无煤柱切顶沿空留巷矿压显现规律

赵萌烨 黄庆享 黄克军

摘 要:为了掌握无煤柱切顶留巷的矿压显现规律并检验巷道支护效果,以澄合矿区董东煤矿50107工作面为研究对象,采用现场监测的手段对无煤柱切顶沿空留巷受采动影响条件下的顶板下沉规律、帮部变形规律及单体支柱受力变化规律进行了实测,并同时对切顶效果、挡矸效果及巷道稳定性进行了分析与评价。结果表明,巷道矿压随工作面的临近而逐渐增大,采动过程中靠近采空区侧的巷道矿壓显现程度更为剧烈,表现出明显的非对称性特征,巷道顶板的回转运动是造成巷道非对称矿压显现的主要原因。此外,无煤柱切顶沿空留巷阶段性变化特征明显,初始变化阶段位于工作面后方0~35 m;快速变形阶段位于工作面后方35~75 m;缓慢变形阶段位于工作面后75 m以外,巷道变形及支柱受力均达到稳定状态。巷道矿压显现的主要过程集中在快速变形阶段,需加强对巷道围岩的控制。实践表明,无煤柱切顶沿空留巷采用锚网配合单体支柱的支护方式可行。

关键词:无煤柱开采;切顶沿空留巷;矿压显现规律;巷道变形;巷道支护

中图分类号:TD 823 文献标志码:A

DOI:10.13800/j.cnki.xakjdxxb.2019.0406 文章编号:1672-9315(2019)04-0597-06

Abstract:To explore the pressure behavior and to test the supporting effect of gob-side entry retaining with roof cutting and non-pillar mining, a variety of on-site monitoring techniques are used to test the law of roof subsidence, rib deformation and stress of the single prop with the working face 50107 from Dongdong coal mine in Chenghe mining area as the subject, a variety of analysis and an evaluation have been made of the effects of roof cutting and tamping as well as roadway stability in this paper. The research results show that the pressure of roadway gradually increases with the approaching of the working face. Meanwhile, the pressure in the roadway near the side of the goaf is more intense during the mining process with significant asymmetry demonstrated. The rotation of the roof is the main reason for the apparent mine pressure of the roadway. In addition, the changes are obvious in different stages of the pressure of the coal roadway. The initial change stage is located at 0~35 m behind the working face.Rapid deformation mainly occurs 35~75 m behind the working face; Slow deformation stage is located at 75 m behind the working surface, the roadway is rapidly reduced and tends to be stable. The main process of roadway pressure is concentrated at the stage of rapid deformation, and it is necessary to strengthen the control of surrounding rock of roadway. Practice has proved the feasibility of the anchor net and the support of the single props in the roof.

Key words:non pillar mining;roof cutting at gob side entry retaining;mine pressure behavior;roadway deformation;roadway support

0 引 言

无煤柱切顶沿空留巷是一项高效的采煤新技术[1-2],能够缓解开采效率低、生产成本高的问题。该技术一方面省去一条回采巷道,减少了巷道开拓量;另一方面,开采过程中取消了区段煤柱,采空区直接与巷道相连,减少了资源的浪费,提高了回采率;此外,无煤柱开采方式对解除了煤柱集中应力,有利于减小下部煤层开采过程中的应力集中程度。

无煤柱切顶沿空留巷矿压显现规律受切顶工艺影响[3],巷道变形及受力表现出明显的非对称性、阶段性及持续性。无煤柱切顶沿空留巷技术在传统沿空留巷基础上发展而来,刘听成等最早研究了沿空留巷技术[4-5],提出沿空留巷先后受上下2个工作面的采动影响,服务时间长,总变形量大。华心祝等[6-8]建立了沿空留巷力学模型和巷旁充填支护技术。柏建彪、侯朝炯等给出了沿空留巷充填体参数选择依据,同时提出了沿空留巷围岩控制方法[9-11]。何满潮院士提出了“切顶短壁梁”理论[12]和切顶卸压自动成巷技术[13-14]。目前,国内对切顶留巷的矿压实测研究不多,掌握无煤柱切顶留巷的矿压规律,对巷道支护研究具有重要的意义。

通过对巷道顶板下沉量、巷帮水平变形量及单体支柱受力进行实测,掌握澄合矿区董东煤矿50107工作面无煤柱切顶留巷矿压规律,为无煤柱切顶沿空留巷支护设计提供了科学依据。

1 巷道基本条件

1.1 工作面条件

董东矿50107工作面煤层倾角3°~6°,工作面宽度117 m,走向长度为224 m.工作面开采5#煤层,采高3.4 m,直接顶厚度2 m左右,岩性为砂质泥岩和炭质泥岩。基本顶厚度约8 m,岩性为粉砂岩。

1.2 巷道支护方式

50107工作面回采巷道宽度4.6 m,高度3.4 m。巷道顶部采用长度2.8 m的无纵助左螺纹钢锚杆,直径为20 mm,间排距为700 mm×600 mm;锚索长度8.3 m,直径为21.8 mm,间距600 mm.采煤侧帮部采用直径20 mm,长度2.4 m的左螺纹钢锚杆,间排距为700 mm×600 mm.非采空侧帮部,采用直径22 mm,长度300 mm的右旋等强螺纹钢,间排距700 mm×600 mm,锚杆托盘采用螺形托盘,尺寸为150 mm×150 mm.巷旁支护采用挡矸柱和单体柱联合支护的方式,挡矸柱通过锚网相互连接,每隔600 mm设置一根,单体柱的间排距为300 mm×300 mm,如图1所示。

1.3 切顶留巷参数

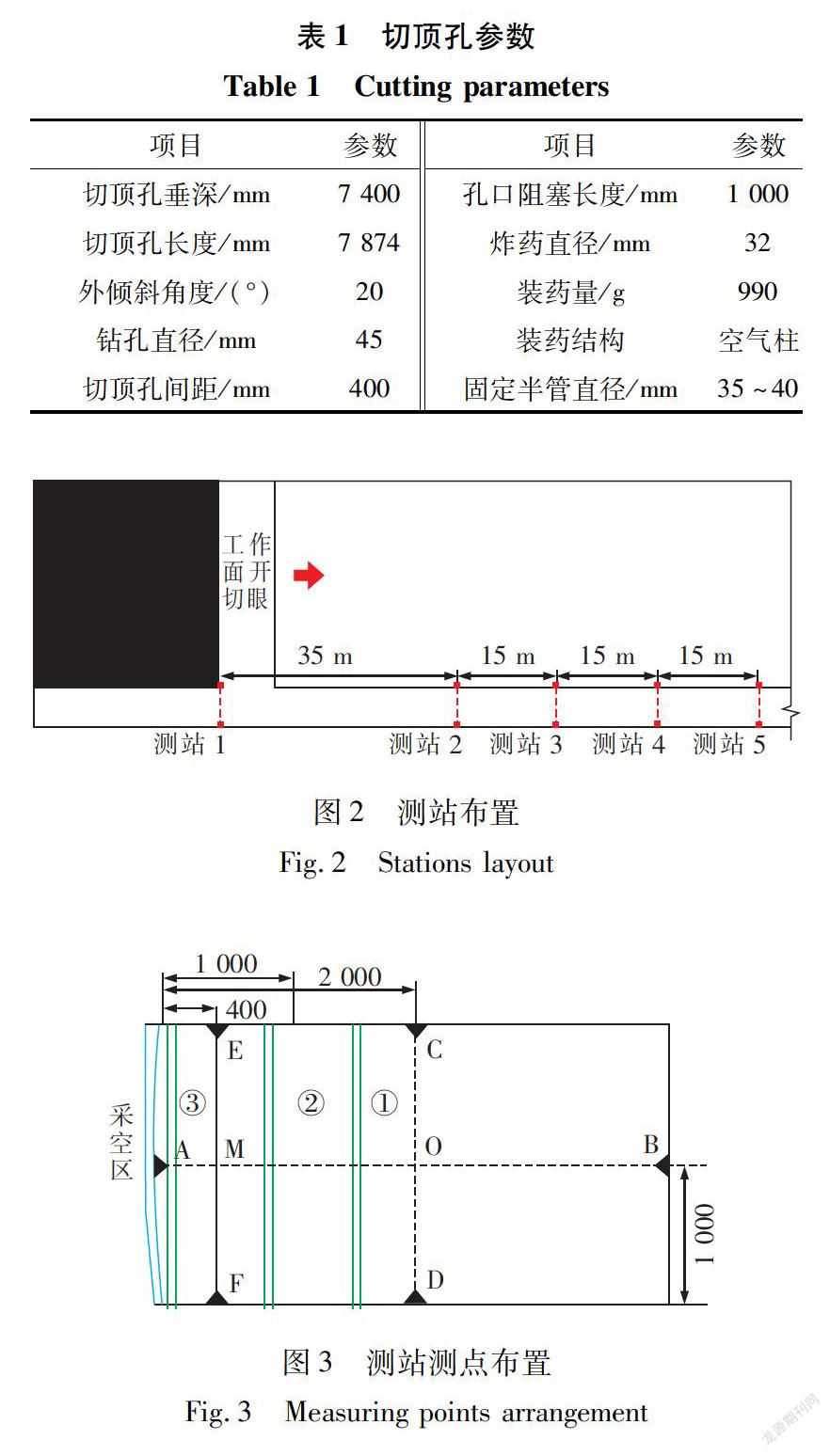

超前切顶的工艺及效果是无煤柱切顶沿空留巷成功与否的关键,董东煤矿50107工作面采用打孔定向爆破的方式进行超前切顶作业,垂直孔深7 400 mm,倾角20°,具体参数见表1.

2 巷道矿压显现规律

2.1 监测方案

巷道测站布置如图2所示,测站断面布置方式如图3所示,AB为两帮移近测线,CD和EF为顶底移近测线,①②③为巷旁单体支柱受力测点。

2.2 巷道变形规律

2.2.1 顶板下沉规律

实测切顶沿空留巷测站顶板下沉曲线,如图4所示。有如下规律。

1)巷道顶板的非对称下沉说明了巷道顶板的回转现象[13-14]。采空区侧巷道顶板下沉量平均在330 mm左右,巷道中部顶板下沉量平均为250 mm.采空区侧巷道顶板下沉量比巷道中部位置大将近32%.董东煤矿未采用切顶巷道的顶板平均下沉量达400 mm;

2)工作面后方0~35 m,巷道顶板未发生明显下沉;35~50 m巷道顶板下沉量最大,是下沉的主要区域;50~75 m顶板下沉量减小,工作面后方75 m,顶板趋于稳定。前期变形主要受老顶回转运动的影响,大约为2~3个周期来压步距(17 m);后期变形主要是采空区破碎岩体压实引起的顶板缓慢沉降[15];

3)无煤柱切顶巷道受采动影响存在“影响范围大、稳定时间长”的变形特点。较传统沿空留巷而言,切顶卸压作用降低了顶板应力的传递,巷道变形存在一定的滞后。

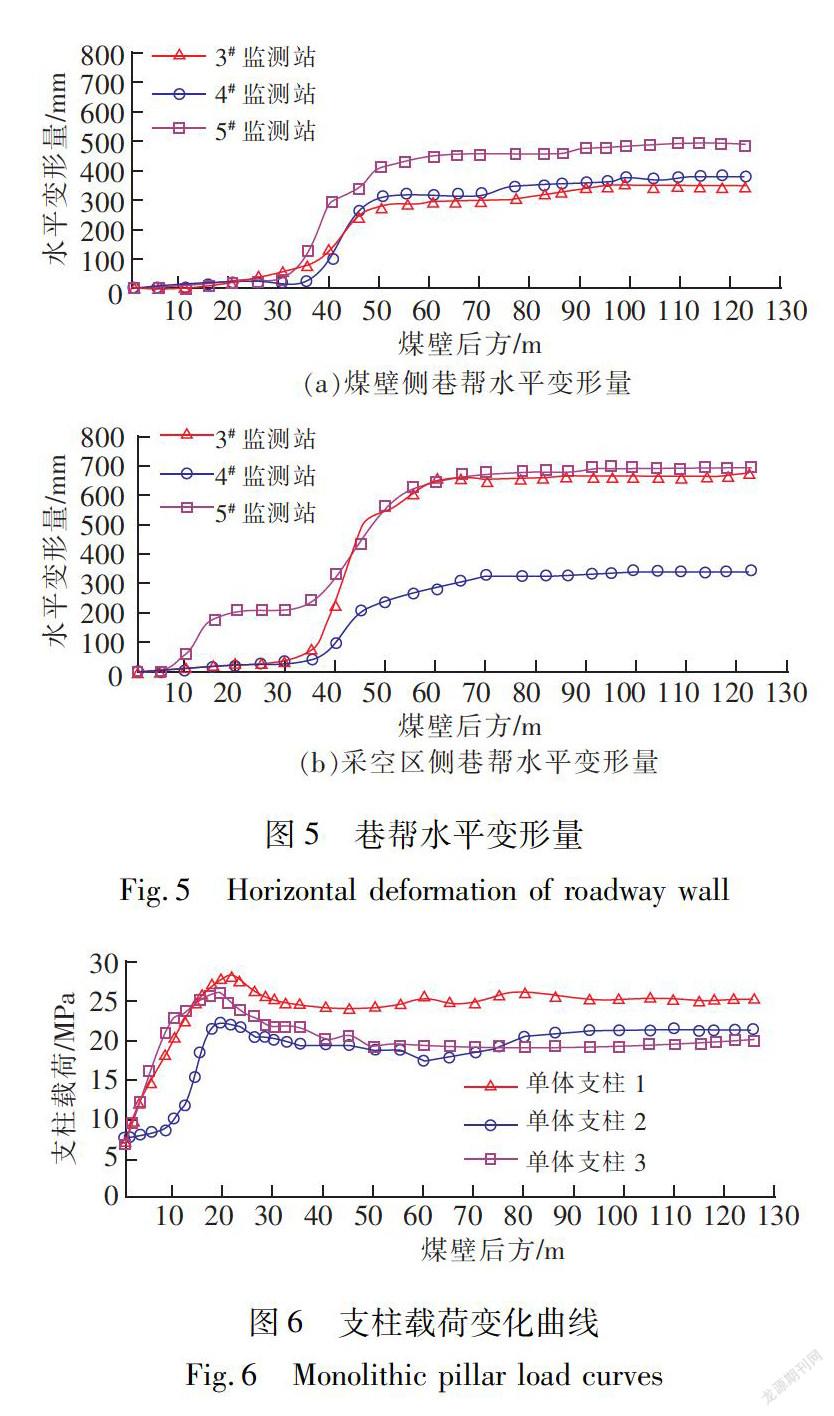

2.2.2 巷帮变形规律

实测无煤柱切顶沿空留巷煤壁侧帮如图7(a)所示,采空区侧人工帮变形曲线如图5(b)所示。

煤壁侧巷帮变形集中于巷帮中部,水平变形量平均350 mm.采空区侧巷帮水平变形量(指支护网向巷道内的挤进量)平均672 mm.采空区侧的帮部挤进量为煤壁侧的水平变形量的1.9倍。帮部水平变形分为3个阶段。

1)初始变形阶段:位于工作面后方0~35 m,约2倍周期来压步距内,处于工作面端头弧三角板保护区,巷帮水平变形量较小;

2)快速变形阶段:位于工作面后方35~50 m,约2~3倍周期来压步距(平均17 m),处于顶板结构回转运动区。本阶段巷帮水平变形量占总变形量的70%以上。采空区顶板回转运动,导致巷帮变形具有非对称性;

3)缓慢变形阶段:位于工作面后方50~75 m以外,大于3倍周期来压步距,进入采空区顶板压实区,巷帮水平变形缓慢变化,达到稳定状态。

2.3 巷道支柱受力

单体支柱受力曲线如图6所示,其中1号支柱紧靠近采空区一侧,2号支柱居中,距离采空区1 m,3号支柱距离采空区1.8 m.

1)靠近采空区一侧的1号支柱平均载荷24.3 MPa,比靠巷帮3号支柱载荷大20%.支柱的平均初始载荷7.1 MPa,稳定载荷22.1 MPa,平均變化量达到15 MPa;

2)单体支柱所受载荷经历“增大-减小-稳定”的动态变化过程[16-17],支柱受力增大的区域主要集中在工作面后方20 m范围内;工作面后方20~30 m经历明显的卸压过程,随后受力继续增大;工作面后方75 m单体支柱受力达到稳定,采空区一侧单体稳定受力在25 MPa左右,巷道中部稳定受力在20 MPa.

3 无煤柱切顶沿空留效果

3.1 切顶效果

现场使用钻孔窥视仪观察切顶效果,如图7所示,在孔口处可看出切顶孔之间的裂隙明显发育。巷外切顶效果是留巷的关键,50107工作面巷切顶有效切断了顶板的应力联系,减小了沿空留巷的矿压显现程度。

3.2 巷道稳定性

根据现场观测,已切顶但未受采动影响的超前巷道表现出较好的稳定性。巷道未进行超前支护,也未发生明显变形,如图8所示。

当巷道处于工作面后方时,由于巷道一侧已采空,顶板发生向相邻采空区一侧的下沉,靠近采空区一侧下沉量较大,但巷道整体变形量允许范围之内,巷道稳定且可足以满足生产要求,支护效果如图8所示。

3.3 巷旁挡矸效果

切顶留巷下巷旁挡矸支护效果的关键是沿空一侧巷旁支护体的材料和性能的选择[18-20]。巷旁挡矸支护体设置后应能够快速增阻,支护顶板保持顶板自承能力,在工作面后方周期来压前达到切顶阻力切落采空区一定高度的顶板[21-22];上覆岩层剧烈活动稳定前有较大的变形能力,支护提还要具有足够的可缩性,适应顶板回转下沉;具有较高的后期强度,保持顶板结构的平衡[23-24]。实践表明,无煤柱切顶留巷采用锚网配合单体支柱与曲线挡矸柱的支护方式可行,支护效果如图9所示。

4 结 论

1)董东50107工作面切顶留巷,切顶作用有效切断了巷道顶板应力传递,降低了巷道整体的矿压显现程度。实践表明,切顶后顶板垮落效果良好,无煤柱切顶留巷采用锚网配合单体支柱的支护方式可行。

2)巷道矿压显现表现出一定的非对称性。采空区一侧顶板下沉量及单体支柱受力均大于巷道中部,顶板下沉量大出32%,单体支柱受力大近24%,体现了巷道顶板的回转运动特征。受顶板压力的作用,采空区一侧锚网帮的变形量为煤壁侧帮部1.9倍。

3)巷道变形及受力经历初始变化、快速变化及持续变化阶段。初始变化阶段位于工作面至后方35 m内,巷道受弧三角悬顶保护,变形程度低,支柱受力小。快速变形阶段位于工作面后方35~75 m,受顶板回转运动影响,巷道变形及单体支柱受力均达到整体值的70%以上。缓慢变形阶段位于工作面采动75 m后,处于垮落顶板压实区,巷道变形缓慢并趋于稳定。

参考文献(References):

[1] 何满潮,宋振骐,王 安,等.长壁开采切顶短壁梁理论及其110工法——第三次矿业科学技术变革[J].煤炭科技,2017,34(1):1-9,13.

HE Man chao,SONG Zhen qi,WANG An,et al.Theory of longwall mining by using roof cutting shortwall team and 110 method:the third mining science and technology reform[J].Coal Science & Technology Magazine,2017,34(1):1-9,13.

[2]张国锋,何满潮,俞学平,等.白皎矿保护层沿空切顶成巷无煤柱开采技术研究[J].采矿与安全工程学报,2011,21(4):511-516.

ZHANG Guo feng,HE Man chao,YU Xue ping,et al.Research on the technique for no pillar mining with gob side entry formed by advanced roof caving in the protective seam in Baijiao Coal Mine[J].Journal of Mining & Safety Engineering,2011,21(4):511-516.

[3]陸士良.无煤柱巷道的矿压显现与受力分析[J].煤炭学报,1981,6(4):29-37.

LU Shi liang.Analysis of the rock behaviour and the stress in sur rounding rook of the roadway in pillarless mining[J].Journal of China Coal Society,1981,6(4):29-37.

[4]刘听成.无煤柱护巷的应用与进展[J].矿山压力与顶板管理,1994,10(4):2-10,80.

LIU Ting cheng.Application and development in maintaining roadways without chain pillars[J].Ground Pressure and Strata Control,1994,10(4):2-10,80.

[5]肖永福,刘听成.沿空留巷合理支护和卸压保护的研究[J].西安矿业学院学报,1991,11(3):1-8.

XIAO Yong fu,LIU Ting cheng.Research on the rational support and the defense by unloading of roadways retained along gob side entry retaining[J].Journal of Xi’an Mining Institute,1991,11(3):1-8.

[6]李迎富,华心祝.沿空留巷围岩结构稳定性力学分析[J].煤炭学报,2017,42(9):2262-2269

LI Ying fu,HUA Xin zhu.Mechanical analysis of the stability of surrounding rock structure of gob side entry retaining[J].Journal of China Coal Society,2017,42(9):2262-2269

[7]文志杰.无煤柱沿空留巷控制力学模型及关键技术研究[D].青岛:山东科技大学,2011.

WEN Zhi jie.Study on the key technologies and mechanical model of gob side retaining entry without coal pillar[D].Qingdao:Shandong University of Science and Technology,2011.

[8]郑桂荣,杨万斌.煤巷煤体破裂区厚度的一种计算方法[J].煤炭学报,2003,28(1):37-40.

ZHENG Gui rong,YANG Wan bin.A calculation method for the failure zone width of side coal wall of roadway in seams[J].Journal of China Coal Society,2003,28(1):37-40.

[9]柏建彪,侯朝炯.复合顶板极软煤层巷道锚杆支护技术研究[J].岩石力学与工程学报,2001,20(1):53-56.

BAI Jian biao,HOU Chao jiong.Research on control mechanisms and supporting technology of surrounding rock of god side entry by fully mechanized caving mining[J].Chinese Journal of Rock Mechanics and Engineering,2001,20(1):53-56.

[10]郭育光,柏建彪,侯朝炯.沿空留巷巷旁充填体主要参数研究[J].中国矿业大学学报,1992,31(4):8-12.

GUO Yu guang,BAI Jian biao,HOU Chao jiong,Research on the main parameters of filling body stress in gob side entry retaining[J].Journal of China University of Mining & Technology,1992,31(4):8-12.

[11]柏建彪,王卫军,侯朝炯,等.综放沿空掘巷围岩控制及机理支护技术研究[J].煤炭学报,2000,25(5):478-480.

BAI Jian biao,WANG Wei jun,HOU Chao jiong,et al.Research on blot inject support technology of complex roof in extremely soft coal seam roadway[J].Journal of China Coal Society,2000,25(5):478-480.

[12]何满潮,王 炯,孙晓明,等.负泊松比效应锚索的力学特性及其在冲击地压防治中的应用研究[J].煤炭学报,2014,39(2):214-221.

HE Man chao,WANG Jiong,SUN Xiao ming,et al.Mechanics characteristics and applications of prevention and control rock[J].Journal of China Coal Society,2014,39(2):214-221.

[13]高玉兵,杨 军,何满潮,等.厚煤层无煤柱切顶成巷碎石帮变形机制及控制技术研究[J].岩石力学与工程学报,2017,36(10):2492-2502.

GAO Yu bing,YANG Jun,HE Man chao,et al.Mechanism and control techniques for gangue rib deformations in gob side entry retaining formed by roof fracturing in thick coal seams[J].Chinese Journal of Rock Mechanics and Engineering,2017,36(10):2492-2502.

[14]張晓虎,郭鹏飞,王 炯,等.沿空留巷卸压钻孔间距优化试验研究[J].煤炭技术,2016,35(6):6-8.

ZHANG Xiao hu,GUO Peng fei,WANG Jiong,et al.Study on pressure relief drilling spacing optimization in gob side entry retaining[J].Coal Technology,2016,35(6):6-8.

[15]惠兴田,崔英哲.沿空留巷预支撑技术研究及应用[J].煤矿安全,2014,45(4):47-50.

HUI Xing tian,CUI Ying zhe.Study and application of pre support technique for gob side entry retaining[J].Safety in Coal Mines,2014,45(4):47-50.

[16]NING Jian guo,WANG Jun,LIU Xue sheng,et al.Soft strong supporting mechanism of gob side entry retaining in deep coal seams threatened by rockburst[J].International Journal of Mining Science and Technology,2014,24(6):805-810.

[17]XU Ying,SHEN Le.Mechanical characteristics and control technology of floor in gob side entry retaining[J].Springer Singapore:2018,29(5):45-47.

[18]惠兴田,胡梓俊.切顶留巷下挡矸支护研究[J].煤炭技术,2018,37(6):8-11.

HUI Xing tian,HU Zi jun.Research on blocking Gangue supporting in roof cutting roadway[J].Coal Technology,2018,37(6):8-11.

[19]张 农,张志义,吴 海,等.深井沿空留巷扩刷修复技术及应用[J].岩石力学与工程学报,2014,33(3):468-474.

ZHANG Nong,ZHANG Zhi yi,WU Hai,et al.Technology and application of reparation in deep gob side entry retaining[J]. Chinese Journal of Rock Mechanics and Engineering,2014,33(3):468-474.

[20]高玉兵,郭志飚,杨 军,等.沿空切顶巷道圍岩结构稳态分析及恒压让位协调控制[J].煤炭学报,2017,42(7):1672-1681.

GAO Yu bing,GUO Zhi biao,YANG Jun,et al.Steady state analysis of gob side entry retaining formed by roof fracturing and control techniques by optimizing mine pressure[J].Journal of China Coal Society,2017,42(7):1672-1681.

[21]魏锦周.浅埋中厚煤层沿空切顶自动成巷的稳定性分析[J].煤炭与化工,2018,41(3):61-63.

WEI Jin zhou.Stability analysis of gob side cutting roof roadway of shallowly buried coal seam[J].Coal and Chemical Industry,2018,41(3):61-63.

[22]FAN Ke gong,LIANG Hong guang,MA Chi shuai,et al.Non harmonious deformation controlling of gob side entry in thin coal seam under dynamic pressure[J].Journal of Rock Mechanics and Geotechnical Engineering,2014,6(3):269-274.

[23]张 农,韩昌良,阚甲广,等.沿空留巷围岩控制理论与实践[J].煤炭学报,2014,39(8):1635-1641.

ZHANG Nong,HAN Chang liang,KAN Jia guang,et al.Theory and practice of surrounding rock control for pillarless gob side entry retaining[J].Jouranl of China Coal Society,2014,39(8):1635-1641.

[24]DENG Yue hua,WANG Shou quan.Feasibility analysis of gob side entry retaining on a working face in a steep coal seam[J].International Journal of Mining Science and Technology,2014,24(4):499-503.