Optimization of Preservation on Fresh-cut Yam under Simulated Cold-chain Process

Dongdi XIE Rongling HUANG

Abstract [Objectives] This study was conducted to investigate the effect of compound fresh-keeping liquid on the browning and quality of fresh-cut yam during the cold chain process. [Methods] Under the simulated cold chain condition of 4 ℃, a uniform design (U6* (64)) experiment was carried out to optimize the compound preservative formula, and a better compound preservative formula was obtained using the regression equation. [Results] The compound preservative formula was: AA 0.25%, CA 0.5%, Nisin 0.09%, GSH 0.15%. The compound fresh-keeping liquid effectively delayed the browning of fresh-cut yam and the accumulation of MDA, maintained the content of TSS, inhibited the activity of PAL and delayed the appearance of the maximum activity of POD and POD. [Conclusions] This study provides technical support for the actual extension of the shelf life of fresh-cut yam.

Key words Fresh-cut yam; Cold chain process; Uniform design; Preservation

Fresh-cut fruits and vegetables originated in the United States, also known as the least processed fruits and vegetables. As people's lives become increasingly busy, food processing will serve the purpose of responding to people's "quick preparation" solutions. The fresh fruit and vegetable raw materials will be washed, peeled, trimmed, and packaged to keep them fresh and make them a new type of processed fruits and vegetables that people eat or use immediately[2]. Chinese yam (Dioscorea opposite Tbunb), also known as Shuyu, Huaishanyao, Shuyao, etc., is also suitable for fresh cutting. However, due to the influence of air exposure, mechanical damage, distribution and transportation of peeling, it is easy to cause enzymatic browning and decay of yam[3], shortening the shelf life. Meanwhile, fresh cutting is also the pre-treatment link in the processing of yam products. The browning and decay caused by the primary processing seriously affects the quality of the products, thus restricting the rapid development of yam industry[4]. Related studies have found that through physical, chemical and biological methods, browning inhibitors such as citric acid, ascorbic acid, EDTA, glutathione, and chitosan are used to inhibit yam browning[5-9]. However, there are few studies on the mixed use with the preservative ninhibifory substance (Nisin) to inhibit both browning and decay. In this study, under simulated cold chain process at a temperature of 4 ℃, with fresh-cut yam as the test material, ascorbic acid (AA), citric acid (CA), nisin (Nisin) and reduced glutathione (GSH) in different concentration ranges were adopted to carry out a uniform design experiment to optimize the optimal concentration of the compound preservative for controlling the deterioration of yam, thereby prolonging the shelf life of yam.

Materials and Methods

Materials and Methods

Fresh yam was purchased from the "Hejie yam" base and tested on the day of harvest. Complete undamaged yams with uniform thickness were randomly selected.

Ascorbic acid (AA), citric acid (CA), reduced glutathione (GSH): Sangon Biotech (Shanghai) Co., Ltd.; Nisin: Zhejiang Xinyinxiang Bioengineering Co., Ltd., all domestic food grade.

Instrument and equipment

722-type visible spectrophotometer: Shanghai Youke Instrument Co., Ltd.; UV-1901PC ultraviolet spectrophotometer: Shanghai AuCy Scientific Instrument; WAY-2WAJ Abbe refractometer: Shanghai Shenguang Instrument Co., Ltd.; KH30R-11 high-speed refrigerated centrifuge: Hunan Kaida Scientific Instrument Co., Ltd.; JJ500 electronic balance: Changshu Shuangjie Test Instrument Factory; BCD-251WBCY Haier Refrigerator: Qingdao Haier Co., Ltd.; ZT-100 simulated automobile transportation vibration table: Tianjin Kangpurui Technology Co., Ltd.

Methods

Fresh-keeping test treatment methods

Fresh yams were cut and put in a ventilated place to dry slightly. The dried yams were peeled with a stainless steel knife, and cut into 1.5 cm thick yam slices, each 2 kg. The uniform design table U6* (64) was adopted to carry out an equal-level uniform design scheme[10]. Compound preservative liquids were prepared, and the yam slices were soaked for 5 min, taken out and blew for drying with the cold air, and then sealed on trays using plastic wrap before entering the cold chain process. The test simulated the cold chain process at 4 ℃ for 7 d (cold storage 1 d-simulated transportation 2 d-cold fresh cabinet sales 4 d). The simulated transportation vibration frequency was 200 RPM (revolutions per minute) and the amplitude was 25.4 mm. On the 7th d, the degree of browning of each treatment was measured. After obtaining the optimal solution, a verification test was carried out, and a clear water immersion group was also set as the control group (CK). Various physical and chemical indexes were detected before treatment (0 d) and 1, 3, 5, 6 and 7 d after treatment, including PPO and POD, PAL activity, browning degree (BD), total soluble solids (TSS) content, and malondialdehyde (MAD) content. The factor levels are shown in Table 1.

Determination items and methods

The browning degree (BD) was determined by the extinction value method[11]. The POD activity was determined by the guaiacol method[7]. For the determination of PPO activity, the catechol method was adopted referring to Hu et al.[12]. As to the determination of PAL activity, the ultraviolet spectrophotometric method was applied referring to Sun et al.[13]. The TSS content was determined with a refractometer. The MDA content was determined by TBA colorimetry referring to Liu et al.[14].

Data processing

With the 7 d browning degree (BD) as the response value, the DPS (Data Processing System) software data processing system was used to establish an equation model to perform the second-order polynomial stepwise analysis, and the significance test of the equation model was carried out.

Results and Analysis

Determination of compound preservative formula

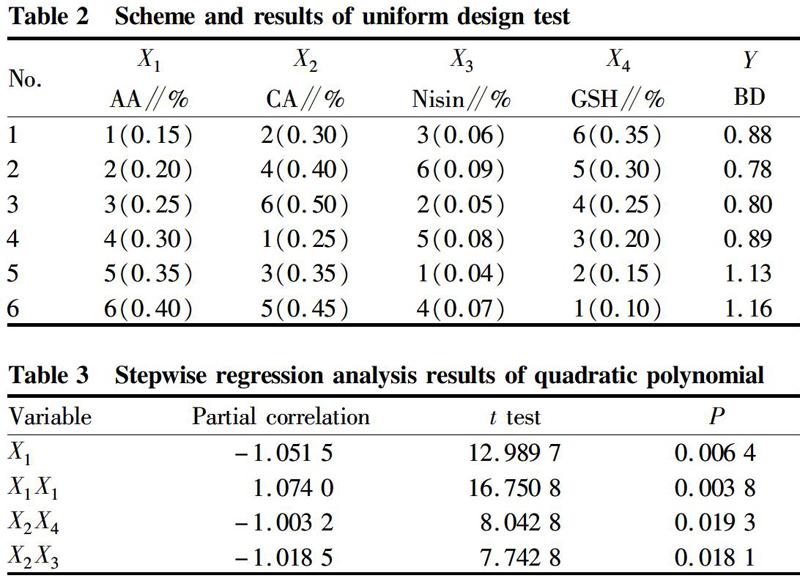

The uniform design table U6* (64) was adopted to arrange a 4-factor 6-level scheme for testing. The test scheme and results are shown in Table 2.

With the 7 d browning degree (BD) as the response value, the DPS software data processing system was used to establish an equation model, and second-order polynomial stepwise analysis was carried out to obtain the equation model of the compound fresh-keeping liquid of yam. The significance test of the model was performed, and the results are shown in Table 3. A regression equation was obtained as Y=1.474 8-5.203 0X1+11.926 6X1X1-4.447 8X2X3, with following parameters: multiple correlation coefficient R=0.999 1, F value=389.280 0, significance level P=0.002 6, residual standard deviation SSE=0.011 0, adjusted correlation coefficient Ra=0.997 861, and adjusted coefficient of determination Ra2=0.995 726, indicating that the regression equation could fit the compound process of yam fresh-keeping liquid well. From the regression equation, items X2, X3 and X4 did not appear, it can be seen that the single preservatives CA, Nisin and GSH had no significant effect on the browning degree; and according to the analysis results and the significance test P value of each variable in Table 3, it can be known the effects on the browning degree of yam ranked as X1X1>X1>X2X3, and factors X2 and X3 had an interactive effect. From the regression equation, the optimal solution for the compound fresh-keeping liquid of fresh-cut yam was: 0.25% AA+0.50% CA+0.09% Nisin+0.15% GSH, and the predicted Y value was 0.76. Through the verification test, the measured value of the browning degree (BD) of yam on the 7th d was 0.77, the absolute relative error of which with the predicted value was 1.30%, which meant that the two values were basically consistent.

Effect of the compound fresh-keeping liquid on the quality of fresh-cut yam

Effect of the compound fresh-keeping liquid on browning degree and TSS content of fresh-cut yam

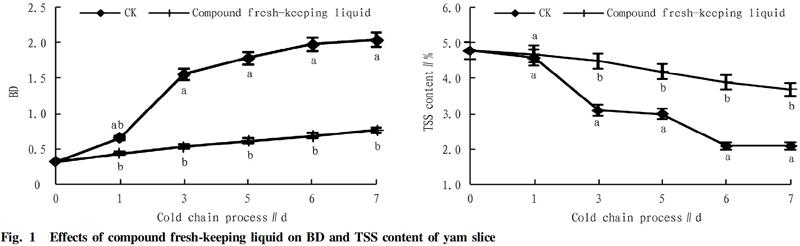

The compound fresh-keeping liquid (AA 0.25%, CA 0.5%, Nisin 0.09%, GSH 0.15%) was used to treat yam. The browning degree and TSS content of yam during the cold chain process are shown in Fig. 1. It can be seen that the browning degree of yam in the simulated cold chain process was on the rise, but the browning degree of yam in the compound fresh-keeping liquid treatment was always kept at a low level. Specifically, there was no significant difference between the compound fresh-keeping liquid treatment and the control (P>0.05); at 2 d after transportation and 4 d after sales, the browning degree of the compound fresh-keeping liquid treatment was much lower than that of the control, and the differences were significant (P<0.05). It can be seen from Fig. 1 that the change of TSS content of yam in the simulated cold chain process was negatively correlated with the change of the browning degree. The reason was that the tissue composition of fresh-cut yam changed under the effect of mechanical damage and self-aging, and various physiological and invasive diseases occurred, which caused the browning of yam and the loss of soluble nutrients[15]. The TSS content of yam treated with composite preservation liquid was always higher than that of control. Specifically, there was no significant difference between the compound fresh-keeping liquid treatment and the control after 1 d of storage (P>0.05); after 2 d of transportation and 4 d of sales, the decline of the TSS content of yam treated with the compound fresh-keeping liquid was delayed, and there was a significant difference from the control (P<0.05). It showed that the compound fresh-keeping liquid could effectively inhibit the browning of yam, while slowing down the loss of nutrients.

Different lowercase letters on the bar represented significant difference during the same period (P<0.05). The same was applied in Fig. 2 and Fig. 3.

Effect of the compound fresh-keeping liquid on PPO and POD activity of fresh-cut yam

The compound fresh-keeping liquid (AA 0.25%, CA 0.5%, Nisin 0.09%, GSH 0.15%) was used to treat yam, and the PPO and POD activity test results of yam during the cold chain process are shown in Fig. 2. As shown in Fig. 2, the PPO activity of yam in the simulated cold chain process generally increased first and then decreased. Specifically, After 1 d of storage, there was no significant difference between the compound fresh-keeping liquid treatment and the control (P>0.05); when it was transported for 2 d and sold for 2 d, that is, on the 5th d of the cold chain process, the PPO activity of the control treatment peaked and then declined rapidly, while the peak value of PPO activity of yam treated with compound fresh-keeping liquid was not obvious, and the value was much lower than the control from the 3rd to 6th d of the cold chain process, with a significant difference (P<0.05). It can be seen from Fig. 2 that the POD activity of yam in the simulated cold chain process generally increased first and then decreased. Specifically, there was no significant difference between the compound fresh-keeping liquid treatment and the control after 1 d of storage (P>0.05); when it was transported for 2 d and sold for 2 d, that is, on the 5th day of the cold chain process, the POD activity of yam peaked and then slowly decreased, while the peak POD activity of yam treated with the compound fresh-keeping liquid was 47.02% lower than that of the control; from the 3rd to the 7th d of the cold chain process, the POD activity of the compound fresh-keeping liquid treatment was lower than that of the control, with a significant difference (P<0.05). It showed that the compound fresh-keeping liquid slowed down the increase of the browning degree of yam by inhibiting the PPO and POD activity of yam.

Dongdi XIE et al. Optimization of Preservation on Fresh-cut Yam under Simulated Cold-chain Process

Effect of the compound fresh-keeping liquid on PAL activity and MDA content of fresh-cut yam

The compound fresh-keeping liquid (AA 0.25%, CA 0.5%, Nisin 0.09%, GSH 0.15%) was used to treat yam, and the PAL activity and MDA content of yam during the cold chain process were tested in Fig. 3. It can be seen that the PAL activity of yam in the simulated cold chain process was on the rise. Specifically, after 1 d of storage, there was no significant difference between the compound fresh-keeping liquid treatment and the control (P>0.05); and the PAL activity of the control treatment at the 3rd, 5th and 7th d of the cold chain process was at a higher level, which was significantly different from the compound fresh-keeping liquid treatment (P<0.05). It showed that the compound fresh-keeping liquid treatment weakened the induction of PAL activity by mechanical damage and inhibited the PAL activity of yam. It can be seen from Fig. 3 that the MDA content of yam in the simulated cold chain process was on the rise. It was due to that with the maturation and senescence of fruits and vegetables and the influence of environmental stress, certain free radicals produced in the metabolic process peroxidized membrane lipids, leading to an increase in MDA content[16]. Specifically, after 1 d of storage, there was no significant difference between the compound fresh-keeping liquid treatment and the control (P>0.05); and from the 3rd to the 7th d of the cold chain process, the MDA content of the excellent scheme was lower than that of the control, and the difference was significant (P<0.05). It might be because the compound fresh-keeping liquid effectively inhibited the activity of PAL, PPO and POD, slowed down the accumulation of MDA content, and could delay aging to a certain extent.

Conclusions and Discussion

In this study, we simulated the cold chain process at 4 ℃ (storage 1 d-transportation 2 d-sales 4 d), and established an equation model using DPS software data processing system by the uniform design method with the 7 d browning degree (BD) as the response value, obtaining a regression equation: Y=1.474 8-5.203 0X1+11.926 6X1X1-4.447 8X2X3, the predicted value (BD) by which was 0.76. From the regression equation, the optimal solution for the fresh-cut yam compound fresh-keeping liquid was 0.25% AA+0.50% CA+0.09% Nisin+0.15% GSH, and the measured value (BD) was 0.77, suggesting an obvious optimization effect. Compared with the control, the compound fresh-keeping liquid effectively reduced the increase in browning degree and the loss of TSS content of yam during the cold chain process, inhibited the activity of PAL, PPO, POD and the accumulation of MDA content, and had a good fresh-keeping effect.

References

[1] Editorial Board of Flora of China, Chinese Academy of Sciences. Flora of China[M]. Beijing: Science Press, 1988. (in Chinese)

[2] ALARCN-FLORES MI, ROMERO-GONZLEZ R, MARTNEZ-VIDAL JL, et al. Monitoring of phytochemicals in fresh and fresh-cut vegetables: a comparison[J]. Food Chemistry, 2014(142): 392-399.

[3] MARTINEZ-FERRER M, HARPER C, PEREZ-MUROZ F, et al. Modified atmo-sphere packaging of minimally processed mango and pineapple fruits[J]. Food Science, 2002(67):3365-3371.

[4] CHEN FZ. Research progress on enzymatic browning of fresh-cut yam and its inhibitory methods[J]. Biology Teaching, 2013, 38(8): 7-9. (in Chinese)

[5] ZHAO XT, ZHAO YL, WANG M, et al. Study on characteristics of peroxidase in Dioscorea opposita Thunb. cv. Tiegun and its browning inhibition[J]. Journal of Henan Agricultural Sciences, 2011, 40(1): 107-111. (in Chinese)

[6] XU CM, LI T, WANG YY, et al. Researching optimal color-protecting process of fresh-cut Chinese yam slice by uniform design[J]. Journal of Food Science and Technology, 2015, 33(1): 55-58. (in Chinese)

[7] FAN MR. Study on the processing technology and preservation technology of fresh-cut yam[D]. Fuzhou: Fujian Agriculture and Forestry University, 2011. (in Chinese)

[8] WANG M. Study on natural preservation technology of fresh-cut yam[D]. Guiyang: Guizhou University, 2017. (in Chinese)

[9] QIU SS, WANG YA, CHEN XF, et al. Effects of intermediate temperature treatment on quality of fresh-cut yam[J]. Science and Technology of Food Industry, 2016, 37(6): 325-329. (in Chinese)

[10] LI YY, HU CR. Experiment design and data processing[M]. Beijing: Chemical Industry Press, 2008. (in Chinese)

[11] XIE DD, LI DM, GONG ZW. Application of papain compound to inhibit enzymatic browning of yam[J]. Jiangsu Agricultural Sciences, 2017, 45(24): 179-182. (in Chinese)

[12] HU RB, LI X, WANG HY, et al. Isolation, purification and characterization of peroxidase from cucumber[J]. Food Science, 2014, 35(11): 168-173. (in Chinese)

[13] SUN GY, ZONG ZF. Plant pathology experimental technology[ M]. Beijing: China Agriculture Press, 2002. (in Chinese)

[14] LIU HT, LIU YY, PAN QH, et al. Novel interrelationship between salicylic acid, abscisic acid, and PIP 2-specific phospholipase C in heat acclimation-induced the rmotolerance in pea leaves [J]. Journal of Experimental Botany, 2006, 57(12): 3337-3347.

[15] MO YW, ZHENG JX, LI WC, et al. Effects of ascorbic acid and glutathione treatments on litchi fruits during post harvest storage[J]. Transactions of the Chinese Society of Agricultural Engineering, 2010, 26(3): 363-368. (in Chinese)

[16] SONG MB, FANG F, CHEN ZL, et al. Effects of different storage methods on storage quality of water chestnut[J]. Food Research and Development, 2016, 37(23): 178-183. (in Chinese)

- 农业生物技术(英文版)的其它文章

- Construction and Identification of Intestine-specific Expression Vector of Xylanase Gene (XynB)

- Sequence Mutation of Exon 7 of Badh2 Gene and Aroma Identification of Fragrant Rice Varieties

- Development of Specific DNA Markers for Detecting the Rice Blast Resistance Gene Alleles Pi2/9/z-t

- Design and Realization of Image Database of Pitaya Disease

- Cultivation Technology and Research Advance on the Germplasm Resources of Angelica dahurica

- Study on Genetic Toxicity of Solidago decurrens