Design and Implementation of Bus Network Real-time Monitoring System

CHEN Shi-you, LU Hai, ZHANG Shao-quan, CHEN Xiao-yun

Design and Implementation of Bus Network Real-time Monitoring System

CHEN Shi-you, LU Hai, ZHANG Shao-quan, CHEN Xiao-yun

(Institute of Electric Power Reasearch, Kunming 650217)

The experimental device is a distributed monitoring system based on configuration king and ADAM5000 intelligent modules. System PC PC monitor software adopts kingview, the next bit machine adopts research China ADAM5000programmable controller for field data collection, and the main loop of the inverter ac circuit breaker closing and contactor switch and brake and switch state monitoring. Upper machine and lower machine communication through the RS485 bus, a machine under temperature of thermocouple and thermal resistance acquisition information real-time display and transmitted to the PC, PC by controlling the frequency inverter to control motor speed, and simulation to achieve the purpose of regulating temperature.

Kingview; Monitoring system; Distributed; RS485 bus

0 Introduction

Monitoring configuration software has been developed for more than 20 years since its birth in the early 1980s. Along with the computer technology development changes with each passing day, around the industrial control computer automation integrated system of new products, new technology innovation, monitoring configuration software will play an increasingly important role. At present, there are many different kinds of configuration software in the world, but in our country and foreign configuration software in the market accounted for most of the market, such as Wonderware InTouch, Intellution company ifixes, etc., and the domestic configuration software, such as Beijing and the control of Kingview (Kingview) market is quite high. Kingview is a universal configuration software with ease of use, openness and integration capability. Application of kingview can make engineers focus on control objects, rather than a variety of communication protocols, complex graphics, boring Numbers, only need to fill out a form type operation can generate a supervisory control and data acquisition system. It can integrate various systems and applications within the entire production enterprise to achieve the goal of enterprise integrated automation [1]. This paper designed a distributed monitoring system of the monitoring part of the upper machine use kingview, mainly using the programming is simple, beautiful and friendly interface, and support a number of commonly used hardware devices, including the major manufacturers of PLC, intelligent module, intelligent instrument, the board and frequency converter, etc. The lower computer adopts the adam5,000-485 distributed data acquisition controller of yanhua, and realizes accurate and real-time data information exchange between the upper computer and ADAM5000 through serial communication.

1 System Design

This experiment device of room temperature, power supply circuit breaker closing and the main loop of the inverter ac contactor with closing and opening, the inverter frequency, and the main loop of the inverter output voltage of multiple I/O point data real-time acquisition and monitoring. The upper part adopts industrial control machine equipped with kingview, and the lower part USES ADAM5000 distributed data acquisition controller equipped with enghua technology. The system structure is shown in figure 1. This system makes full use of the good man-machine interface function of kingview and the stable and reliable features of ADAM5000[2]to realize a small distributed monitoring system. At the same time, this system USES the modular structure can detect and control the number of I/O easily extensible, extend the functionality of its support of monitoring points can amount to thousands of points, can satisfy the actual industrial process monitoring and control system of extended needs[3-5]; Meanwhile, ADAM5000 has an RS485 interface and an RS232 interface, which makes it easy to connect and communicate with other devices of the monitoring system.The scheme of the system consists of the following:

Hardware platform: yanhua industrial control machine. It can adapt to the bad environment in the industrial field and operate continuously for a long time.

Operating system: WindowsXP.

Upper monitor software: configuration king. Hot standby redundancy function of two, with temperature control curve, and can do statistical analysis and calculation of the various statements, timing can generate report printing real-time data, and can print the entire work cycle of each time period historical data report, for each temperature point can do real time alarm[7].

Communication network: RS485. Transmission range 500 m, baud rate 9600, no check.

Data acquisition controller: ADAM module of yanhua, ADAM-5000/485. Four slots, up to 28 temperature points, can be connected to the RS485 network, up to 256 slots, and the maximum transmission distance is 1200 meters. 18 sets are actually used on site.

Data acquisition module: ADAM module of yanhua ADAM module ADAM-5018. Type K thermocouple, with linearization, with cold end compensation, room temperature measurement. ADAM module ADAM-5013 module. Thermocouple, measure room temperature. ADAM 5017 analog quantity input module: frequency converter output frequency feedback detection, frequency converter output voltage feedback detection, frequency converter frequency AO control. ADAM - 5056 - d digital output module, power supply circuit breaker closing operation and control, power supply circuit breaker brake control, control the main loop of the inverter ac contactor is closed, the main loop of the inverter ac contactor disconnect control. ADAM 5024 power distribution circuit breaker status detection, converter ac main circuit contactor status detection.

2 Composition of process control experimental device

2.1 ADAM-5000 distributed data acquisition controller

The adam-5000 is a programmable controller based on PC that can independently complete data acquisition and control [8-9]. The adam-5000 has the advantages of compact structure, intelligent processing unit, universal programming function, and can be used for signal program-controlled amplification, analog I /O, digital I /O and communication parameter setting. The ADAM 5000 has the following four features.

2.1.1 simulate the open PC environment

ADAM - 5000 is similar to a compact type computer, including the 80188 CPU, FLASH ROM and SRAM, COM1, COM2, and a programming port, the built-in ROM - DOS operating system, ms-dos operating system compatibility, can through BORLAND C or C + + and other high-level language compile the application. The program can be downloaded to the ROM space of ADAM5510 through the programming port for the program to run. Before downloading any program, it should be converted to ADAM 5000 compatibility code, which USES the communication program attached to the program.

2.1.2 built-in rs232/485 communication port

To realize the communication between ADAM5000 and other software, ADAM5000 provides two serial communication ports :COM1 is RS232 mode; COM2 is RS485 mode. The system is generally used in high stability requirements.

2.1.3 complete I/O module and library function support

ADAM5000 adopts modularized system interface, which consists of host and I /O modules. It is made up of a complete I /O module for users to choose from Choose, provide the maximum convenience for the user to access the data. In order to facilitate the dismantling of the I/O module, the ADAM 5000 adopts the floor structure.

All ADAM modules support 10 ~ 30 VDC voltage output and relay output. All analog modules provide 16-bit resolution.

近年来有学者研究后指出,造成卵巢子宫内膜异位囊肿排卵障碍的主要原因,即为初始状态下的异常募集使得小窦卵泡过多、优势卵泡选择障碍及卵泡发育停滞等[14]。卵巢储备是表示女性生育潜质的指标之一,包括卵巢中未排出卵子的质量及数量[15]。应用于临床的卵巢储备评估检测项目较多,其中生化检测包括基础FSH、基础E2等[16]。本研究显示两组的体质量指数、不孕时间等比较差异无统计学意义(P>0.05),两组血清FSH与E2水平比较差异也无统计学意义(P>0.05),表明常规生化检测对于判断卵巢子宫内膜异位囊肿排卵障碍的效果有待提高。

Fig.1 Electrical working principle diagram of the monitoring system

2.1.4 input range can be set programmatically

ADAM5000 provides complete C library functions at random. These subroutines [10-12] are easily invoked by users in C in MSC6.0 and Borlandc2.0 environments to perform all I /O functions of ADAM5000.

2.2 Analog input module

The analog input module is used to convert voltage, current, thermocouple (TC) and thermal resistance (RTD) signals from sensors into digital quantities.

ADAM-5013 3 channel RTD thermal resistance input module

ADAM-5013 can connect PT100 or Ni thermal resistance

ADAM-5017/H is a 16-bit 8-channel differential input module, and the channel input range is programmable. The input range includes:

MV (+ 150 mV, + 150 mV), V (+/-1 V, + 5 V, + 10 V) and current input (plus or minus 20 ma, need 250 Ω resistance).

ADAM-5018 is a 16-bit 7-channel thermocouple input module, all channels are programmable input range. Input range includes: mV (plus or minus 15 mV, plus or minus 50 mV, + 100 mV, + 500 mV), V (+/-1 V, +/-2.5 V), current input (plus or minus 20 ma, need 250 Ω thermocouple) and thermocouple input (J, K, T, E, R, S, B). The terminal of the module is connected all the wayCJC circuit.

2.3 Analog output module

ADAM-5024 4 channel analog output module

ADAM 5024 is a 4-channel analog output module, which is used to convert digital analog signals into analog signals. The output can be configured as current or voltage by configuring software to customize slope and starting current.

2.4 The digital quantity input module

ADAM 5051 has 16 digital quantity input/output channels, each of which can be configured as input or output by DIP switch. The digital output is the collector open-circuit output, which can be used to control the solid state relay (SSR), and then control the heater, pump and power equipment. Digital input can be used to monitor signals such as limits, safety switches, etc.

2.5 Digital output module

The adam-5056d provides 16 output channels, and the digital output is the open-circuit output of the collector. Users can switch the solid-state relay (SSR).

3 Description of module wiring diagram and working principle

In this experiment, the ADAM -- 5013 analog input module was connected to the thermocouple, and the ADAM -- 5013 module was equipped with cold end compensation to accurately measure the temperature, as shown in figure 2.

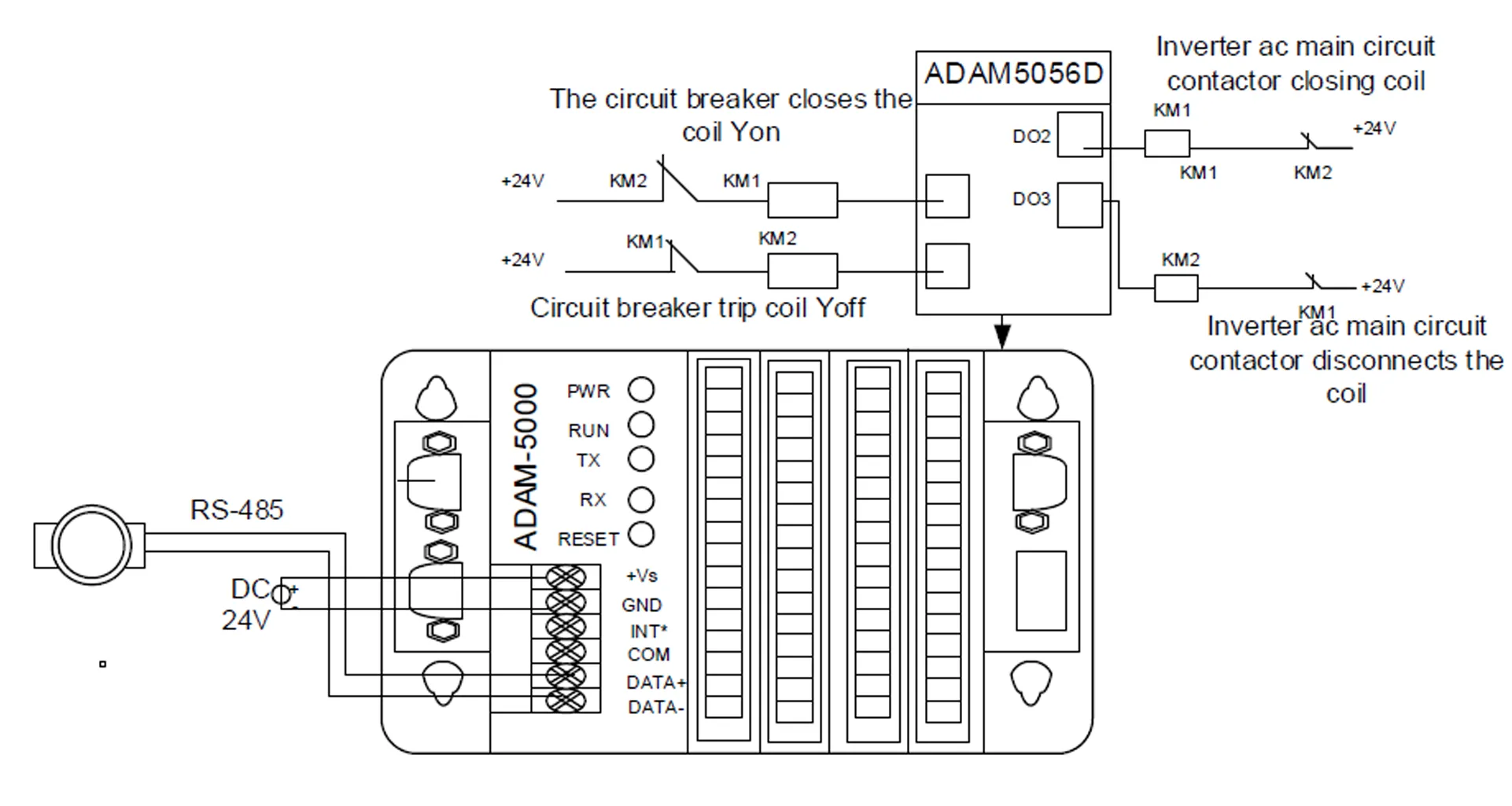

Experiment using ADAM5056D module through an external dc relay line package, module to drive line package, output level, in turn, control the auxiliary contact action, control power supply circuit breaker, frequency converter and ac contactor is closed off. When the KM1 coil works, its normally closed contacts operate in an open state, thus ensuring that the KM2 wire packet does not work and achieves interlocking effect. The specific experimental wiring diagram is shown in figure 3.

Fig.2 wiring schematic diagram of ADAM5013

Fig.3 wiring schematic diagram of ADAM5056D

4 System implementation

In the upper monitor computer, external device definition and database construction are completed through the project browser of kingview. With the rich graphics library of kingview, users can greatly reduce the time of design interface, and the operation is very simple and convenient. Finish the interface design, the definition of animation connection and the implementation of control algorithm in the screen development system of kingview. In this system, the upper configuration king contains the main interface system, boot screen window. We can click the control to close the circuit breaker and ac contactor, and at the same time increase or decrease the frequency of the converter to realize remote control. The configuration screen also provides real-time feedback on frequency, output voltage, circuit breaker and ac contactor.

The structure of the experimental device, including frequency converter, industrial control machine, motor, circuit breaker, ac contactor, etc. At the same time, in the diagram can also clear in the indoor temperature, frequency converter, inverter voltage, ac contactor closing or opening state, power supply circuit breaker closing or opening state or state information such as real-time data.

5 Conclusion

Using a ADAM5000 series experimental device, a distributed monitoring system based on configuration king is designed and developed. Real-time data collection at room temperature is realized. The on-off state of the circuit breaker and contactor can be monitored in real time through the on-off control of the upper computer. When the control circuit breaker and contactor are closed, the frequency converter is energized, and the output frequency of the converter can be controlled by clicking the mouse, so as to control the motor speed. The distributed monitoring system has certain practicability and universality and can be extended to other monitoring systems in industrial production process.

[1] Xu jianghua, sun rong, shao hui-he. PID parameter self-tuning system based on ADAM5510[J]. Automated instrument, 2003, 24(1): 9-11.

[2] Ma bingzhi, sun zhiyi, zhao zhicheng. Application of configuration software MCGS in boiler liquid level control [J]. Control engineering, 2003, 11(1): 84-86.

[3] peng daogang, Yang ping, xu chunmei, et al. Design of data acquisition and monitoring system based on VC++ [C] proceedings of the 6th academic conference on industrial instrumentation and automation, 2005: 122-125.

[4] Chen guanling. Three ways of data exchange between industrial control configuration software and other software [J]. Computer measurement and control, 2002, 10(11): 754-764.

[5] Shao xinhua, jin yuanyu, lu xuefang. Real-time monitoring system based on configuration software and VB[J]. Control engineering, 2003, 10(5): 339-459.

[6] Li bin. Hierarchical design and application of industrial control software[D]. Suzhou university 2014[8] Cheded. Al-Mulla. Control of a four-level elevator system using a programmable logic controller. International Journal of Electrical Engineering Education., 2003.

[7] Matsushita Electric Works Ltd., Automation Control Group. FPO programming manual [EB/OL]. (2004-10-05) [2008-09-10].

[8] He yong yi. A Control System of Material Handling in FMS. Journal of shanghai university. Vol.1.No.1.1997.

[9] Ren Sheng-le. Development of PLC-based Tension Control System.Chinese Journal of Aeronautics20 (2007): 266-271.

[10] M. Paredes, M. Sartor, C. Masclet. An optimization process for extension spring design. Computer Methods in Applied Mechanics and Engineering. 2001, 191(8): 783-797.

总线网络实时监控系统的设计与实现

陈世游,陆 海,张少泉,陈晓云

(云南电网有限责任公司电力科学研究院,云南 昆明 650217)

该实验装置是一种基于配置王和ADAM5000智能模块的分布式监控系统。系统PC监控软件采用组态王,下位机采用研究中国ADAM5000可编程控制器进行现场数据采集,并将逆变器交流断路开关的主回路及触点切换和制动开关状态监测。上位机与下位机通讯通过RS485总线,在热电偶温度和热电阻采集信息的实时显示和传输到PC机上,通过控制变频器控制电机转速、仿真达到调节温度的目的。

组态王;监控系统;分布;RS485总线

TP2

A

10.3969/j.issn.1003-6970.2018.10.016

陈世游(1993-),男,硕士,研究方向为新能源发电与智能电网技术。

陈世游,陆海,张少泉,等. 总线网络实时监控系统的设计与实现[J]. 软件,2018,39(10):74-78