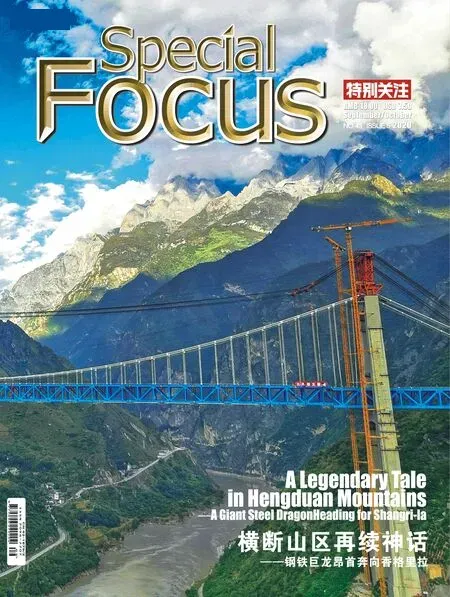

A Legendary Tale in Hengduan Mountains

——A Giant Steel Dragon Heading for Shangri-laA Giant Steel Dragon Heading for Shangri-la

Planned by He Sai &Bai Ning Text by Chen Shi &Xiong Wangping Photos by Chen Jin &Yao Sichao

At 11:18 am on October 13,with the last segment of steel truss girder that weighs around 640 tons being hoisted in place,the two sides of the Jinsha River Bridge on the Lijiang-Shangri-la (Lixiang) Railway,designed by China Railway Eryuan Engineering Group Co.,Ltd (CREEC) and constructed by China Railway Major Bridge Engineering Group Co.,Ltd (MBEC),were finally connected.This connection marks the completion of the main structure of the first long-span suspension bridge for railway service in the world,and lays a solid foundation for the railway’s opening to traffic as scheduled.This is another grand achievement and world record created by China’s “construction army,” marching into the Hengduan Mountainous Region,following the completion of some large hydropower stations—namely,the Xiluodu Dam,Xiangjiaba Dam,Baihetan Dam,and Wudongde Dam on the Jinsha River by the China Three Gorges Corporation.

“World’s No.1 Crane” Works Wonders

Deck of Jinsha River Bridge金沙江特大桥桥面

The Lixiang Railway enjoys a reputation as a “heavenly pathway” that links Lijiang and Shangri-la.The two cities are both in the northwest of Yunnan Province,southwest of China.the Jinsha River Bridge is bound to be the key part of the project.With a main span of 660 meters,this bridge has a total length of 882.5 meters,and the vertical distance from the bridge deck to the surface of the Jinsha River is 250 meters,which is equivalent to the height of an 80-story building.“The bridge is flanked by steep mountain slopes,with the maximum angle reaching 45 degrees,so there is very limited space for the construction roads,mixing station,and pre-assembly yard for steel beams.This has brought huge challenges for the construction,” said Zhang Lu,the chief engineer of the Jinsha River Bridge project,they’ve overcome high safety risks,a narrow working space,rainy season construction in the highlands and problems in linear control.As the pioneer in conquering the challenges of building a suspension bridge in a mountainous area,they’ve realized a batch of technological innovations and achievement transformations,and accumulated valuable experience in the construction of the Sichuan-Tibet Railway.

Workers working on plate connections工人们在进行连接板施工

According to Wu Xiaoyuan,the project manager,the bridge was assembled from 71 segments of steel truss girders,with the largest truss girder weighing 640 tons—equivalent to the weight of over 120 adult elephants altogether.In order to hoist those heavy items smoothly,MBEC designed and developed the heaviest cable crane in the world,with a maximum lift capacity of 800 tons which is reputed as the “World’s No.1 Crane.” The vertical distance from the top of the crane to the assembly yard of steel girders is 330 meters,which is equivalent to the height of a 117-story building,making it the largest hoisting height in the world.Equipped with an intelligent safety monitoring system and information management system,the crane boasts a high level of rated capacity,a high degree of automatic control,a safe and reliable monitoring system,an advanced lifting traction system,a fast installation speed,and high precision.Meanwhile,the large-tonnage double section lifting technology has laid a solid foundation for the safe and rapid construction of steel girders in the mountainous area.

The bridge used 23,000 tons of steel girders altogether,and 16,000 tons of which were used for the bridge deck.Its two main cables are made of 16,129 pieces of steel wire,with a diameter of 5.4 mm each that can withstand a wind speed of 30.5 m/s and a magnitude-8 earthquake.

An Environment-friendly Construction

The Jinsha River Bridge is situated in an AAAA National Tourist Attraction—the Tiger Leaping Gorge Scenic Spot,which is flanked by the Jade Dragon Snow Mountain and Haba Snow Mountain Natural Reserves,so environmental protection is a top priority for the project.

In order to minimize the impact of foundation construction on the stability of the mountain bodies and ecological environment,the main tower of the bridge has a rectangular embedded foundation,which reduces the size of the foundation and excavation area.So far,it is the largest embedded foundation for a railway bridge in China.

Grinding the beams for painting工人在打磨梁面以便刷油漆

Meanwhile,the project team has adopted a series of measures to protect the environment to the greatest extent:frame beams with anchor cables have been installed on the side slopes to maintain slope stability,selfmade water-spraying devices have been attached at the front end of the construction machines to reduce dust pollution,grass has been planted timely on the construction area to reduce water and soil loss on the side slopes,and waste residues during construction have been cleared at fixed time and location.

A Deep Chasm Turned into a Throughfare

Lijiang-Shangri-la Railway is located in the Hengduan Mountainous Region in the northwest part of Yunnan Province,with rolling snow mountains and deep valleys along the way.Starting from Lijiang,the railway spans northward across the Tiger Leaping Gorge,the largest canyon on the Jinsha River,to Shangri-la,stretching for 140 kilometers,with a design speed of 120 km/h.At present,people mainly rely on road traffic to go from Lijiang to Shangri-la,taking approximately 4 hours by bus,and there are frequent occurrences of natural disasters along the way.After the completion of Lijiang-Shangri-la Railway,it will connect the Dali-Lijiang Railway,Guangtong-Dali Railway and Chengdu-Kunming Railway,marking the end of the history when Shangri-la was excluded by railway networks.When the project is open to traffic,it will be possible to travel from Kunming to Shangri-la in just four hours,while it may take only one hour from Lijiang to Shangrila,which will strongly boost the tourism industry of Yunnan and the economic development of Shangri-la.

What’s more,the construction of Lijiang-Shangri-la Railway has accumulated valuable experiences for railway construction in the highlands of China,and greatly improved the development of heavy machinery in railway construction.

Over 60 years ago,when Chairman Mao Zedong caught sight of the Wuhan Yangtze River Bridge during his inspection,he composed a famous poem,“Prelude to Water Melody:Swimming.” “A bridge spans across the Yangtze River,turning a deep chasm into a thoroughfare.” In the verse,Chairman Mao has reflected the heroic spirit of the Chinese people in building up their motherland.MBEC was founded for the construction of the Wuhan Yangtze River Bridge,and,after building many bridges across the Yangtze River over the past six decades,MBEC has shifted its attention to one of the most challenging mountainous regions in the world,and succeeded in one stroke.It has not only pushed forward the giant “steel dragon” deeper into the Hengduan Mountainous Region,but also sent out the bright signs of an early completion of the Yunnan-Tibet Railway,or even the connection of Yunnan-Tibet Railway,Sichuan-Tibet Railway,and Qinghai-Tibet Railway at the Sunlight City of Lhasa.