改进烟花算法和概率神经网络智能诊断齿轮箱故障

陈如清,李嘉春,尚 涛,张 俊

改进烟花算法和概率神经网络智能诊断齿轮箱故障

陈如清1,李嘉春2,尚 涛1,张 俊3

(1. 嘉兴学院机电工程学院,嘉兴 314001;2. 嘉兴学院数理与信息工程学院,嘉兴 314001;3. 浙江大学生物系统工程与食品科学学院,杭州 310058)

针对复杂环境下农机设备的齿轮箱系统在故障诊断时存在易受现场噪声干扰和故障识别率低等问题,提出了一种基于改进的烟花算法和概率神经网络的齿轮箱智能故障诊断方法。为提高现有概率神经网络模式分类方法的性能,定义了一项样本相似度衡量指标以提高建模过程中训练样本的质量。将烟花算法与概率神经网络技术有机融合提出了一种改进的烟花算法-概率神经网络模式分类方法,利用烟花算法优化概率神经网络的平滑参数以确定网络参数的最优值,提高模式分类与识别精度。将改进的烟花算法-概率神经网络模式分类方法用于噪声环境下齿轮箱的故障诊断建模,构建故障特征参量与齿轮箱工作状况间的复杂非线性映射关系。应用结果表明,与基于BP神经网络、GABP(genetic algorithm back propagation)神经网络和概率神经网络的故障诊断模型相比,在不同程度噪声影响下烟花算法-概率神经网络模型均具有最高故障识别率。当噪声控制系数为0.01、0.02、0.04和0.06时,模型的故障识别率分别为100%、95.83%、93.33%和88.33%。该研究可为非线性复杂系统的故障诊断提供了一种可行的解决方案。

齿轮;算法;噪声;概率神经网络;故障诊断建模

0 引 言

农业机械装备是提高农业生产效率及推动农业可持续发展不可或缺的工具。齿轮箱既是用于转速调节和动力传递的常用传动部件,也是农机设备的重要机械部件。工作过程中其故障发生率较高,是引发机械设备故障的重要原因[1]。为确保其安全可靠运行,对齿轮与轴承等关键部件进行故障检测与分类定位具有重要意义[2-3]。大型农机设备通常具有系统结构复杂、工作条件多样且工作环境恶劣等特征,故障特征参量和设备工作状况间形成了较为复杂的非线性映射关系[4-5]。机械设备故障机理分析和故障诊断方法研究一直受到广泛关注,现有方法主要有模式识别方法、神经网络方法和专家系统方法等。随着人工智能技术的发展,基于人工智能融合技术的故障诊断方法也成为一大研究热点[6-7]。各种智能诊断理论和方法的集成和融合,如小波分析与神经网络集成、模糊系统与神经网络集成和进化计算与神经网络融合等,较好构建了故障征兆与故障类别之间的映射关系,有效实现了机械设备的故障诊断[8-10]。但对于齿轮箱等复杂非线性动态系统,现有故障诊断方法存在故障建模复杂、易受噪声干扰和诊断精度不高等缺陷[11-12]。

从机器学习角度看,机械设备的故障诊断本质上是一个模式分类问题。概率神经网络(probabilistic neural networks, PNN)是由Specht提出,其主要思想是将贝叶斯决策理论引入传统神经网络,网络结构按照贝叶斯判别函数来设置,以实现错误分类的期望风险最小[13]。PNN吸收了径向基神经网络与经典的概率密度估计原理的优点,在模式分类与识别领域获得广泛应用[14-15]。与传统BP、RBF神经网络比较,PNN具有以下优势:网络学习过程简单,学习速度快;分类更准确,对错误噪声容忍性高;容错性好,分类能力强[16]。PNN的不足之处主要体现在以下2个方面:1)对训练样本的代表性要求高,需要的存储空间更大;2)网络参数(如平滑参数)的选取直接影响PNN识别性能。此外,基本PNN通常对于每个模式类别平滑参数的取值均相同(即假设1=2=…=),不能将概率特性完整地表示出来,从而降低了PNN的识别精度。因此,如何提炼更具代表性的建模训练样本和选定合适的参数是PNN研究的关键问题。

为解决复杂环境下齿轮箱故障诊断系统易受噪声干扰且故障识别率低等问题,本文设计了一种代表性训练样本提取方法,通过将PNN网络与烟花算法(fireworks algorithm, FWA)有机结合提出了一种改进的FWA-PNN方法,利用FWA算法优化PNN的平滑参数,对于每个模式类别都不同(即→σ)。最后将本文所提出的方法用于农业机械装备领域齿轮箱系统的故障诊断与分类定位,应用结果表明,基于改进的FWA-PNN智能诊断方法可有效提高齿轮箱故障诊断的性能。

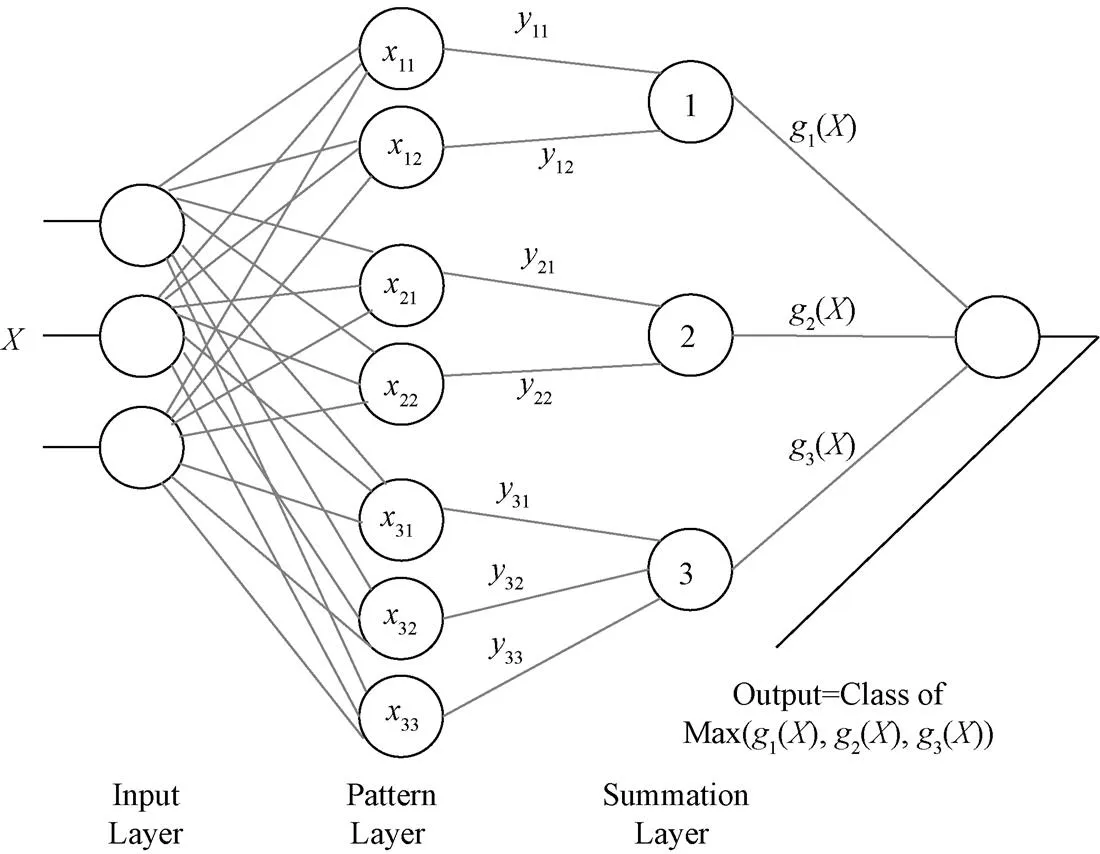

1 PNN模式分类模型

PNN模型包括输入层、模式层、求和层和输出层。假设特征向量维数为3,为方便阐述,以3类模式分类器为例(即=3),PNN模型可用图1进行描述[13,15]。图1中,为输入向量,11~33为训练样本,11~33为模式层各节点的输出,1()~3()为求和层各节点的输出,Output为PNN的最终输出,表示属于哪一类。

Note: ,,, (i=1,2,3; n1=2, n2=2, n3=3; σ is the smoothing parameter of PNN).

输入层神经元个数为特征向量的维数。在输入层中,网络计算输入向量与所有训练样本向量之间的距离。样本层神经元个数为训练样本的个数,通常其激活函数为高斯函数。求和层神经元个数为类别个数,主要功能是将样本层的输出按类相加,相当于个加法器。竞争层的神经元个数为1。整个网络判决的结果通过竞争层输出,输出结果中只有一个1,其余为0,概率值最大的那一类输出结果为1。根据Speeht博士提出的PNN基本模型并参照现有研究文献,基本PNN学习算法的总结如下[13-15]。

1)归一化处理

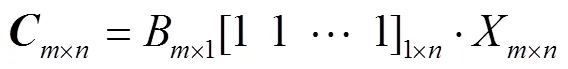

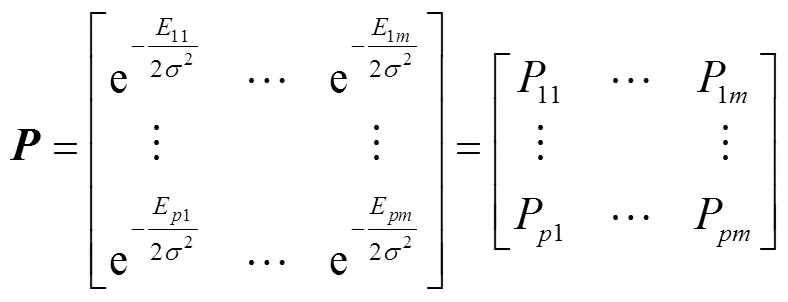

式中为训练样本矩阵,样本个数为,样本维数为,1k~x为矩阵中的一个元素。计算下面矩阵以求解归一化因子。

2)将归一化好的样本送入网络输入层。归一化处理后的学习样本用表示,即

3)模式距离计算。计算待识别样本矩阵与学习矩阵相对应元素之间的距离(欧氏距离)。

4)激活模式层高斯函数的神经元。学习样本与待识别样本归一化处理后,通常取标准差=0.1的高斯型函数。激活后得到初始概率矩阵。

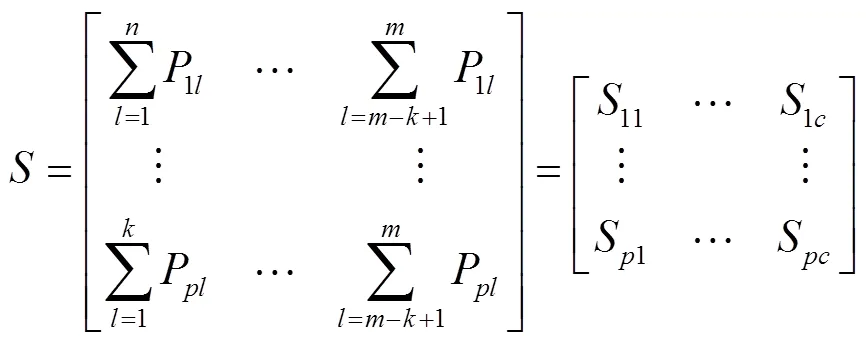

5)求和层求解各样本属于各类的初始概率和。

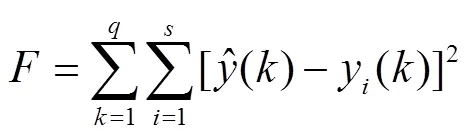

设样本数为,可分为类,且各类样本的数量相同。则样本属于各类的初始概率和为

6)计算概率,即第个待识别样本属于第类的概率,其中S为的第行第列元素,S为的第行第列元素。

2 模式分类代表样本的获取

为提高PNN模式分类方法的性能,建模过程对样本的质量要求较高。采用样本间的相似度度量方法从原始样本数据中筛选更具代表性的建模样本。相似度分析时,常以样本间的距离(如欧氏距离、马氏距离和余弦距离等)作为度量方式。

由欧氏距离和余弦距离的定义可知,欧氏距离和余弦距离分别从不同的角度描述数据间的相似度。两者区别主要体现在:余弦距离在描述数据间的相似度时强调两组数据方向上的差异;欧氏距离则注重两组数据的空间距离或位置上的差异。为更好度量数据间的相似度,发挥欧氏距离和余弦距离各自在描述数据间相似性的优势,将余弦距离和欧式距离2种度量方法有机融合,形成一种新的样本相似度衡量指标,即

式中dist和cos分别表示样本间的欧氏距离和余弦距离,Abs为绝对值函数。相似度衡量指标数值越大则表示2组数据间的差异性越大,反之亦然。采用新的相似度衡量方法对PNN模式分类原始建模数据进行分析,提取更具代表性的建模样本。获取过程为:通过计算原始数据集中样本两两之间的相似度值并设置相应的阈值,当相似度值小于设定阈值,则去除其中一个样本。重复以上筛选过程,直至剩余样本的数量满足建模要求为止。提取后的样本数据具有良好的代表性,即数据间的差异性最大或相似性最小,作为PNN的建模数据。

3 改进的FWA-PNN模式分类算法

将PNN用于解决模式分类问题时,平滑参数的选取直接影响PNN识别性能。通常平滑参数的选取并无统一规则,如何确定合适的参数是PNN建模的关键问题。谭营等[17-18]根据烟花爆炸产生火花这一现象提出烟花算法,其基本实现思路是将烟花视为最优化问题解空间中的一个可行解,通过烟花爆炸产生一定规模的火花,实现邻域搜索最优解。FWA属于有导向的随机性启发式算法,作为一种新型群体智能优化算法,相比传统优化方法,其具有鲁棒性较强、全局优化性能较好,局部和全局搜索能力自调节机制灵活等优势,受到不同领域学者的广泛关注。目前已成功用于解决神经网络权值的训练、连续和离散系统的参数优化及组合优化问题的求解等方面问题,取得良好的应用成效[19-21]。

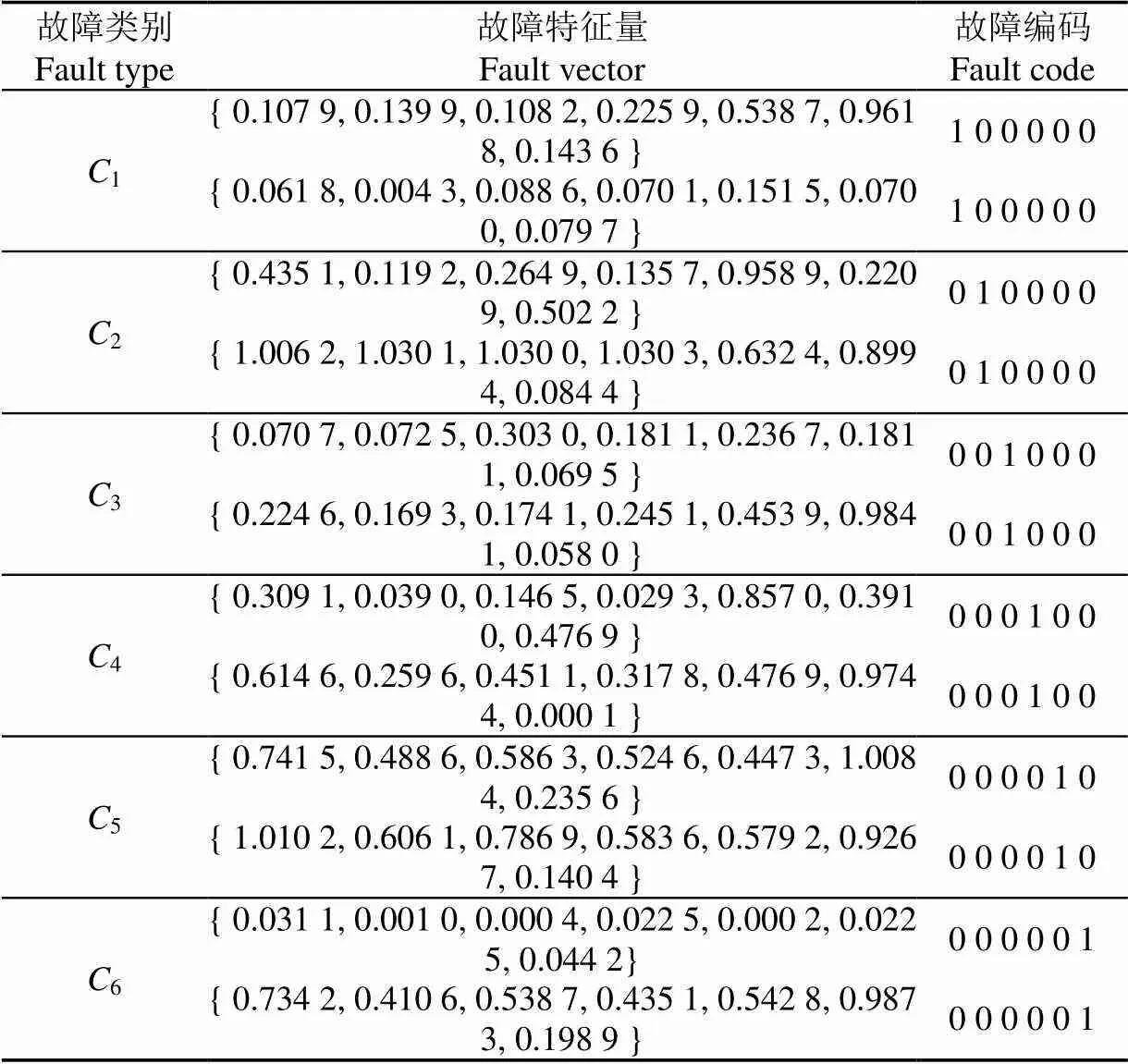

针对现有PNN模式分类方法存在的分类识别精度不高和平滑参数难以确定等问题,本文将FWA优化算法与PNN神经网络技术有机融合提出了一种改进的FWA-PNN模式分类方法。将FWA用于求解PNN平滑因子σ的优化问题,以提高PNN的模式分类与识别精度。

用于故障分类识别的改进FWA-PNN算法,运行过程具体包括以下6个步骤:

1)初始化设置。设定平滑因子σ的取值范围,随机产生规模为的维初始烟花种群1, …σ, …,σ∈R,1,表征平滑因子σ优化问题的个初始解,为待分类样本模式的种类数;根据FWA算法的搜索机理初始化FWA的爆炸半径及爆炸火花数调节常数、最大搜索次数和寻优精度等相关参数;并设当前代数=1;

3)产生爆炸火花和高斯变异火花,从烟花、爆炸火花和高斯变异火花种群中选择个体作为下一次迭代计算的烟花种群;

4)更新迭代次数(即增加1);

5)检查并根据群体最优适应度值计算误差,判断是否满足终止条件。若满足则停止搜索,否则返回步骤2);

6)利用FWA优化算法得到的最优平滑因子σ确定PNN的网络模型,输入测试样本数据,完成故障分类识别。

4 故障诊断建模与验证

4.1 故障数据采集

齿轮箱是农机设备传动系统中的重要部分,经常工作在强噪声干扰、重载和特殊介质等恶劣条件下,齿轮和轴承的故障时有发生[22]。现场运行表明,较为常见的故障类型主要有齿轮崩齿、中间轴窜动、输入轴弯曲、轴承外圈有剥落坑和轴承内圈划伤等5类。

为获取齿轮箱的故障建模数据,以JZQ250型齿轮箱(型号:ZQ-250;品牌:江苏国茂;总中心距:250 mm;传动比:40.17)为对象在实验室模拟了6种工作状态(含1种正常状态和5种典型故障状态)。利用信号采集系统的加速度传感器获取齿轮箱多处测试点的振动信号(采样点数设置为2 048,采样频率分别设置为800、1 000和1 250 Hz,对应齿轮箱额定转速分别为1 000、1 200和1 500 r/min。此外,为使所采集的振动信号能更加全面和真实地反映齿轮箱的工作状态,将测试点布置在齿轮箱箱体的平面和轴承座的受力方向上[23]。

齿轮箱故障诊断系统结构如图2所示。试验过程中,首先利用传感器采集正常工况下齿轮箱的振动信号。受客观条件限制,短期内难以收集大量故障状态下的振动信号用于故障诊断研究。通过在试验对象中间轴的相关部位人为设置齿轮箱的上述几种典型故障状态(包括齿轮崩齿、中间轴窜动、输入轴弯曲、轴承外圈有剥落坑、轴承内圈划伤等故障情况),模拟故障工况。试验过程中保持负载恒定,待齿轮箱转速平稳后再次利用压电加速度传感器(型号:YD-81D;品牌:秦皇岛协力科技)分别测试故障工况下齿轮箱的振动信号。

图2 齿轮箱故障诊断系统结构

4.2 故障特征描述与代表样本获取

对不同工况下从现场采集的齿轮箱振动信号进行预处理,并对其振动特征进行时域和频域分析,得到反应齿轮箱工况的21项时域特征参数(即最大值、最小值、均值、均方值、有效值、方差、方根幅值、绝对平均幅值、偏度、峭度、峰值、波形指标、峰值指标、脉冲指标、裕度指标、峭度指标、偏态指标、偏度系数、8阶矩系数、16阶矩系数和6阶矩)和6项频域特征参数(相关因子、谐波因子、谱原点矩、频谱重心、均方谱和频域方差)[24-25]。

为简化故障诊断模型,根据齿轮箱体的实际工作情况,进行故障特征参数分析和故障敏感参数选取。采用KPCA方法对高维原始数据进行特征提取,分析表明前7个特征值的累积贡献率(即携带的变异信息)大于85%,可以用于进行齿轮箱工作状况识别。从特征参数集中提取对齿轮箱故障较为敏感的7个特征值,即波形指标、峭度指标、裕度指标、偏态指标、频谱重心、频域方差和相关因子,作为齿轮箱故障特征向量。基于PNN的故障诊断系统就是用PNN建立故障特征与故障类型间的映射关系。

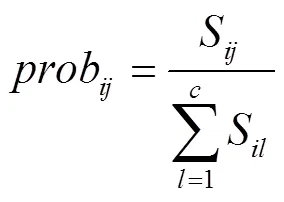

通过对振动信号的时域和频域分析,得到波形指标等7维故障特征向量。典型故障样本如表1所示。诊断模型输入为7维故障特征量,输出为6维故障编码。

表1 齿轮箱典型故障样本

注:1~6分别代表齿轮箱正常工况、齿轮崩齿、中间轴窜动、输入轴弯曲、轴承外圈有剥落坑和轴承内圈划伤等6种工作状态。故障编码中“1”表示故障发生,“0”表示不发生。

Note: C1~C6 represent 6 working conditions of the gearbox, there are normal operating condition, fault of gear breaking, fault of intermediate shaft playing, fault of input shaft bending, fault of spalling pits on the bearing outer ring and fault of scratching on the bearing inner race. In the fault code, the number 1 indicates fault occurring and 0 indicates normal condition.

式中为人为添加的均值为0,方差为1的随机噪声;为噪声控制系数,本文分别取=0.01, 0.02, 0.04, 0.06。利用式(13)在每类工作状态下分别产生100组带噪声的样本,归一化处理后共600组样本。针对不同程度噪声下的故障样本,采用前文所述“模式分类代表样本的获取”方法分别对6类工作状态下的600组故障样本进行相似度分析并剔除其中的冗余样本。

以=0.01情况下产生的故障样本为例,代表样本获取过程为:计算预处理后故障样本集中两样本间的欧氏距离、余弦距离和相似度值,得到矩阵D=(δ)×l(600,1),≥时δ取值为0。根据预处理后故障样本的实际情况设置阈值,即当|δ|<0.18时去除当中的一个样本。处理后故障建模样本规模由600组精简至339组。随机选取其中的219组故障样本(每类故障类别的样本数量约36组)作为神经网络故障诊断建模的训练数据,其余120组作为测试数据。

4.3 基于改进FWA-PNN的故障诊断建模与验证

将改进的FWA-PNN模式分类方法用于齿轮箱故障诊断建模,根据齿轮箱的实际运行工况,本文在进行故障诊断建模时选取的PNN拓扑结构为7-219-6-6,即输入层神经元个数为7,对应7维故障特征量;样本层神经元个数为219,对应219组训练样本的个数;求和层神经元个数为6,对应齿轮箱的6类工作状态;竞争层神经元个数为6,与求和层相同,输出故障诊断结果(即将求和层求解的具有最大后验概率密度的神经元输出为1,其余为0)。

为与FWA-PNN神经网络故障诊断建模方法形成对比,本文还引入了BP神经网络、GABP神经网络(遗传算法优化的BP神经网络)和PNN神经网络,分别建立不同类型的齿轮箱故障诊断模型。主要参数设置情况描述如下:

BP神经网络:结构为7-13-6,学习算法为梯度下降法,学习率为0.01,最大迭代次数为5 000,网络训练目标为0.01;GABP神经网络:初始种群规模和维数分别为20和6,交叉概率p为0.65,变异概率p为0.01,网络结构及其他参数设置与BP神经网络相同;PNN神经网络:结构为7-219-6-6,平滑参数=0.1;FWA-PNN神经网络:结构为7-219-6-6,平滑参数σ(16)通过FWA优化获取。FWA优化算法的烟花成员规模和维数分别为20和6、爆炸半径及爆炸火花数调节常数分别为100和80、爆炸火花数上限和下限分别为20和1、高斯变异火花数=50,参数优化过程最大迭代次数为3 000,优化精度(求和层实际输出与理想输出之间的偏差)为0.01。

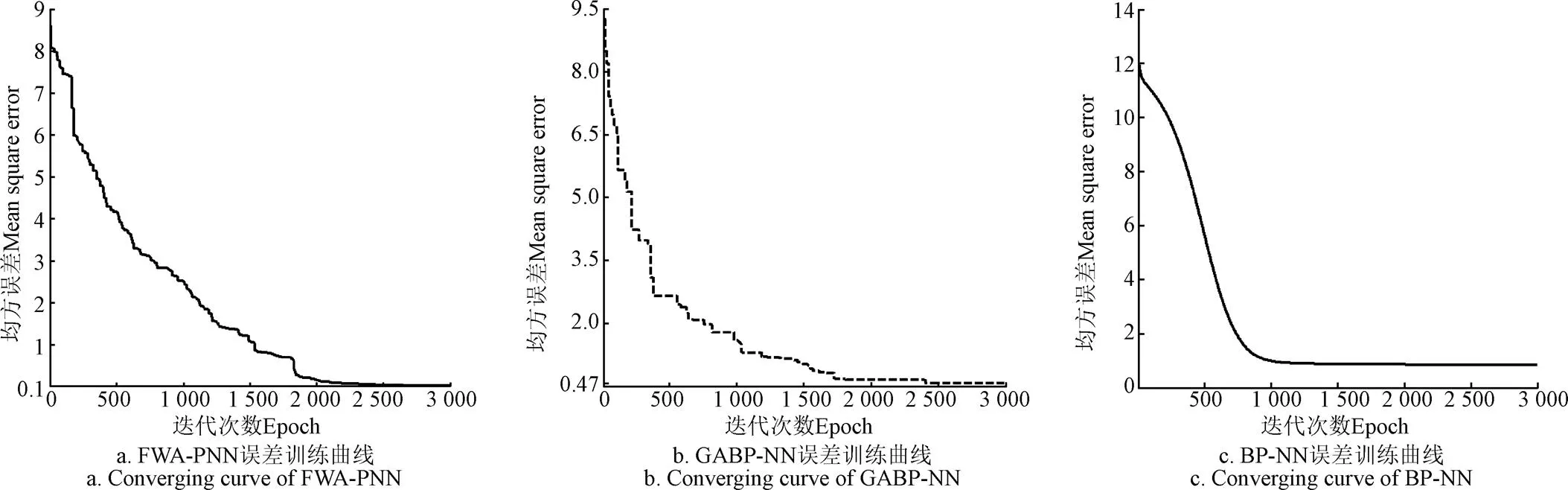

图3为噪声控制系数=0.01时,基于常规BP神经网络、GABP神经网络和FWA-PNN神经网络的训练样本误差变化曲线。由图3可知:基于改进的FWA-PNN故障诊断模型经过3 000次迭代后训练精度达到0.101 6,误差收敛速度和精度明显优于GABP神经网络和常规BP神经网络。展现出良好的容错性和较强的故障分类能力;相同条件下GABP神经网络经3 000次迭代训练精度为0.471 2;而常规BP神经网络表现最差,经3 000次迭代训练精度仅为0.865 7,经过1 200迭代后收敛速度明显减慢,训练精度无明显变化,网络陷入局部极值。

图3 3种神经网络训练误差曲线(噪声控制系数a=0.01)

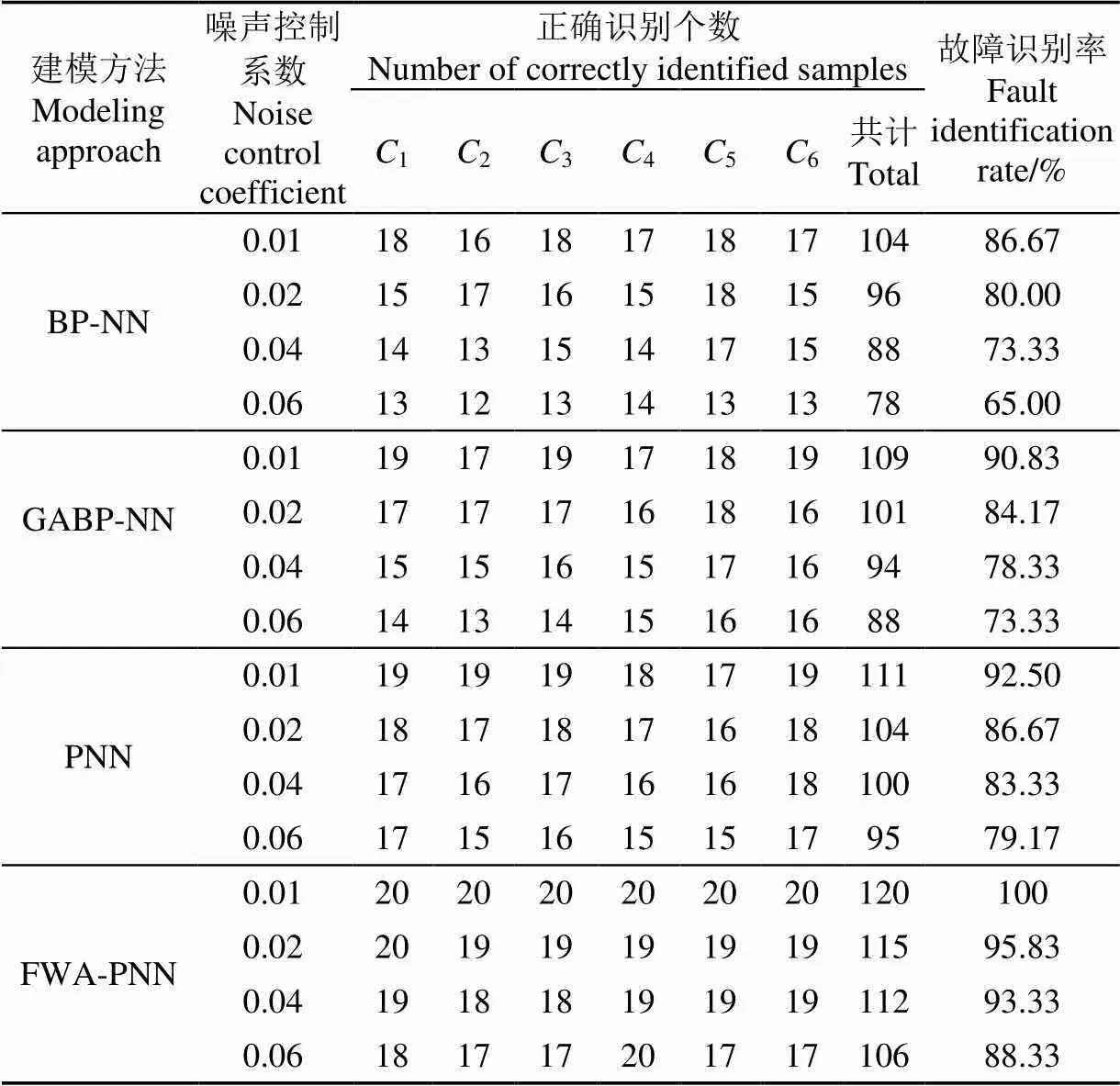

采用4种神经网络故障诊断模型,分别对不同噪声控制系数下的测试样本进行故障诊断与分类定位试验,故障识别结果对比如表2所示。故障识别率为累计正确识别个数与测试验本总数之比值。

表2 3种故障诊断模型故障识别结果对比

由表2可知,故障样本在噪声控制系数取值较小(如0.01)的情况下,4种故障诊断模型的故障识别率均大于85%,故障识别性能较好,其中FWA-PNN模型性能最优,故障识别率达到100%;随着噪声程度的递增,由于常规BP神经网络噪声适应能力及容错能力较弱,模型的故障诊断精度有较大程度下降,在=0.06时,故障识别率仅为65%;GABP神经网络模型,将全局优化性能较强的GA算法和BP神经网络有机融合,利用GA算法对神经网络的权阈值进行优化,有效提高了常规BP神经网络的非线性映射能力。故障识别率有一定程度提高,但噪声抗干扰能力不够强;PNN神经网络由于吸收了径向基神经网络与经典的概率密度估计原理的优点,具有较强的噪声抗干扰能力,在模式分类方面较BP网络更有优势,整体故障识别性能优于BP网络;FWA-PNN神经网络由于采用FWA算法对每个模式类别的平滑参数σ进行优化,有效提高了PNN的识别精度,在不同程度的噪声影响下FWA-PNN神经网络模型均具有最高的故障识别率。

5 结 论

复杂噪声环境下齿轮箱的状态监测与故障诊断对于保障设备安全可靠运行具有重要理论意义和实用价值。为更好地实现齿轮箱的智能故障诊断,本文融合烟花算法和概率神经网络,提出一种改进的模式分类方法并成功用于噪声环境下齿轮箱的故障诊断建模。主要结论为:

1)为解决现有PNN模式分类方法在实际应用过程中存在对训练样本的代表性要求高及平滑参数难以确定等问题,一方面定义了一种样本相似度衡量指标并设计了一种代表性训练样本提取方法,可有效提高PNN建模过程中训练样本的质量;另一方面引入一种全局优化性能较强的FWA算法用于优化PNN每个模式类别的平滑参数,以提高噪声环境下PNN模式分类与识别的精度。

2)通过对6类典型故障情况下齿轮箱的振动信号进行分析和处理,得到相应的故障特征向量。为模拟齿轮箱的实际工况,在典型故障样本中人为添加不同程度的噪声并产生相应的故障诊断建模样本。将提出的改进FWA-PNN模式分类方法用于齿轮箱故障诊断建模,建立了故障特征参量与齿轮箱工作状况间的非线性映射关系。试验结果表明在噪声控制系数为0.01、0.02、0.04和0.06的情况下,该故障诊断模型的故障识别率分别为100%、95.83%、93.33%和88.33%,优于BP-NN、GABP-NN和PNN 3种故障诊断模型。本文所构建的模型能较为准确地检测齿轮箱的各种典型故障,有效地提高了现有方法的故障诊断性能,为复杂噪声环境下齿轮箱等非线性复杂系统的故障诊断提供一种通用可行的解决方案。

[1] 谢有浩,刘晓乐,刘后广,等. 基于改进移频变尺度随机共振的齿轮故障诊断[J]. 农业工程学报,2016,32(8):70-76.

Xie Youhao, Liu Xiaole, Liu Houguang, et al. Improved frequency-shifted and re-scaling stochastic resonance for gear fault diagnosis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(8): 70-76. (in Chinese with English abstract)

[2] Jing L Y, Zhao M, Li P. A convolutional neural network based feature learning and fault diagnosis method for the condition monitoring of gearbox[J]. Measurement, 2017, 111: 1-10.

[3] Zhao Ming, Jia Xiaodong, Lin Jing, et al. Instantaneous speed jitter detection via encoder signal and its application for the diagnosis of planetary gearbox[J]. Mechanical System and Signal Processing, 2018, 98: 16-31.

[4] Wang L, Liu Z W, Miao Q. Time-frequency analysis based on ensemble local mean decomposition and fast kurtogram for rotating machinery fault diagnosis[J]. Mechanical System and Signal Processing, 2018, 103: 60-75.

[5] 胥永刚,孟志鹏,赵国亮,等. 基于双树复小波包变换能量泄漏特性分析的齿轮故障诊断[J]. 农业工程学报,2014,30(2):72-77.

Xu Yonggang, Meng Zhipeng, Zhao Guoliang, et al. Analysis of energy leakage characteristics of dual-tree complex wavelet packet transform and its application on gear fault diagnosis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(2): 72-77. (in Chinese with English abstract)

[6] 孟宗,胡猛,谷伟明,等. 基于LMD多尺度熵和概率神经网络的滚动轴承故障诊断方法[J]. 中国机械工程,2016,27(4):433-437.

Meng Zong, Hu Meng, Gu Weiming, et al. Rolling bearing fault diagnosis method based on LMD multi-scale Entropy and Probabilistic Neural Network[J]. China Mechanical Engineering, 2016, 27(4): 433-437. (in Chinese with English abstract)

[7] Jiang Guoqian, Xie Ping, Wang Xiao. Intelligent fault diagnosis of rotary machinery based on unsupervised multiscale representation learning[J]. Chinese Journal of Mechanical Engineering, 2017, 30(6): 1314-1324.

[8] Sun R B, Yang Z B, Chen X F. Gear fault diagnosis based on the structured sparsity time-frequency analysis[J]. Mechanical System and Signal Processing, 2018, 102: 346-363.

[9] Sharma Vikas, Parey Anand. Gearbox fault diagnosis using RMS based probability density function and entropy measures for fluctuating speed conditions[J]. Structural Health Monitoring-an International Journal, 2017, 16(6): 682-695.

[10] 周士帅,窦东阳,薛斌. 基于LMD和MED的滚动轴承故障特征提取方法[J]. 农业工程学报,2016,32(23):70-76.

Zhou Shishuai, Dou Dongyang, Xue Bin. Fault feature extraction method for rolling element bearings based on LMD and MED[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(23): 70-76. (in Chinese with English abstract)

[11] 张淑清,徐剑涛,姜安琦,等. 基于极点对称模态分解和概率神经网络的轴承故障诊断[J]. 中国机械工程,2017,28(4):425-431.

Zhang Shuqing, Xu Jiantao, Jiang Anqi. Fault diagnosis of bearings based on extreme-point symmetric mode decomposition and probabilistic neural network[J]. China Mechanical Engineering, 2017, 28(4): 425-431. (in Chinese with English abstract)

[12] Jia F, Lei Y G, Guo L. A neural network constructed by deep learning technique and its application to intelligent fault diagnosis of machines[J]. Neurocomputing, 2018, 272: 619-628.

[13] Chen X Y, Zhou J Z, Xiao H. Fault diagnosis based on comprehensive geometric characteristic and probability neural network[J]. Applied Mathematics and Computation, 2014, 230(3): 542-554.

[14] 钟金童,李国龙,刘达斌,等. 基于概率神经网络的蜗杆砂轮磨齿机径向热误差建模[J]. 计算机集成制造系统,2017,23(3):534-541.

Zhong Jintong, Li Guolong, Liu Dabin, et al. Radial thermal error modeling of CNC worm wheel gear grinding machine based on probabilistic neural network[J]. Computer Integrated Manufacturing Systems, 2017, 23(3): 534-541. (in Chinese with English abstract)

[15] 梁晴晴,韩华,崔晓钰,等. 基于主元分析-概率神经网络的制冷系统故障诊断[J]. 化工学报,2016,67(3):1022-1031.

Liang Qingqing, Han Hua, Cui Xiaoyu, et al. Fault diagnosis for refrigeration system based on PCA-PNN[J]. CIESC Journal, 2016, 67(3): 1022-1031. (in Chinese with English abstract)

[16] Liu J X, Wen X B, Yuan L M. A robust approach of watermarking in contourlet domain based on probabilistic neural network[J]. Multimedia Tools and Application, 2017, 76(22): 24009-24026.

[17] 谭营,郑少秋. 烟花算法研究进展[J]. 智能系统学报,2014,9(5):515-528.

Tan Ying, Zheng Shaoqiu. Recent advances in fireworks algorithm [J]. CAAI Transactions on Intelligent Systems, 2014, 9(5): 515-528. (in Chinese with English abstract)

[18] Li J, Zheng S U, Tan Y. Adaptive fireworks algorithm[C]// Proceedings of 2014 IEEE Congress on Evolutionary Computation. Piscataway, NJ, USA: IEEE, 2014: 3214-3221.

[19] Zheng S Q, Li J Z, Janecek A. A cooperative framework for fireworks algorithm[J]. IEEE/ACM Transactions on Computational Biology and Bioinformatics, 2017, 14(1): 27-41.

[20] 吴琼,曾庆鹏. 基于多目标烟花算法的关联规则挖掘[J].模式识别与人工智能,2017,30(4):365-376.

Wu Qiong, Zeng Qingpeng. Association rules mining based on multi-objective fireworks optimization algorithm[J]. Pattern Recognition and Artificial Intelligence, 2017, 30(4): 365-376. (in Chinese with English abstract)

[21] Pavao L V, Costa C B B, RavagnaniM A D S. Large-scale heat exchanger networks synthesis using simulated annealing and the novel rocket fireworks optimization[J]. Aiche Journal, 2017, 63(5): 1582-1601.

[22] 李志星,石博强. 自适应奇异值分解的随机共振提取微弱故障特征[J]. 农业工程学报,2017,33(11):60-67.

Li Zhixing, Shi Boqiang. Extracting weak fault characteristics with adaptive singular value decomposition and stochastic resonance[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(11): 60-67. (in Chinese with English abstract)

[23] 魏秀业,潘宏侠,黄晋英. 齿轮箱传感器优化布置研究[J]. 兵工学报,2010,31(11):1508-1513.

Wei Xiuye, Pan Hongxia, Huang Jinying. Study on sensor optimal layout for gearbox[J]. Acta Armamentarii, 2010, 31(11): 1508-1513. (in Chinese with English abstract)

[24] He Q B, Kong F R, Yan R Q. Subspaced-based gearbox monitoring by kernel principal component analysis[J]. Mechanical System and Signal Processing, 2007, 21: 1755-1772.

[25] 李怀俊,刘越琪,谢小鹏. 齿轮箱振动与输入能量信号的频域相干分析与关系识别[J]. 农业工程学报,2015,31(4):175-182.

Li Huaijun, Liu Yueqi, Xie Xiaopeng. Frequency domain coherence analysis and relationship recognition between gearbox vibration and input energy signal[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(4): 175-182. (in Chinese with English abstract)

Intelligent fault diagnosis of gearbox based on improved fireworks algorithm and probabilistic neural network

Chen Ruqing1, Li Jiachun2, Shang Tao1, Zhang Jun3

(1.,,314001,; 2.,,314001,; 3.,,310058,)

In the field of agricultural machine and equipment, gearbox was a key mechanical part that was widely applied in speed regulation and power transmission. The gearbox had a high fault rate in actual operating process due to the severe working condition and its complex configuration. State monitoring and fault diagnosing were of great significance to guarantee the safety and stability of gearbox. A fault diagnosis method based on the improved fireworks algorithm (FWA) and probabilistic neural network (PNN) was proposed to overcome the shortcomings, such as the sensitivity to environmental noise and low fault recognition rate, when conducting the fault diagnosis system of gearbox under complex operating conditions. To enhance the pattern classifying performance of traditional methods based on PNN, a new similarity measure for samples was defined, which made the quality of PNN training data increase in modeling process. An improved FWA-PNN classification method was proposed by combining FWA optimization algorithm with PNN technology. The FWA was applied to optimize the smoothing parameters of PNN to determine the optimal values of network parameters, and thus in some way the pattern classification and identification accuracy of PNN could be improved. The proposed FWA-PNN classification method was applied in fault diagnosis modeling for gearbox under noisy environment, and the complex non-linear mapping relationship between fault characteristic parameters and equipment working conditions was constructed. Experiments were carried out on JZQ250 gearbox in laboratory and the process of the fault diagnosis modeling was summarized as follows: At first, 6 working states of the gearbox that included normal state and 5 typical fault states were simulated during the experiments. And then the vibration signals of the gearbox were gained by using the accelerometers of signal acquisition system under different working conditions. After the pretreatment, time and frequency domain analysis of vibration signals were carried out and 27 time and frequency parameters reflecting the working status of the gearbox were obtained. Kernel principal component analysis (KPCA) method was applied to extract the features of the original high-dimensional data, and 7 characteristic parameters were selected as the fault feature vectors of gearbox at last. As a result, the original fault samples were generated according to the fault feature vectors. Given that the fault vibration signals of gearbox were easy to be interfered by different noises in practice, the fault modeling sample sets were regenerated by adding random noises of different levels in the original fault samples. Two thirds of the samples were randomly selected as the training data and the remaining samples were as the test data to establish fault diagnosis model for gearbox based on FWA-PNN. Next, in order to validate the effectiveness and robustness of this new model, BP (back propagation) neural network (BP-NN), genetic algorithm based BP-NN (GABP-NN) and normal PNN methods were introduced to compare with the improved pattern classification method, and 4 different fault diagnosis models were built. The training results of different neural network models indicated that FWA-PNN had better performance in error convergence speed and precision than GABP-NN and BP-NN, which had an excellent fault tolerance and fault classification capability. Finally, 4 different models were applied in fault diagnosis and classification by using the noise samples as the test data. Comparison results indicated that FWA-PNN model could effectively improve the precision of fault detection due to the smooth parameters of all pattern categories optimized by FWA. Application results showed that by compared with the fault diagnosis models based on BPNN, GABPNN and traditional PNN, the FWA-PNN model had the highest fault recognition rate under different noise levels. In conclusion, a novel fault diagnosis program for nonlinear and complex mechanical systems is provided in this paper. It has good application prospects and popularized value in fault diagnosing for agricultural machinery and equipment.

gears; algorithms; noises; probabilistic neural network; fault diagnosis modeling

2018-01-29

2018-06-30

浙江省基础公益研究计划项目(LGG18F030011);国家自然科学基金资助项目(61603154)

陈如清,副教授,博士,主要从事复杂工业过程建模、机械系统状态监测与故障诊断的有关研究。Email:10555322@qq.com

10.11975/j.issn.1002-6819.2018.17.025

TH165+.3; TH132.46

A

1002-6819(2018)-17-0192-07

陈如清,李嘉春,尚 涛,张 俊. 改进烟花算法和概率神经网络智能诊断齿轮箱故障[J]. 农业工程学报,2018,34(17):192-198. doi:10.11975/j.issn.1002-6819.2018.17.025 http://www.tcsae.org

Chen Ruqing, Li Jiachun, Shang Tao, Zhang Jun. Intelligent fault diagnosis of gearbox based on improved fireworks algorithm and probabilistic neural network[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(17): 192-198. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.17.025 http://www.tcsae.org