Uster Technologies:Stop poor quality at source

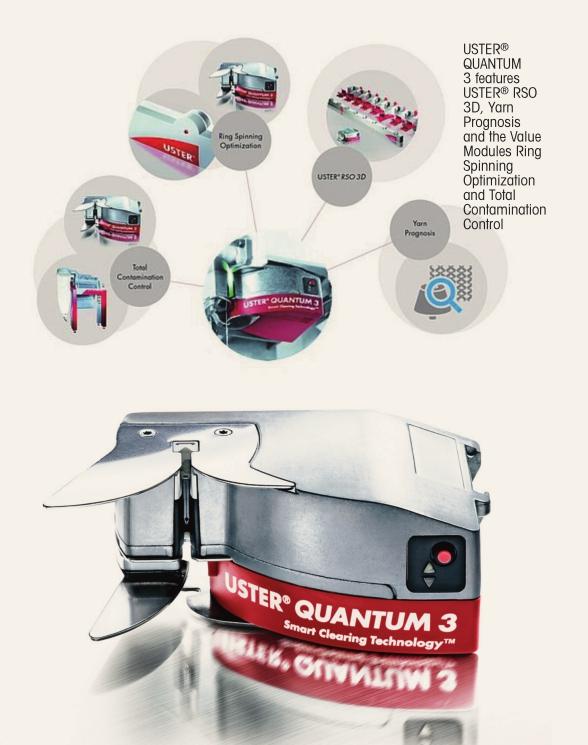

Yarn producers no longer need to rely on expensive clearer cuts at winding to protect their quality. Now, USTER? QUANTUM 3 brings the ultimate in connected intelligence: prevention of yarn faults at source. Data from fiber cleaning and ring spinning is integrated with in-line monitoring of 100% of yarn, to unlock optimization potential for the entire mill.

USTER has devised three special Value Modules– introduced at ITMA 2019 – enabling preventive actions to improve quality, reduce waste and maximize performance. The Value Modules apply comprehensive analysis of data from quality systems at the blowroom, spinning machines and winders to provide all-round protection, actually preventing bad quality before it is produced.

Clearers are the final safeguard against disturbing faults and outliers in yarns. Unique technology for USTER? QUANTUM 3 means it now fulfills the timetested concept: “prevention is better than cure.”

Tackling contamination at both ends

Spinners can implement Total Contamination Control by combining information from the USTER? JOSSI VISION SHIELD fiber cleaning system and USTER? QUANTUM 3 clearers. Proven technology eliminates foreign matter at both ends of the yarn manufacturing process, so that mills can manage remaining yarn contamination and avoid unnecessary waste. Contamination control in the blowroom results in less contamination– and fewer cuts – at winding, with ultimately reduced contamination in both yarn and fabric. Balancing waste levels and clearer cuts controls quality and reduces costs, optimizing the whole process.

Stop poor quality, instead of cutting it

USTER Ring Spinning Optimization (RSO) works at the most costly stage in yarn manufacturing, allowing mills to analyze combined quality data from spinning and winding in a single system. Information from USTER? SENTINEL and USTER? QUANTUM 3 is intelligently translated by RSO into enhanced options for improvements, while the Roving Stop function stops defective yarn production. Spinners benefit from significant profitability increases and protection against claims.

Even greater potential for improvement comes with the state-of-the-art USTER? RSO 3D, for extended Ring Spinning Optimization. This delivers quality data for each individual spindle position. The facility for quality mapping across the entire ring spinning machine helps to identify outlier sides, sections or spindles, as well as assisting maintenance decisions.

USTER? QUANTUM 3 also collaborates seamlessly with Muratec QPRO EX/FPRO EX, Spin Inspector and USTER? SENTINEL. Outlier quality data from these connections activates Roving Stop at individual spindle positions where a quality problem is detected –again showing how USTER? QUANTUM 3 prevents the production of poor quality yarn.

Preventing claims with yarn prognosis

It is becoming more important for spinners to understand the quality perspectives of their customers in weaving and knitting – so that issues such as claims can be prevented before the yarn is shipped. Combining USTER? QUANTUM 3 with USTER? TENSOJET and USTER? QUALITY EXPERT helps provide the‘customer viewpoint, by giving an accurate prognosis of weaving performance, based on an easy-to-understand grading system. No fabric samples are needed, and testing costs are virtually zero. Feedback suggests that the prognosis information is an accurate reflection of real yarn behavior on both warping and weaving machines.

Productivity plus

A further advantage of the Ring Spinning Optimization Value Module is its impact on cop build-up quality. Yarn clearer data from USTER? QUANTUM 3 flows into the RSO Module of USTER? QUALITY EXPERT and a comprehensive speed curve analysis is made. The results guide spinners to the best machine settings for higher production yields and the required quality. This reduces quality variations over the cop and boosts the overall performance of the ring spinning machine.

In one smart system, USTER? QUANTUM 3 has the power to create a future of better quality and productivity for spinners – in which defects are prevented rather than merely cleared.

- China Textile的其它文章

- New report forecasts excellent worldwide outlook for nonwovens through 2023

- Status quo of industrial textiles in Xinjiang Uygur Autonomous Region

- HK Fashion Week S/S:Latest fashion tech equips the industry for market expansion

- MILANO UNICA 29th edition:Italy holds steady

- Yarn Expo exhibitors offer a sustainable,traceable starting point for fashion brands

- July 2019