炉火淬炼的青铜巅峰

文/五花肉

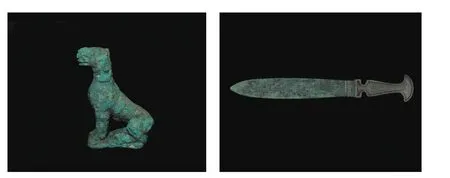

铜狗和铜剑·古巴比伦大英博物馆藏

青铜是金属冶炼史上最早的合金,最早可追溯至6 000年前的古巴比伦两河流域文明。它的出现,标志着人类从新石器时代迈进青铜器时代。

Bronze is the earliest alloy in the history of metallurgy, dating back to the ancient Babylonian rivers of 6,000 years ago. Its emergence marked the beginning of the human age from the Neolithic Age to the Bronze Age.

始于意外

Origin from Occasional Events

据荷马史诗《伊利亚特》记载,在古希腊神话中被视为工匠始祖的火神赫斐斯塔司,偶然把铜、锡投入铸造金银器的熔炉,却意外炼就一面青铜盾牌,战神阿喀琉斯凭借这面盾牌成为最伟大的战士。

According to“The Iliad of Homer”, the god of fire, Hephasta, who was regarded as the ancestor of artisans in ancient Greek mythology, accidentally put copper and tin into the furnace, and manufactured a bronze shield occationally. Achilles,the warrior ,won great honor in the Battle for Troy with this shield and became the greatest hero of Greek army.

青铜的熔点仅有799 ℃,是彼时冶炼技术下唯一可以量产的可塑性金属。早期青铜极为珍贵,通常用于祭祀的皇家礼器,国家博物馆的镇馆之宝后母戊鼎就是其中的典型代表。

Bronze has a melting point of only 799 centi-degree,which was the only plasticity metal that could be mass produced under the metallurgy technology at that time.The early bronzes were extremely precious, and were often used as royal sacrificial vessel.The Houmuwu square cauldron (sacrificial vessel in ancient China),treasure of National Museum of China, was a typical representative.

定于六齐

Standard Ratio of 5:1

到了战国时代,工匠长期实践发现,使用不同的铜、锡配比标准可以冶炼出不同强度的青铜。其中,锡的含量越高,青铜的硬度越强,脆度也相应提高。

In the Warring States Period, artisans found that bronze of different strengths could be manufactured with different copper and tin ratio. Among them,the higher the ratio of tin, the stronger the hardness of bronze and the corresponding increase in brittleness.

比如,制作钟鼎的青铜,其铜、锡配比为5:1,斧子、戈戟、剑刃、箭头等铜、锡配比依次递减,这也是世界上最早的青铜合金配比标准,谓之“六齐”,标志着青铜制造工艺进入成熟的巅峰期。

For example, the bronze made by Zhong Ding(sacrificial vessel with a shape of Chinese ancient bell) had a copper to tin ratio of 5:1. The ratio of copper and tin in the axe, the scorpion, the blade and the arrow declined in turn. This was also the world's first standard ratio for bronze alloys in the world.

后母戊鼎·商中国国家博物馆藏

青铜冰鉴·战国中国国家博物馆藏

“子禾子”青铜釜·战国中国国家博物馆藏

成于纯青

Achievement in Furnace Quenching

炉火淬炼是青铜冶炼的最后一个环节,也是决定成败的关键环节。其中,对温度的控制至关重要。当时,没有精确测温器具的工匠只能凭肉眼和经验观察。

Furnace quenching was the last process in bronze manufacturing, which was the key to determining success or failure. Among them, the temperature control was crucial. At that time, artisans without accurate temperature measuring instruments could only observe with the naked eye and experience.

铜、锡等金属熔点不同,不同温度淬炼时挥发的气体颜色也各不相同。熔点低的杂质率先挥发,产生黑浊之气。随着温度上升,先后产生黄白之气和青白之气,“青白之气竭,青气次之,然后可铸也。”青气的出现,代表铜、锡完全熔化,此时浇铸的青铜器质量最佳。此后,“炉火纯青”也成为工匠技艺纯熟的最佳褒奖。

“王”字青铜衡·战国中国国家博物馆藏

Copper, tin and other metals had different melting points, and the color of gases volatilized during quenching at different temperatures was also different. The impurities with a low melting point were first volatilized, resulting in a black turbid gas. As the temperature rose, there were yellow and white gas and white gas. According to "Kaogongji" The Artificers' Record,time of green gas suggested that cooper and tin were fully melted, which was the best temperature for bronze.The saying "The stove fire is pure green" implied the supreme honor of craftsmanship.

结 语

Conclusion

得益于标准化,青铜器逐渐从皇家礼器走向寻常百姓,迈入高质量发展的巅峰时期,直至公元前5世纪才逐渐被更具效率的铁器所取代,被誉为点燃华夏文明的火光。

Thanks to standardization, bronzes gradually became popular from royal rituals to ordinary families, and entered the peak period of high-quality development.Until the 5th century BC, bronze was gradually replaced by irons hardware of more efficiency, which was regarded as one of the greatest achievement of Chinese Civilization.