Decay resistance and dimensional stability improvement of wood by low melting point alloy heat treatment

Kufre Edet Okon•Fengcai Lin•Yandan Chen•Biao Huang

Abstract Wood has no inherent natural resistance against agents of biodegradation.We evaluated the effects of metal bath heat treatment(MBHT)on decay resistance and dimensional stability of Chinese parasol(Firmiana simplex)and Chinese fir(Cunninghamia lanceolata)wood.A low melting point alloy was used as heating medium in the treatment of the wood samples at 150,180,and 210°C for 2,4,and 8 h.Heat-treated and control samples were exposed to brown rot fungus(Poria placenta)and white rot fungus(Coriolus versicolor)for decay resistance testing and anti-swelling efficiency(ASE).The improved decay resistance with increase temperatures with low mass losses of 7.3 and 7.3%for F.simplex,and 3.9 and 3.6%for C.lanceolata at 210°C for 8 h against Coriolus versicolor and Poria placenta,respectively.ASE indicated that MBHT contributed to improved dimensional stability of both wood species after treatment.Scanning electron micrograph results indicate that metal bath-treated samples showed strong decay resistance.Therefore,our approach to thermally modify wood should be explored to overcome the energy utilization by using low melting point alloy for the heat treatment of wood.

Keywords Heat treatment·Decay resistance·Dimensional stability ·Chinese fir·Chinese parasol·Rot fungi

Introduction

Lignocellulosic materials are known to have little or no inherent natural durability against agents of biodegradation such as fungi,insects,bacteria and marine borers when left unprotected(Erakhrumen 2014).To increase biological durability,wood is usually impregnated with chemical products,which leads to the emission of active ingredients into the environment after the fixation of preservative products(Calonego et al.2010).In addition,the use of some toxic preservatives has been restricted due to environmental concerns(De Vetter and Van Acker 2005;Hill et al.2004;Mai and Militz 2004).Recently,much effort has been concentrated on finding a non-biocidal thermal and environmentally-friendly alternative approach to improve wood properties.

Thermal modification is an alternative method to improve the properties of wood without using harmful conventional preservatives.Presently,there are different technologies for heat treatment of wood in Europe(Kocaefe et al.2007),including the Thermo wood process in Finland(Viitanen et al.1994),Plato wood in the Netherlands(Tjeerdsma et al.1998),Le Bois Perdure and Rectification processes in France(Dirol and Guyonnet 1993b),and Oil Heat treatment(OHT)in Germany(Rapp 2001).However,in all these processes,wood is heated at temperatures between 140 and 260°C under very poor oxygen atmospheres for several hours to avoid wood combustion(Hakkou et al.2006).Processing conditions such as the use of oxygen and nitrogen,steaming,wet or dry processes,and the use of oils are the main differences between the various processes(Militz 2002).

Thermal wood modification has been long known to improve the biological durability and dimensional stability of wood(Esteves et al.2008,2011;Scheiding et al.2016),decrease wood equilibrium moisture content(Hill 2006),and induce a darker coloration(Chen et al.2012)without additional chemical products.The increase in decay resistance by the thermal process is generally explained by various hypotheses:low affinity of heat-treated wood to water;formation of compounds which act as biocides against decay fungi;and chemical modification of wood components and degradation of hemicelluloses which are the main source of fungi nutrition(Del Menezzi et al.2008;Hakkou et al.2006;Weil and and Guyonnet 2003).

In the search for a more sustainable,cost effective and eco-friendly method of wood modification,this study used low melting point alloy as a heating medium for the treatment of wood.The main compositions of the alloy are bismuth(0.69%)and tin(0.26%)and the melting point is 97°C.Low melting point alloys are potential phase change thermal storage materials and heat transfer agents due to their properties such as high thermal conductivities,high thermal storage densities,excellent thermal stability,low melting points and high boiling points.They present much higher thermal conductivities than most other heating media by excluding oxygen from the treated samples and minimizing thermal degradation of some wood constituents(Dubey et al.2012).Low melting point alloys can be considered as an efficient,energy-saving,green approach to wood modification,which cause equal and rapid heat transfer to improve the biological durability and dimensional stability of wood.They are inherently low eco-toxic and non-toxic to humans and have low net carbon dioxide contribution to the atmosphere.In recent years,energy costs and demand have been increasing.The pursuit of less energy consuming or more energy efficient treatment process is desired.In addition,there has been growing global environmental concerns and legislative pressures over the use of biocide-based treatment methods(Homan and Jorissen 2004).The metal bath heat treatment(MBHT)method is used to create more durable wood products that serve as alternative environmental-friendly wood modification method without toxic chemicals.Furthermore,the availability of low melting point alloys makes them the most preferred heating medium to be used in the thermal modification of wood.

MBHT,like other well-established heat treatment methods,has positive effects on the resistance of wood to white and brown rot fungi(Hill 2006).As a new approach to the heat treatment of wood,it can produce wood materials with relatively high performance and environmental friendly characteristics.The durability of heat-treated wood may be predicted by mass loss after exposure to fungi(Chaouch et al.2010;Inari et al.2009;Šušteršic et al.2010).In another study,heat treatment modified the durability of beech wood from non-resistant to moderately resistant or resistant,depending on the fungus species(Kamdem et al.2002).Bazyar(2012)demonstrated the decay resistance of OHT on aspen against the white rot fungus(Coriolus versicolor(L.Quélet)and brown rot fungus(Coniophora puteana(Sham.Fr.)P.Karst).The effect of heat treatment under vacuum on decay durability was also investigated and compared to treatments under nitrogen leading to similar mass loss due to thermo degradation reactions(Candelier et al.2013).

Currently,the information on the use of low melting point alloy baths for wood modification is scarce.This seriously limits the development and application of low melting point alloys in the thermal modification of wood.We studied the effects of low melting point alloy heat treatments at different temperatures on the decay resistance of Chinese parasol(Firmiana simplex(L.)W.F.Wight)and Chinese fir(Cunninghamia lanceolata(Lamb.)Hook.)against brown rot fungus(Poria placenta)and white rot fungus(Coriolus versicolor)and the anti-swelling efficiency of both wood species after treatment.

Materials and methods

Materials

The low melting point alloy was purchased from Suzhou Chuangmao Metal Materials Suzhou,China.Firmiana simplex and Cunninghamia lanceolata wood were obtained from a local sawmill in Fuzhou,China.Both species were 25-year-old.The test fungi were brown rot fungus(CFCC accession number 5608,China Forest Culture Collection Center)and white rot fungus(CFCC accession number 5336,China Forest Culture Collection Center),both obtained from the College of Plant Protection,Fujian Agriculture and Forestry University,Fuzhou.A malt agar medium consisted of 20 g malt extract,15 g agar,and 1000 mL deionized water.

Sample preparation

Defect free F.simplex and C.lanceolata wood samples were prepared in the College of Material Engineering,Fujian Agriculture and Forestry University.Test sample dimensions were 20 mm×20 mm×10 mm (tangential× radial× longitudinal)prepared from mature sapwood of both species used for decay resistance tests and 20 mm×20 mm×20 mm for anti-swelling ef ficiency.Weight and dimensions of the samples were measured and oven-dried at 103°C to a constant weight.The moisture content of the samples was approximately 18–20%prior to treatment.Metal bath-treated and control samples were tested against brown rot fungus and white rot fungus.For each wood species,samples were divided into 9 treatments plus one as control,and 12 samples were used per fungi and per treatment for a total of 480 samples plus controls.

Metal bath heat treatment(MBHT)

Heat treatment of test samples was carried out in a laboratory metal bath filled with tin-based molten alloy as heating medium.The samples were pre-treated in a microwave for 5 min to ease heat transfer within the wood.After this step,pre-treated samples were transferred and immersed in a pre-heated metal bath at 150,180 or 210°C for 2,4 or 8 h.During the treatment of samples,the metal bath was covered to sustain the heat flow while the operating temperature was maintained constant within± 1°C.After MBHT,the samples were wiped and cooled in a silica gel desiccator and weighed.Finally,the samples were conditioned in a climate chamber at 65±5%relative humidity and 20± 2°C for 8 weeks until EMC was attained.

Natural decay resistance test

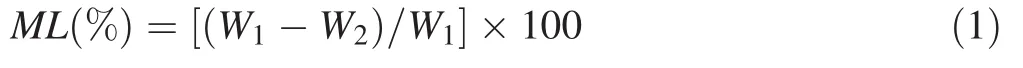

This was performed on oven-dried sapwood of metal bath treated and control samples of F.simplex and C.lanceolata by determining the mass loss caused by fungal attack according to Chinese standard GB/T 13942.1-2009 using the two fungi Poria placenta and Coriolus versicolor.Samples were sterilized in an autoclave at 121± 1°C after the measurement of initial oven-dried weights(W1).A 500 mL bottle was filled with 160 g sieves air-dried river sand with a pH 5 and 7+16 g of Chinese parasol/Chinese fir sawdust+8.5 g corn flour+80 mL medium of potato dextrose agar composed of 2 g of granulated sugar+feeder chips,sterilized at 121± 1°C for 1 h and inoculated with fungi.The sterilized treated and control samples were placed in culture bottles,each with four samples and each specimen placed on a wood feeder chip.They were incubated for 12 weeks(84 days)under a relative humidity of75±2% and a temperature of 28± 2°C.At the end of the exposure period,the samples were removed and all adhering fungal hyphae were removed from the surfaces.Samples were then oven-dried at 103± 2°C and weighed(W2).The mass losses of the samples were used to determine the decay resistance of the wood according to Eq.1.The rating for classification of wood durability is shown in Table 1.

where ML(%)=mass loss,W1=weight of the samples prior to decay test,W2=weight of the samples after decay test.

Anti-swelling efficiency(ASE)test

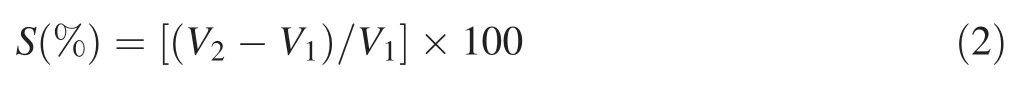

To determine the ASE of F.simplex and C.lanceolata samples,a set of metal bath-treated and control samples were soaked in a water bath of deionized water at room temperature of 20°C for 1 week.The water was replaced every 24 h until the weight changes of the samples were constant.The samples were weighed and the volumetric swelling coefficient(S)calculated according to Eq.2,and the ASE using Eq.3,based on the swelling differences between controls and the metal bath-treated samples as follows:

where V1and V2are the volume of samples before and after soaking in deionized water,respectively.

where S1and S2are the volumetric swelling coefficients of control and metal bath-treated samples.

Scanning electron microscope(SEM)analysis

The 25 μm sections were cut from F.simplex and C.lanceolata samples after exposure to brown rot fungus using a Reichert-Shandon microtome.The sliced samples were mounted on holders with double-sided adhesive tape and coated with a gold sputter.Morphological properties of the wood were examined using a SU8010 Scanning Electron Microscope.

Statistical analysis

Mass loss and ASE data were analyzed using Analysis of Variance(ANOVA)and the means separated using Student–Newman–Keuls(SNK)test at a significance level of p<0.05.Percentages were arcsine-transformed before subjecting the data to ANOVA.All the analyses were implemented in R version 3.1.1 statistical software(R Core Team 2014).

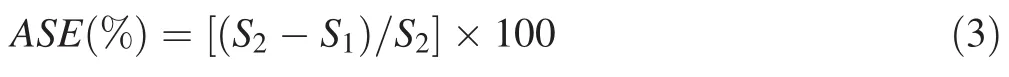

Table 1 Classification of wood natural decay resistance.Source Chinese standard GB/T 13942.1-2009

Results and discussion

Decay resistance

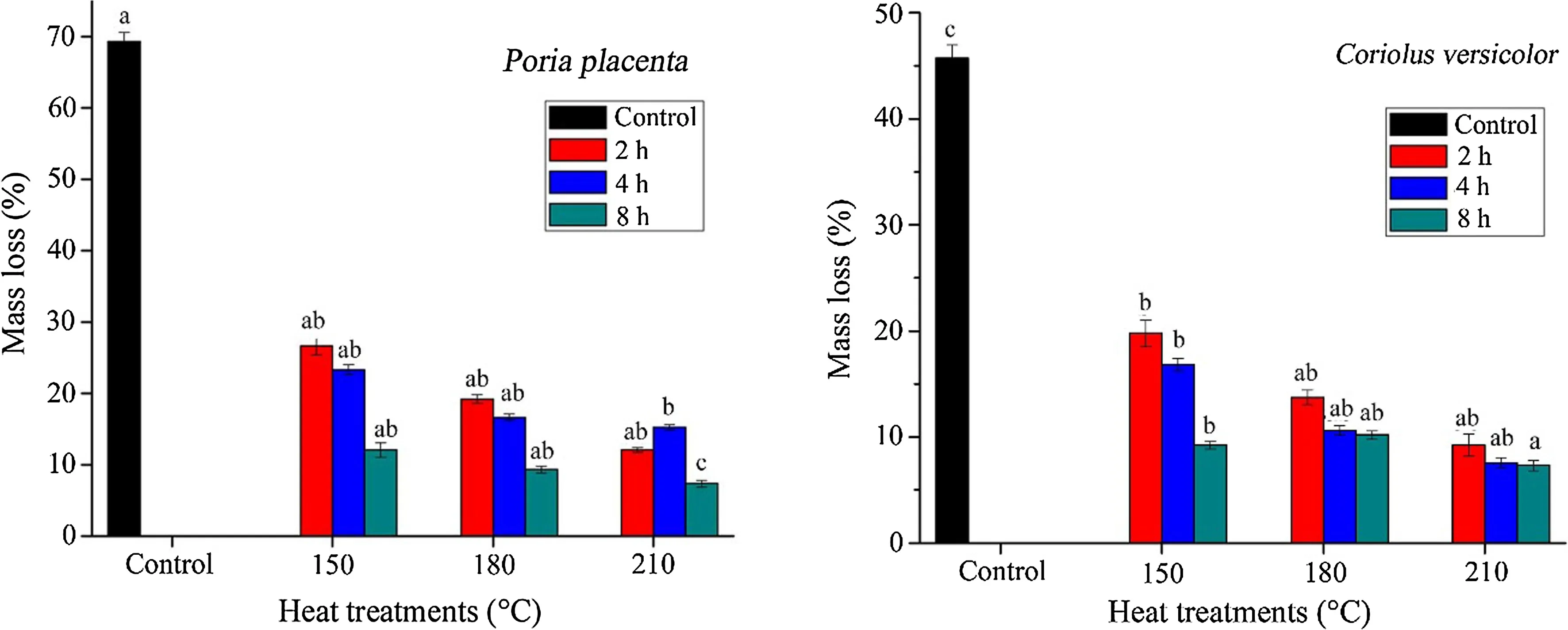

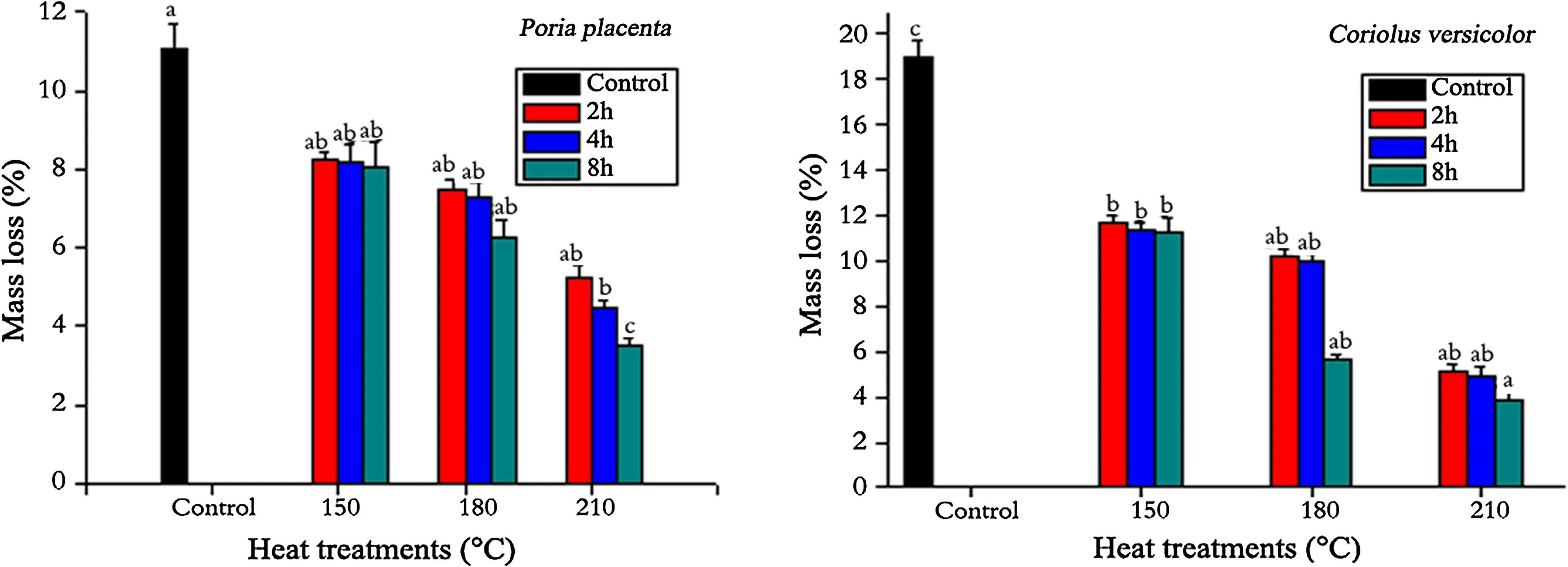

Mass losses for F.simplex and C.lanceolata wood as a result of decay by white rot and brown rot fungi are presented in Figs.1 and 2.There were significant differences in the mass loss for F.simplex when exposed to white rot fungus(F=19.64,p<0.0001)and brown rot fungus(F=31.22,p<0.0001).The mass loss for C.lanceolata when exposed to white rot fungus(F=2.41,p<0.01562)and brown rot fungus(F=27.31,p<0.0001)were significantly different among treatments.In this study,control samples of both species with mass loss of more than 31%for softwood and 51%for hardwood are in durability class IV(Table 1).This suggests an increase in decay resistance of metal bath-treated F.simplex and C.lanceolata wood after 12 weeks of exposure to white and brown rot fungi.

The mass loss for F.simplex against brown and white rot fungi in the control samples were 69.3 and 45.7%respectively(Fig.1).While for C.lanceolata,the mass loss in the control samples after exposure to white and brown rot fungi were 18.9 and 11.1%(Fig.2),respectively.The control samples of the two wood species were severely attacked by the decay fungi with very high mass losses compared to the treated samples and based on the Chinese standard GB/T 13942.1-2009 classification in Table 1.Both F.simplex and C.lanceolata are in durability class IV,i.e.,one in which mass loss is>51.0 and>31.0%,respectively.The mass loss values of the control samples of F.simplex were higher compared to those of C.lanceolata after exposure to both fungi species.Previous studies reported that different wood species had differences in their resistance to decay fungi(Jesus et al.1998),and the same types of wood did not necessarily possess the same type of resistance across all decay fungi(ASTM D-2017 2005).In general,samples exposed to white rot fungus experienced low mass loss compared to brown rot fungus with high mass loss.

The mass loss for metal bath treated F.simple at 150°C for 2 h against P.placenta and C.versicolor were 26.6 and 19.8%,respectively,with decay resistance improved by 61.6 and 57.8%.However,for samples heat treated at 210°C for 8 h against Poria placenta and C.versicolor,their mass losses were 7.3 and 7.3%respectively,with decay resistance improvement of 89.0 and 84.0%,respectively(Fig.1).Less mass loss after MBHT is considered a useful parameter that could be used to assess the effect of the treatment temperature to increase the decay resistance.Momohara et al.(2003)investigated the effect of high temperature-treatment on wood durability against brown rot fungus.Their results indicated that wood durability increased with an increase of temperature and time.Similarly,Kim et al.(1998)reported improvements in decay resistance of thermally modified radiata pine sapwood against Fomitopsis palustris as the heating period and temperature increased.This result indicated that decay resistance of metal bath-treated F.simplex against both P.placenta and C.versicolor improved remarkably compared to controls,thus bringing the wood up to durability class II(Table 1).It was also noticed that heat-treated wood samples exhibited high decay resistance against C.versicolor compared to P.placenta with less mass loss.The significant improvement in the resistance of wood to fungal attack after heat treatment could be linked to the loss of polysaccharide content and decrease of equilibrium moisture,which by itself leads to better resistance against biological degradation(Hill 2007;Weiland and Guyonnet 2003).

Fig.1 Mass losses in Firmiana simplex wood samples exposed to Poria placenta and Coriolus versicolor for 12 weeks after MBHT.Bars with the same letter indicate that there was no significant difference between treatments at p≤0.05

Fig.2 Mass losses in Cunninghamia lanceolata samples exposed to Poria placenta and Coriolus versicolor for 12 weeks after MBHT.Bars with the same letter indicate no significant difference between treatments at p≤0.05

In the case of C.lanceolata,MBHT at different temperatures and times effectively improved decay resistance with less than 20%mass loss against C.versicolor and P.placenta(Fig.2).The results indicate that there were significant differences (C. versicolor with F=2.41,p<0.01562 and P.placenta with F=27.31,p<0.0001)between mass loss in the control samples and those of MBHT samples at 210°C for 8 h.Mass losses for heattreated samples at 150°C for 2 h were 11.7 and 8.3%against C.versicolor and P.placenta,respectively,while samples treated at 210°C for 8 h had low mass losses against C.versicolor and P.placenta,respectively,indicating a high decay resistance.Improved resistance of the heat-treated samples at high temperatures against both fungi occurs as a result of reduced hygroscopicity(absorbing moisture from the air)(Tjeerdsma et al.2002).This result is in line with those of Militz and Tjeerdsma(2001)who reported that weight loss caused by C.versicolor and Coniophora puteana(Shum.:Fr.)P.Karst was less than 4%in tests of thermally modified Pinus Radiata D.Don,Pinussylvestris C.Linnaeus,Pseudotsuga menziesii(Mirb.)Franco and Picea abies treated at 220°C.The decay resistance of C.lanceolata was classified in class I(Table 1)after exposure to both decay fungi with less than 10%mass loss.This suggests that the MBHT method used in this study provided good protection to C.lanceolata against C.versicolor and P.placenta under laboratory conditions.

The white rot fungi C.versicolor caused the lowest mass loss on all F.simplex samples,while significantly higher mass losses were the result of the brown rot fungi P.placenta,indicating that P.placenta was more aggressive than C.versicolor on F.simplex wood.Contrary to this,when C.lanceolata wood was exposed to the decay fungi,high mass losses were obtained with C.versicolor compared to Poria placenta(Figs.1,2).Furthermore,F.simplex was more susceptible to P.placenta while C.lanceolata was less resistant to C.versicolor.Increase in heat treatment temperature increased wood resistance against both fungi,especially at 210°C for 8 h.The degradation of hemicelluloses and their cross links with lignin as a result of thermal treatment increased decay resistance due to the formation of molecules which act as fungicides,therefore making it difficult for the fungi to develop or grow on the substrate(Hill 2007).Heat treatment was best at 210°C for 8 h,allowing full protection of the samples compared to treatments at 150°C for 2 h.It is well known that thermal treatments modify the chemical components of wood,therefore inhibiting the availability of food(hemicelluloses)to fungi.Heat treatment at temperatures between 150 and 280°C was reported to effectively improve the biological durability of wood(Boonstra et al.2007).The low affinity of heat-treated wood to water and the generation of toxic compounds during heating provides protection against wood degrading agents(Hakkou et al.2006).

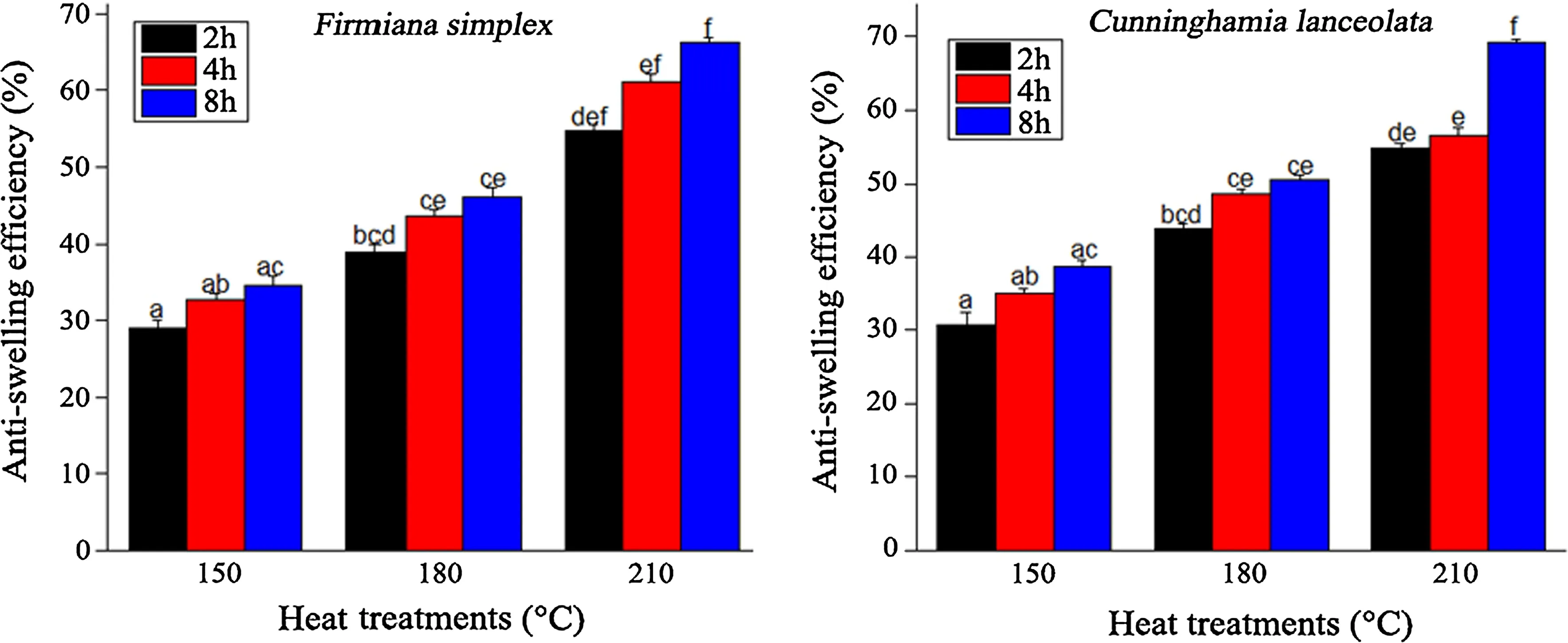

Dimensional stability

There were significant differences between the treatments as regards to anti-swelling ef ficiency(ASE)for F.simplex(F=15.83,p<0.0001)and C.lanceolata (18.79,p<0.0001).ASE increased with a rise in temperature and time resulting in an increase in the dimensional stability of both species.The samples treated at 210°C for 8 h had the maximum ASE of 66.2%for F.simplex and 69.2%for C.lanceolata.The minimum ASE was reached at 150°C for 2 h with 29.0%for F.simplex and 30.8%for C.lanceolata(Fig.3).These results show that low temperatures gave a limited increase in dimensional stability while high temperatures had a positive influence on both tree species,a reflection of a reduction of accessible hydroxyl groups during the heating process.MBHT was effective for both species when exposed to the same conditions,although C.lanceolata had relatively higher dimensional stability improvement compared to F.simplex(Fig.3).Increase in dimensional stability is related to the decrease in the hygroscopic characteristics of the heat-treated wood with regards to the degradation of hemicelluloses at high temperatures(Burmester 1981).Similar results were also reported by Tjeerdsma et al.(1998)for beech,spruce,Scots pine and Monterey pine.Stamm and Baechler(1960)reported decay resistance for Sitka spruce with 45.0%ASE,whereas Dirol and Guyonnet(1993a)found that decay resistance for poplar,spruce and fir ranged between 46.0 and 73.0%ASE.Welzbacher et al.(2007)reported that 25.0–30.0%ASE was sufficient to provide decay resistance in Norway spruce.

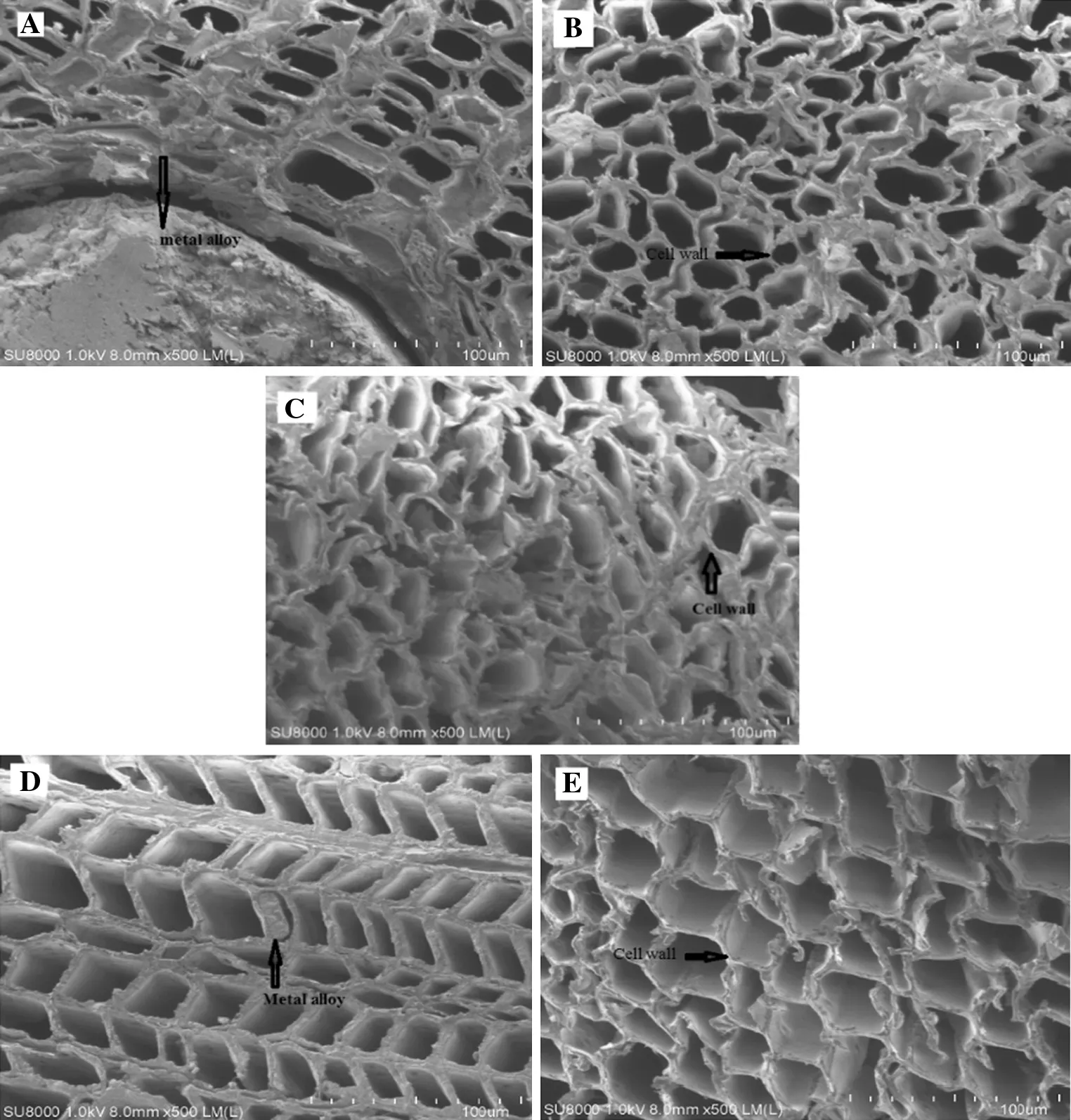

Scanning electron microscope

Figure 4 shows SEM morphologies of F.simplex and C.lanceolata samples in a metal bath-treated at 180°C for 8 h and 210°C for 8 h against brown rot fungus.Cell walls were completely protected without Poria placenta hyphae growth on the wood matrix,suggesting that cell walls remained intact even in the advanced stages of a fungus attack(Cho et al.2008).The decaying fungi did not destroy the size or the distribution of the wood microspores as the surface of the samples remained smooth and the organizational structure was complete,particularly for samples treated at 210°C for 8 h(Fig.4).In contrast,the wood matrix of the control samples exposed to Poria placenta was destroyed,with a large amount of mycelia penetrating into the cell wall and the cell boundaries were completely broken(micrograph not shown).In Fig.4b,d,however,the volume of the void spaces increased remarkably and the thickness of the cells wall decreased after MBHT,indicating better decay resistance which might be due to the removal of some cell wall components during heating.Irregular rupturing at some points on the surface and the breaking of the fiber boundaries indicate that the wood was slightly eroded by Poria placenta,but the erosion was weak because of the heat treatment(Fig.4c,e).These results suggest that MBHT not only inhibited directly the growth of wood rot fungi but also performed well in protecting the wood.The melted metal alloy penetrated into the cell walls,occupied the cell lumens(Dong et al.2016)(Fig.4a),and this accounted for the improvement in decay resistance.Comparisons with other heat treatment processes showed that MBHT could improve the durability of F.simplex and C.lanceolata wood against brown rot and white rot fungi(Welzbacher and Rapp 2002).Furthermore,structural changes due to MBHT are not significant,suggesting that plasticization of wall material occurred to a very limited degree during treatment(Huang 2012).Comparable features were found in spruce after thermal treatment at 190 and 240°C(Boonstra et al.2006).

Fig.3 Anti-swelling efficiency of Firmiana simplex and Cunninghamia lanceolata as a result of MBHT temperature and time.Bars with the same letter indicate no significant difference between treatments at p≤0.05

Fig.4 Cross sectional SEM micrographs of Firmiana simplex and Cunninghamia lanceolata wood exposed to Coriolus versicolor and Poria placenta for 12 weeks after MBHT.a metal bath-treated F.simplex at 180°C for 8 h indicating melted metal alloy penetration into the cell wall,b metal bath-treated F.simplex at 180°C for 8 h,c metal bath-treated F.simplex at 210°C for 8 h,d metal bath-treated C.lanceolata at 180°C for 8 h,e metal bath-treated C.lanceolata treated at 210°C for 8 h

Conclusion

This research investigated the effect of metal bath heat treatment on the decay resistance and anti-swelling efficiency of Chinese parasol and Chinese pine wood.From the results obtained,MBHT significantly modified the wood properties of both species,providing better resistance against Poria placenta and Coriolus versicolor and as well improved their ASE.The durability and dimensional stability of the wood were remarkably enhanced with an increase in temperatures.SEM results indicated that the cell walls were completely protected against fungal attack.MBHT of wood using low melting point alloys as heating media may be considered an efficient and environmental benign,energy-saving method to wood modification with improved application performance.

Further studies are warranted to determine strength and physical properties such as water absorption and swelling of metal bath-treated Chinese parasol and Chinese fir wood with regards to treatment temperatures and time in order to have a better understanding of the property modification mechanisms.

Journal of Forestry Research2018年6期

Journal of Forestry Research2018年6期

- Journal of Forestry Research的其它文章

- Black locust(Robinia pseudoacacia L.)as a multi-purpose tree species in Hungary and Romania:a review

- The impact of the environmental factors on the photosynthetic activity of common pine(Pinus sylvestris)in spring and in autumn in the region of Eastern Siberia

- Osmoregulators in Hymenaea courbaril and Hymenaea stigonocarpa under water stress and rehydration

- Effect of nitrogen levels on photosynthetic parameters,morphological and chemical characters of saplings and trees in a temperate forest

- Free amino acid content in trunk,branches and branchlets of Araucaria angustifolia(Araucariaceae)

- Exogenous application of succinic acid enhances tolerance of Larix olgensis seedling to lead stress