入射角度对气力射播小麦种粒入土参数影响的试验研究

王 超,李洪文,何 进,王庆杰,程修沛,魏忠彩,刘俊孝

入射角度对气力射播小麦种粒入土参数影响的试验研究

王 超,李洪文※,何 进,王庆杰,程修沛,魏忠彩,刘俊孝

(1. 中国农业大学工学院,北京 100083;2. 农业部河北北部耕地保育农业科学观测实验站,北京 100083)

针对稻麦轮作区黏湿土壤条件下的小麦机械化播种,为避免传统接触式小麦播种技术存在的粘附堵塞严重和作业阻力、功耗大等问题,该文采用非接触式小麦气力射播技术理论,通过自制的小麦气力射播试验台,开展整洁种床土壤条件下入射角度对气力射播小麦种粒入土参数影响的试验研究。试验结果表明:随着入射角度的增加,相同加速气压下小麦种粒的射播速度垂直分量和射播深度不断增加,小麦种粒触土后产生水平滑移和弹跳的几率变小,且各入射角度下射播深度与射播速度呈正相关关系,不同入射角度下小麦种粒呈现出不同射播深度和土壤冲击效果,小麦种粒未产生损坏情况;当入射角度≥45°和射播速度垂直分量≥25 m/s时,小麦种粒可被完全射播入土壤中且出苗率大于86%,90°入射角度下的射播效果最好。同时,为实现田间作业时小麦种粒的垂直射播入土,应使射播速度水平分量与机具作业速度相等且射播速度垂直分量≥25 m/s。试验结果可为非接触式小麦射播装备的研制提供基础数据和技术支撑。

农业机械;试验;小麦;气力射播;入射角度;非接触式

0 引 言

长江中下游稻麦轮作区是中国主要的粮食生产基地[1],其种植面积达900~1300万hm2[2],约占全国小麦总面积的37%以上。该区域光热资源丰富、降雨充沛、地下水位高[3],小麦生长受水资源限制作用小[4],使得稻茬田小麦种植适宜采用浅播浅种的农艺方式[5-6],与北方旱地小麦种植相比差异较大。然而,由于稻茬麦播种机具缺乏,且现有小麦机械化播种装备无法适应稻茬田含水量大、质地黏重的土壤环境[7-9],导致稻麦区小麦机械化播种困难。

近年来,国内外专家围绕稻茬麦机械化播种进行了大量研究,并研制出多种适应稻茬田播种小麦的播种机具。Sidhu等[10]研制的Happy Seeder播种机通过秸秆捡拾后抛装置、带状浅旋装置与开沟器的科学匹配,可在较低土壤含水率的稻茬田播种小麦。Pannu等[11]针对稻茬田小麦播种机开沟器粘附堵塞问题,设计了一种减粘防堵型播种机具,能够实现较为稳定的稻茬麦播种作业。李兵等[12]研制了一种GBSL-180型双轴式旋耕灭茬播种机,该机通过合理配置双轴旋耕结构和采用钝角开沟器,能够降低稻茬麦播种时的机具粘附堵塞问题。胡红等[13]设计了一种稻茬田小麦宽幅精量少耕播种机,该机采用低粘附的双圆盘开沟器在条带旋耕后的种床开出种沟完成稻茬麦条播播种。然而,目前国内外研究成果多是在传统小麦播种机的基础上优化改进而来[14-15],普遍采用浅旋浅开沟、开沟器优化或旋耕刀与开沟器匹配减粘防堵的技术,这种接触式播种技术仍存在因开沟器与黏湿土壤接触而导致的粘附堵塞和作业阻力、功耗增大等问题[16-18],制约了稻茬地小麦机械化生产。

本文根据非接触式播种技术理论[19],采用无开沟器的气力射播技术方法避免播种部件与土壤接触,将小麦高速投置于土壤,同时为研究入射角度对小麦种粒气力射播入土参数的影响,开展了无秸秆残茬整洁种床土壤条件下的小麦气力射播试验,以期为非接触式小麦射播装备的研制提供基础数据和技术支撑。

1 气力射播试验装置结构及工作原理

1.1 气力射播试验装置结构

根据气体引射原理和预试验研究得到气力射播试验装置,其结构示意图如图1所示,主要由调角支架、调角板、耐压气管I、引射器、气嘴、加速管和胶套等组成。耐压气管I与引射器的气嘴连通,引射器和加速管连接后固接在调角支架上,调角支架通过调角板实现不同入射角度的调节。

1.调角支架 2.调角板 3.耐压气管I 4.引射器 5.加速管 6.气嘴 7.胶套 8.进种口 9.土壤

1.Angle adjusting rack 2.Angle adjusting plate 3.Pressure resistant trachea I 4.Ejector 5.Accelerating tube 6.Air nozzle 7. Rubber sleeve 8.Seed entrance 9.Soil

注:H为射播高度,mm;L为射播距离,mm;为入射角度,(°)。

Note:His pneumatic seeding height, mm;Lis pneumatic seeding distance, mm;is incident angle, (°).

图1 气力射播试验装置结构示意图

Fig.1 Structure of pneumatic seeding device

1.2 工作原理

试验时,使加速管最下端与土壤耕层表面保持一定的射播高度H,高压气体自耐压气管I输入并从气嘴下端喷射,在加速管内形成稳定的高速气流,随后从进种口投放小麦种粒,小麦种粒在引射器内空气负压的作用下被吸入并与高速气流混合,胶套避免吸入的小麦种粒与钢制气嘴发生碰撞而产生损坏,小麦种粒受高速气流作用在加速管(加速管长度为600 mm,内径为10 mm)内加速后射出,以一定的速度和入射角度(0~90°)射入土壤中,最后关闭高压气体输送完成单次小麦气力射播试验过程。

2 射播试验设计与方法

2.1 试验设备

本试验采用自制的小麦气力射播试验台进行试验研究,如图2所示。该试验台主要包括台架、气力射播装置、气压调节装置、耐压气管、空气压缩机和计算机等。试验时,打开空气压缩机为试验提供持续稳定气压,通过气压调节装置控制加速气压(气压为0~1 MPa)大小以实现小麦种粒不同射播速度的调节。

1.空气压缩机 2.耐压气管II 3.气压调节装置 4.气力射播装置 5.试验土壤 6.台架 7.电子测角仪 8.计算机 9.高速摄像机 10.太阳灯

主要仪器及设备:5F01C-16G高速摄像机(合肥君达高科信息技术有限公司),EF-200太阳灯(上海金贝摄影器材实业有限公司),电子数显卡尺(哈尔滨量具刃具集团有限责任公司),三角板(得利集团有限公司),电子测角仪(西安胜利仪器有限责任公司)。

2.2 试验材料

试验土壤样品取自湖北省农业科学院作物研究所试验田(114°32¢28²E,30°49¢23²N),取样时间为2018年10月,该试验田常年稻麦轮作,土壤类型为壤质黏土,土壤pH值为6.1,塑限为23.20%,液限为41.62%。采集耕作层0~5 cm的土样,依据《土工试验规程》(SL237- 1999)[20],将土样经自然风干、去杂、研磨和过筛等操作后,分别装入自制的方形土槽(200 mm´200 mm´50 mm)内压实并用保鲜膜密封供试验[21-22],试验用土样的土壤含水率为37%,土壤容重约为1.20 g/cm3。试验用小麦品种为湖北省大面积种植的郑麦9023。

2.3 试验方法

为研究入射角度对小麦气力射播入土参数结果的影响,根据实际播种作业中存在机具作业速度的工况,分别开展入射角度为15°、30°、45°、60°、75°、90°共6个水平下的小麦种粒气力射播试验,根据引射器实际作业压力范围,每个入射角度水平下分别进行加速气压为0.2、0.4、0.6、0.8和1 MPa下的5组射播试验,每组试验在同一加速气压下重复射播3个点,每个射播点射播1粒小麦种粒。

2.3.1 射播时间

对小麦种粒自加速管最下端飞出至射入土壤的射播过程进行高速拍摄,设置5F01C-16G高速摄像机的拍摄模式为按帧采集、并行曝光,采集长度为8 000帧,采集周期为200s,曝光时间为100s。按照以上参数设置,每次射播时由高速摄像机高速采集模式下的软件界面得到高速摄像机的实际拍摄帧率F;试验结束后,从每个射播点试验拍摄得到的所有图片中提取射播过程图片,射播时间计算公式为

式中T为第个水平第组第个射播点的射播时间,s;N为第个水平第组第个射播点提取到的射播过程的图片张数;F为实际拍摄帧率,帧/s。

2.3.2 射播速度

根据前期预试验,试验设置射播高度H约为90 mm,为提高试验结果准确性,每次射播试验用电子数显卡尺测量每次射播的实际射播高度。考虑到小麦射播时间极短,以及高速气流自加速管下端喷出后的紊流射流特性[23-25],故视射播过程中小麦种粒匀速运动,同时定义使小麦种粒刚好被完全射入土壤中时的射播速度为临界射播速度。射播速度计算公式为

式中v为第个水平第组的平均射播速度,m/s;L为第个水平第组第个射播点的实际射播距离,mm。其中

式中H为第个水平第组第个射播点的实际射播高度,mm。

2.3.3 射播深度

射播深度为小麦通过气力射播冲击土壤所形成的种穴最底部与土壤表面的垂直距离,根据稻茬麦播种农艺要求,射播深度最大应不超过50 mm[10-11,15]。将小麦种粒刚好被完全射入土壤中时的射播深度称为临界射播深度。每个入射角度水平的射播试验结束后,分别测量每个射播点的小麦种粒射播深度。射播深度计算公式为

式中H为第个水平第组的平均射播深度,mm;H为第个水平第组第个射播点的射播深度,mm。

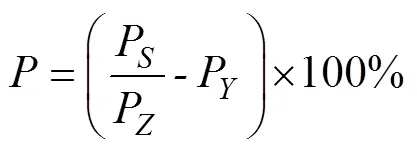

2.3.4 种子破损率

参照GB/T9478-2005《谷物条播机试验方法》[26]和GB/T 6973-2005《单粒(精密)播种机试验方法》[27],射播试验前观察挑取未损伤的小麦种粒开展试验,试验结束后挑选和计算试验中破碎损伤的种粒并计算小麦种子破损率。小麦种子破损率计算公式为

式中为小麦种子破损率,%;P为试验中破损的小麦种子总个数;P试验用小麦种子总个数;P为小麦种子的原始破碎率(试验总样本中破损的小麦种子个数与总样本中小麦数量的比值。由于试验样本为挑选的未损伤小麦种粒,该试验中小麦种子的原始破碎率为0),%。

3 结果与分析

3.1 气力射播效果

试验中,小麦种粒经气力加速后,均可自加速管最下端飞出并高速冲向土壤。以入射角度45°、加速气压1 MPa时的射播过程(图3)为例,初始时小麦种粒飞出后在空中不断翻滚,经过约2 412s进入土壤。

图3 小麦气力射播过程示例

不同入射角度下,小麦种粒经加速后射向土壤产生“倾斜撞击-水平滑移-弹跳飞出”、“倾斜撞击-水平滑移-入土”和“垂直撞击-翻滚-入土”3种射播入土效果。试验中随着入射角度的增加,小麦种粒触土后产生水平滑移和弹跳的几率变小,不同入射角度的小麦种粒呈现出不同的射播深度和土壤冲击效果,各射播点的小麦种粒均未产生损坏情况。当入射角度为15°时,小麦种粒触土后即产生不同程度滑移和弹跳,且均无法被射入土壤,小麦种粒从方形土槽左侧射入,触土并撞击土壤表面形成不同深度的划痕后从右侧弹出土槽,如图4a所示;当入射角度为30°时,小麦种粒在较高加速气压(0.8、1 MPa)下由左向右水平滑移3~8 mm后可实现射播入土,如图4b所示,而加速气压分别为0.2、0.4和0.6 MPa时,小麦种粒触土撞击并产生自左向右的水平滑移后弹出土槽;当入射角度为45°、60°°和75°时,不同加速气压下小麦种粒虽产生不同程度的水平滑移但均可被射入土壤中;当入射角度为90°时,小麦种粒均可被垂直射入土壤并形成单粒种穴,未产生滑移和弹跳现象,入土效果最佳,如图4c所示。

3.2 射播入土参数拟合关系

试验中,不同入射角度和加速气压下的小麦种粒气力射播试验结果如表1所示。

图4 不同入射角度的小麦气力射播入土效果示意图

表1 小麦种粒气力射播试验结果

利用Matlab 2014a软件[28-30],分别对小麦气力射播过程的射播速度与射播深度、垂直速度与射播深度进行拟合,结果如图5所示。由图5可知,各拟合方程的决定系数均达到0.9以上,拟合关系较好。

整体上看,随着入射角度的提高,小麦种粒的射播深度不断增加,且各入射角度下的射播深度与射播速度均呈正相关关系。当入射角度足够大时,小麦种粒在较小的射播速度下便可实现相对较深的射播深度,如在入射角度为15°(图5a)的条件下,小麦种粒以约61.50 m/s的最大射播速度仍无法射入土壤,而入射角度为45°、90°时,以同样的射播速度可分别达到约6和10 mm的射播深度(图5c、图5f);提高射播速度有利于小麦种粒在较小的入射角度下实现射播入土,如入射角度为30°(图5b)时,结合前述射播入土效果可知,当射播速度≥52.14 m/s时小麦种粒可被射入土壤,射播速度≤44.46 m/s时种粒触土即被弹飞。此外,在15°入射角度下小麦种粒无法被射入土壤中,而入射角度为30°、45°、60°、75°、90°时,小麦种粒达到临界射播深度(约为3 mm)时所需的临界射播速度分别为50~55、45~50、40~45、35~40和25~30 m/s。

当入射角度不同时,相同加速气压下的射播速度差别较小而垂直速度却差异较大,如当加速气压为1 MPa时,90°入射角度下的射播速度和垂直速度均为66.63 m/s(图5f),分别比入射角度为30°时的射播速度61.74 m/s、垂直速度30.87 m/s(图5b)提高约7.92%、53.67%。因此,随着入射角度的增加,相同加速气压下的垂直速度不断提高,小麦种粒的射播深度也逐渐增加。当入射角度为30°、45°、60°、75°时,小麦种粒刚好实现完全射播入土时所需的垂直速度为25~30 m/s,与90°入射角度下的结果一致;当入射角度为15°时,最大垂直速度约为15.92 m/s,无法实现小麦种粒射播入土。

因此,当入射角度为30°~90°且垂直速度≥25 m/s时,小麦种粒可被完全射入土壤中;当入射角度为90°时,相同加速气压下的射播深度最大为11.27 mm。

3.3 出苗情况

为进一步观察气力射播方式对小麦出苗效果的影响,在相同试验条件下,重复进行各入射角度下的小麦气力射播试验,其中由于入射角度15°时小麦种粒均被弹飞,故不再进行相应的出苗试验。试验后将土槽在18 ℃室温下放置10 d后观察小麦出苗情况,结果如表2所示。

表2 不同入射角度的小麦出苗情况

整体上,小麦在低入射角度下的出苗率较低。由表2可知,入射角度为45°~90°时的小麦出苗率大于86%,结合前述射播试验中未观察到小麦种粒明显损坏情况,说明在该入射条件下采用气力射播方式将小麦种粒射入土壤的播种方式可行,但后续仍需大量田间试验以进一步观察和统计出苗效果。当入射角度为30°时,小麦出苗率约为66.7%,低于GB 4404.1-2008《粮食作物种子第一部分:禾谷类》[31]中规定的小麦种子85%发芽率标准,其原因可能为低入射角度下,小麦种粒水平滑移较长导致小麦种粒磨损加大而产生内部微小裂纹,进而种粒不能萌发。入射角度为45°~90°时,小麦出苗率大于86%,出苗效果较好,符合播种要求。

3.4 射播速度分析

综上所述,采用气力射播方式播种小麦,在入射角度≥45°和射播速度垂直分量≥25 m/s时,小麦种粒可实现稳定的完全射播入土和良好的出苗效果;相同加速气压下通过增加入射角度可获得更深的射播深度,且入射角度为90°时的射播效果最好。同时,为明确田间射播播种作业时,入射角度与机具作业速度的关系,对小麦种粒的射播速度进行分析,如图6所示。

图5 不同入射角度下速度与射播深度的拟合关系

注:Om为小麦种粒质心;v1为机具作业速度,m·s-1;vS为射播速度,m·s-1;vSx为射播速度水平分量,m·s-1;vSy为射播速度垂直分量,m·s-1。

为实现小麦种粒的垂直射播入土,应使射播速度的水平分量与机具作业速度相等且射播速度垂直分量≥25 m/s;由图6中关系可知,实现垂直射播时机具作业速度分别与射播速度和入射角度呈正相关、负相关关系,即当机具作业速度提高时,可通过增加射播速度或减小入射角度以实现不同作业速度下的小麦种粒的垂直气力射播。

4 结 论

1)采用非接触式气力射播播种理论,通过气力加速将小麦种粒射入无秸秆残茬的整洁种床土壤,并以此开展不同入射角度对小麦气力射播入土参数影响的试验研究。结果表明当入射角度≥45°和射播速度垂直分量≥25 m/s时,小麦种粒可实现稳定的完全射播入土壤中且出苗率大于86%,90°入射角度下的射播效果最好,射播深度最大为11.27 mm。

2)小麦气力射播试验表明,随着入射角度的增加,相同加速气压下射播速度垂直分量和射播深度不断增加,小麦种粒触土后产生水平滑移和弹跳的几率变小,且各入射角度下射播深度与射播速度均呈正相关关系,不同入射角度下小麦种粒呈现出不同射播深度和土壤冲击效果,同时小麦种粒均未产生损坏情况。

3)试验结果表明,在进行田间射播作业时,为实现小麦种粒的垂直射播入土,应使射播速度水平分量与机具作业速度相等且射播速度垂直分量≥25 m/s。

[1] 马力,杨林章,沈明星,等. 基于长期定位试验的典型稻麦轮作区作物产量稳定性研究[J]. 农业工程学报,2011,27(4):117-124. Ma Li, Yang Linzhang, Shen Mingxing, et al. Study on corp yield stability in a typical region of rice-wheat rotation based on long-term fertilization experiment[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(4): 117-124. (in Chinese with English abstract)

[2] 邱让建,杨再强,景元书,等. 轮作稻麦田水热通量及影响因素分析[J]. 农业工程学报,2018,34(17):82-88. Qiu Rangjian, Yang Zaiqiang, Jing Yuanshu, et al. Analysis of water and heat flux over rice-wheatrotation field and influencing factors[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(17): 82-88. (in Chinese with English abstract)

[3] Qi Jing, Herman Van Keulen, Huib Hengsdijk. Modeling biomass, nitrogen and water dynamics in rice-wheat rotations[J]. Agricultural Systems, 2010, 103(7): 433-443.

[4] 张秀梅,张居敏,夏俊芳,等. 水旱两用秸秆还田耕整机关键部件设计与试验[J]. 农业工程学报,2015,31(11):10-16. Zhang Xiumei, Zhang Jumin, Xia Junfang, et al. Design and experiment on critical component of cultivator for strawreturning in paddy field and dry land[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(11): 10-16. (in Chinese with English abstract)

[5] 李朝苏,汤永禄,吴春,等. 播种方式对稻茬小麦生长发育及产量建成的影响[J]. 农业工程学报,2012,28(18):36-43. Li Chaosu, Tang Yonglu, Wu Chun, et al. Effect of sowing patterns on growth, development and yield formation of wheat in rice stubble land[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(18): 36-43. (in Chinese with English abstract)

[6] 李朝苏,汤永禄,解立胜,等. 2BMFDC-6型稻茬麦半旋播种机设计与性能试验[J]. 西南农业学报,2011,24(2):789-793. Li Chaosu, Tang Yonglu, Xie Lisheng, et al. Design and experiment of 2BMFDC-6 half-tillage seeder of wheat after rice[J]. Southwest China Journal of Agricultural Sciences, 2011, 24(2): 789-793. (in Chinese with English abstract)

[7] 赵广才. 中国小麦种植区域的生态特点[J]. 麦类作物学报,2010,30(4):684-686. Zhao Guangcai. Ecology characteristics of Chinese wheat planting region[J]. Journal of Triticeae Crops, 2010, 30(4): 684-686. (in Chinese with English abstract)

[8] 刘世平,陈后庆,聂新涛,等. 田土壤肥力的综合评价[J]. 农业工程学报,2008,24(5):51-56. Liu Shiping, Chen Houqing, Nie Xintao, et al. Comprehensive evaluation of tillage and straw returning on soil fertility in a wheat-rice double cropping system[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008,24(5):51-56. (in Chinese with English abstract)

[9] 朱惠斌. 稻茬地种床破茬粉碎式防堵装置研究[D]. 北京:中国农业大学,2013. Zhu Huibin. Study on Anti-Blocking Device of No-Till Wheat Planter for Broken and Crushing Rice Crop Stubble[D]. Beijing: China Agricultural University, 2013. (in Chinese with English abstract)

[10] Sidhu H S, Singh M, Humphreys E, et al. The happy seeder enables direct drilling of wheat into rice stubble[J]. Australian Journal of Experimental Agriculture, 2007, 47(7): 844-854.

[11] Pannu C J S, Shukla L N. Tractor front-mounted cross-conveyor paddy straw thrower[J]. AMA-Agricultural Mechanization in Asia Africa and Latin America, 2010, 41(2): 35-42.

[12] 李兵,王继先,张健美,等. GBSL-180型双轴式旋耕灭茬播种机设计[J]. 农业机械学报,2008,39(3):180-182. Li Bing, Wang Jixian, Zhang Jianmei, et al. Design of GBSL-180 seeder with two-axel rotary tillaging and stubble cleaning[J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 39(3): 180-182. (in Chinese with English abstract)

[13] 胡红,李洪文,李传友,等. 稻茬田小麦宽幅精量少耕播种机的设计与试验[J]. 农业工程学报,2016,32(4):24-32. Hu Hong, Li Hongwen, Li Chuanyou, et al. Design and experiment of broad width and precision minimal tillage wheat planter in rice stubble field[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(4): 24-32. (in Chinese with English abstract)

[14] 朱惠斌,李洪文,何进,等. 稻茬地双轴驱动防堵式小麦免耕播种机[J]. 农业机械学报,2013,44(6):39-44. Zhu Huibin, Li Hongwen, He Jin, et al. No-till wheat seeder with two-axel drive anti-blocking in rice stubble field[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(6): 39-44. (in Chinese with English abstract)

[15] 曹卫华,杨敏丽. 江苏稻麦两熟区机械化生产模式的效率分析[J]. 农业工程学报,2015,31(增刊1):89-101. Cao Weihua, Yang Minli. Efficiency of mechanical production mode in paddy rice-wheat double cropping area of Jiangsu province [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(Supp.1): 89-101. (in Chinese with English abstract)

[16] Gathala M K, Ladha J K, Saharawat Y S, et al. Effect of tillage and crop establishment methods on physical properties of a medium-textured soil under a seven-year rice-wheat rotation[J]. Soil Science Society of America Journal, 2011, 75(5): 1851-1862.

[17] Ladha J K, Dawe D, Pathak H, et al. How extensive are yield declines in long-term rice-wheat experiments in Asia[J]. Field Crops Research, 2003, 81(2): 159-180.

[18] 秦宽,丁为民,方志超,等. 稻麦联合收获开沟埋草一体机播种系统设计与试验[J]. 农业机械学报,2017,48(5):54-62. Qin Kuan, Ding Weimin, Fang Zhichao, et al. Design and experiment of seeding system for harvest ditch and stalk-disposing machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(5): 54-62. (in Chinese with English abstract)

[19] 刁培松,杜瑞成,杨自栋,等. 气动射种理论研究[J]. 农机化研究,2005(1):94-96. Diao Peisong, Du Ruicheng, Yang Zidong, et al. Theoretical research on pneumatic seeding[J]. Journal of Agricultural Mechanization Research, 2005(1): 94-96. (in Chinese with English abstract)

[20] 中华人民共和国水利部. GB/T50123-1999土工试验方法标准[S]. 北京:中国计划出版社,1999.

[21] 韦杰,史炳林,李进林. 紫色土坡耕地埂坎土壤抗剪性能对含水率的响应[J]. 农业工程学报,2016,32(20):153-160. Wei Jie, Shi Binglin, Li Jinlin. Response of soil shear strength to soil water content in purple soil slope cropland bunds[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(20): 153-160. (in Chinese with English abstract)

[22] 孟凤英,丁启朔,鹿飞,等. 冲击作用下粘性土壤破碎体的分形维数与影响因[J]. 农业机械学报,2009,40(3):108-111. Meng Fengying, Ding Qishuo, Lu Fei, et al. Fractal dimensions of cohesive soil under impact and its influencing factors[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(3): 108-111. (in Chinese with English abstract)

[23] 谢晶,柳雨嫣,王金锋. 喷嘴结构对气流冲击式速冻机钢带表面换热特性的影响[J]. 农业工程学报,2018,34(18):292-298. Xie Jing, Liu Yuyan, Wang Jinfeng. Effects of nozzle structures of air impinging freezer on heat transfer characteristics of steel strip surface[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(18): 292-298. (in Chinese with English abstract)

[24] 王超,朱金波,胡标. 环空淹没射流吸气性能与能量耗散特征研究[J]. 农业机械学报,2016,47(8):14-21,13. Wang Chao, Zhu Jinbo, Hu Biao. Suction performance and energy dissipation characteristics of annular submerged jets[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(8): 14-21, 13. (in Chinese with English abstract)

[25] 于贤龙,高振江,代建武,等. 苜蓿气体射流冲击联合常温通风干燥装备设计及试验[J]. 农业工程学报,2017,33(15):293-300. Yu Xianlong, Gao Zhenjiang, Dai Jianwu, et al. Design and experiment of air-impingement jet combined with normal temperature ventilation dryer for alfalfa[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(15): 293-300. (in Chinese with English abstract)

[26] 中国国家标准化管理委员会. GB/T 9478-2005,谷物条播机试验方法[S]. 北京:中国标准出版社,2005.

[27] 中国国家标准化管理委员会. GB/T 6973-2005,单粒(精密)播种机试验方法[S]. 北京:中国标准出版社,2005.

[28] 张伏,王亚飞,马田乐,等. 山羊蹄底部非规则曲面仿生形貌数学模型构建及验证[J]. 农业工程学报,2018, 34(15):30-36. Zhang Fu, Wang Yafei, Ma Tianle, et al. Mathematical model establishment and validation of bionic irregular plantar surface of goat’s hoof[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(15): 30-36. (in Chinese with English abstract)

[29] 雷小龙,廖宜涛,丛锦玲,等. 油菜小麦兼用气送式直播机集排器参数优化与试验[J]. 农业工程学报,2018,34(12):16-26. Lei Xiaolong, Liao Yitao, Cong Jinling, et al. Parameter optimization and experiment of air-assisted centralized seed-metering device of direct seeding machine for rape and wheat[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(12): 16-26. (in Chinese with English abstract)

[30] Bunce C. Correlation, agreement, and bland-altman analysis: Statistical analysis of method comparison studies [J]. Am J Ophthal, 2009, 148(1): 4-6.

[31] 中国国家标准化管理委员会. GB 4404.1-2008,粮食作物种子第一部分:禾谷类[S]. 北京:中国标准出版社,2008.

Effect of incident angle on wheat soil-ripping parameters by pneumatic seeding

Wang Chao, Li Hongwen※, He Jin, Wang Qingjie, Cheng Xiupei, Wei Zhongcai, Liu Junxiao

(1.,,100083,; 2.(),,100083,)

Rice-wheat rotation area, with heavy clay soil texture, that it iswheat planting area accounts for more than 37% of the total wheat sowing area in China as one of the major grain production bases, and rice-wheat rotation is the main cropping pattern in this region. Meanwhile, because of the shortage crop stubble and more rainfall in autumn, which lead to serious wet damage during the tilling and seeding stage for this field. Currently, most of the existing no-tillage and less-tillage seeding equipment for wheat sowing in rice stubble areas were optimized and developed on the basis of traditional contact-type wheat seeding technology, which lead to adhesion and serious blockage phenomenon, as well as increasing of operating resistance and power consumption during working. Therefore, a innovative technical proposal of non-contact type pneumatic seeding technology that could avoid contacting between sowing parts and soil was introduced in this paper, which in order to solve the problems of soil adhesion, blockage, drag increment as well as poor sowing quality for wheat seeders under the condition of sticky heavy loam clay in rice-wheat rotation areas. Experiment that utilized a self-made platform for wheat pneumatic seeding was conducted, which could rip wheat seed into the soil condition of clean seed bed without straw and stubble mulching by high pressure accelerating airflow. During the pneumatic seeding experiment, keeping a certain pneumatic seeding height and incident angle between the accelerating tube and topsoil surface, high-pressure gas was injected from the upper apex of the air nozzle and ejected from the bottom of it, which a stable high-speed airflow was formed in the accelerator tube (the length of the accelerator tube is 600 mm and the diameter is 10 mm). Then wheat seeds were put into the seed entrance and absorbed at a high speed under the negative air pressure of the ejector, during which the rubber sleeve could protect wheat seeds from damaging. After mixing with airflow, wheat seeds were accelerated by high-speed air flow in the accelerating tube. Finally, the wheat seeds flew out and ripped into the soil at a certain incident angle and high pneumatic seeding velocity.At the same time, high-speed photography technology was used to study the parameters of pneumatic seeding velocity, vertical velocity and pneumatic seeding depth under six levels (15°, 30°, 45°, 60°, 75°, 90°) of incident angles, and pneumatic seeding experiments under five different accelerating air pressures of 0.2 MPa, 0.4 MPa, 0.6 MPa, 0.8 MPa and 1 MPa for each incident angle were carried out respectively. Pneumatic seeding experimental results showed that: For pneumatic seeding in soil without straw and stubble mulching, when the incident angle increases continuously, wheat seeds can achieve higher vertical component of pneumatic seeding velocity deeper and pneumatic seeding depth at the same accelerating air pressures, the probability of horizontal slip and bounce of wheat seeds after touching soil show an decreasing trend, and pneumatic seeding depth has a positive correlation with pneumatic seeding velocity under each incident angle. Moreover, wheat seeds show various pneumatic seeding depth and soil impact effect without damage after pneumatic seeding. When the incident angles and the vertical component of pneumatic seeding velocity were more than 45° and 25 m/s respectively, wheat seeds can be completely ripped into the soil and the emergence rate is more than 86%. The best pneumatic seeding effect achieved as incident angle is 90°. In order to realize wheat vertical pneumatic seeding in field operation, the horizontal component of pneumatic seeding velocity should be equal to the operating speed of seeder and the vertical component of pneumatic seeding velocity should be greater than 25 m/s, which the seeder operating speed shows positively and negatively correlated with pneumatic seeding velocity and incident angle, respectively. The experimental results can provide basic data and technical support for the development of non-contact wheat seeding equipment in rice-wheat rotation area.

agricultural machinery; experiment; wheat; pneumatic seeding; incident angle; non-contact type

2019-02-17

2019-03-29

国家现代农业小麦产业技术体系专项经费项目(CARS-03);教育部创新团队发展计划项目(IRT13039)

王 超,博士生,主要从事保护性耕作研究。Email:superwang_999@sina.com

李洪文,博士,教授,主要从事保护性耕作研究。Email:lhwen@cau.edu.cn

10.11975/j.issn.1002-6819.2019.16.004

S223.2+3

A

1002-6819(2019)-16-0032-08

王 超,李洪文,何 进,王庆杰,程修沛,魏忠彩,刘俊孝. 入射角度对气力射播小麦种粒入土参数影响的试验研究[J]. 农业工程学报,2019,35(16):32-39. doi:10.11975/j.issn.1002-6819.2019.16.004 http://www.tcsae.org

Wang Chao, Li Hongwen, He Jin, Wang Qingjie, Cheng Xiupei, Wei Zhongcai, Liu Junxiao. Effect of incident angle on wheat soil-ripping parameters by pneumatic seeding[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(16): 32-39. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.16.004 http://www.tcsae.org