Bearing ratio and leachate analysis of pond ash stabilized with lime and lime sludge

Manju Suthar,Praveen Aggarwal

Department of Civil Engineering,National Institute of Technology,Kurukshetra,136119,Haryana,India

Keywords:Class F pond ash Lime and lime sludge Bearing ratio Leachate analysis

ABSTRACT Recycling of industrial waste is one of the effective ways to overcome their disposal problem.Ash produced by thermal power plants and lime sludge produced by paper mills require huge disposal land and may create environmental problems such as dusting and leaching of harmful heavy metals.Stabilization of the ash can improve its engineering properties and address the environmental problems.This paper reports the laboratory test results of a Class F pond ash stabilized with lime(2%,4%,6%and 8%by weight)alone and in combination with lime sludge(5%,10%and 15%by weight).The X-ray diffraction(XRD)and scanning electron micrograph(SEM)tests were also performed to identify the possible formation of crystalline phases after stabilization.The effects of lime sludge on the unsoaked and soaked bearing ratios of pond ash with different lime contents,after 7 d,28 d and 45 d of curing,were observed.Test results indicated that the bearing ratio increased considerably up to a 4%lime content which can be taken as the optimum lime content.Further increase in lime content increased bearing ratio gradually but at a slower rate.The effect of lime sludge was more pronounced at the optimum lime content,particularly at a low curing period.Lime sludge improved the bearing ratio in soaked condition significantly.Leachate analysis of stabilized ash was performed using toxicity characteristic leaching procedure(TCLP-1311)method.The concentrations of toxic elements Zn,Cu,Cd,Ni and Cr in the stabilized mixes were lower than those in the unstabilized waste.The results indicated that the pond ash-lime-lime sludge mixes have potential application as road subbase material.

1.Introduction

Coal ash is produced by coal-based thermal power plants(TPPs)for power generation in many countries.There are two types of ash produced by TPPs,i.e. fly ash(80%)and bottom ash(20%).The fly ash is collected by electrostatic precipitators from the flue gases of power plants,and the bottom ash is collected from the bottom of the boilers.The ash generated by TPPs is generally disposed by one of following two ways:(1) fly ash is transported in dry-form for advantageous recycle or disposal in on-site or off-site land fills,or(2) fly and bottom ashes are mixed with suitable proportion of water and pumped out from the TPPs as slurry in the ash pond.The second method is known as wet-disposal,which is most commonly used and an inexpensive management practice worldwide.The mix of fly and bottom ashes in ash pond is called pond ash.

The constant increasing need for wet-disposal storage capacity and concerns for fly ash leachate and dusting(Ghosh,2010),groundwater contamination(Mehra et al.,1998)and impoundment failure(Ruhl et al.,2010)present environmental and logistical difficulties.As a result,the situation is expected to deteriorate further worldwide,with elapsed time.The favorable method to address these problems is to reuse the pond ash in construction,such as rail and road embankments,dykes and structural fill,afterconverting it into a nonhazardous,good-performance engineering material in a cost-effective means.Utilization of pond ash in construction is a solution to the disposal of pond ash and also to the scarcity of natural construction materials.

According to the ASTM classification(ASTM C618-08a,2008), fly ash is classified as Classes C and F fly ash.Class C fly ash with high calcium content undergoes high reactivity with water evenwithout addition of lime(Parsa et al.,1996).Class F fly ash contains lower percentages of lime.There are numerous studies(Ghosh,1996;Pandian,2004;Ghosh and Subbarao,2007;Tastan et al.,2011)on Class F fly ash,stabilized with lime,cement,gypsum,or in combination,to improve the engineering properties of fly ash.

Table 1 Physical properties of pond ash sample(Suthar and Aggarwal,2015).

Table 2 Chemical composition of pond ash,lime and lime sludge(%).

A number of studies have been conducted on effective utilization of fly ash in bulk quantity in many civil engineering applications,such as using fly ash as fill material(DiGioa and Nuzzo,1972;Faber and DiGioa,1974;Joshi et al.,1975;Horiuchi et al.,2000),lightweight aggregate(Bin-Sha fique et al.,2004),subbase material(Sherwood and Ryley,1966;Leelavathamma et al.,2005;Ghosh and Subbarao,2006),and volume replacement and self-compacting material for increasing the workability of concrete(Ganesh and Siva,1993;Siddique,2003;Jaturapitakkul et al.,2004;Yen et al.,2007;Mustafa et al.,2009),and also for soil stabilization(Tastan et al.,2011),replacement of cement(Xu and Sarkar,1994),coastal land reclamation(Kim and Chun,1994),and the manufacture of clay flooring and terracing tiles(Bou et al.,2009).

Lime sludge is another waste material,generated from paper,acetylene,sugar,fertilizer,sodium chromate,soda ash industries and water softening plants.Approximately 4.5 million tons of lime sludge is generated annually from these industries in India(Sahu and Gayathri,2014),and disposal of the lime sludge is also a problem(Calacea et al.,2005;Mahmood and Elliot,2006;Battaglia et al.,2007).As lime sludge contains calcium carbonate(Medhi et al.,2005),researchers proposed to utilize lime sludge in many civil engineering applications as building material(Singh and Garg,2008),partial replacement material of cement in mortar(Sahu and Gayathri,2014),subgrade material(Zhang and Yu,2012)and even subbase material in village road(Talukdar,2015).

Table 3 Summary of mixes.

Few studies are reported on the characteristics of pond ashlime-lime sludge(PA-L-LS)mixes.The present study investigates the bearing ratio of Class F pond ash with lime(2%-8%by weight)alone and lime combined with lime sludge(5%-15%by weight),after different curing periods(7 d,28 d and 45 d)under unsoaked and soaked conditions.The X-ray diffraction(XRD)and scanning electron micrograph(SEM)tests were also carried out on the stabilized pond ash samples.Further,to study the leaching behavior of selected harmful metals from lime sludge,unstabilized and stabilized pond ash samples,leaching tests was conducted using toxicity characteristic leaching procedure(TCLP-1311)method.

2.Materials and method

2.1.Experimental materials

2.1.1.Pond ash

Pond ash was collected from Deenbandhu Chhotu Ram Thermal Power Plant,Yamuna Nagar,India.According to ASTMC 618-08a(2008),the ash belongs to Class F.The physical properties and chemical composition(Suthar and Aggarwal,2015)of the pond ash are presented in Tables 1 and 2,respectively.

2.1.2.Lime

Hydrated lime was used in the study.The chemical composition of the lime is presented in Table 2.

Table 4 MDD and OMC of various pond ash mixes.

Fig.1.Bearing ratio of lime-stabilized pond ash at 7 d,28 d and 45 d of curing period:(a)Unsoaked test and(b)Soaked test.

2.1.3.Lime sludge

Lime sludge was collected from the Ballarpur Industry Limited(paper mill),Yamuna Nagar,India,which is also a waste from the industry.The chemical composition of the lime sludge is presented in Table 2.

2.2.Experimental program

A series of laboratory test was performed on the pond ash stabilized with varying percentages of lime(2%,4%,6%and 8%).Effect of lime sludge(5%,10%and 15%)on lime-modified pond ash was also studied.In order to assess the engineering properties of stabilized pond ash,Proctor compaction and bearing ratio tests were performed after curing periods of 7 d,28 d and 45 d under unsoaked and soaked conditions.

To identify the substantial changes in the stabilized pond ash structure,mineralogical and morphological analyses were also carried out using XRD and SEM tests,respectively.Finally,leachate analysis was performed on selected soaked stabilized pond ash samples.A summary of mixes along with designations is presented in Table 3.

Fig.2.Bearing ratio of stabilized pond ash with varying lime and lime sludge contents for 7 d of curing period:(a)Unsoaked test and(b)Soaked test.

2.3.Testing procedure

2.3.1.Compaction test

The maximum dry density(MDD)and optimum moisture content(OMC)of each mix were determined using standard Proctor compaction test as per IS 2720-7(1980).The values of MDD and OMC for all mixes are presented in Table 4.

2.3.2.Bearing ratio test

The bearing ratio is a vital parameter used in the empirical flexible pavement design approaches.The bearing ratio tests were performed on all the mixes as per IS 2720-16(1987)under unsoaked and soaked conditions.To study the effect of curing/pozzolanic reaction on bearing ratio,compacted samples were sealed in the plastic bag(to prevent rapid moisture loss)at room temperature,for 7 d,28 d and 45 d.To evaluate the effect of soaking on the bearing ratio,the cured samples were soaked in water for 96 h before testing.

Fig.3.Bearing ratio of stabilized pond ash with varying lime and lime sludge contents for 28 d of curing period:(a)Unsoaked test and(b)Soaked test.

2.3.3.XRD and SEM tests

To understand the mineralogical and morphological behaviors,XRD and SEM tests were carried out on stabilized pond ash samples,respectively.For XRD test,a smallamountof samplewas ovendried at 105°C for 24 h,and powdered and sieved through a 50 μm sieve.The sample finer than 50μm was placed onto the X-Ray diffractometer equipment and scanned over a scattering angle 2θof 10°-70°.An XRD pattern of the sample was then compared to the standard patterns(JCPDS data files)for possible compounds in the stabilized samples.SEM tests were performed by using a model JEOL JSM-6510LV.For SEM analysis,a solid piece of approximate 10 mm size was selected from the stabilized sample.Solid piece of the sample was oven-dried at 105°C for 24 h.Then,the dried sample was mounted on the sample holder and coated with a thin layer of gold-palladium alloy with a JEOL JFC-1600 auto fine coater to make them good conductor.The coated sample was placed in SEM equipment and the photographs were recorded.

Fig.4.Bearing ratio of stabilized pond ash with varying lime and lime sludge contents for 45 d of curing period:(a)Unsoaked test and(b)Soaked test.

2.3.4.Leaching test

The TCLP-1311 test method was used to investigate the leaching behavior of the ash samples.TCLP is one of the main leaching procedure tests that have been used to analyze the risk of heavy metal leachability from the stabilized pond ash sample.

In order to perform the test,leachate solution was prepared by adding 5.7 mL glacial acetic acid to 500 mL distilled water.Further,1 mol/L NaOH was added to the solution and the final solution was made to 1 L by adding additional distilled water.During this process,the pH value of this solution was maintained at 4.94.The selected sample of 100 g was immersed in this solution(acetic acid-NaOH buffer solution).The prepared leachate solutions were preserved in a closed container and were kept in desiccators at room temperature for the one-month duration.The leachate solutions were shaken at a rate of 30±2 RPM(revolutions per minute)to aggravate the reaction between the sample and leachate solutionon a daily basis.Although,as per CLP-1311,the leachate solution should be filtered as soon as possible after agitating for 16 h,but when reviewing in the literature,the concentration of toxic elements in stabilized samples is significant up to 30 d.According to Guleria and Dutta(2013a,2013b),a marginal increase has been observed when the different leachate solutions were tested after 90 d corresponding to the leachate results obtained after 30 d.Keeping this in mind,superannuated leachate solution was filtered after 30 d through a 0.45 mm filter paper by vacuum filtration system for analyzing the selected heavy metals.The MP-atomic emission spectrophotometer(MP-AES)was used to determine the concentration of elements.

Table 5 Percentage increase in bearing ratio of pond ash stabilized with lime.

Table 6 Percentage increase in bearing ratio due to addition of lime sludge to lime-stabilized pond ash.

3.Results and discussion

3.1.Compaction test

The results of the compaction tests of pond ash stabilized with lime(2%,4%,6%and 8%)and lime plus lime sludge(5%,10%and 15%)are shown inTable 4.The results indicate that there is an increasing trend in the MDD value and a decreasing trend in the OMC value with increase in lime/lime sludge doses.However,some localized variations are observed there.The values of MDD and OMC of the pond ash were 1.093 g/cm3and 32.2%,respectively.The value of MDD of stabilized pond ash varies from 1.094 g/cm3to 1.17 g/cm3,and OMC varies from 31.7%to 26.1%.The observations are in agreement with Ghosh(2010).

3.2.Bearing ratio test

The bearing ratiotest results of pond ash,stabilized with varying percentage of lime under unsoaked and soaked conditions,are presented in Fig.1aand b,respectively.The bearing ratiotestresults of pond ash stabilized with lime only and lime plus lime sludge for 7 d,28 d and 45 d of curing period,under unsoaked and soaked conditions,are presented in Figs.2-4,respectively.The effects of lime and lime sludge content,curing period and soaking on the bearing ratio behavior of stabilized pond ashes are presented in the following sections.

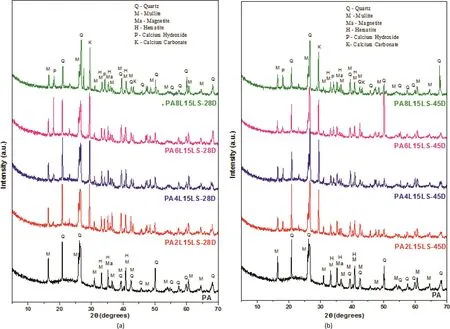

Fig.5.XRD patterns of pond ash with varying percentage of lime along with 15%lime sludge at(a)28 d and(b)45 d of curing.

Fig.6.SEM photographs of pond ash with varying percentage of lime along with 15%lime sludge at 28 d of curing period:(a)PA,(b)PA2L15LS-28D,(c)PA4L15LS-28D,(d)PA6L15LS-28D,and(e)PA8L15LS-28D.

3.2.1.Effect of lime content

Table 5 shows the percentage increase in bearing ratio of limestabilized pond ash as compared to unstabilized pond ash under unsoaked and soaked conditions.The bearing ratio increases with increase in lime content,at a steeper rate up to 4%of lime.From the results,it is evident that the soaked bearing ratio of unstabilized pond ash(after 7 d of curing)reduces from 23%to 4%,due to the softening of the unstabilized sample during soaking.The addition of lime increases the bearing ratio value in both unsoaked and soaked conditions,but the percentage increase in bearing ratio is much higher in soaked conditions.Addition of lime increases the bearing ratio,which may be due to pozzolanic reaction that has taken place in the presence of lime.The results also show that as the quantity of lime increases,the effect of soaking on bearing ratio reduces at all curing periods.

3.2.2.Effect of lime sludge content

Table 6 shows the percentage increase in bearing ratio due to the addition of lime sludge along with lime in pond ash as compared to lime alone.It can be observed from Figs.2-4 and Table 6 that effect of lime sludge is more significant at lower doses of lime,i.e.up to 4%and in soaked condition.At higher doses of lime,i.e.6%and 8%,the effect of lime sludge on soaked bearing ratio is marginal.It is also observed that addition of lime sludge reduces the effect of curing period.

From the above results,it can be concluded that the lime sludge plays a predominant role in the improvement of pond ash bearing ratio particularly with low lime content and at low curing periods.

3.2.3.Effect of curing period

To study the effect of curing period on the bearing ratio of stabilized pond ash,the samples were cured for 7 d,28 d and 45 d.The bearing ratios in both unsoaked and soaked conditions increase continuously with an increase in curing period of lime-stabilized pond ash for each lime content(Fig.1).The increasing trend in the bearing ratio of pond ash stabilized with lime and lime sludge content is also observed in Figs.2-4 for curing period up to 45 d.The reason for increase in bearing ratio with curing period is pozzolanic reactions.As per Sahu et al.(2013),the pozzolanic reaction is a slow process,and the amount of gel formed in the mix increases with an increase in curing period resulting in a higher strength.In all the mixes,the bearing ratio after 28 d of curing period is approximately 80%-90%of bearing ratio after 45 d of curing period.

Fig.7.SEM photographs of pond ash with varying percentage of lime along with 15%lime sludge at 45 d of curing period:(a)PA,(b)PA2L15LS-45D,(c)PA4L15LS-45D,(d)PA6L15LS-45D,and(e)PA8L15LS-45D.

3.2.4.Effect of soaking

To investigate the effect of soaking on the bearing ratio of stabilized pond ash,cured samples were soaked in water for 96 h.The soaked bearing ratio is about 80%of that of the unsoaked bearing ratio for all the mixes and all curing periods except for samples PA,PA2L(curing periods of 7 d,28 d and 45 d),PA4L,PA6L and PA2L5LS(curing period of 7 d).The soaked bearing ratio is so high because particles are suf ficiently bonded due to adequate pozzolanic reaction that has taken place during curing,hence the effect of soaking is reduced.For samples PA,PA2L(curing periods of 7 d,28 d and 45 d),PA4L,PA6L and PA2L5LS(curing period of 7 d),soaked bearing ratio is relatively lower,about 20%-70%of respective unsoaked bearing ratio.The reason may be attributed to an insufficient quantity of lime/lime sludge and curing period for necessary pozzolanic reaction.

As per Indian Road Congress guidelines(IRC 37,2001),the subbase material should have a minimum bearing ratio of 20%for cumulative traf fic up to 2 million standard axles(msa)and 30%for traf fic exceeding 2 msa.The results show that after 28 d of curing,the sample PA2L5LS is good enough to be used as a subbase course.A minimum quantity of lime in the pond ash mix satisfying the subbase course requirement is 2%,i.e.mixes PA2L10LS(7 d of curing)and PA2L5LS(28 d of curing).

3.3.XRD analysis

The XRD test results of the unstabilized and stabilized(with lime and 15%lime sludge)pond ash samples after 28 d and 45 d of curing and soaking are shown in Fig.5a and b,respectively.Results show that the major crystalline phase in the unstabilized pond ash is quartz(Q)and others in small amount are mullite(M),hematite(H)and magnetite(Ma).Fig.5a and b reveals the formation of new peaks of calcium hydroxide(P)and calcium carbonate(K)in all stabilized pond ash samples which came from addition of lime and lime sludge.Formation of these new peaks of calcium hydroxide(at 18°and 34.1°)and calcium carbonate(at 29.4°and 43.2°)were found to match well with the JCPDS Nos.44-1481 and 85-1108,respectively.Thus,the increase in bearing ratio as observedexperimentally for stabilized samples with lime and lime sludge after curing periods of 28 d and 45 d is attributed to the formation of these new peaks.

Table 7 Concentration of heavy metals in lime sludge,unstabilized and stabilized pond ash(mg/kg).

3.4.SEM analysis

The SEM test results of the unstabilized and stabilized(with lime and 15%lime sludge)pond ash samples after 28 d and 45 d of curing and soaking are shown in Figs.6 and 7,respectively.The SEM photographs(Fig.6b-e)of stabilized pond ash show a better bonding among pond ash particles and formation of ettringite needles on the surface of pond ash particles.A gradual increase(Fig.6b-d)was observed in the bonding and ettringite needles up to PA6L15LS,with an increase in lime content from 2%to 6%and 15%lime sludge.But the ettringite peak was not identified by the XRD test,probably because of lesser amount of lime/lime sludge content.Contrary to this,the SEM results of unstabilized pond ash(Figs.6a and 7a)show no bonding among the pond ash particles.Furthermore,with the increase in curing period to 45 d of the stabilized pond ash(Fig.7b-e),there is an increase in the formation of the ettringite needle which is filling the void space among the pond ash particles.The filling of void spaces by ettringite needles makes the sample denser,which increases the bearing ratio.Similar observations were reported by Shi(1996),Das and Yudhbir(2005),Yang et al.(2008)and Sivapullaiah and Moghal(2011)for fly ash-lime-gypsum mixtures.From the results,it is concluded that with the increase in the curing period from 28 d to 45 d,there is an increase in the bonding and ettringite formation in stabilized ash samples results in a higher bearing ratio.

3.5.Leachate analysis

The TCLP test was performed on lime sludge,unstabilized and stabilized pond ash with lime(2%,4%,6%and 8%)and 15%lime sludge.The concentration of the selected elements(Zn,Cu,Pb,Cd,Ni and Cr)in solutions obtained from TCLP leaching test was analyzed by MP-AES.The results of the leachate analysis are shown in Table 7 along with the limiting values of waste acceptance for land filling as per Annex 2 of the 2003/33/CE Council Decision(based on 1999/31/EC Directive)(Akar et al.,2012).

Concentrations of higher toxic elements Zn,Cu,Cd,Ni and Cr as detected in unstabilized pond ash,stabilized pond ash and lime sludge samples are very low and within inert limit.Concentrations of these elements are further reduced in stabilized ash sample than unstabilized one.Further,in unstabilized and stabilized waste materials,the concentration of Pb is higher than the inert limit but lower than the nonhazardous limit for waste acceptance criteria.Based on the above results,it can be concluded that concentrations of the selected trace elements are detected within nonhazardous limit of waste acceptance for land filling as per EC Directive.

4.Conclusions

In the present study,a sample of pond ash is stabilized with lime(2%-8%)alone and in combination with lime sludge(5%-15%).The bearing ratio under unsoaked and soaked conditions was determined after curing periods of 7 d,28 d and 45 d.The XRD and SEM studies were carried out on stabilized pond ash samples to examine changes in chemical composition and bonding among the particles.Further,the TCLP tests were also conducted to determine the potential contamination of groundwater by toxic elements.Based on the results,the following conclusions may be drawn:

(1)With the increases in lime and lime sludge contents,the MDD increases and OMC decreases with minor variations.

(2)The bearing ratio increases with the increase of lime content,at a steeper rate up to 4%of lime.

(3)Contribution of lime is more significant in increasing the soaked bearing ratio of stabilized pond ash as compared to unsoaked bearing ratio.

(4)Increase in soaked bearing ratio is higher as compared to unsoaked bearing ratio when the pond is stabilized with lime and lime sludge instead of lime only.

(5)Lime sludge along with lime increases the bearing ratio at lower curing periods.

(6)The bearing ratio increases with curing period due to pozzolanic reaction which is evident from the XRD and SEM results.

(7)Concentrations of toxic elements Zn,Cu,Cd,Ni and Cr in unstabilized and stabilized pond ash samples are within the inert limit.There is a reduction in the concentration of these elements in stabilized pond ash samples as compared to unstabilized pond ash sample.The concentration of Pb is larger than the inert limit in both unstabilized and stabilized waste materials.However,it is lower than the nonhazardous limit for waste acceptance criteria of solid wastes imposed by the EC Directive.

Addition of lime sludge to lime-stabilized pond ash enhances its engineeringpropertiesforpotentialapplication in roadway embankment and as subbase material.This may address the problems of waste disposal and scare natural resources.

Conflicts of interest

We wish to confirm that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work that could have in fluenced its outcome.

Journal of Rock Mechanics and Geotechnical Engineering2018年4期

Journal of Rock Mechanics and Geotechnical Engineering2018年4期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Experimental testing of low-energy rockfall catch fence meshes

- Soil-cement mixture properties and design considerations for reinforced excavation

- Revising the unified hardening model by using a smoothed Hvorslev envelope

- Application of perfectly matched layer to soil-foundation interaction analysis

- Constitutive model for monotonic and cyclic responses of loosely cemented sand formations

- Impact of open dumping of municipal solid waste on soil properties in mountainous region