Effects of Zn- and Sn-Doped MgO Powdered Functional Layer on Discharge Characteristics in AC Plasma Display Panels

DENG Jiang and YU You

(College of Optoelectronic Technology, Chengdu University of Information Technology Chengdu 610225)

Abstract Zn- and Sn-doped MgO powder preparing via a chemical coprecipitation method was spin-coated on alternating current plasma display panel (AC PDP) front panel as a functional layer to improve the discharging performance of AC PDP. The new products were characterized by X-ray diffraction (XRD), X-ray photoelectrom spectroscopy (XPS), scanning electron microscope (SEM) and an ultraviolet-visible spectrophotometer. The results showed that zinc and tin atoms had been successfully incorporated into the crystal lattice of MgO, which made the transmission only decrease by 4%~7%. Within 7% Xe-Ne pressure range of 200~450 torr, the new functional layer consistently showed lower firing and sustain maximum voltages than that of the conventional MgO layer.Therefore, this functional layer was important for improving the discharge efficiency of AC PDP and reducing its power consumption.

Key words alternating current plasma display panel (AC PDP); firing voltage; protective layer; sustain voltage; transmission; Zn- and Sn-doped MgO

Alternating current plasma display panel (AC PDP) has many advantages, such as high brightness,good color rendition, rich gray scale, fast response speed of moving picture, strong electric and magnetic immunity, and thin thickness[1-4]. Until the beginning of this century, AC PDP has been considered to be one of the most promising alternatives to the traditional cathode ray tubes. However, the market share of AC PDP in the commercial FPD market is declining now.The most fundamental reason is attributed to its low power efficiency and high cost. To reduce the power consumption, researches on discharge gas components,discharge cell structure, and driving circuit have been done. Furthermore, many studies on the performance improvement of the protecting layer of AC PDP have emerged recently. One of the methods is to dope impurities into MgO, such as Na-doped MgO[5],Si-doped MgO[6], Ca-doped MgO[7], and Zn-doped MgO[8]. Another method is to coat some films or nanoparticles on MgO film, such as LaB6/MgO[1],SrO/MgO[9], Au nanoparticles/MgO[10], MgO nanoparticles/MgO[11], Mg particles/ MgO[12], and MgCaO/Li-doped MgO[13].

In this paper, Zn- and Sn-doped MgO powder was prepared by a chemical coprecipitation process. Then the Zn- and Sn-doped MgO powder was formulated into slurry and coated on MgO protective layer by the spin coating technology. The structure, appearance,and visible light transmission of Zn- and Sn-doped MgO powdered functional layer on the surface of AC PDP front panel were studied. The discharge voltages of Zn- and Sn-doped MgO functional layers measurement confirmed that the Zn- and Sn-doped MgO particle leaded to a notable improvement of power efficiency of AC PDP.

1 Experiments

Metal precursor solution of fabricating Zn- and Sn-doped MgO powder was prepared by dissolving 5.0×10-4mol zinc acetate dihydrate[Zn(CH3COO)2·2H2O], 2.5×10-4mol tin (II) chloride[SnCl2·2H2O], and 0.025 mol magnesium nitrate hydrate [Mg(NO3)2·6H2O]in absolute ethyl alcohol(100 mL). Then 4 mL ethanol amine and 16 mL polyethylene glycol (PEG 400) were mixed and added to the above solution. Subsequently, 20 mL absolute ethyl alcohol and 20 mL ammonia were mixed and added dropwise to the metal ion solution at 70 ℃,followed by constant magnetic stirring for 2 h and standing for 8 h. The obtained precipitate was washed with ethanol and deionized water repeatedly several times, and annealed at high temperature for 4 h. Next,the powder was mixed with PEG-400 and ethanol in a mass ratio of 1:1:10 and this slurry was spin coated onto AC PDP front panel with speed of 100 r/min.

Fig. 1 Structure of AC PDP front panel with Zn- and Sn-doped MgO powdered functional layer.

The schematic diagram of the panel with functional layer was shown in Fig.1 and specific parameters were reported in our previous work[14].XRD and XPS were used to analyze the structure of the functional layer. Moreover, in order to study the effect of functional layers on the morphology and transmittance of AC PDP, SEM and an ultraviolet-visible spectrophotometer were introduced,respectively.

2 Results and Discussions

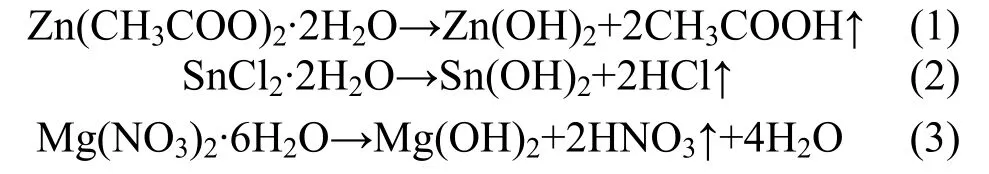

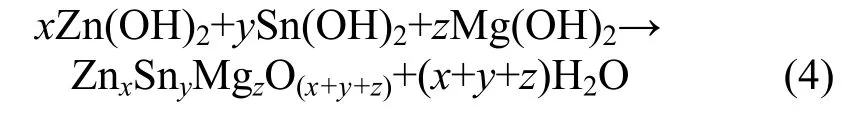

The XRD patterns of the Zn- and Sn-doped MgO powder annealed at different temperatures are shown in Fig.2a~Fig.2c. At 450 ℃ (Fig.2a), each orientation peak of MgO was low, indicating the poor crystallinity.At 550 ℃ (Fig.2a), the sample had excellent crystallinity and no feature peaks from zincite or tin oxide were observed. The (200) orientation of MgO presents the strongest intensity. When the annealing temperature was up to 650 ℃ , (200), (220) and (222)orientation peaks of MgO decreased and some impurity peaks appeared. Thus, 550 ℃ was accepted as our final annealing temperature. The possible reactions existing in this experiment were discussed as follows.First, ammonia hydrolyzed and released OH-. In the alkaline conditions, Zn(CH3COO)2·2H2O, SnCl2·2H2O and Mg(NO3)2·6H2O hydrolyzed, respectively, i.e.

Then, Zn(OH)2, Sn(OH)2and Mg(OH)2decomposed in the annealing furnace and the corresponding reaction were:

According to the above reactions, the Zn- and Sndoped MgO powder was fabricated successfully.

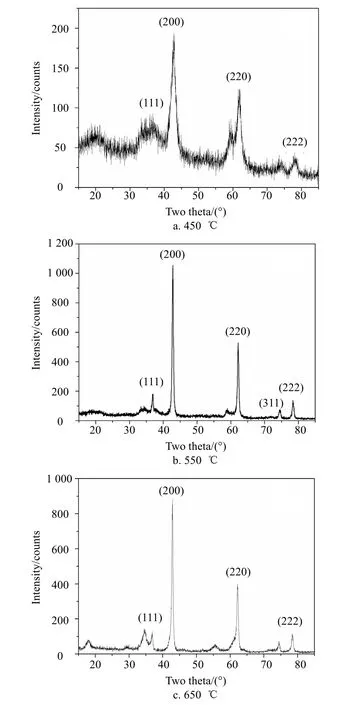

Fig.3 shows the XPS pattern of fabricated Zn- and Sn-doped MgO powder. The Mg, Zn, Sn and O characteristic peaks could be clearly detected, which confirmed the existence of Zn and Sn element.Compared with the Mg and O feature peaks, the intensities of Zn and Sn peaks were relatively weak,which attributed to the less quantity of the dopant. The XRD and XPS results implied that Zn2+and Sn2+had been incorporated into the lattice of MgO. Moreover, itcould be found that the diffraction angles of all diffraction peaks of the Zn- and Sn-doped MgO sample were nearly identical with pure MgO. The possible reason was that the doping amount of Zn and Sn in MgO was very small, although the ionic radius of Zn2+and Sn2+was larger than Mg2+(Mg2+: 0.072 nm, Zn2+:0.074 nm, Sn2+: 0.112 nm).

Fig. 2 XRD patterns of Zn- and Sn-doped MgO powder as a function of annealing temperature

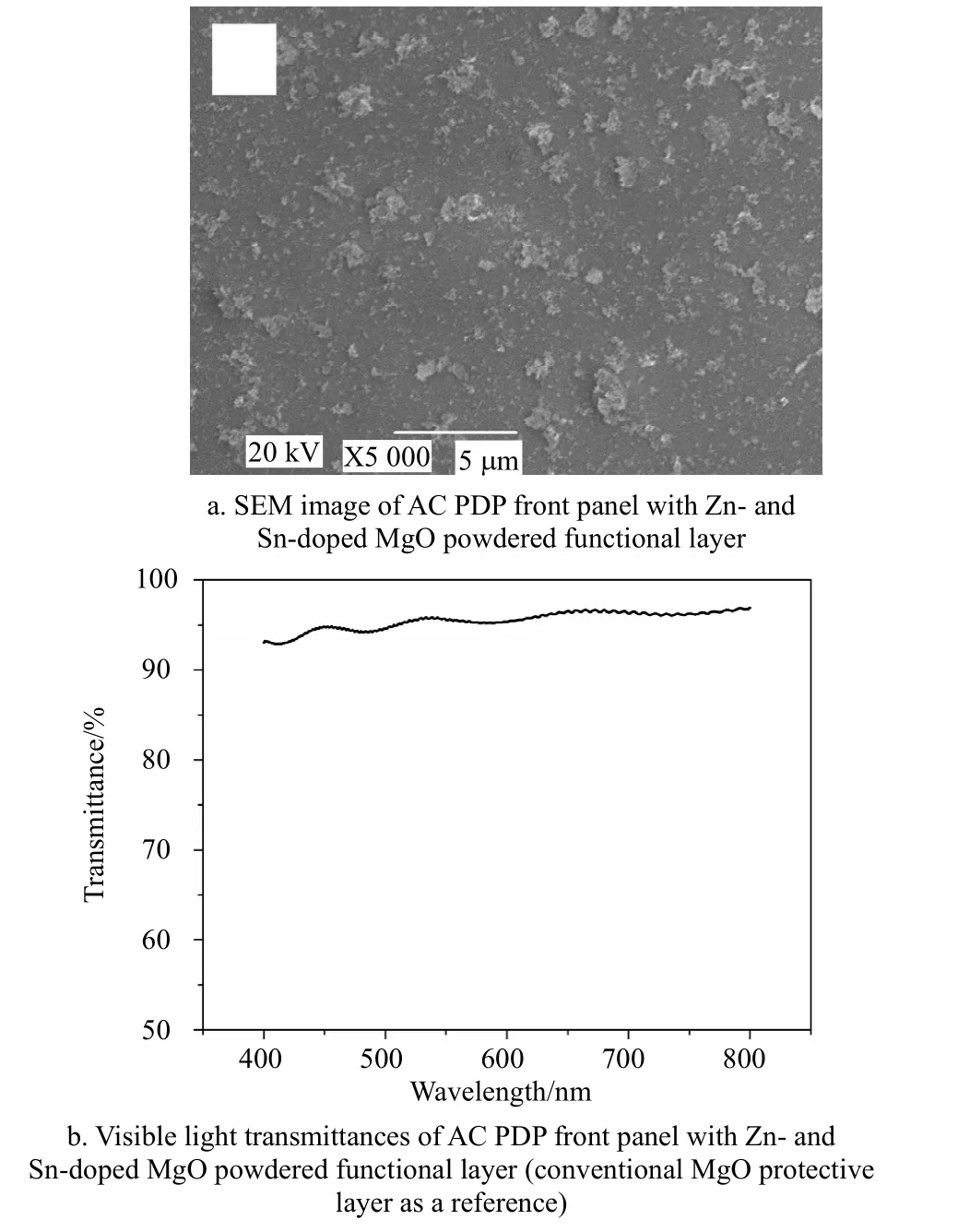

Fig.4a shows the SEM image of the AC PDP front panel coated with Zn- and Sn-doped MgO powdered functional layer. The particles were evenly distributed on the substrate surface. Fig.4b shows the visible light transmittances, in which the conventional AC PDP front panel without functional layer was used as a reference. Because of the favorable light transmittance of Zn- and Sn-doped MgO material and the discontinuous distribution of particle, the functional layer made the transmission only decreased by 4%~7% in the visible light wavelength, which was fit for application in AC PDP.

Fig. 3 XPS pattern of Zn- and Sn-doped MgO powder

Fig. 4 Effect of functional layers on the morphology and transmittance of AC PDP

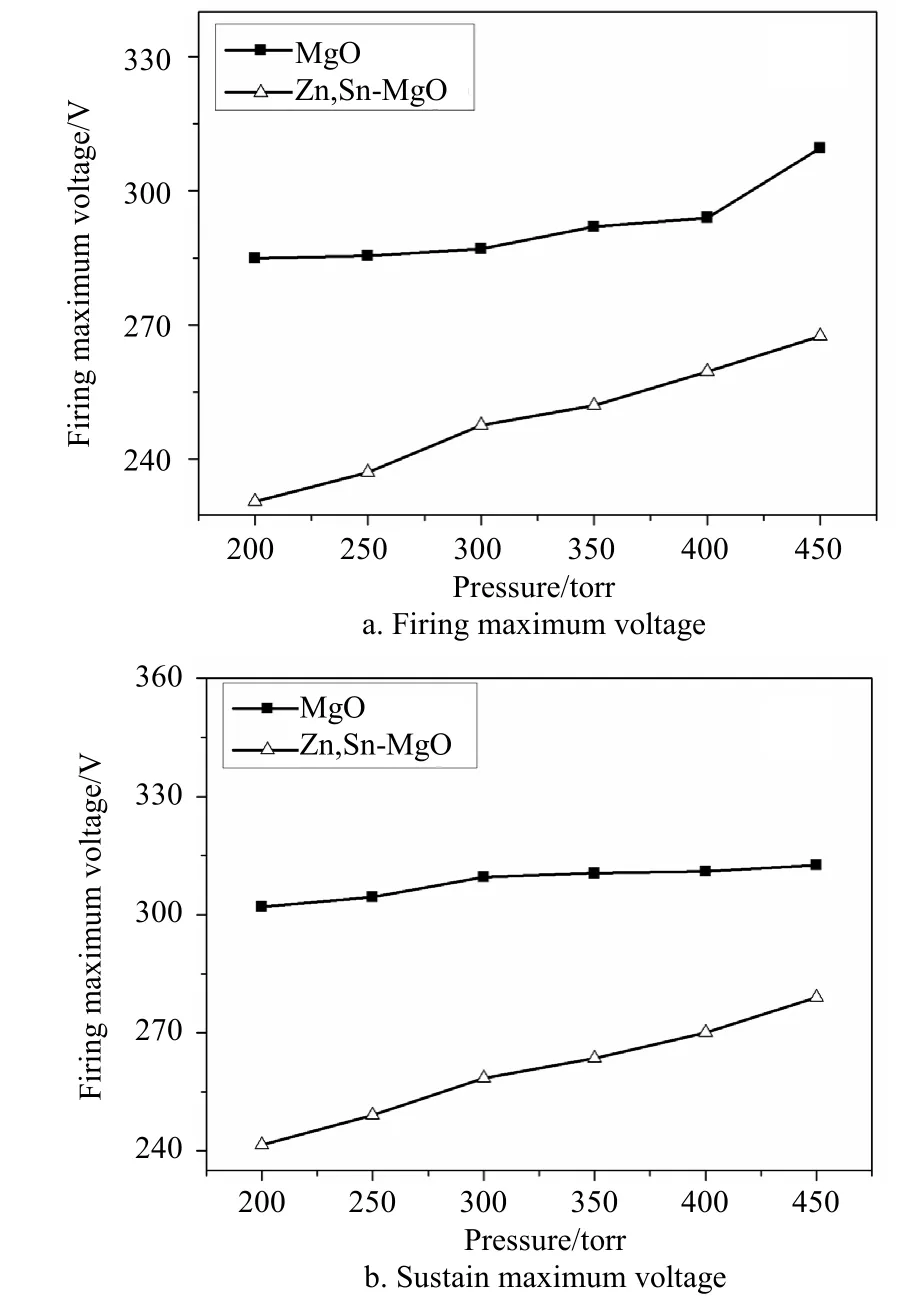

Fig.5 compares the firing and sustaining maximum voltages of AC PDP test panels with Znand Sn-doped MgO powdered functional layer and conventional MgO layer in 7% Xe-Ne. Within the gaspressure range of 200~450 torr, the panel with Znand Sn-doped MgO powdered functional layer always presented lower discharging voltage (firing and sustaining maximum voltages) than that with the conventional MgO layer.

Fig. 5 Discharge characteristics of AC PDP test cells with Znand Sn- doped MgO powdered functional layer and pure MgO protective layer

For example, the firing and sustaining maximum voltages of Zn- and Sn-doped MgO powdered functional layer were 237 V and 249 V at 250 torr,which were about 17.1% and 18.4% lower than the pure MgO protective layer (286 V, 305 V), respectively.According to the Hagstrum theory[15], Auger neutralization is the main mechanism of secondary electrons emission in AC PDP, and valence electrons of the protective layer in AC PDP can be emitted to vacuum levels when the energy level meets the following condition[16]:

3 Conclusions

In conclusion, Zn- and Sn-doped MgO powder has been prepared by a chemical coprecipitation method. It was spin coated on the commercial MgO protective layer in the AC PDP front panel. It was found that zinc and tin atoms were incorporated into the lattice of MgO, which was confirmed by XRD pattern and XPS spectra. The test panel with the Znand Sn-doped MgO powdered functional layer presented lower firing and sustain maximum voltages than the pure MgO protective layer did. With 250 torr 7% Xe-Ne pressure, the firing and sustain maximum voltages of the test panel with the Zn- and Sn-doped MgO functional layer were about 17.1% and 18.4%lower than that with a conventional MgO protective layer, respectively.