基于多面齐聚倍半硅氧烷的形状记忆聚合物的研究进展(下)

赵冰洁,郑思珣

(上海交通大学化学化工学院,上海 200240)

(接上期)

1.4 基于POSS的聚降冰片烯(PN)形状记忆材料研究进展

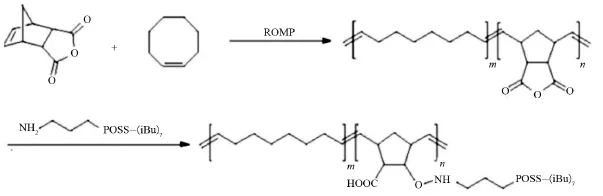

Yang等人[52]首次通过开环易位聚合制备了聚辛烯(PCOE)和双羧基的聚降冰片烯(PNBEDCA)的嵌段共聚物,然后将含氨基官能团的POSS与该嵌段共聚物上的酸酐进行反应,从而得到一种新型的功能化的P(COE-co-NBEDCA-g-POSS),其中羧基和POSS作为侧链接枝到降冰片烯上。反应过程如图14所示,通过DMA和形状恢复速度进行了表征了其形状记忆性能。Yang等人认为,玻璃态的弹性模量与橡胶态的弹性模量下降的程度可用来衡量形状记忆性能的好坏,下降程度越大,说明共聚物在降温时表现出更好的形状固定性,升温时表现出更大的形状回复。通常采用分别比Tg高与低20℃的弹性模量的比值来衡量弹性模量下降的程度。其中POSS含量为20%的P(COE-co-NBEDCA-g-POSS20)其比值为45.6,POSS含量为10%的P(COE-co-NBEDCA-g-POSS10)比值为27.0,并且P(COE-co-NBEDCA-g-POSS 20)仅需44 s便可恢复其初始形状,而P(COE-co-NBEDCA-g-POSS10)需58 s。说明,POSS含量更高的聚合物具有更好的形状记忆性能。

Mather等人[53]将一个角为降冰片烯剩下七个角为环己基或环戊基的POSS与降冰片烯通过开环易位聚合制备了降冰片烯-POSS杂化复合材料,通过热机械分析测得的Tg上的回复应变表征了这种拉伸的样品的形状记忆性能。结果发现引入POSS后,聚降冰片烯材料的应变回复率有轻微的下降,这可能是因为聚降冰片烯链的松弛由于POSS分子的体积位阻和聚集的存在受到阻碍。他们还发现,POSS端基官能团的类型同样影响着形状记忆行为,含端基为环己基POSS的杂化复合材料的应变回复率要比含端基为环戊基POSS的低,这主要是因为环己基POSS的聚集。

1.5 基于POSS的其他聚合物形状记忆材料研究进展

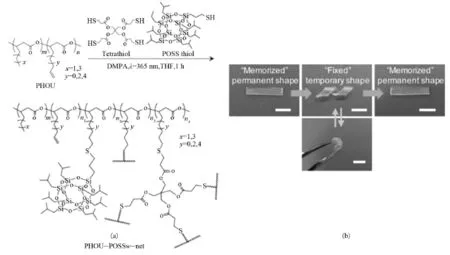

Mather课题组对含有POSS的SMP研究作了大量工作。2011年,他们[54]利用侧基带有双键的生物降解性聚酯[Poly(3-hydroxyoctanoate-co-3-hydroxyundecenoate),PHOU]与含巯基 (-SH)的POSS通过光交联点击反应合成了具有柔软弹性的网络状PHOU-POSS新型SMP纳米复合材料,过程如图15(a)所示。与其他一次固定成型的SMP不同,PHOU-POSS纳米复合材料的纳米结构具有重构性,这是由于PHOU与POSS之间的共价键随外部热力学条件的变化表现为解聚态和聚合态。这一特点赋予了PHOU-POSS纳米复合材料优异的形状固定和恢复性(图15(b))。对于本体系,在POSS重量含量较低时(<20%)的PHOU-POSS聚合物,由于缺乏POSS的结晶结构,形变的固定性较差,外力撤消后便可回复。而随着POSS含量的增加,当含量大于30%时,聚合物表现出较良好的形状记忆性能(Rf>=96%,Rr>=98%),在加热到POSS的熔融温度上后,在5 s内就迅速回复其初始形状。

图14 含POSS的共聚物的制备

图15 (a)柔软弹性的PHOU-POSS复合材料的合成 (b)PHOU-POSS膜的形状记忆行为

POSS也被引入到纤维素中对其形状记忆性能进行改性。Xie等人[55]利用含多个羟甲基的POSS作为交联剂,制备了POSS/纤维素的交联网络体系,发现将POSS引入后,纤维素的折皱回复角明显增加,且SEM图显示,与不含POSS的纤维素相比,含有POSS的体系表现出更为光滑有韧性的表面。

2 结论及展望

基于POSS的形状记忆聚合物中具有良好的形状记忆效果,POSS的的引入对传统SMPs材料机械强度低和形变回复驱动力小等缺点有较大的改善,同时还提高了聚合物形变回复率及回复速度。目前报导的基于POSS的形状记忆聚合物大多数为只有一元形状记忆行为的聚合物,关于二元、三元甚至多元的还很少,因此未来的研究方向可能会多关注基于POSS的具有多元形状记忆行为的SMPs,并且,目前报导的基于POSS的SMPs均为热响应的聚合物,其他如光、电磁等响应的基于POSS的SMPs可能也是未来的发展方向之一。

[1] LiuC,QinH,MatherPT.Review of progress in shapememory polymers.JMaterChem,2007,17:1 543~1 558.

[2] Lendlein A,KelchS.Shape-memory polymers.Angew Chem Int Ed,2002,41(12):2 034~2 057.

[3] HagerMD,BodeS,WeberC,etal.Shape memory polymers:Past,present and future developments.Prog Polym Sci,2015,49:3~33.

[4] Zhao Q,Qi HJ,Xie T.Recent progre ss in shapememory polymer: New behavior,enabling materials,and mechanistic unders tanding.Prog Polym Sci,2015:79~120.

[5] LandleinA,Langer R.Biodegradable,elastic shapememory polymers for potential biomedical applications.Science,2002,296(5 573):1 673~1 676.

[6] XieT.Tunable polymer multi-shape memorye ffect.Nature,2010,464(7 286):267~270.

[7] Le DM,Kulangara K,AdlerAF,LeongK W,AshbyVS.Dynamic Topographical Control of Mesenchymal Stem Cells by Culture on Res ponsivePoly(ε-caprolactone)Surfaces.AdvMater,2011,23(29):3 278~3 283.

[8] Yu X,Zhou S,Zheng X,etal.A biodegradable shapememory nanocomposite with excellent magnetism sensitivity.Nanotechnology,2009,20(23):10 314~10 322.

[9] Wei K,Zhu G,Tang Y.Research Progress in Electroinduced Shape Memory PolymerComposites.MaterRev,2011,25:9~12.

[10] Habault D,Zhang H,Zhao Y.Light-triggered self-healing and shape-memorypoly mers.ChemRev,2013,42(17):7 244~7 256.

[11] OhkiT,Ni Q Q,Ohsako N,etal.Mechanical and shape mem ory behavior of composites with shape memory polymer.ComposPartA-Appl S,2004,35(9):1 065~1 073.

[12] Hollander D S,Assche GV,Mele B V,et al.Nove lsynthetic strategy to.ward shape memory polyurethanes with a welldefined switching temperature.Polymer,2009,50(19):4 447~4 454.

[13] Xie T,Rousseau,I A.Facile tailoring of thermal transiti on temperatures of epoxy shape memory polymers.Polymer,2009,50(8):1 852~1 856.

[14] Yakacki CM,Shandas,R,Lanning C,Rech,B,Eckstein A,Gall K.Unconstrained recovery characterization of shapememory polymer netw orks for cardiovascular applications.Biomaterials,2007,28(14):2 255~2 263.

[15] Xue L,DaiS,LiZ.Synthesis and characterization of elastic star shape-memory polymers as self-expandable drugeluting stents. J Mater Chem,2012,22(15):7 403~7 411.

[16] Guo B,Chen Y,LeiY et al.Biobased Poly(propylenesebacate)as Shape Memory Polymer with Tunable Switching Temperature for Potential Biomedical Applications.Biomacromolecules,2011,12(4):1 312~1 321.

[17] Hardy J G,PalmaM,Wind S J,et al.Responsive Biomate rials:Advances in Materials Base don Shape-Memory Polymers.Adv Mater,2016,28(27):5 717~5 724.

[18] Chen,H,Cao,X,Zhang,J,et al.Electrospun shape memory film with reversible fibrous structure.J Mater Chem,2012,22(42):22 387~22 391.

[19] Zheng Z,Li Z,Pan Y,et al.Shape-memory polymer having soft/hard network structure and its preparation method.CN101381433A,2009.

[20] Madbouly S A,Lendlein A.Shape-memory polymer composites.Adv PolymSci,2010,226:41~95.

[21] Cordes D B,Lickiss P D,Rataboul F.Recent Developments in the Chemistry of Cubic Polyhedral Oligosilsesquioxanes.Chem Rev,2010,110(4):2 081~2 173.

[22] Zha oY,Schiraldi D A,Zhao Y,et al.Thermal and mechanicalpro perties of polyhedral oligomeric silsesquioxane(POSS)/polycarbonate composites.Polymer,2005,46:11 640~11 647.

[23] McmullinE,Rebar H T,Mather PT Biodegradable Thermoplastic Elastomers Incorporating POSS:Synthesis,Microstructure,and Mechanical Properties.Macromolecules,2016,49:3 769~3 779.

[24] Huang J,He C,Xiao Y.Polyimide/POSS nanocomposites:Interfacial interaction,thermal properties and mechanical properties.Polymer,2003,44:4 491~4 499.

[25] LiuY,Zheng S,Nie K.Epoxy nanocomposites with octa(propy lglycidyl ether)polyhedral oligomeric silsesquioxane.Polymer,2005,46:12 016~12 025.

[26] FuHK,Huang C F,Huang J M.Studies on thermal properties of PS nanocomposites for the effect of intercalated agent withside groups.Polymer,2008,49:1 305~1 311.

[27] HuangKW,Tsai L W,Kuo S W.Influence of octakisfunctionalized polyhedral oligomeric silsesquioxanes on the physical properties of their polymer nanocomposites.Polymer,2009,50:4 876~4 887.

[28] Liu Y,Zheng S,Nie K.Epoxy nanocomposites with octa(propylglycidyl ether)polyhedral oligomeric silsesqu ioxane.Polymer,2005,46(46):12 016~12 025.

[29] HuangJ,Xiao Y,MyaK Y,et al.Thermomechanical properties of polyimide-epoxy nanocomposites from cubic silsesquioxane epoxides.J Mater Chem,2004,14(19):2 858~2 863.

[30] Choi J,Ryo Tamaki,And S G K,et al.Organic/InorganicImide Nanocomposites from Aminophenylsilsesquioxanes.Chem Mater,2003,15(17):3 365~3 375.

[31] Huang Y,Zhang S,Niu B,et al.Poly(ɛ-caprolactone)modified with fusion proteincontaining self-assembled hydrophobin and functional peptide for selective capture of human blood outgrowth endothelial cells.ColloidsSurf B Biointerfaces,101(0):361~369.

[32] Zhang H,XiaH,Zhao Y.Optically triggered and spatially controllable shape-memory polymer-gold nanoparticle composite materials.J Mater Chem,2012,22(3):845~849.

[33] XueL,DaiS,LiZ.Synthesisandcharacterization of elastic starshape-memory polymers as self-expandable drugeluting stents.J Mater Chem,2012,22(15):7 403~7 411.

[34] Schoener C A,Weyand C B,Murthy R,Grunlan M A.Shap ememory polymers with silicon-containing segments.J Mater Chem,2010,20(9):1 787~1 793.

[35] XueL,DaiS,Li Z.Biodegradable shape-memory block co-polymers for fast self-expandable stents.Biomaterials,2010,31(32):8 132~8 140.

[36] Le DM,Kulangara,K,Adler A F,etal.Dynamic Topographical Control of Mesenchymal Stem Cells by Culture on Responsive Poly(ε-caprolactone)Surfaces.Adv Mater,2011,23(29):3 278~3 283.

[37] Lee K M,Knight P T,Chung T,etal.Polycaprolactone-POSS Chemical/Physical Double Networks.Macromolecules,2008,41(13):4 730~4 738.

[38] Alvarado T B,Romo U A,Mather P T.Microstructure and Phase Behavior of POSS/PCL Shape Memory Nanocomposites.Macromolecules,2011,44(14):5 682~5 692.

[39] Alvarado T B,Romo U A,Mather P T.Nanoscale Order and Crystallization in POSS-PCL Shape Memory Molecular Networks.Macromolecules,2015,48(16):5 770~5 779.

[40] Ya n g P,Z h u G,S h e n X,Ya n X,N i e J.P o l y(εcaprolactone)-based shape memory polymers crosslinked by polyhed raloligo mericsilses quioxane.RSC Adv,2016,6(93):90 212~90 219.

[41] Lee K S,Chang Y W.Thermal and mechanical properties of poly(ε-caprolactone)/polyhedral oligomeric silsesquioxane nanocomposites.PolymInt,2013,62(1):64~70.

[42] Shirole A,SapkotaJ,Foster EJ,Weder C.Shape Memory Composites Based on Electrospun Poly(vinylalcohol)Fibers and a Thermoplastic Polyether Block AmideElastomer.ACS Appl MaterInterfaces 2016,8(10):6 701~6 708.

[43] Knight P T,Lee K M,Qin H,et al T.Biodegradable Thermoplastic Polyurethanes Incorporating Polyhedral Oligosilsesquioxane.Biomacromolecules,2008,9(9):2 458~2 467.

[44] Mya K Y,Gose H B,Pretsch T,et al.Star-shaped POSS-polycaprolactone polyurethanes and their shapememory performance.J Mater Chem,2011,21(13):4 827~4 836.

[45] BotheM,MyaKY,JielinEM,et al.Triple-shape properties of star-shapedPOSS-polycaprolactone polyurethanen etworks.Soft Matter,2012,8(4):965~972.

[46] Gu S Y,Gao X F.Improved shape memory performance of star-shaped POSS-polylactidebasedpolyurethanes(POSSPLAUs).RSC Adv,2015,5(109):90 209~90 216.

[47] Gu S Y,JinSP,Liu L L.Polyurethane/polyhedral oligomeric silsesquioxane shape memory nanocomposites with low trigger temperature and quick response.J PolymRes,2015,22(7):1~9.

[48] Jung Y C,So H H,Cho J W.Water in esponsive Shape Memory Polyurethane Block Copolymer Modified with Polyhedral Oligomeric Silsesquioxane.J MacromolSciB:phys,2006,453~461.

[49] Yin G,Zhang L,Li Q.Preparation and characterization of POSS-crosslinked PCLbased hybrid materials.J Polym Res,2016,23(7):1~11.

[50] Knight P T,Lee K M,Chung,Mather P T.PLGA-POSS End-Linked Networks with Tailored Degradation and Shape Memory Behavior.Macromolecules,2009,42(17):6 596~6 605.

[51] Xu J,Song J.High performance shape memory polymer networks based on rigid nanoparticle cores.Proc Natl Acad SciUSA,2010,107(17):7 652~7 673.

[52] Yang D,Gao D,Zeng C,et al.POSS-enhancedshape-memory copolymer of polynorbornene derivate and polycycloocten ethrough ring-opening metathesis polymerization.React Funct Polym,2011,71(11):1 096~1 101.

[53] Jeon H G,Mather P T,Haddad T S.Shape memory and nanostructure in poly(norbornyl-POSS)copolymers.Polym Int,2000,49(5):453~457.

[54] Ishida K,Hortensius R,Luo X,etal.Soft bacterial polyester-based shape memory nanocomposites featuring reconfigurable nanostructure.J Polym SciPart B:Polym Phys,2012,50(6):387~393.

[55] Xie K,Liu X,Zhang Y.Modification of cellulose fabrics with reactive polyhedral oligomeric silsesquioxanes to improve their shape-memory performance.J Appl Polym Sci,2010,118(4):1 872~1 877.