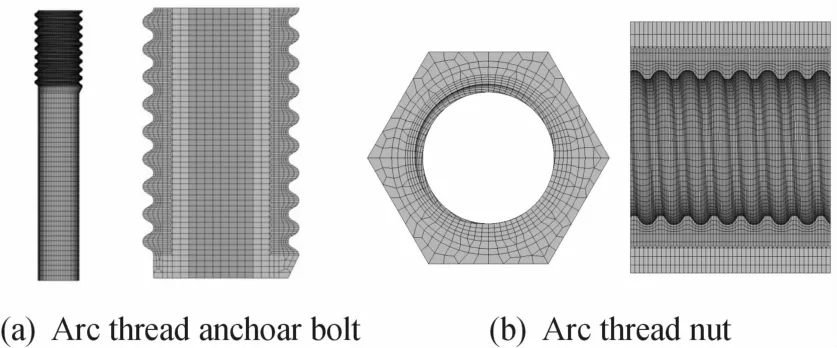

3.3 The grid division and evaluation

The calculation of the anti-loosening performance of the anchor boltmust take into account the angle of the thread.Due to the presence of the angle of the thread,the anchor and the nut have great difficulty in dividing the grid.A reasonablemeshmodel is the basis of simulation calculation.The quality of themesh model can also significantly affect the accuracy and calculation time of the calculation results[6].Therefore,in the process of meshing,by continuously repeating,translating,rotating andmerging the nodes of the thread processing,a continuous,beautiful and high-quality hexahedralmesh is obtained.Fig.4 is a grid diagram of arc thread anchor assembly.

Fig.4 Grid diagram of arc thread bo It assemb Iy

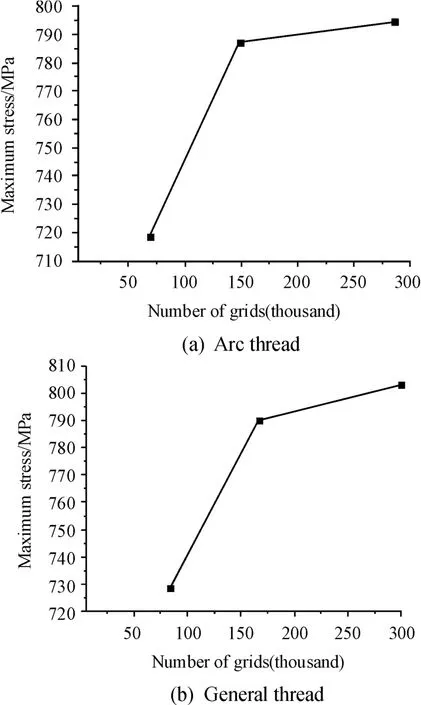

In the simulation calculation process,the number of grids has a great influence on the calculation results.In general,the smaller the mesh size,the more the number ofmeshes,the more accurate the calculation results,but themore computational effort is required.Therefore,it is necessary to check the number of grid before simulation calculation,and reduce the number of grid on the premise of ensuring the accuracy of calculation.The number of different networks was set,and the grid was examined with the maximum stress and strain.Fig.5 shows the relationship between the maximum stress and the number of grids of the two threaded anchor bolt assemblies.Therefore,149 000 grids were selected for the calculation of arc anchor bolts,and 163 000 grids were selected for general thread anchor bolts.

Fig.5 Re Iationship between m aximum stress and num ber of grids

4 Calcu lation resu lts and analysis

4.1 Residual preload force extraction

The axial preload of the anchor bolt is themost important factor affectingwhether the anchor bolt and the connected part are loose.In order to obtain the accurate residual preload,when calculating the pre-tightening force of the anchor bolt from the calculation results,avoid the lower end face of the anchor bolt and the position under the support plate,select themiddle position between the two,and use this section as a reference to solve the average stress value of the section,and then obtain the anchor bolt Residual preload.The residual preload force changes of the arcthread anchor bolt and the general thread anchor bolt section under different preload and lateral displacement loadswere extracted.

4.2 Variation of residual preload

As shown in Fig.6(a),in the process of bearing transverse load,the preload of the arc thread anchor has two obvious stages with the increase of cycle times:rapid decline stage and gentle stage.When the transverse displacement load is 2.0 mm,after several cycles,the initial preload drops rapidly and rapidly to about99.4%.In the subsequent cycles,the decreasing trend becomes slow.However,when the initial preload is 396 MPa and the transverse displacement load is 2.5 mm,the residual preload of anchor bolt decreasesmuch faster than that of other working conditions after passing through the rapid drop zone,indicating that the preload is too small and the anti-loosening performance is poor.As shown in Fig.6(b),the variation trend of residual preload of common thread anchor bolts is not as stepped as that of arc anchor bolts.When the initial preload is 396 MPa and the transverse displacement load is 2.5 mm,the decline rate of residual preload increases significantly with the increase of cycle compared with other working conditions.

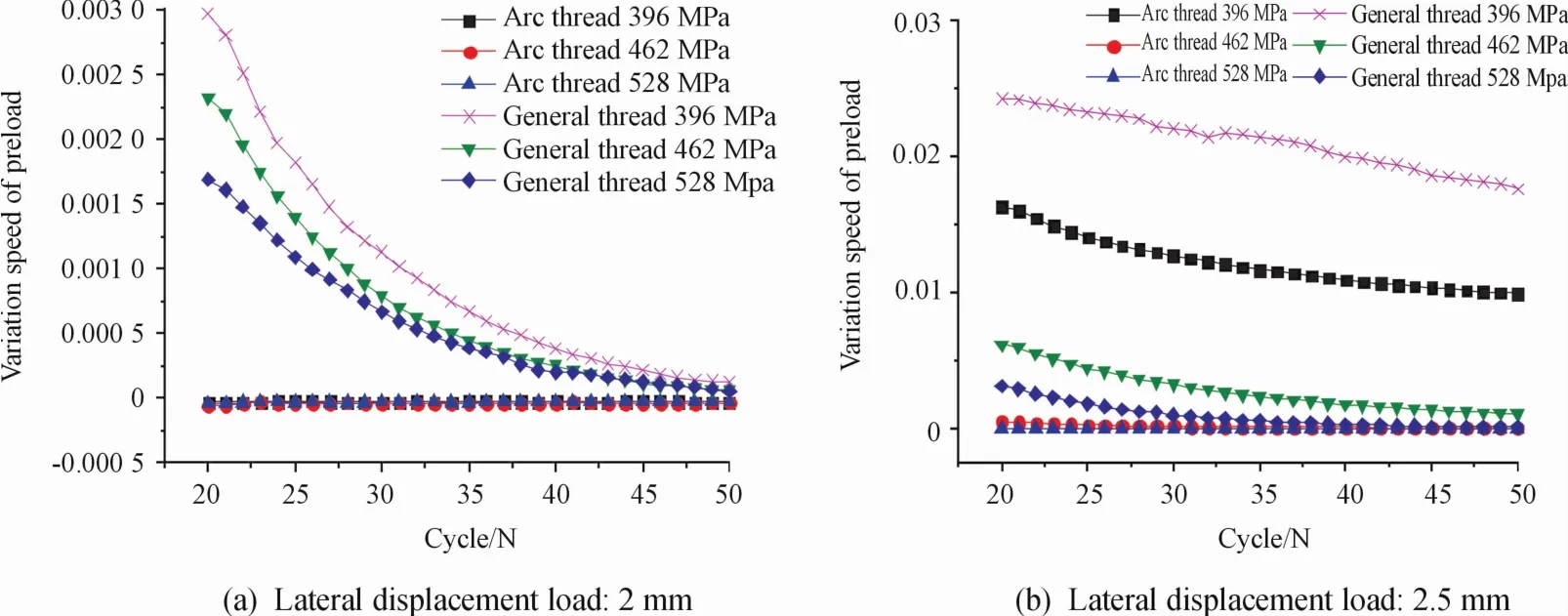

4.3 Rate of decrease of residual preload

For the residual preload of the two kinds of threaded structure anchor bolt in the steady decline phase(20 to 50 cycles),the derivative of the variation curve of the preload is carried out,and the derivative curve of the variation curve of the preload of the two kinds of bolts is solved.Fig.7(a)is a graph showing the rate of decrease of the preload force of the two anchors under the action of the lateral displacement load of 2 mm.It can be seen that the residual preload of the arc threaded anchor ismaintained within 20 to 50 cycles,and the rate of descent is basically maintained.When the value is constant and the value approaches zero,the rate of residual preload force of the general thread anchor is gradually reduced in the cycle of 20 to 50,but is always greater than the rate of decrease of the residual preload of the arc thread anchor.Fig.7(b)is a graph showing the rate of decrease of the preload force of the two anchor bolts under the action of lateral displacement load of2.5mm.It can be seen that the variation speed of the residual preload of the two threads is approximately linear.Under the same initial preload force,the residual preload force reduction rate of the arc thread anchor is smaller than that of the general thread anchor.

Fig.6 Reduction of p re Ioad of anchor bo It

Fig.7 Reduction rate of residua Ipre Ioad of anchor bo It

5 Summ ary

(1)In the process of bearing transverse load,the residual preload of the arc thread anchor assembly presents two distinct stages.The residual preload of general threaded bolt assembly has no obvious stepwise property and shows a linear decreasing trend.The pretension force of the anchor boltwith arc thread is basically unchanged after a certain period,and its comprehensive anti-loosening effect is obviously better than that of general thread.

(2)According to the falling speed of residual preload of anchor boltswith two kinds of thread structure,the anti-loosening effect of the arc-threaded anchor bolt is significantly better than that of the ordinary thread.

- 机床与液压的其它文章

- Decoupling control of single DOF supporting system ofmagnetic-liquid double suspension bearing

- Influence of the thermal effect on the sealing performance of the hydraulic combined dynam ic seal

- Dynam ic GRNNmodel of hydraulic system fault detection based on the internet of things technology

- Form ing modeling and sensitivity analysis of sandwich composites

- Research of aerodynam ic characteristics of heavy commercial vehicles under crosswind for different urban road layout

- Design ofmulti-parameter ultrasonic measuring instrument for fluid