Modeling investigation of geometric size effect on pervaporation dehydration through scaled-up hollow fiber NaA zeolite membranes☆

Jiacheng Wang,Peng Ye,Xuechao Gao,Yuting Zhang,Xuehong Gu*

State Key Laboratory of Materials-Oriented Chemical Engineering,College of Chemical Engineering,Nanjing Tech University,5 Xinmofan Road,Nanjing 210009,China

Keywords:Pervaporation NaA zeolite membrane Hollow fiber Lumen pressure drop Geometric parameters

ABSTRACT A mass transfer model in consideration of multi-layer resistances through NaA zeolite membrane and lumen pressure drop in the permeate side was developed to describe pervaporation dehydration through scaled-up hollow fiber supported NaA zeolite membrane. It was found that the transfer resistance in the lumen of the permeate side is strongly related with geometric size of hollow fiber zeolite membrane,which could not be neglected. The effect of geometric size on pervaporation dehydration could be more significant under higher vacuum pressure in the permeate side. The transfer resistance in the lumen increases with the hollow fiber length but decreases with with lumen diameter.The geometric structure could be optimized in terms of the ratio of lumen diameter to membrane length.A critical value of dI/L(Rc)to achieve high permeation flux was empirically correlated with extraction pressure in the permeate side.Typically,for a hollow fiber supported NaA zeolite membrane with length of 0.40 m,the lumen diameter should be larger than 2.0 mm under the extraction pressure of 1500 Pa.

1.Introduction

Membrane pervaporation(PV)is a promising technology to separate liquid mixtures for its high separation efficiency and low energy consumption.NaA zeolite has well-defined frameworks and narrow pores(~0.42 nm)with strong hydrophilicity,which can be fabricated as PV membranes to dehydrate organic solutions with extremely high selectivity.The separation technology is particularly suited for separations of azeotropic or close-boiling aqueous-organic systems[1,2].Since the first large-scale PV plant based on tubular NaA membranes was established by Mitsui Engineering&Shipbuilding Co.Ltd.in 1999[3,4],considerable laboratorial and industrial efforts have been made in membrane fabrications and engineering applications[5,6].

So far,most of commercial NaA zeolite membranes are prepared on single-channel or four-channel tubular ceramic supports[7],which lead to high investment cost in membrane facilities.In order to boost industrial applications of the zeolite membrane,large packing density and high permeation flux are highly desired for zeolite membranes.Recently,hollow fiber supported zeolite membranes have been considered as an effective alternative to tubular membranes.Because of its small outer diameter and thin wall thickness,hollow fiber supported zeolite membranes exhibit ultra-high permeation flux and packing density as well.For instance,Wang et al.[8]prepared high performance NaA zeolite membranes on α-Al2O3hollow fiber supports and achieved a permeation flux up to 9.0 kg·m−2·h−1for dehydration of 90 wt%ethanol/water mixtures at 348 K.In our recent work,T-type and puresilica MFI zeolite membranes prepared on yttria-stabilized zirconia(YSZ)hollow fibers also exhibited high permeation fluxes for organic dehydration and ethanol extraction,respectively[9,10].To promote large-scale production,vacuum-assisted seeding method was proposed to prepare hollow- fiber NaA zeolite membranes[11].Four-channel Al2O3hollow fibers with high mechanical strength were also developed to support NaA zeolite membranes[12].These studies suggested the technical feasibility for hollow fiber zeolite membranes applied in practical industrial processes.

Generally,the permeation flux of zeolite membranes is related with the inherent micro structure concerning zeolite membrane layer and support layer[13–18].In our previous work,we developed a multilayer(zeolite membrane layer/sponge-like layer/ finger-like layer)series-resistance(MLSR)model to describe PV dehydrations of ethanol through hollow fiber NaA zeolite membranes[19].It was revealed that the transfer resistance of the sponge-like region of hollow fiber support is significant since the permeation has large mean free path in the vacuum environment.On the other hand,it should be noted that the MLSR model is only suitable for analysis of lab-scale hollow fiber zeolite membranes with short length,where the pressure drop in the lumen side is negligible.For scaled-up hollow fiber NaA zeolite membranes,however,the lengtho fhollow fiber was found to have a significant Influence on the average permeation flux[11].For example,a membrane with a length of 0.40 m only had a permeation flux of 3.87 kg·m−2·h−1,while a cut piece of 0.10 m showed a high flux between 5.8 and 8.1 kg·m−2·h−1.It was suggested that the transfer resistance through the lumen of hollow fiber was not negligible for long hollow fiber zeolite membranes.The similar Influence of fiber length and lumen diameter on average permeation flux was also found in hollow fiber polyvinylidene fluoride membranes for liquid separation[20].For pervaporation process,the effect could be more significant as a vacuum was exerted on the permeation side,in which the permeation was evacuated out of the hollow fiber lumen in low-pressure vapor.Therefore,it is of great importance to systematically explore the effect of lumen geometric size(e.g.length and diameter)on separation performance of hollow fiber zeolite membranes in consideration of industrial applications.

Herein,a mass transfer model in consideration of multi-layer resistances through NaA zeolite membrane and lumen pressure drop in the permeate side was developed to describe PV dehydration through hollow fiber supported NaA zeolite membrane.Although the viscous flow was widely used to describe the pressure-driven liquid flow in the lumen channel of hollow fiber membranes[21–24],a combination of viscous flow and Knudsen diffusion was adopted to fully account for the transport resistance of gases in the lumen.Experimental investigation was conducted to validate the modeling results.The effect of lumen geometric sizeon permeation flux of membrane was extensively investigated to derive the optimal lumen geometric size under specific operating conditions.

2.Theory

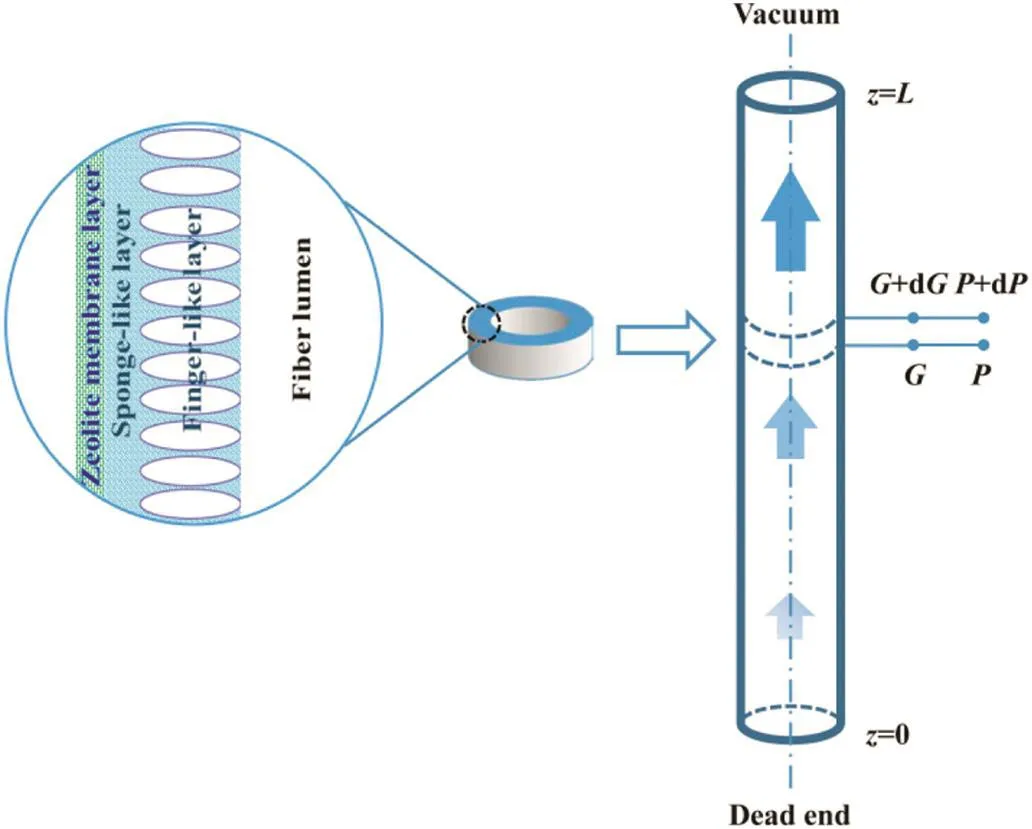

Fig.1 shows a schematic diagram of the mass transfer process in a hollow fiber NaA zeolite membrane for PV dehydration.The membrane,vertically immersed in the feed solution,has a dead end at the bottom and the permeation is evacuated from the top by a vacuum pump.We previously used a MLSR model to describe component permeation through any local position on the hollow fiber membrane[19].In the MLSR model,the cross-section of the membrane is divided into three layers,including a zeolite membrane layer,a sponge-like layer and a finger-like layer.Several assumptions are made in the model derivation as:

1.The mass flow rate through different layers should be equal at steady state;

2.The transport on the permeate and shell side follows piston flow without any radial concentration distribution and axial back-mixing;

Fig.1.A schematic diagram of pervaporation through a hollow fiber NaA zeolite membrane.

3.The feed pressure and concentration are constant;

4.The whole process of operation is isothermal;

5.The flow in the fiber lumen is laminar and stationary.

Based on the simulation of the permeate pressure gradient,it is necessary to take account of the continuous mass increase over the unit length in a differential mass balance.Subject to the above assumptions,the following equation can be written:

in which G is the mass flow rate of the permeate components in lumen,kg·h−1;z is the length coordinate,m;dmequals to(dO−dI)/ln(dO/dI),representing the geometric average of the fiber diameter,m;andJis the local permeation flux of components at position z,kg·m−2·h−1.The boundary condition for the above equation is:z=0;G=0.

For the compressible fluid,Thor man and Hwang[25]discovered a general pressure gradient equation based on the first order perturbation theory,where the pressure drop change caused by gas expansion can be ignored when the wall Reynolds number is far less than 1,just as the membrane separation process,so that the pressure drop can be expressed by the differential form of the Hagen–Poiseuille equation for laminar flow.Given the low pressure limits of the permeate vapor in the permeate channel,ideal gas equation of state(PPV=GVisRT/M)is applied,where the volume flow rate(V),equals to πdI2¯ν/4,m3·h−1,and Mis the molecular weight of the per meate vapor,kg·mol−1.Thus,the mass flowrate for the viscous can be derived as:

On account of the low pressure condition in the permeate side,it is necessary to calculate the Knudsen number to define the flow regime for the permeate vapor flowing through the lumen by

where kBis the Boltzmann constant;T corresponds to the thermodynamic temperature,K;dprepresents the particle hard-shell diameter,m;P is the total pressure,Pa;and L equals to the representative physical length scale,m.The obtained Knudsen number is about 0.02,which is between 0.01 and 0.5,so the flow regime belongs to the transitional region and the Knudsen diffusion should be included in the model[26–31].The flow rate contribution from the Knudsen diffusion is described as:

Therefore,the total flow rate can be seen as a superposition of the two fluxes.

The pressure drop for the permeate side of hollow fiber as follows:

where μ can be regarded as a constant parameter for the gas viscosity is hardly affected by the pressure.The boundary condition is:z=L;PP=PL.

The local permeation flux at position z in the membrane system is modeled by a MLSR mass transfer model.For the zeolite membrane layer,the permeation flux of each component is described by a generalized Maxwell–Stefan equation by:

Eqs.(7)and(8)represents steady-state permeation flux of component water and ethanol(JZ,wandJZ,e)through the zeolite membrane,respectively.The adsorption and diffusion parameters were obtained by molecular simulation,and the detailed simulation methods were described in our previous work[19,32].

The permeation flux of the mixture through the hollow fiber support is characterized by the slip flow,in which the mass flux of component i through the sponge-like region and the finger-like region is described by Eqs.(9)and(10)for Knudsen diffusion and viscous flow,respectively.

Since the permeate pressure pro file across the hollow fiber is unknown,Eqs.(1)and(6)contain a two-point boundary value problem.To solve the differential equations,a trial-and-error shooting method is adopted to convert the boundary value problem into an initial value problem.In other words,a value of PPatz=0 is assumed and integrated to z=L.The obtained value of PPat z=L is subsequently compared with the appointed boundary condition,and then the integration is repeated withane wguess of PPatz=0until the convergence is achieved.Afterwards,the permeate pressure pro file and the mass flow rate inside the lumen of hollow fiber membrane are eventually determined.By combining the MLSR permeation equations with the mass transfer model inside the lumen,a general equation system is readily obtained to estimate the pressure drop in the lumen of hollow fiber NaA zeolite membrane and the water permeation fluxat different positions.The average permeation flux(Jav)through the whole hollow fiber membrane can be obtained by integrating the local permeation flux in z-axial direction.

The above equations are derived based on the laminar flow in the lumen of hollow fiber Na Azeolite membrane,which should be rationalized by evaluating the Reynolds number.Obviously,the maximum zaxis Reynolds number is located at the extraction point for the corresponding flow velocity is the largest,which can be calculated by Eq.(12).It is evident that the assumption of the laminar flow in the lumen is applicable if the maximum Reynolds number in z-axis is less than 2300.

3.Experimental

The NaA zeolite membranes used in this study were hydrothermally synthesized on the outer surfaces of the α-Al2O3hollow fiber supports as the separation layer.The detailed preparation of the hollow fiber NaA zeolite membranes was described in our previous work[11].The mean pore size of the support was measured by a gas bubble pressure instrument,and the porosity and to rtuosity were characterized by a mercury porosimeter(Pore Master GT60,Quanta chrome Instruments).The separation performances of Na Azeolite membranes were evaluated by PV dehydration of 95 wt%ethanol/water at 348 K.In the PV experiments,ethanol/water feed mixture externally flowed over the surface of hollow fiber membrane under atmospheric pressure,and the lumen of the hollow fiber was extracted by a vacuum pump through a vacuum line,where the pressure was maintained around 200 Pa throughout the experiment.The permeated vapor mixture was collected by cold traps cooled by liquid nitrogen.The feed and permeate composition were analyzed by a gas chromatograph(GC-2014A,Shimadzu)with a thermal conductivity detector(TCD)and a packed column of Parapak-Q(Alltech).The PV performance is determined by permeation flux(Jexp)and separation factor(αw/e),defined as:

where miis the mass of permeate i,kg;A represents the effective membrane area,m2;Δt is the permeation time,h;Xwand Xeare mass fractions of water and ethanol in the feed;Ywand Yecorrespond to mass fractions in the permeate.

4.Results and Discussion

4.1.Model validation

We have previously observed length-dependence of average water flux for hollow fiber supported NaA zeolite membrane,which was attributed to driving force loss along the permeate lumen side[11].To validate the mathematic model,we further investigated the effect of membrane length on water permeation flux by both experimental and modeling.A hollow fiber NaA zeolite membrane with 20 cm length was cut gradually and evaluated by PV experiment.The thickness of the membrane layer was 8 μm.The porosity and tortuosity of the support were 45.2%and 2,respectively;the mean pore sizes for the sponge-like and finger-like layer were 0.54 μm and 2.75 μm,respectively,and the corresponding thicknesses were 0.16 mm and 0.26 mm,respectively.Fig.2 presents the calculated and experimental water fluxes through the membranes used for dehydration of 95 wt.%ethanol/water at348 K.As can be seen,the predicted permeation fluxes are slightly higher than the experimental results.However,the dependences of permeation flux over membrane length are quite similar.For instance,when the membrane length increases from 0.05 to 0.20 m,the experimental water flux decreases from 6.35 kg·m−2·h−1to 4.27 kg·m−2·h−1,which is similar to the decrement in the model prediction,i.e.,from 7.14 kg·m−2·h−1to 5.90 kg·m−2·h−1by using a slip flow in the lumen.The decreasing tendency can be explained by the driving force loss along the permeate side.As the membrane length is extended,more products accumulate in the lumen,which requires a larger pressure drop to extract the products,i.e.,the lumen bottom pressure becomes higher,thereby decreasing the pressure drop across the membrane layer.The above results indicate the intrinsic behavior of the fluid transport in the supported membrane is essentially captured in the developed model.

Fig.2.Comparison of calculated and experimental water fluxes under different lengths of hollow fiber NaA zeolite membrane for separation of 95 wt%ethanol/water mixture at 348 K.

The Reynolds numbers calculated by Eq.(12)are summarized in Table 1.Since all of the values are below 2300,the initial assumption of laminar flow in the lumen is physically solid.Therefore,it can be concluded that despite in the transitional region,the viscous flow can be treated as the dominated term for describing the mass transfer in the lumen of the hollow fibers.

Table 1 Remaxfor different fiber lengths and lumen diameters(T=348 K,PL=200 Pa)

4.2.Influence of fiber length

Fig.3 depicts the pressure and local permeance pro files of water along the lumen as a function of fiber length.The general microstructure parameters of the hollow fiber NaA zeolite membrane used for calculation are listed in Table 2,which are also applied in the discussion sections that follow.The hollow fiber has an inner diameter of 1 mm.As can be seen,the permeate pressure and local permeation flux of water vary with z-axial positions of hollow fibers.Pressure is built up in permeate sides to provide driving forces for product extraction.The lowest permeate pressure,leading to the highest local water flux,occurs in the extraction position.Interestingly,although the lumen exit pressure(z=L)is constant,the dead end pressure(z=0)increases with the extension of the fiber length(Fig.3a).For instance,when the fiber length increases from 0.05 to 0.5 m,the pressure at the dead end climbs from 1273 to 7734 Pa,which causes the local water permeation flux at the dead end decreasing from 6.90 to 2.16 kg·m−2·h−1,as shown in Fig.3b.The larger lumen pressure drop of water between the dead end and exit suggests more permeate accumulated in the lumen,and a stronger transport resistance is thus observed[33].

Fig.3.(a)Modeled permeate pressure distribution in the lumen and(b)local permeation flux pro file of water along the axial position of hollow fiber zeolite membrane with different lengths for separation of 95 wt%ethanol/water mixture(T=348 K,dI=1 mm,PL=200 Pa).

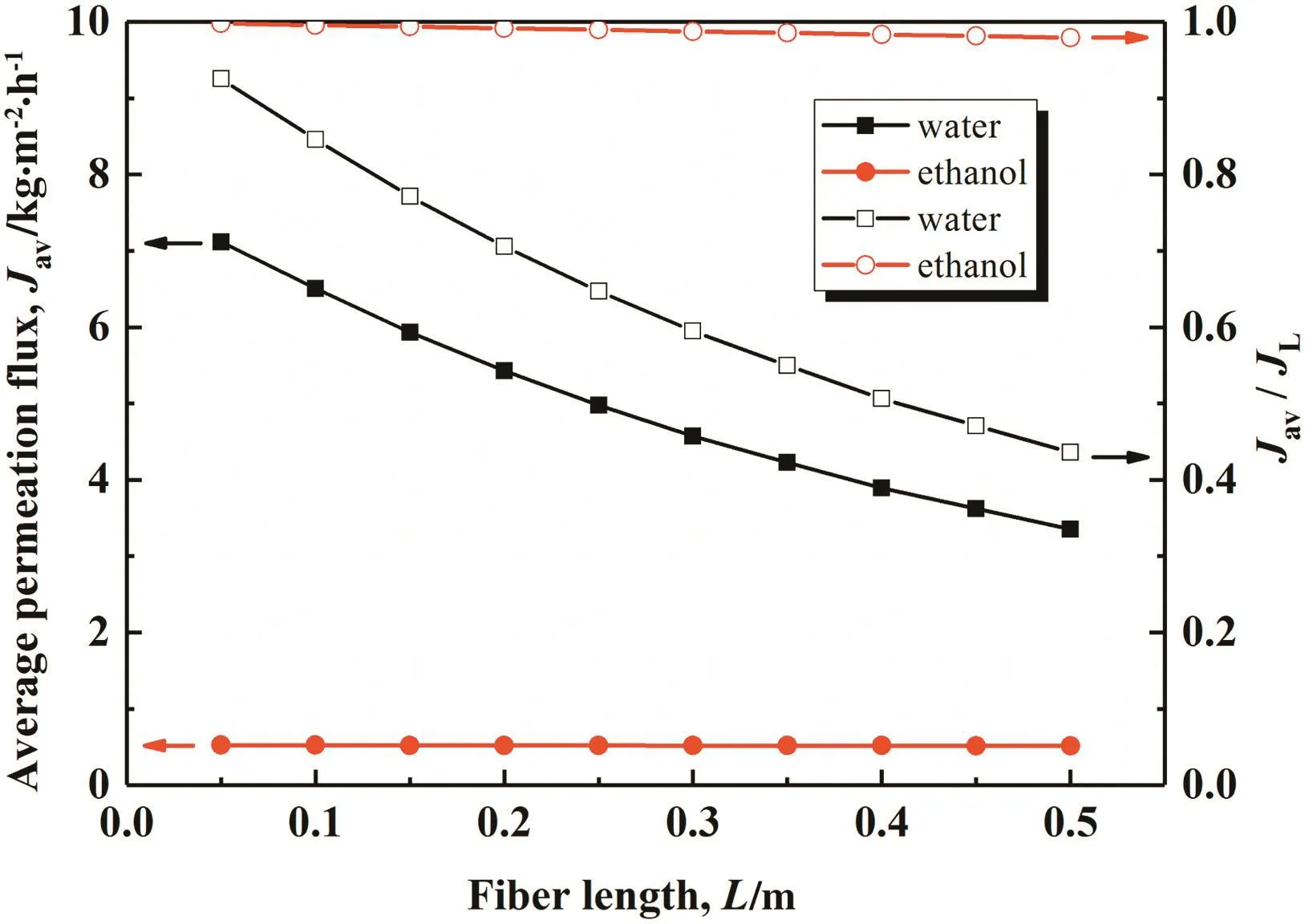

The average permeation flux as a function of membrane length is illustratedin Fig.4.Asshownin the figure,the average water permeation flux is almost halved(from 7.12 kg·m−2·h−1to 3.35 kg·m−2·h−1)when the hollow fiber membrane extends from0.05m to0.5 m.There sults suggest that the impact of membrane length is moresignificant for the scaled up products.It can be seen that the ethanol permeation flux maintains nearly constant at around 0.5 kg·m−2·h−1,probably due to its low permeability,which allows a relatively smaller partial pressure drop in the lumen.As discussed above,the highest local water permeation fluxis located at the lumen exit of hollow fiber-supported NaAzeolitemembrane.Fig.4alsopresentstheratioofaverage permeation flux to the local permeation flux at the lumen exit.It can be seen that theratio varies from 0.93 to 0.44 for water permeation flux when the fiber length increases from 0.05 m to 0.5 m.For the hollow fiber NaA zeolite membrane with a length of 0.5 m,over 60%of membrane area has the local water flux lower than the average water flux.This means that the long hollow fiber zeolite membrane cannot display high separation performance in the region nearby the dead end,suggesting the necessity to optimize the geometric size of scaled-up hollow fiber membranes to obtain high permeation performance.

Table 2 Microstructure parameters of the hollow fiber NaA zeolite membrane for modeling

Fig.4.Modeled average permeation flux and the ratio of average permeation flux to local permeation flux at lumen exit of hollow fiber NaA zeolite membrane with different membrane lengths for separation of 95 wt%ethanol/water mixture(T=348 K,dI=1 mm,PL=200 Pa).

4.3.Influence of lumen diameter

According to Eq.(6),the lumen diameter is another geometric parameter to affect the mass transfer resistance in the permeate side of hollow fiber zeolite membrane.Fig.5 shows the pressure distribution in the permeate side and the local permeation flux pro file of water along axial direction for hollow fiber NaA zeolite membranes with different lumen diameter.The separation are operated for dehydration of 95 wt.%ethanol/water mixture at 348 K and the hollow fiber membranes have a fixed length of 0.10 m.All the other microstructural parameters of hollow fiber NaA zeolite membrane are summarized in Table 2.As expected,the lumen pressure for all the membranes gradually reduces along the axial direction from the dead end to the exit.However,the pressure gradient becomes steeper for smaller lumen dimensions,implying higher transport resistance built up in the lumen side.For instance,when the lumen diameter reduces from 2 mm to 1 mm,the pressure at the dead end increases from 868 Pa to 2387 Pa.Accordingly,the local water flux drop between the dead end and exit varies from 0.49 kg·m−2·h−1to 1.60 kg·m−2·h−1,which suggests that more uniform permeation flux exists along axial coordinate for the enlarged lumen.Therefore,the enlargement of the lumen diameter is helpful to maintain a high separation performance of the hollow fiber zeolite membrane.

Fig.6 illustrates variation of average permeation fluxes with different lumen diameters,and the ratio of average permeation flux to local permeation flux at lumen exit.As suggested,when the lumen diameter increases from 0.5 mm to 1.0 mm,the average water flux readily increases from 4.46 kg·m−2·h−1to 6.51 kg·m−2·h−1.However,only a slight increase of the average water flux(from 7.09 kg·m−2·h−1to 7.47 kg·m−2·h−1)is achieved for the lumen diameter from 1.5 mm to 2.5 mm.The average water fluxes are very close to the water flux at the exit.Accordingly,it can also be seen in Fig.6 that the ratio of average permeation flux to local permeation flux at lumen exit varies from 0.58 to 0.85 for water when the lumen diameter increases from 0.5 mm to 1.0 mm.For a further diameter enlargement from 1.5 mm to 2.5 mm,the permeation ratio varies from 0.92 to 0.97.The result suggests that the mass transfer resistance in the lumen is negligible for lumen diameter larger than 1.5 mm.An increase of lumen diameter attenuates the pres sure accumulates inside the fiber lumen.However,the lumen diameters should not be too big in consideration of the membrane packing density.

Fig.5.Modeled pressure distribution in the permeate side(a)and water permeation flux pro file(b)along the axial coordinates of hollow fiber NaA zeolite membrane with different lumen diameters for separation of 95 wt%ethanol/water mixture(T=348 K,L=0.10 m,PL=200 Pa).

Fig.6.Modeled results for the effect of lumen diameter on the average permeation flux and the ratio of average permeation flux to local permeation flux at lumen exit of hollow fiber NaA zeolite membrane for separation of 95 wt%ethanol/water mixture(T=348 K,L=0.10 m,PL=200 Pa).

4.4.Influence of extraction pressure

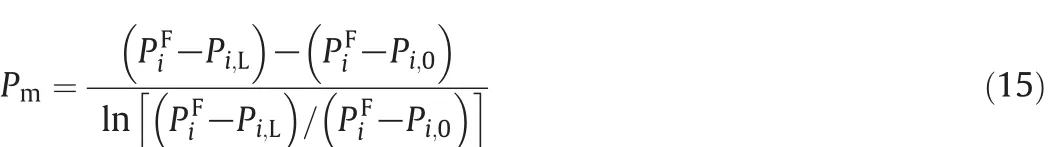

Fig.7 depicts the Influence of extraction pressure(PL)on the mean transmembrane pressure and average permeation flux for separation of 95 wt%ethanol/water mixture at 348 K.The mean trans membrane pressure is indicated by the logarithmic mean value of transmembrane pressure(Pm)at the dead end and exit of the hollow fiber NaA zeolite membrane which is calculated as:

Fig.7.(a)Variation of mean transmembrane pressure and(b)average permeation flux for separation of 95 wt%ethanol/water mixture versus different extraction pressures(T=348 K,dI=1 mm,L=0.10 m).

4.5.Synergistic effect

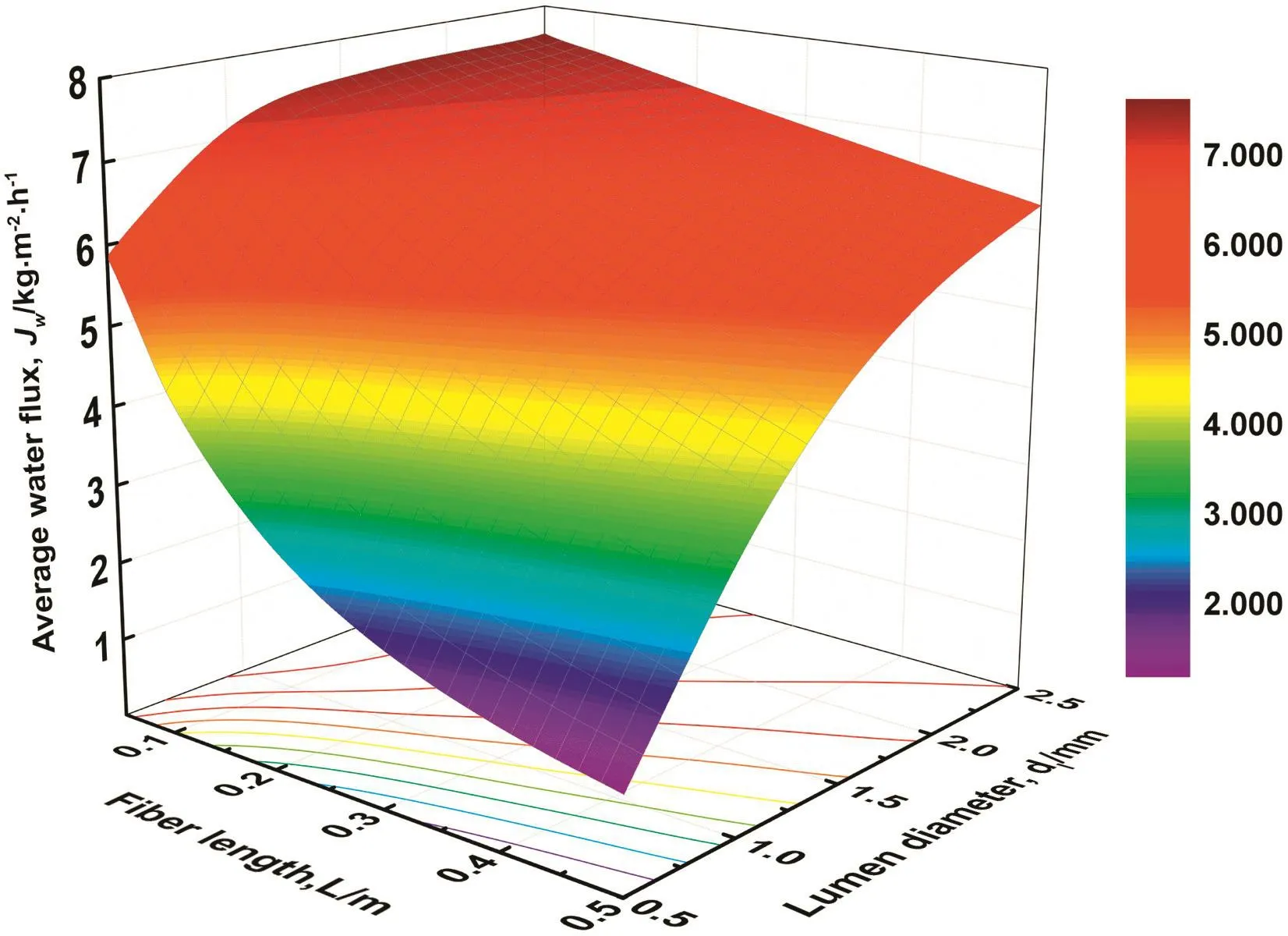

Since the fiber length,lumen diameter and extraction pressure are influential on the water permeation,we further consider the synergistic effect by the three factors.Using the model micro structure parameters provided in Table 2,Fig.8 describes the average water permeation flux as functions of lumen diameter and fiber length for separation of 95 wt%ethanol/water mixture at 348 K.It can be seen that the average water permeation flux varies with both lumen diameter and fiber length.It is suggested that for scaled-up hollow fiber membranes with extended length,and the lumen size should be enlarged to maintain high permeation performance.It seems that the permeation flux is more sensitive to lumen diameter than fiber length.For a fiber with a length of 0.4 m and a lumen diameter of 1.0 mm,the achieved average water flux is about3.90kg·m−2·h−1.When the lumen diameter is doubled to 2.0 mm,the average water flux increases to 6.14 kg·m−2·h−1.On the other hand,the fiber length should be reduced to about 0.125m to have a similar flux.This is primarily due to the inversely proportion of pressure gradient to the fourth power of lumen radius based on the Hagen–Poiseuille law.Owing to the higher pressure gradient in the narrow lumen,the nonuniform degree of permeate flux is also enhanced.

Fig.8.Modeled result for the effect of fiber length and lumen diameter on the average water flux for separation of 95 wt%ethanol/water mixture(T=348 K,PL=200 Pa).

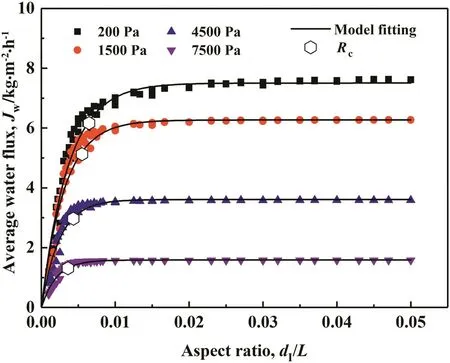

Fig.9 shows the average water permeation flux versus the ratio of lumen diameter to fiber length(dI/L)for different extraction pressures.As suggested,the average permeation flux increases with dI/L for each case,and the average permeation flux could continuously reach up to the maximum value equaling to the local permeation fluxat the exit.Further,the average permeation flux demonstrates a significant variation at lowdI/L before the flattening curves at highdI/L.Forinstance,at a low extraction pressure of 200 Pa,the average water flux increases from 1.31 kg·m−2·h−1to 6.16 kg·m−2·h−1when dI/L becomes from 0.001 to 0.01.On the contrary,the flux changed slightly between 7.12 and 7.61 kg·m−2·h−1for dI/L varying from 0.013 to 0.05.It is suggested that the effect of trans fer resistance in the permeate side is not significant when dI/L exceeds a critical value(Rc).From the view point of practical application,the criticaldI/L is import ant to achieve both high separation performance and low fabrication cost for a membrane module.In this work,we select different Rcvalues for each extraction pressure,where the corresponding fluxes are about 80%of the local permeation flux at the exit.The critical dI/L can be used for designing geometric size of hollow fiber.For the hollow fiber with dI/L larger than Rc,although a high permeation performance is achieved,the membrane packing density is sacrificed.

Fig.9.Variation and empirical nonlinear fitting of the aspect ratio effect of lumen diameter to hollow fiber length on the average water flux at different extraction pressures for separation of 95 wt%ethanol/water mixture at T=348 K,where the hexagon symbols()represent the critical ratio of dI/L(Rc)derived from empirical nonlinear fittings.

To quantitatively analyze the relationship between Rcand extraction pressure,nonlinear fitting is performed for the given data.For a certain extraction pressure,the average water flux of Jwvarying with dI/L matches the formula below:

where Jmand k correspond to the maximum flux and coefficient,respectively.The obtained diagrams for the fitting functions are also plotted in Fig.9,and the fitted model parameters are summarized in Table3.Good agreements are obtained for each extraction pressure with a high coefifcient of determination(r2)of 0.9.

Table 3 The obtained parameters for Eq.(17)by mathematic fitting

Since the current empirical model accurately describes the relationship of flux and dI/L under all the conditions of extraction pressures,the theoretical values of Rcfor each extraction pressure can be estimated from Eq.(17)based on the aforementioned assumption that 80%of the theoretical maximum flux should be required in practical application.The values of Rcare also marked in Fig.9.As expected,the value of Rcdecreases with increases in PL.For instance,Rcreduces from 0.00587 to 0.00327 when PLincreases from 200 Pa to 7500 Pa.A fitting is also performed to describe the relationship between the parameters Rcand PL.Considering Rcis exceptionally determined by k in a form of Rc=1.61/k,only the relationship between k and PLis explored.For the purpose of simplicity,liner fitting models are conducted for the estimation of k,which provides a new approach to predict Rc.The eventual expression for Rc(r2>0.99)is shown as follows:

For an extraction pressure of1500 Pain practical application,the optimal lumen diameter would be no less than 2.0 mm when the fiber length rises to 0.4 m in order to achieve enough permeation flux for dehydration of ethanol.

5.Summary and Conclusions

A mass transfer mathematical model based on the combination of lumen pressure drop equation using slip flow and a multi-layer(zeolite membrane layer/sponge-like layer/ finger-like layer)series-resistance model is developed to investigate PV dehydration through scaled-up hollow fiber NaA zeolite membranes.A parametric analysis shows that the dimensions of the hollow fiber(lumen diameter and fiber length)and extraction pressure have significantly synergistic effect on the overall pervaporation performance of a hollow fiber zeolite membrane.Therefore,the geometric parameters of hollow fiber should be optimized in order to achieve high permeation flux.The model results indicate that an increase in lumen diameter could improve the permeation flux of hollow fiber NaA zeolite membranes.In contrast,an increase in the extraction pressure and fiber length could cause the decrement of the average permeation flux.To facilitate the application of the simulation discoveries in practical industries,the critical value of dI/L,Rc,which yields80%of the theoretical maximum flux,is correlated with PL,and an inverse relationship is derived.The results suggest a reasonable lumen diameter for a certain fiber length is beneficial to maintain high pervaporation performance.In general,the developed model can be extended to the other types of feed solutions and membranes by adjusting the corresponding adsorption and diffusion parameters.

Nomenclature

AIcross sectional area of lumen,m2

Dsself-diffusivity,m2·s−1

dIinside diameter of hollow fiber NaA zeolite membrane,m

dOoutside diameter of hollow fiber NaA zeolite membrane,m

dppore diameter,m

G mass flow rate,kg·h−1

J permeation flux,kg·m−2·h−1

Jmmaximum average water flux,kg·m−2·h−1

K adsorption constant,Pa−1

k empirical constant(dimensionless)

L hollow fiber length,m

M molecular weight,kg·mol−1

P pressure,Pa

PLpressure at the exit of hollow fiber NaA zeolite membrane,Pa

qMsaturated loading,mol·kg−1

R gas constant(8.314 Pa·m−3·mol−1·K−1)

Rccritical value of dI/L(dimensionless)

V volume flow rate,m3·h−1

z length coordinate at any point,m

αw/ewater/ethanol separation factor

γ activity coefficient

δ thickness,m

ε support porosity

η viscosity,Pa·s

ρZdensity of zeolite layer,kg·m−3

τ support tortuosity

v axial flow rate,m·h−1

Subscripts

av average value

e ethanol

F finger-like layer

I inner side

Kn Knudsen flow

max maximum

O outer side

S sponge-like layer

Vis Viscous flow

w water

Z NaA zeolite layer

Superscripts

F feed side

int,1 zeolite/support interface

int,2 sponge-like/ finger-like interface

P permeate side

Chinese Journal of Chemical Engineering2018年7期

Chinese Journal of Chemical Engineering2018年7期

- Chinese Journal of Chemical Engineering的其它文章

- High efficiency production of ginsenoside compound K by catalyzing ginsenoside Rb1 using snailase☆

- Preparation of vapreotide-templated silver nanocages and their photothermal therapy efficacy☆

- DNA-assisted rational design of BaF2linear and erythrocyteshaped nanocrystals☆

- On the database-based strategy of candidate extractant generation for de-phenol process in coking wastewater treatment☆

- Hierarchical porous MgBO2(OH)microspheres:Hydrothermal synthesis,thermal decomposition,and application as adsorbents for Congo red removal☆

- Degradation analysis of A2/O combined with AgNO3+K2FeO4on coking wastewater