Effects of Bagging on the Aroma of ‘Alexandrine Douillard’Pear Fruit

Shuwei WEI Yao TONG Jizhong WANG

Abstract [Objectives] This study was conducted to explore the effects of bagging on the aroma of ‘Alexandrine Douillard pear fruit.

[Methods] The static headspace (SHS) and gas chromatography-mass spectrometry (GC-MS) techniques were used to analyze ethylene release and aroma components from the ‘Alexandrine Douillard pear fruit in no bagging (CK), single-layer bagging (KK) and double-layer bagging (KW) treatments.

[Results] Bagging during growth period to some extent inhibited ethylene production during storage of ‘Alexandrine Douillard pear at normal temperature. Single-layer bagging could significantly reduce ethylene release during late storage of fruits, and double-layer bagging delayed the appearance time of ethylene release peak during fruit storage. Bagging changed the composition and content of the aroma substances of ‘Alexandrine Douillard fruit. The aroma substance contents ranked as no bagging>single-layer bagging>double-layer bagging.

[Conclusions] The study provides a theoretical basis for the research on bagging technology of ‘Alexandrine Douillard pear.

Key words ‘Alexandrine Douillard pear; Bagging; Ethylene; Aroma

Received: January 25, 2020Accepted: March 21, 2020

Supported by National Key R&D Program of China (2019YFD1001404); Major Science and Technology Innovation Engineering of Shandong Province (2018CXGC0208; 2019JZZY020623); Pear Research System (CARS-28-36); Science and Technology Innovative Engineering of Shandong Province (CXGC2018F03); National Natural Science Foundation of China (31601708).

Shuwei WEI (1981-), male, P. R. China, associate researcher, PhD, devoted to research about fruit tree cultivation and breeding.

*Corresponding author. E-mail: weisw2007@163.com.

China is the world餾 largest producer of pear, and its area and output are among the highest in the world. ‘Alexandrine Douillard pear tastes sweet with plenty of water and dense and soft flesh, and is suitable for all ages[1-2]. Bagging is a common technical measure in fruit production in China, which can improve the commerciality of fruits and reduce pesticide residues. It is an important cultivation measure in production[3]. The results of Liu[4] showed that bagging treatment could inhibit the ethylene release rate of Snow pear at the initial storage period. Ma et al. [5] showed that bagged Gala apples had ethylene peak and respiration peak 20 d earlier than the control fruit, and the fruit began to age early. Previous studies have shown that bagging reduced the types and contents of apple aroma substances, especially esters[6], and reduced the types and components of peach, especially fruit-flavor compounds, resulting in a lighter fruit flavor and affecting edible value[7]. At present, there is no related research report on bagging on post-harvest ethylene release and aroma components and content of ‘Alexandrine Douillard pear. In this study, the effects of different bagging methods on fruit ethylene release and ester aroma substances during normal temperature storage with ‘Alexandrine Douillard pear as an experimental material, hoping to provide a theoretical basis for the research on ‘Alexandrine Douillard pear bagging technique.

Materials and Methods

Experimental materials

This experiment was conducted from 2018 to 2019. The test fruit was ‘Alexandrine Douillard pear, collected from the Tianping Lake Demonstration Base of Shandong Institute of Pomology. Three treatments were set: no bagging (CK), single-layer bagging (KK) and double-layer bagging (KW). Each treatment included three trees and was done in three repetitions. On August 25, the fruits with the same maturity and no mechanical damage from diseases and insects were harvested from the periphery of the canopy. 150 fruits were harvested from each replicate of each treatment, and placed in containers for transhipment and transported to laboratory. The experiment was performed at room temperature (about 20 ℃).

Experimental reagents and instruments

ShimadzuGCMS-QP2010 gas chromatography-mass spectrometer; 3-nonanone; ethylene gas; deionized water; magnetic heating and stirring apparatus; analytical balance; polytetrafluoroethylene butyl rubber; 50 ml conical flask; 10 ml test tube; 1 000 ml beaker; 1 ml syringe; electronic balance; GC-9A gas chromatograph; SPME extraction head (blue); tin foil paper; plastic wrap; freezer; PerkinElmer Turbo Matrix 40 Trap headspace sampler.

Experimental methods

Ethylene determination

During the experiment, refrigerated fruits were taken out, and 30 fruits of similar size and shape without mechanical damage were selected from each of no bagging (CK), single-layer bagging (KK) and double-layer bagging (KW) treatments. Each group of samples was added into a large beaker, which was sealed with plastic wrap for 2 h. The air was repeatedly drawn with a 1 ml syringe, and injected into a GC-9A gas chromatograph for measurement. The measurement was continued for one week. Qualitative analysis was performed according to the retention time of the chromatographic peaks, and compared with the standard spectrum, the area external standard method was used to calculate the content in the sample by the following formula, with the average value of three experiments recorded:

Content= A sample / A standard × C standard

Ester determination

The selected fruits of the CK, KK and KW groups were pitted, and each group of samples was evenly cut into 0.5 cm×0.5 cm×0.5 cm pieces. After mixing, 20 g was weighed, added with 10 μl of 0.4 μg/ml 3-nonanone and sealed with tin foil. Each obtained sample was heated at 40 ℃ for 30 min , and an SPME extraction head (blue) was used to adsorb the aroma. After adsorption, the sample was injected and analyzed. The percentage contents of different components were determined by the area normalization method, in which the content of each component was calculated by comparing with the standard peak of known concentration according to the following formula:

Content= A sample / A standard × C standard

Results and Analysis

Effects of different bagging treatments during the growth period on the ethylene release from ‘Alexandrine Douillard pear during shelf life

It can be seen from Fig. 1 that the trends of ethylene release from ‘Alexandrine Douillard pear in the CK and KW groups were generally the same, and they all rose first, then decreased, and then rose again. The ethylene release from ‘Alexandrine Douillard pear in the KK group first increased and then decreased at room temperature during shelf life. The CK, KK and KW groups all had peaks of ethylene release, but the occurrence time and peak value were different. In the CK and KK groups, the ethylene release increased rapidly during the first day to the second day of storage, and reached a peak on the second day, which was 11 483.10 and 11 596.68 ppm, respectively, which were not significantly different. In the CK group, the decline was gentle from day 2 to day 4, and the ethylene release was significantly lower than that of KK and KW-treated fruits by day 5 ( P <0.05), and then began to rise rapidly, reaching 12.76 times of the initial value by day 6. After reaching the peak on the second day, the KK group餾 ethylene release continued to decrease, and by day 6, it was 15.05% and 14.05% of the CK and KW groups, respectively, showing significant differences ( P <0.05). The ethylene release in the KW group showed a continuous upward trend in the first 3 d of storage, and reached a peak on the 3rd day. The peak was significantly lower than the CK and KK groups ( P <0.05), and was 81.02% and 80.23% of the peaks of the CK and KK groups, respectively. After that, it began to decline rapidly, and then began to rise rapidly after day 5. On day 6, it was 7.11% and 611.73 higher than the CK and KK groups, respectively, showing a significant difference from the KK group ( P <0.05).

Effects of different bagging treatments during growth period on the aroma from ‘Alexandrine Douillard pear during shelf life

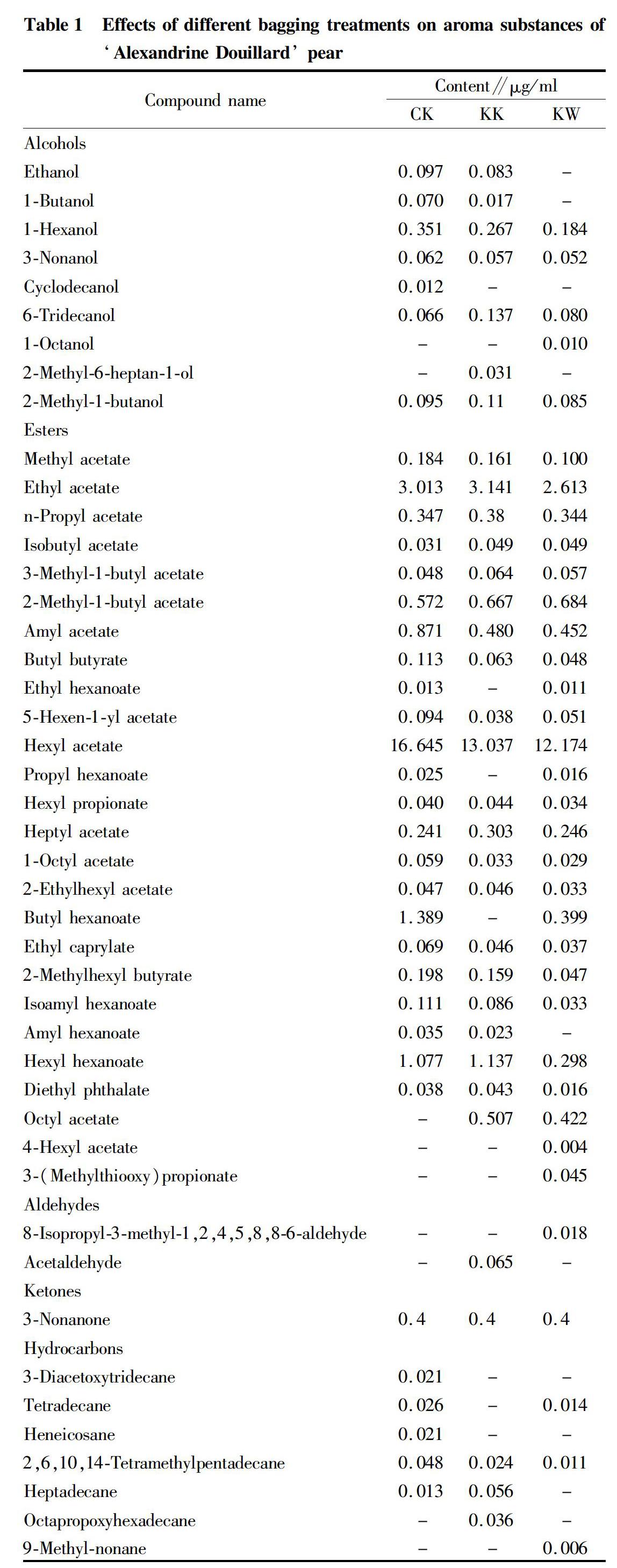

As can be seen from Table 1, a total of 64 compounds were detected in ‘Alexandrine Douillard pear of the CK, KK and KW groups. In the CK group, 44 compounds were detected, including 7 alcohols (15.91%), 23 esters (52.27%), 1 ketone (2.27%) and 12 hydrocarbons (27.27%). The KK group was detected with 44 compounds, including 7 alcohols (15.91%), 21 esters (47.73%), 1 aldehyde (2.27%), 1 ketone (2.27%) and 13 hydrocarbons (29.55%). In the KW group, 40 compounds were detected, of which 5 were alcohols (12.5%), 25 were esters (62.5%), 1 ketone (2.5%) and 9 hydrocarbons (22.5%). Specifically, 1-hexanol, 3-nonanol, 6-tridecanol, 2-methyl-1-butanol, methyl acetate, ethyl acetate, n-propyl acetate, isobutyl acetate, 3-methyl-1-butyl acetate, 2-methyl-1-butyl acetate, amyl acetate, butyl butyrate, 5-hexen-1-yl acetate, hexyl acetate, hexyl propionate, heptyl acetate, 2-octyl acetate, 2-ethylhexyl acetate, ethyl octanoate, 2-methylhexyl butyrate, isoamyl hexanoate, hexyl hexanoate, diethyl phthalate, 2,6,10,14-tetramethylpentadecane, α-olefine copper, α-farnesene and 3-nonanone were common in the CK, KK and KW groups. Among the 64 compounds detected, cyclodecanol, 3-acetoxytridecane, heneicosane, decamethylcyclopentyloxane, caryophyllene, α-isopropene, 1,5,9,9-tetramethyl-1 ,4,7-caryophyllene and estragole were compounds unique to the CK group; 2-methyl-6-heptan-1-ol, 5,5-diethyltridecane, 8-methyl-heptadiane, 5-(2-methylpropyl)nonane, bicyclo[10.6]octadecyl-1 (12),15-diene, longifolene, Z-5-nonene and anisole were compounds unique to the KK group; and 1-octanol, 1h-3a,7-methanoazulene-5-octahydrool-3,8,8-trimethyl-6-methylene, 4-hexyl acetate, 3-(methylthiooxy)propionate, 9-methyl-nonane, n-heptane and 8-isopropyl-3-methyl-1,2,4,5,8,8-6-aldehyde were compounds unique to the KW group.

In terms of compound content, the CK, KK and KW groups showed highest relative amounts of ester compounds, accounting for 82.74%, 83.59% and 88.77%, respectively, followed by hydrocarbons, accounting for 11.39%, 11.60% and 7.14%, respectively. The relative contents of ketones, aldehydes and ketones were relatively small. Changes in the contents of various compounds after fruit bagging led to differences in fruit flavors. Except aldehydes, alcohols, esters and hydrocarbons all decreased to varying degrees, and the total aroma substance contents were also lower than that of the CK group, and were 80.36% and 67.31% of the CK group, respectively. Bagging reduced the aroma substance content of ‘Alexandrine Douillard pear, and the aroma substance content of the double-layer bagging treatment was lower than that of the single-layer bagging treatment.

Yao TONG et al. Effects of Bagging on the Aroma of ‘Alexandrine Douillard Pear Fruit

Conclusions and Discussion

Wu et al. [8] found that the peak value of ethylene release from bagged fruit was 66.99% of that of fruits free of bagging for Cuiguan pear stored at room temperature. Zeng et al. [9] pointed out that bagging inhibited ethylene release during Cuiguan pear storage and delayed fruit senescence. The results of this study showed that bagging during the growth period had a significant effect on the ethylene release of ‘Alexandrine Douillard pear during normal temperature storage. The peaks of ethylene release appeared in the fruits of CK, KK and KW groups. There were no significant differences in the peak ethylene release time and amount of ‘Alexandrine Douillard fruit in the CK and KK groups, but single-layer bagging inhibited the ethylene release in the late storage period. The peak value of ethylene release of the KW group was significantly different from that of the CK group, and the appearance time was delayed compared with the CK group. There were no significant differences in ethylene release amount between the KW group and CK group during the later storage period. It indicated that double-layer bagging could inhibit the ethylene release in the early storage of ‘Alexandrine Douillard fruit, which is consistent with the results of Liu餾 study on Snow pear bagging, but this study also found that double-layer bagging delayed the peak time of ethylene release, which is inconsistent with the results of Liu餾 study. It is speculated that it may be caused by the difference in variety.

Aroma is the decisive factor for fruit flavor[10]. Its content and type have an important effect on fruit flavor. Fruits with higher aroma substance content and more types have a stronger overall flavor[11]. Studies have shown that different types of fruit bags affect fruit aroma to varying degrees[12]. Feng et al. [13] showed that bagging inhibited the production of esters and olefins in ‘Ruixue apple and promoted the production of aldehydes, which is consistent with the results of this study. In this study, bagging significantly changed the aroma substance content and composition of ‘Alexandrine Douillard pear. On the one hand, there was a decrease in the types of aroma substances. Specifically, the aroma substances of the KW group were reduced by 4 kinds compared with the CK group. On the other hand, the aroma substance content was reduced. The fruits in the KK group and KW group had lower aroma substance contents than those in the CK group, which were 80.36% and 67.31% of the CK group, respectively. It could be concluded that bagging is not conducive to the synthesis of aroma substances in ‘Alexandrine Douillard fruit, which is the same as those of Wang et al. [14] on ‘Yali fruit and Wei et al. [15-16] on ‘Qixia Daxiangshui and Royal Gala apples. The results of this study found that, regardless of bagging or not, the esters showed the highest relative content among aroma substances in ‘Alexandrine Douillard fruit. Therefore, although bagging significantly inhibited the production of aroma substances, it did not change the main aroma components of the fruit, which is the same as the result of the study of Liu et al. [17] on ‘Zaofu 1 apple. Jia et al. [18] studied the fruits of ‘Hujingmilu peach, and found that the content of aroma substances in the fruits with single-layer bagging was higher than that in fruits without bagging, which is inconsistent with the conclusion of this study, which might be caused by the characteristics of the fruits themselves or the differences of bags.

References

[1] LI ZR, WANG WH, JIA XH, et al. Study on the suitable harvesting time of 4 western pear varieties[J]. China Fruits, 2007(5): 22-25. (in Chinese)

[2] HIWASA K, NAKANO R, HASHIMOTO A, et al. European, Chinese and Japanese pear fruits exhibit differential softening characteristics during ripening[J]. Journal of Experiment Botany, 2004, 55(406): 2281-2290.

[3] KE FJ. Effects of fruit bag selection and bagging on fruit quality and sugar accumulation-related enzyme activity in pear varieties with different skin colors[D]. Nanjing: Nanjing Agricultural University, 2011. (in Chinese)

[4] LIU JJ. Effects of bagging on snow pear fruit quality and postharvest physiology[D]. Shijiazhuang: Hebei Normal University, 2014. (in Chinese)

[5] DENG R, YUAN ZY, XIA X, et al. Fruit quality comparison on bagged and non-bagged ‘Ruiyangapple[J]. Journal of Gansu Agricultural University, 2019, 54(1): 74-79, 88. (in Chinese)

[6] MA H, FAN CH, ZHENG WJ, et al. Storage quality of the bagged fruits of Gala apple[J]. Journal of Henan Agricultural Sciences, 2007(2): 89-91. (in Chinese)

[7] LUO H, LI M, SONG HR, et al. Effects of bagging treatment on aroma components of Feicheng peach[J]. Hubei Agricultural Sciences, 2012, 51(22): 5072-5075. (in Chinese)

[8] WU YG, CHEN JY. Influences of bagging on the shelf lives and physio-biochemical changes in Cuiguan pears during storage[J]. Acta Botanica Boreali-Occidentalia Sinica, 2004(9): 1630-1634. (in Chinese)

[9] ZENG KF, JIANG WB. Growth bagging effects of mango fruit on postharvest fruit quality and ripening[J]. Food Science, 2007(12): 507-511. (in Chinese)

[10] XI WP, YU SL, ZHOU ZQ. Advances in aroma compounds biosynthesis of peach fruit[J]. Acta Horticulturae Sinica, 2013, 40(9): 1679-1690. (in Chinese)

[11] BULT JH, SCHIFFERSTEIN HN, ROOZEN JP, et al. Sensory evaluation of character impact components in an apple model mixture[J]. Chemical Senses, 2002, 27(6): 485-494.

[12] LI HF, WANG HB, LI LG, et al. Effects of bagging on “Hanfu” apple aroma compounds[J]. Chinese Journal of Eco-Agriculture, 2011, 19(4): 843-847. (in Chinese)

[13] FENG SS, YAN CT, ZHANG TH, et al. Effect of bagging on aroma volatiles and related gene expression in ‘Ruixue apple fruit[J/OL]. Food Science: 1-14. (in Chinese)

[14] WANG SM, WEI SW. Effects of bagging on the aroma and sugar and acid components of Ya pear fruit[J]. Journal of Qingdao Agricultural University: Natural Science, 2011, 28(2): 115-117. (in Chinese)

[15] WEI SW, WANG SM. Effects of bagging on the aroma components of ‘Qixia Daxiangshui pear fruit[J].Agricultural Science & Technology, 2015, 16(8): 1676-1680. (in Chinese)

[16] WEI SW, WANG SM, ZHOU GF, et al. Effects of bagging on aroma components of Royal Gala apple during storage[J]. Journal of Fruit Science, 2009, 26(1): 82-85. (in Chinese)

[17] LIU Y, LU MY, WANG T, et al. Effects of bagging on aroma components of Zaofu 1 apple fruit[J]. Heilongjiang Agricultural Sciences, 2017(5): 70-73. (in Chinese)

[18] JIA HJ, ARAKI A, OKAMOTO G. Influence of fruit bagging on aroma volatiles and skin coloration of‘Hakuhopeach ( Prunus persica Batsch)[J]. Postharvest Biology and Technology, 2005, 35(1): 61-68.

Editor: Yingzhi GUANGProofreader: Xinxiu ZHU

- 农业生物技术(英文版)的其它文章

- Effects of Different Planting Densities on the Yield of Rice Developed from Seedlings Dry Raised in Plug Trays

- Effects of NaCl and NaHCO3 Stress

- Variety Characteristics and Cultivation Techniques of High-yield and High-resistance Wheat Variety Xindong No.48

- Effects of Different Line Spacing and Seedling Belt Width on Yield Formation of Broad-Width Fine Sowing Wheat

- Efficacy Tests of Nine Insecticides on Tetranychus truncatus Ehara

- Research Progress and Prospect of Sugarcane Smut