采棉机摘锭磨损失效分析

张有强,王 伟,廖结安

采棉机摘锭磨损失效分析

张有强,王 伟,廖结安

(塔里木大学机械电气化工程学院现代农业工程重点实验室,阿拉尔 843300)

新疆是中国棉花主产区,机械化收获程度相对较高。采棉机是高端农机装备,摘锭是其核心零部件在采摘过程中与棉纤维、硬质棉秆接触摩擦导致表面涂层磨损,降低田间采净率及摘锭使用寿命,故其性能好坏直接影响采棉机的运行效率和机采棉品质。该文建立了采棉机摘锭的实体模型,通过有限元方法分析摘锭在脱棉过程中应力与应变的分布规律,旨在揭示摘锭失效的力学机制。数值结果表明表面涂层磨损是作用在钩齿表面上的摩擦力合力在采摘过程中不断撕裂涂层引起、摘锭断裂是扭转变形所致及锥齿轮磨损归因于过载后产生的塑形变形造成。并基于扫描电子显微镜(scanning electron microscope, SEM)观测失效摘锭的微观结构形貌进行验证,结果表明该有限元分析结果与实际情形基本吻合。

机械化;有限元方法;模型;采棉机;摘锭;磨损

0 引 言

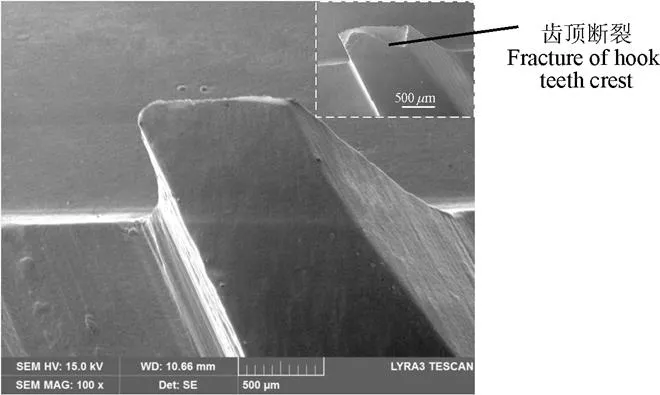

新疆生产建设兵团是中国最大的机采棉基地,拥有近2 000台采棉机,机械化采收率达80%以上。摘锭是采棉机上使用最多的零部件,其表面质量好坏直接影响到采棉机的作业性能。一方面采棉机摘锭在采摘过程中产生严重磨损,特别是摘锭在脱棉过程中承受来自脱棉盘施加的较大载荷,出现摘锭钩齿齿顶断裂,丧失抓取棉花的能力,导致采净率下降而提前失效。另一方面一台采棉机安装2 000多根摘锭,一般情况下摘锭服役约400 hm2,更换周期短且价格较高增加采棉机的运营成本。

中国机采棉区推广使用的采棉机多以进口机型为主,如凯斯、迪尔机型。从更换后的摘锭统计分析表明90%摘锭钩齿顶端出现断裂和80%钩齿表面涂层出现磨穿现象,但现有文献对其研究成果尚未报道。研究者大多从摘锭的采摘工作原理[1-3]、采摘系统结构优化与建模[4-5]展开探讨。张有强等[6-7]从静力学考察了单个摘锭轴向断裂现象,分析了摘锭从根部起第8~11齿之间断裂的原因;将摘锭的采摘过程简化为干摩擦动力学系统,从非线性动力学角度出发分析了参数变化时摘锭的振动行为。另外,摘锭的表面磨损科学本质是金属与生物质材料间的摩擦导致,属于典型软磨硬的磨损机制,这类摩擦副之间的摩擦磨损[8-16]已有研究。摘锭钩齿的断裂与机械结构中齿轮传动出现的齿根折断[17-20],机械加工过程中刀具的断齿[21-24]等都具有相似之处,这些研究成果可为分析摘锭失效提供参考。

另外,电镀铬涂层具有突出的高硬度、耐腐蚀、表面处理成本低和良好的摩擦学特性被许多工程实际广泛应用[25-31]。这些显著的处理优势恰好是摘锭表面所需求的,因此目前市场化摘锭表面进行电镀铬涂层处理,提高耐磨、耐蚀的同时降低了运营成本。

本文通过建立摘锭结构的实体模型,采用有限元数值方法分析摘锭在脱棉过程中钩齿部位的应力与应变分布,探讨摘锭在疲劳和扭转共同作用下产生失效的力学行为。进一步借助于扫描电子显微镜(scanning electron microscope,SEM)观测采棉机摘锭钩齿断裂和表面涂层磨损的微观形貌及演化过程,以期为采棉机摘锭结构优化设计、动力分配及提高表面耐磨性等提供参考。

1 采棉机摘锭工作过程

1.1 摘锭整体结构

采棉机的采摘系统如图1所示。摘锭在一次完整的采摘过程中需完成将棉花接触勾住并在其自身的高速旋转下缠绕,在采摘头滚筒的旋转下将缠绕的棉花从棉铃中拽出,然后经脱棉盘将缠绕在摘锭杆身的棉花脱下,最后通过输棉管道收集在集棉箱中。

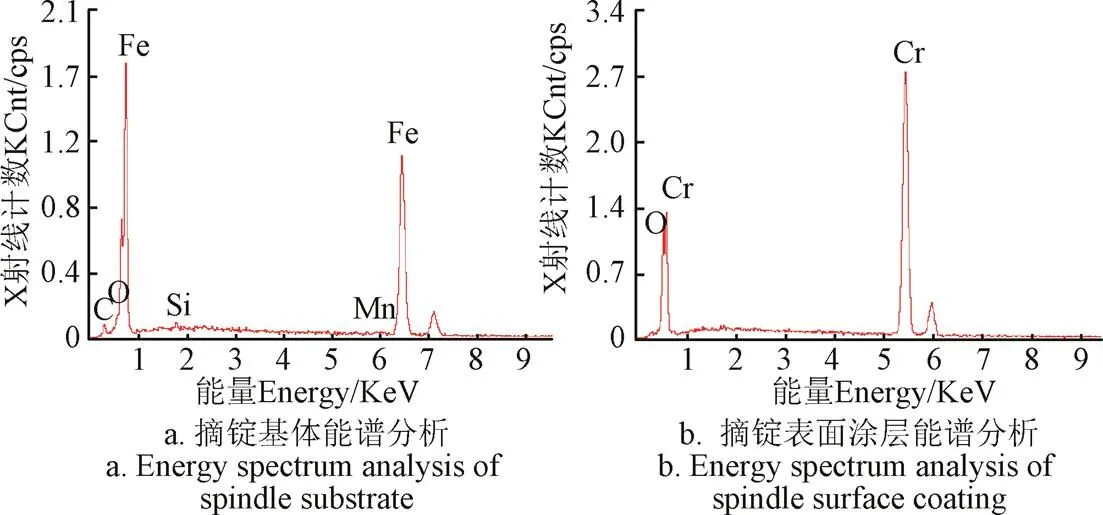

以CASE620采棉机摘锭为例,摘锭采摘工作部分呈圆锥形,头部球面直径5.4 mm,根部直径为12 mm,长度为120 mm,转速4 000 r/min,质量0.094 kg。图2是摘锭横截面的微观结构,由基体和涂层构成。基体材料为低碳合金钢,图3a为摘锭基体材料的能谱分析。为了提高摘锭耐磨性,表面进行电镀铬涂层处理,图3b为摘锭表面涂层材料的能谱,涂层厚度约为30m。

图1 采棉机采摘系统

图2 摘锭的横截面结构

注:KCnt为X射线计数。

1.2 摘锭单个钩齿结构

图4是新摘锭单个钩齿的真实结构,每个钩齿通过机械切削加工形成具有一定的倾斜角度,目前市场化摘锭圆锥表面上具有3排14齿的外部结构。通常机械加工和电镀过程中产生应力集中使钩齿表面、亚表层产生微裂纹。从图2可以清晰地看到涂层区域内微裂纹错综分布、孔洞和亚表层缺陷。此外,受几何结构所限,摘锭钩齿部位是应力最为集中的区域,即使是未使用的新摘锭也会出现齿顶断裂情形,且其断裂位置截面和形状不一,如图4右上所示。

摘锭基体表面经电镀铬涂层后,表面电镀铬颗粒交错堆积形成初始粗糙峰(粗糙度)。表面粗糙度过大会导致脱棉过程摩擦阻力较大、不利于脱棉;过小会降低采摘时抓取棉花的摩擦力、降低采净率。一般新摘锭表面粗糙度为0.7m左右,磨损失效后降低到0.2m左右。

图4 摘锭钩齿的微观形貌

2 摘锭建模及网格划分

摘锭的结构如1.1描述,基体材料以20CrMnTi为例,弹性模量205.67 GPa,泊松比为0.27,剪切模量为80.94 GPa,密度为7.8×103kg/m3,拉压强度为1.1×109N/m2,屈服强度为8.5×108N/m2。为了不失一般性且便于计算,将摘锭尾端的锥齿轮简化为一圆台,同时摘锭套筒简化为一圆柱筒。另外高硬度的电镀铬层主要目的在于提高耐磨性,但镀铬层和基体材料的其他物理特性参数差异不大,故在建模过程中未考虑镀铬层。在网格处理过程中整体采用六面体网格类型,摘锭钩齿进行细化处理,摘锭实体建模及网格化处理如图5a。

a. 摘锭的网格化

a. Grid partition of spindle unit

b. 摘锭采摘过程的约束与加载

如1.1节所述摘锭的采摘原理,假定摘锭与套筒之间形成边界润滑,套筒为固定约束(图5b中已隐藏),取摘锭与套筒之间的滑动摩擦系数为0.1。采用转动约束描述摘锭旋转,脱棉过程中脱棉盘对摘锭施加的载荷采用压力来描述,同时受到滚筒旋转将棉花从摘锭根部移到头部的力采用切向力描述;提供摘锭旋转的动力采用主动扭矩来描述;采用负载扭矩来描述缠绕在摘锭表面上棉纤维滑动时形成的摩擦阻力矩。施加约束的具体参数值如图5b所示。

3 有限元分析与验证

3.1 摘锭钩齿的应力与应变

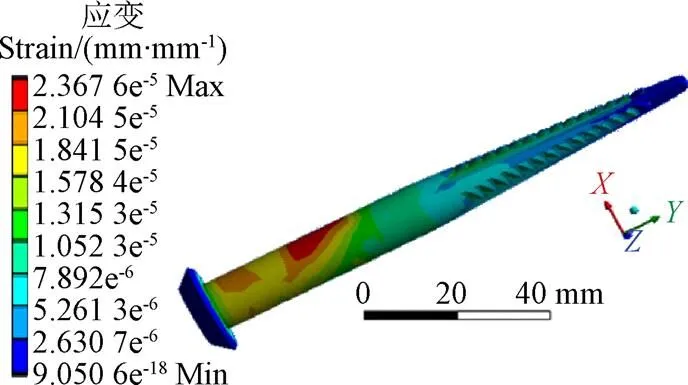

图6表明摘锭最大的应力与应变出现在摘锭圆柱面上,即与套筒接触的位置,这是因为在其圆柱面的两端施加了大小相等、方向相反的扭矩所致。

a. 摘锭杆的应力分布

a. Stress distribution of spindle rod

b. 摘锭杆的应变分布

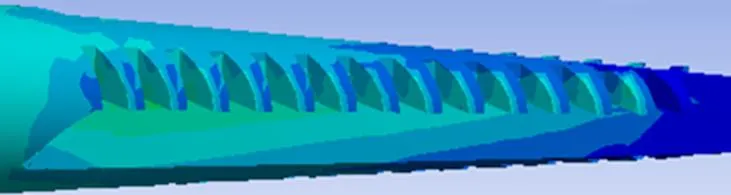

摘锭的圆锥面为棉花采摘的主要工作部位,图6表明摘锭钩齿的应力和应变大于其余圆锥面,从单个钩齿来看直径较大的棱边部位比直径较小的棱边部位承受较大的接触应力,导致摘锭表面沿直径大端棱边开始磨损。数值模拟过程中由于只考虑了摘锭“自转”未同时考虑随滚筒“公转”,所以在钩齿上承受应力较大部位呈“矩形”分布(如图7a所示)。但在实际采摘过程中摘锭既“自转”又“公转”,摩擦力合力方向是沿轴向摩擦力与切向摩擦力的合成,并且合力方向也随滚筒旋转而变化,因此真实应力表现并非规则的“矩形”分布。

a. 应变(图6b)的局部放大

a. Local amplification of strain (Fig. 6b)

b. 实际磨损形貌

为了验证摘锭在采摘过程中表面涂层磨损形貌的演化过程,在采棉季节实时跟踪了一台凯斯620采棉机的田间采摘工作,采摘时间为2016年10月1日至11月7日,地点为新疆生产建设兵团第一师十团七连。对选定的摘锭进行采样,并进行超声处理清洗表面污垢和杂质。图8为连续采摘100、200、300、400 hm2的摘锭钩齿表面磨损形貌,清晰表明钩齿表面涂层是从齿端边缘开始磨穿,并逐渐向摘锭钩齿表面直径大端棱边扩展延伸。随着采摘工作的持续,发展为类似“扫把”型的磨损形貌,最终导致钩齿表面涂层脱落,这与数值模拟结果(图7a所示)基本吻合。

a. 采摘100 hm2的磨痕a. Wear scar after picking 100 hm2b. 采摘200 hm2后磨痕b. Wear scar after picking 200 hm2 c. 采摘300 hm2后磨痕c. Wear scar after picking 300 hm2d. 采摘400 hm2后磨痕d. Wear scar after picking 400 hm2

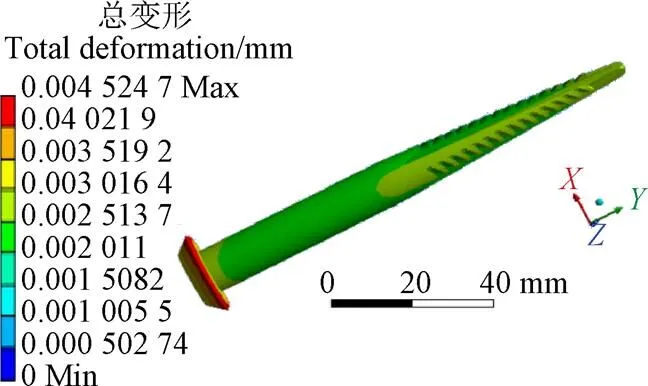

3.2 摘锭杆身的扭转变形

图9a为摘锭杆身的整体变形,表明摘锭圆锥面比圆柱面变形较大,变形量从根部到头部逐渐变大;图9b为摘定杆身总变形的矢量图,其方向呈螺旋形分布,表明摘锭杆身在采棉过程中处于周期性扭转状态,可能引起材料内部微观结构的滑移和塑性疲劳,在脱棉不顺畅或外载荷突增的情况下可能导致扭转断裂,这与实际从根部起第8~11钩齿之间断裂较为吻合[6]。

a. 摘锭杆的扭转变形

a. Torsional deformation of spindle rod

b. 摘锭杆扭转变形的矢量分布

3.3 摘锭锥齿轮的变形

假定其他载荷条件不变,当摘锭锥齿轮主动扭矩和负载扭矩减小到100 N·mm,从图10明显可以看到摘锭的主要变形在锥齿轮上,其他部位变形很小。这表明提高摘锭主动扭矩有利于棉花采摘,在实际中从棉铃中摘取棉花的力(扭矩)很小[5],采棉机摘锭提供的主动扭矩足以顺利完成采摘工作。但农业机械运行工况复杂,外载荷突增时而发生,出现主动扭矩不足以克服外载荷增加时,摘锭锥齿轮将会承受较大应力,产生塑性变形导致疲劳磨损。

注:压力为0.2 MPa,旋转速度为147 rad·s-1, 力为50 N,主动扭矩与负载扭矩均为100 N·mm.

4 结论与讨论

摘锭是采棉机的关键部件,摘锭的失效严重影响了采棉机的运行。本文通过有限元方法分析了摘锭在采摘过程中力学行为,结合观测摘锭结构的微观形貌验证了有限元分析的结果,为摘锭的优化设计提供参考。

1)摘锭主要失效形式是钩齿表面涂层磨损,数值结果表明在脱棉过程中单个钩齿呈现为直径较大的棱边部位比直径较小的棱边部位承受较大的接触应力,导致摘锭钩齿表面涂层沿直径大端棱边开始磨穿,并逐渐扩展形成“扫把”型磨损形貌,与实际摘锭涂层表面的磨损形貌基本一致。

2)摘锭杆身的断裂是由于扭转变形导致,最大变形出现在从根部起第8~11钩齿之间,与实际断裂位置较为吻合。摘锭锥齿轮的磨损是由于主动扭矩不足以克服外载突增负载扭矩时,锥齿轮齿顶将承受较大应力,引起塑性变形导致锥齿轮磨损。

在本文的基础上,下一步将基于多物理场耦合,建立摘锭壳体模型讨论摘锭表面涂层结构参数变化对其力学性能的影响,主要分析涂层的泊松比、涂层厚度及弹性模量变化对摘锭表面涂层结构力学性能影响,为摘锭表面涂层改性提供参考。

[1] 汤骅,梅键. 采棉机纺锭的工作原理及其力学分析[J]. 石河子大学学报,2001,5(4):323-324.

Tang Hua, Mei Jian. The working principles and mechanic analyses for cotton picker of hasp[J]. Journal of Shihezi University, 2001, 5(4): 323-324. (in Chinese with English abstract)

[2] 陈发,王学农,孙颖,等. 4MZ-2(3)型自走式采棉机主传动系技术方案分析与确定[J]. 农业工程学报,2001,17(5):68-71.

Chen Fa, Wang Xuenong, Sun Ying, et al. Analysis and determination of powertrain scheme of self-propelled 4MZ-2/3 cotton picker[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2001, 17(5): 68-71. (in Chinese with English abstract)

[3] 毕新胜,王维新,武传宇,等. 采棉机水平摘锭的工作原理及采摘力学分析[J]. 石河子大学学报,2007,25(6):786-789.

Bi Xinsheng, Wang Weixin, Wu Chuanyu, et al. Working principle and picking mechanics analysis of level spindle on cotton pickers[J]. Journal of Shihezi University, 2007, 25(6): 786-789. (in Chinese with English abstract)

[4] 边金英,吴疆. 基于Pro/E的采棉机水平摘锭的三维建模[J]. 农机化研究,2009,31(1):146-148.

Bian Jinying, Wu Jiang. Three-dimensional modeling of cotton picker's horizontal pick machine based on Pro/Engineer[J]. Journal of Agricultural Mechanization Research, 2009, 31(1): 146-148. (in Chinese with English abstract)

[5] 张宏文,康敏,傅秀清,等. 胶棒滚筒棉花采摘头的设计与试验[J]. 农业工程学报,2011,27(2):109-113.

Zhang Hongwen, Kang Min, Fu Xiuqing, et al. Design and experiment of rubber-bar roller of cotton harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(2): 109-113. (in Chinese with English abstract)

[6] 张有强,马彦,周岭. 采棉机摘锭采摘过程的力学分析及仿真[J]. 塔里木大学学报,2012,24(2):31-36.

Zhang Youqiang, Ma Yan, Zhou Ling. Mechanics analysis and simulation of cotton picker ingots during picking process[J]. Journal of Tarim University, 2012, 24(2): 31-36. (in Chinese with English abstract)

[7] 张有强,马少辉,丁旺才. 采棉机摘锭采摘过程的动力学分析[J]. 农业工程学报,2012,28(13):54-58.

Zhang Youqiang, Ma Shaohui, Ding Wangcai. Dynamic analysis of cotton picker ingots during picking process[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(13): 54-58. (in Chinese with English abstract)

[8] 张炜,吴建民,吴劲锋,等. 苜蓿草粉对45#钢磨损性能的影响[J]. 农业工程学报,2009,25(10):117-120.

Zhang Wei, Wu Jianmin, Wu Jinfeng, et al. Effects of alfalfa powder on friction and wear behavior of 45# steel[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(10): 117-120.(in Chinese with English abstract)

[9] 李耀明,马征,徐立章. 油菜联合收获机筛面粘附物摩擦特性[J]. 农业机械学报,2010,41(12):54-57.

Li Yaoming, Ma Zheng, Xu Lizhang. Tribological characteristics of adhesive materials on cleaning sieve of rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(12): 54-57. (in Chinese with English abstract)

[10] Tuvshin D,Takeshi Y,Kei S,et al. Friction and wear properties of rice husk ceramics under dry condition[J]. Journal of Mechanical Science and Technology, 2010, 24: 85-88.

[11] 霍丽丽,侯书林,田宜水,等. 生物质固体燃料成型机压辊磨损失效分析[J]. 农业工程学报,2010,26(7):102-106.

Huo Lili, Hou Shulin, Tian Yishui, et al. Wear failure analysis on roller assembly of biomass pellet mill[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(7): 102-106. (in Chinese with English abstract)

[12] Wang Ning. Transformation of soft-abrasive wear into hard-abrasive wear under the effect of frictional heat[J]. Tribology Transactions, 1989, 32: 85-90.

[13] Hashmi S A R, Dwivedi U K. Graphite modified cotton fibre reinforced polyester composites under sliding wear conditions[J]. Wear, 2007, 262: 1426-1432.

[14] Klamecki B E. A review of wood cutting tool wear literature[J]. Holz als Roh-und Werkstoff, 1979, 37(7): 265-276.

[15] Virto L, Naik A. Frictional behavior of textile fabrics. Part I: Sliding phenomena of fabrics on metallic and polymeric solid surfaces[J]. Textile Research Journal, 1997, 67(11): 793-802.

[16] Shaw M D, Tabil L G. Compression, relaxation and adhesion properties of selected biomass grinds[J]. Agricultural Engineering International, 2007, 4(6): 1-16.

[17] Sung C K, Tai H M, Chen C W. Locating defects of a gear system by the technique of wavelet transform[J]. Mechanism and Machine Theory, 2000, 35(8): 1169-1182.

[18] Glodez S, Ren Z, Fajdiga G. Computational modeling of the surface fatigue crack growth on gear teeth flanks[J]. Communications in Numerical Methods in Engineering, 2001, 17: 529-541.

[19] Choy F K, Polyshchuk V, Zukrajsek J J. Analysis of the effect surface pitting and wear on the vibration of a gear transmission system[J]. Tribology International, 1996, 29: 77-83.

[20] Lee K. Analysis of thedynamic contact between rotating spur gears by finite element and multi-body dynamics techniques[J]. Proceeding of the Institution of Mechanical Engineers, 2001, 215(4): 423-435.

[21] Vijayrangan S, Ganesan N. A study of dynamic stresses in a spur gear under a moving line load and impact load conditions by a three-dimensional finite element method[J]. Journal of Sound and Vibration, 1993, 162(1): 185-189.

[22] 陈燕,杨树宝,傅玉灿,等. 钛合金TC4高速切削刀具磨损的有限元仿真[J]. 航空学报,2013,34(9):2230-2240.

Chen Yan, Yang Shubao, Fu Yucan, et al. FEM estimation of tool wear in high speed cutting of Ti6Ai4V alloy[J]. Acta Aeronautica Astronautica Sinica, 2013, 34(9): 2230-2240. (in Chinese with English abstract)

[23] Usui E,Shirakashi T,kitagawa T. Analytical predication of cutting tool wear[J]. Wear, 1984, 100(13): 129-151.

[24] Ambarisha V K, Parker P G. Nonlinear dynamics of planetary gears using analytical and finite element method[J]. Journal of Sound and Vibration, 2007, 302(3): 577-595.

[25] DeMello J D B, Goncalves J L, Costa H L. Influence of surface texturing and hard chromium coating on the wear of steels used in cold rolling mill rolls[J]. Wear, 2013, 302: 1295-1309.

[26] Konyashin I Y. Wear resistant coatings for cermet cutting tools[J]. Surface and Coatings Technology, 1995, 71: 284-291.

[27] Nouveau C, Labidi C, Ferreira Martin J P, et al. Application of CrAlN coatings on carbide substrates in routing of MDF[J]. Wear, 2007, 263: 1291-1299.

[28] Saduman S. Influence of chromium carbide coating on tribological performance of steel[J]. Materials and Design, 2006, 27: 85-91.

[29] Chiu L H, Yang C F, Hsieh W C, et al. Effect of contact pressure on wear resistance of AISI H13 tool steels with chromium nitride and hard chromium coatings[J]. Surface and Coatings Technology, 2002, 154: 282-290.

[30] Zeng Z X, Wang L P, Chen L, et al. The correlation between the hardness and tribological behaviour of electroplated chromium coatings sliding against ceramic and steel counterparts[J]. Surface and Coatings Technology, 2006, 201: 2282-2288.

[31] SimaÄo J, Aspinwall D K. Hard chromium plating of EDT mill work rolls[J]. Journal of Materials Processing Technology, 1999, 92: 281-287.

Wear failure analysis on spindle of cotton picker

Zhang Youqiang, Wang Wei, Liao Jiean

(,,,843300,)

Vigorously developing precision and advanced agricultural equipment is one of the ten major areas emphasized in the “Made in China 2025” blueprint, the core strategy of agricultural mechanization centered on improvement of the performance of key mechanical components. With the increase of cotton planting area, the application of modern mechanized cotton pickers becomes more and more attractive, especially in Xinjiang, China, where the mechanization degree in harvesting is relatively higher than the other regions in China. Cotton picker is agricultural machinery of mechanization of cotton harvesting, and spindles in cotton picking machinery are the key component. As the work condition of cotton picker spindle is complex and changeable during the picking process, the contacting interfaces of spindle with cotton fiber involve gradually in the aspects of the stress state, topography, and surface microstructure etc. Surface coating wear of spindle are common with the increase of picking time, leading to the degradation of the spindle and drop of harvesting rate. Accordingly, a lot of effort has been made on improving its wear resistance in the past decades due to the problem of inadequate lifetime of the spindles. However, the previous researches are lack of investigation on failure process of the spindle, especially the mechanical analysis on the spindle surface. The main objective of this study was to reveal the wear process of spindle by analyzing the wear topography of spindle in the cotton picking process. Furthermore, based on the numerical method of finite element analysis, the mechanical performance of spindle was investigated for normal operating parameters of the spindle in field work. Therefore, the solid model of cotton picker spindle in the picking process was established by SolidWorks software along with ANSYS software. The stress and strain distribution of the spindle in the removal cotton process were simulated by the finite element analysis. The numerical simulations results showed that the surface of spindle’s teeth sustained more severe stress than the other portions. In terms of a single spindle’s tooth, the larger diameter edge of spindle’s teeth bore a greater contact stress than smaller diameter edge, leading to the beginning of wearing in the surface coating along the larger diameter edge of spindle’s teeth. In cotton picking process, the spindle is rotated at high speed, at the same time, the spindle rotates with roller while rotating itself. Under the combined actions of tangential friction forces and axial friction forces on the rotating spindle surface, the resultant force direction of the friction force had a certain inclination angle to the axis of spindle, and the inclination angle changed in real time. The surface coating of spindle’s teeth was worn gradually and the characteristic “broom type” wear scar was formed as the picking time increased. Moreover, the fracture of spindle was due to torsion formation, and dangerous section occurred between 8th and 11th teeth from the root of spindle. When the spindle was installed correctly and the lubrication was adequate in the cotton picking process, the wear of the spindle’s bevel gear was caused by the plastic deformation. It was mainly because of spindle deformation was concentrated on the bevel gear when the external load increased instantaneously, such as branches, debris, and gravel was suddenly brought into picking room in cotton picking process. These numerical simulations results were consistent with the microstructure and morphological characteristics of the worn spindle’s surface with electroplated chromium coatings by scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS). The research results will helpful for reducing failure of spindle (fracture and wear), which makes it possible to prolong the service life of spindle used, and has remarkable economic benefits and important social significance.

mechanization; finite element method; models; cotton picker; spindle; wear

10.11975/j.issn.1002-6819.2017.18.006

S225.91

A

1002-6819(2017)-18-0045-06

2017-03-24

2017-07-23

国家自然科学基金项目(11362020)

张有强,男,甘肃定西人,副教授,主要从事生物质材料与金属的摩擦磨损研究。阿拉尔 塔里木大学机械电气化工程学院,843300。Email:zhangyqlzjd@126.com