含稻秸蔬菜育苗基质块成型工艺参数优化

辛明金,陈天佑,张 强,焦晋康,白雪卫,宋玉秋※,赵 瑞,魏 臣(. 沈阳农业大学工程学院,沈阳 0866; . 沈阳农业大学园艺学院,沈阳 0866;. 沈阳中光电子有限公司,沈阳 007)

含稻秸蔬菜育苗基质块成型工艺参数优化

辛明金1,陈天佑1,张 强1,焦晋康1,白雪卫1,宋玉秋1※,赵 瑞2,魏 臣3

(1. 沈阳农业大学工程学院,沈阳 110866; 2. 沈阳农业大学园艺学院,沈阳 110866;3. 沈阳中光电子有限公司,沈阳 110027)

为了确定黄瓜育苗块成型的最优工艺参数,以育苗基质和水稻秸秆的混合物为原料,育苗块的抗破坏强度和尺寸稳定性为成型质量检测指标,采用四元二次回归通用旋转组合试验设计结合响应面法,探讨了原料含水率、压力、秸秆长度和秸秆含量对育苗块成型的影响,建立了黄瓜育苗块成型特性参数与各因素之间的回归模型。综合分析表明,各因素对育苗块抗破坏强度的影响主次顺序为:压力>秸秆长度>含水率=秸秆含量,在交互作用中,含水率与秸秆含量、压力与秸秆长度、秸秆长度与秸秆含量对育苗块抗破坏强度的影响显著(P<0.05);各因素对育苗块尺寸稳定性的影响主次顺序为:秸秆含量>含水率>压力>秸秆长度,含水率与秸秆长度的交互作用对育苗块尺寸稳定性的影响较显著(P<0.05)。利用Design-Expert8.0.6软件得出理论最优工艺参数,并考虑试验的可操作性,对理论最优工艺参数进行调整及试验验证,得到最优工艺参数:含水率为21%,压力为4.5 kN,秸秆长度为10 mm,秸秆质量分数为12%,该组合条件下的育苗块抗破坏强度为23.03 N,尺寸稳定性为82.83%。分析表明,优化后育苗块的理化特性符合黄瓜育苗的农艺要求。该研究可为黄瓜育苗块成型机工艺参数优化提供理论和实践依据。

基质;模型;秸秆;育苗块;抗破坏强度;尺寸稳定性;响应面法

辛明金,陈天佑,张 强,焦晋康,白雪卫,宋玉秋,赵 瑞,魏 臣. 含稻秸蔬菜育苗基质块成型工艺参数优化[J]. 农业工程学报,2017,33(16):219-225. doi:10.11975/j.issn.1002-6819.2017.16.029 http://www.tcsae.org

Xin Mingjin, Chen Tianyou, Zhang Qiang, Jiao Jinkang, Bai Xuewei, Song Yuqiu, Zhao Rui, Wei Chen. Parameters optimization for molding of vegetable seedling substrate nursery block with rice straw[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(16): 219-225. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.16.029 http://www.tcsae.org

0 引 言

蔬菜育苗技术能提高蔬菜抗旱、抗寒、抗病虫害能力,同时秧苗质量高,能达到高产、稳产的目的,而且缩短蔬菜田间生产期,提高土地利用率[1-3]。传统育苗所使用的钵体材料为塑料、再生纸等。为免去脱钵环节、减少塑料污染及节约成本[4-8],白晓虎等[9-11]利用秸秆作为育苗钵材料,实现了钵苗一体栽植,秧苗不缓苗或缓苗期较短,栽植成活率高。秸秆纤维为可降解物质,入土腐烂后,育苗钵将被分解,能增加土壤有机质,改善土壤的理化特性,提高土壤肥力[12-13];同时蔬菜根系可形成一个环状多孔性蓬松层,既可吸纳、集聚雨水,又能有效改善蔬菜根系的水、气环境。

纯秸秆基质持水孔隙小,水气比偏低,pH值和EC值偏高,为满足蔬菜根系对水、气、肥等要求,钵体材料选取育苗基质和秸秆的混合物[14-15],同时增大钵的体积,压制成育苗块。曹红亮等[16]以稻草和玉米芯为调理料,牛粪为主体原料,研究了土壤添加量、原料含水率、成型压力以及成型温度等操作因素对基质块成型品质的影响。刘洋等[17]以泥炭为原料,研究了物料装填量、成型压力、粒度配比和水分含量对压制成型泥炭营养块的密度和抗压强度的影响。赵瑞等[18-19]利用草炭为原料,通过试验得出育苗基质与黄瓜育苗块的体积比为3:1时,育苗块的总孔隙度、通气孔隙、持水孔隙、持水量等有利于蔬菜育苗。

成型育苗块不仅要满足蔬菜栽培的理化特性的要求,还应满足贮运的机械强度要求[17]。尺寸稳定性影响育苗块的容重、总孔隙度等物理特性,抗破坏强度是衡量机械强度的重要指标之一。因此,本研究以育苗基质和水稻秸秆的混合物为原料,通过采用通用旋转组合试验设计结合响应面法分析原料含水率、压力、秸秆长度和秸秆含量对黄瓜育苗块抗破坏强度和尺寸稳定性的影响,并优化育苗块的最佳工艺参数。

1 材料与方法

1.1 试验材料与仪器

试验基质选取由沈阳凡农园艺资材有限公司生产、沈阳农业大学蔬菜种苗研发室监制的育苗基质(主要成分有草炭、蛭石、缓释剂等)。主要试验设备有WDW-200型微机控制电子万能试验机、CP423S电子天平、101-OA型数显式电热恒温干燥箱、量筒、搅拌器等。

本试验于2016年6月期间,在沈阳农业大学物料实验室内进行。室温为26 ℃,空气相对湿度为35%。

1.2 试验方法

1.2.1 原料含水率调节

按照含水率的“烘干法”标准,利用101-OA型数显式电热恒温干燥箱将育苗基质烘干6~8 h,测定基质的含水率并计算特定含水率下的加水量。使用针管和量筒加水,并用玻璃棒进行搅拌。根据试验要求配制不同含水率的材料,用打碎机将其搅拌均匀并密封保存48 h,使水分均匀。

1.2.2 压制工艺

利用WDW-200型微机控制电子万能试验机控制压力(如图1所示),设置加载的速度为50 mm/min,保压时间为10 s,测试速度为10 mm/min[18-19]。压制育苗块前,在工作筒内添加50 g育苗基质,操作WDW-200型微机控制电子万能试验机,使工作横梁带动压头向下运动,工作筒内的育苗基质和秸秆混合物被压制成育苗块,预计尺寸稳定性为85%。根据压制黄瓜育苗块的压缩比要求(3:1),调整压缩比为60:17[18-19]。压制完成后,手动去掉插板,将育苗块推出进行下一循环。压制后的育苗块如图2所示。

图1 育苗块成型试验系统Fig.1 Experimental system for seedling nursery block densification

图2 育苗块Fig.2 Seedling nursery block

1.2.3 成型质量检测指标

1)抗破坏强度的测定

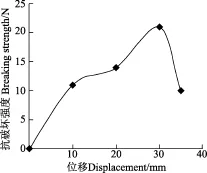

根据预试验,选定试验机的量程为0~30 mm。试验先执行加载程序,育苗块从与横梁上的上压板接触到完全破坏后,系统自动卸载,试验结束。育苗块变形(压头位移)与育苗块受力关系曲线由电脑自动记录并保存(图3)。当育苗块被破碎时,作用力曲线有一个峰值,这个峰值作为育苗块的抗破坏强度。

图3 测试力与位移曲线Fig.3 Force-displacement curve

2)尺寸稳定性的测定

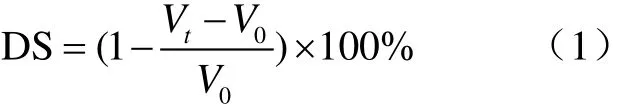

压制成型后,测量并记录压缩成型炭块的高度,计算其体积。放置48 h后,再次测量其直径和高度,计算其体积,根据公式(1)计算育苗块尺寸稳定性[20]。

式中DS为育苗块尺寸稳定性,%;Vt为压制后48 h的育苗块的体积,m3;V0为育苗块成型体积,m3。

1.2.4 试验设计

在单因素试验的基础上,选取育苗基质含水率X1、压力X2、秸秆长度X3、秸秆含量X4为变量,以48 h后育苗块抗破坏强度Y1和尺寸稳定性Y2为育苗块成型特性的衡量指标,采用四元二次回归通用旋转组合设计,将各因素按其水平及取值范围进行编码,得到因素水平表,如表1所示。结合响应面分析法,进行回归方程拟合度检验和显著性检验,建立育苗块成型特性的回归模型,根据拟合模型绘制的响应面分析各因素及交互作用对成型特性的影响规律。

表1 试验因素水平编码表Table 1 Coding of factors and levels

1.2.5 综合优化与试验验证

抗破坏强度直接影响育苗块运输和搬运过程中的破损率;尺寸稳定性影响育苗块的容重、总孔隙度等物理特性。综合分析成型指标对育苗块运输和后续利用的重要性,规定抗破坏强度和尺寸稳定性的权重系数均为0.5[21]。利用Design-Expert 8.0.6软件进行多目标优化,得出最佳条件。考虑试验的操作性,对优化后的最佳条件进行调整,利用调整后的最佳条件对育苗块抗破坏强度和尺寸稳定性进行验证,重复试验3次,结果取平均值。

1.2.6 育苗块理化特性测定方法

1)容重、总孔隙度和通气空隙测定。

利用环割法测定育苗块的容重[19]。总孔隙度和通气空隙测定参照郭世荣[22]的方法。按公式(2)和(3)计算育苗块的总孔隙度和通气空隙。

式中TP为育苗块的总孔隙度,%;AFP为育苗块的通气空隙度,%;W1为量杯和待测育苗块的总质量,g;W2为饱和水下育苗块和量杯的总质量,g;W3为湿纱布的质量,g;W4为自由沥干的育苗块质量,g;V为量杯的体积,mL。

2)pH值及EC值测定

基质EC值、pH值采用饱和浸提法进行测定[23]。用蒸馏水饱和浸提基质,澄清滤液用便携式水质电导率土壤盐度测定仪(HI993310,意大利哈纳仪器公司)测定EC值,手持酸碱度/温度测定仪(Model IQ150)测定pH值。

2 结果与分析

采用四元二次回归通用旋转组合试验,结果见表2,并采用Design-Expert 8.0.6软件对试验结果进行分析。

2.1 回归方程的建立与显著性分析

2.1.1 抗破坏强度回归模型建立与显著性分析

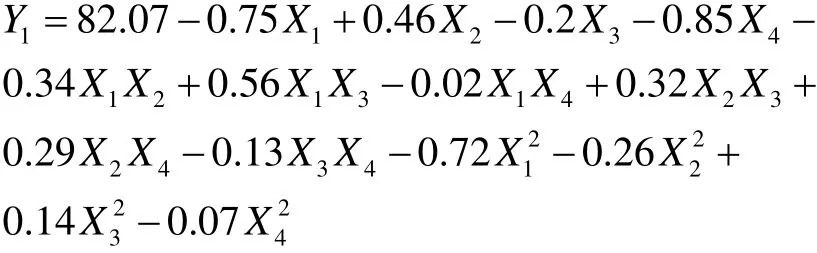

对育苗块成型48 h后的抗破坏强度进行回归分析,求得四元二次回归方程为

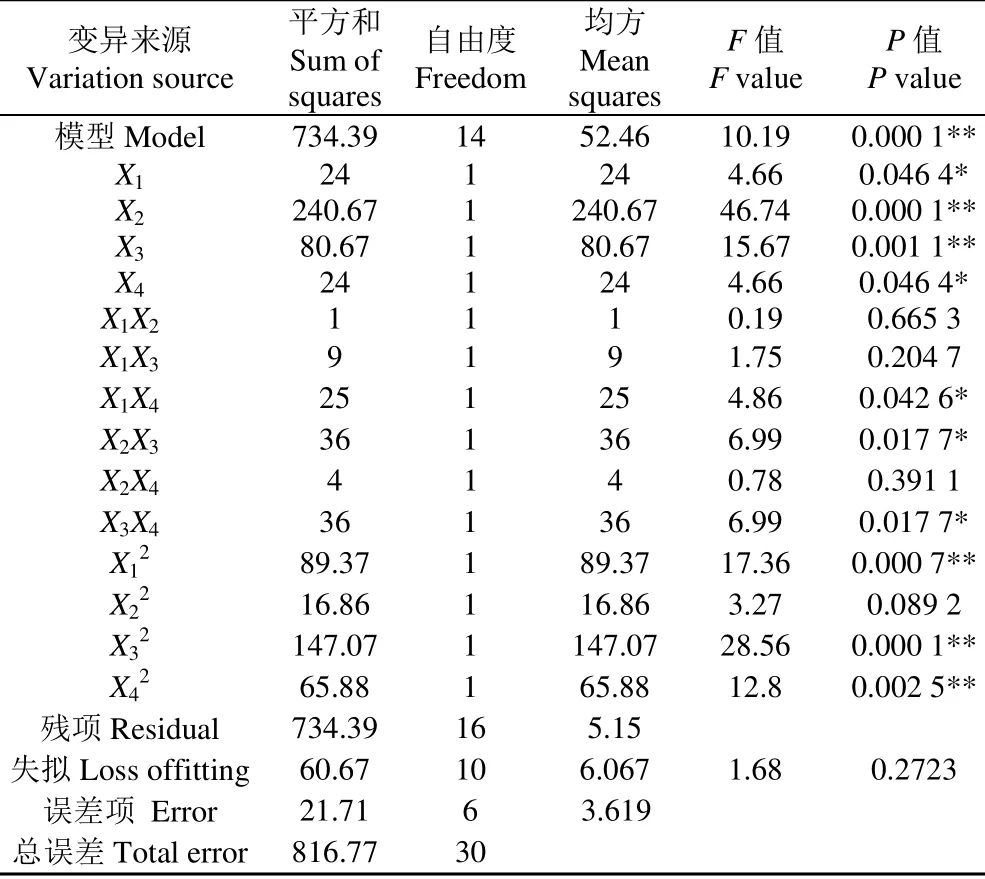

在α=0.05显著水平下,对上述回归的方程进行显著性检验与方差分析,分析结果见表3。

回归方程模型F=10.19>F0.01(14,16)=3.45,P<0.000 1,回归是极显著的;复相关指数R2=0.90,表明约有90%抗破坏强度的变化可以用模型解释;失拟F=1.68

表2 四因素二次通用旋转组合试验设计及结果Table 2 Experimental design and results of second general combination of rotating design

表3 抗破坏强度回归方程的方差分析Table 3 Variance analysis of regress equation of breaking strength

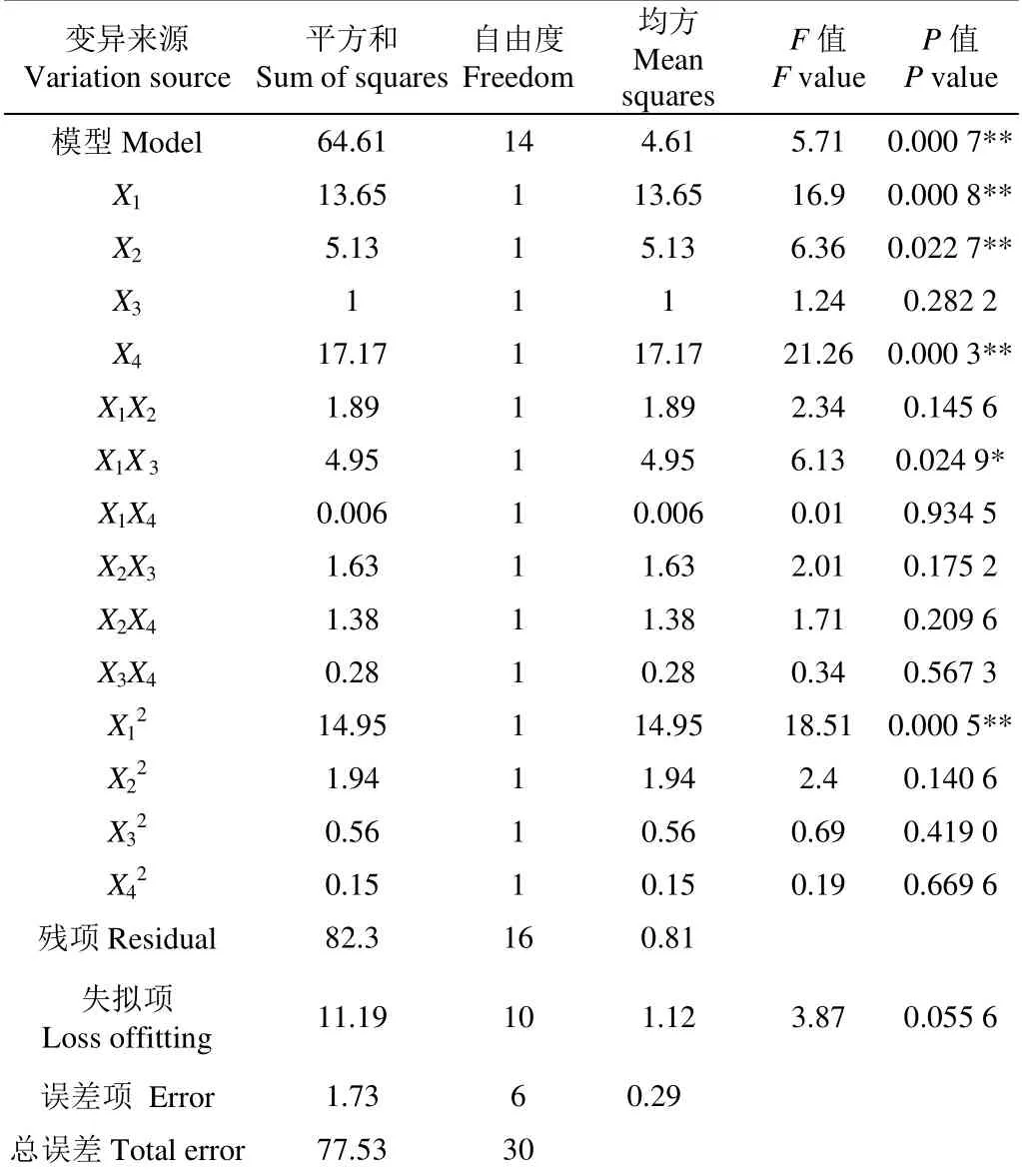

2.1.2 尺寸稳定性回归模型建立与显著性分析

对育苗块成型48 h后的尺寸稳定性进行回归分析,求得四元二次回归方程为

在α=0.05显著水平下,对上述回归的方程进行显著性检验与方差分析,分析结果见表4。

表4 尺寸稳定性回归方程的方差分析表Table 4 Variance analysis of regress equation of dimension stability

回归方程模型F=5.71>F0.01(9.10)=4.95,P=0.000 7,回归是极显著的;复相关指数R2=0.84,表明约有84%尺寸稳定性的变化可以用模型解释;失拟F=3.87

2.2 因素的响应面效应分析及优化结果

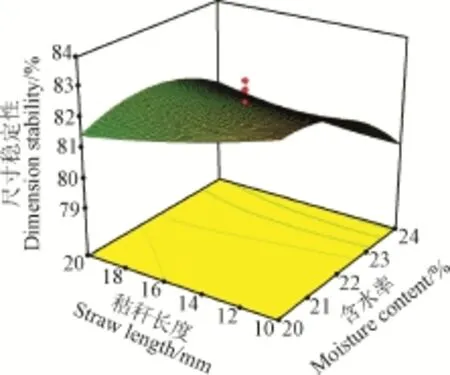

对表2中的试验结果进行响应面分析,各因素对育苗块抗破坏强度的影响结果如图4所示,对育苗块尺寸稳定性的影响结果如图5所示。

图4 各因素对育苗块抗破坏强度的影响Fig.4 Effect of each factors on breaking strength of seedling nursery block

图5 含水率和秸秆长度对育苗块尺寸稳定性的影响Fig.5 Effect of moisture content and straw length on dimension stability of seedling nursery block

2.2.1 抗破坏强度的响应面分析及优化结果

由图4a可知,压力为4 kN、秸秆长度为15 mm时,当含水率一定,随着秸秆含量的增加,育苗块的抗破坏强度增大,达到最大值后,随着秸秆含量的增加,抗破坏强度减小;当秸秆含量一定时,育苗块抗破坏强度随含水率的增加先增大后减小。由图4b可知,含水率为22%、秸秆质量分数为12%、压力一定时,随着秸秆长度的增大,育苗块抗破坏强度先增大后减小;秸秆长度一定时,育苗块抗破坏强度随压力的增大而增大。由图4c可知,含水率为22%、压力为4 kN,当秸秆长度一定时,随着秸秆含量的增加,育苗块的抗破坏强度增大,达到最大值后,随着秸秆含量增加,抗破坏强度减小;秸秆含量一定,随着秸秆长度的增加,育苗块的抗破坏强度先增大后减小。根据多元函数极值理论,对育苗块抗破坏强度回归模型方程求偏导,得到最佳工艺条件:含水率为22.74%,压力为4.5 kN、秸秆长度为12.24 mm、秸秆质量分数为11.25%时,预测育苗块抗破坏强度为24.40 N。

2.2.2 尺寸稳定性的响应面分析及优化结果

由图5可知,压力为4 kN、秸秆质量分数为12%,当秸秆长度一定时,随着含水率的增加,育苗块的尺寸稳定性增大,达到最大值后,随着含水率的增加,抗破坏强度减小;当含水率一定时,随着秸秆长度的增加,育苗块的尺寸稳定性先减小后增大。其他因素交互作用对育苗块尺寸稳定性影响不显著。根据多元函数极值理论,对育苗块尺寸稳定性回归模型方程求偏导,得到最佳工艺条件:含水率为20.05%、压力为4.18 kN、秸秆长度为10 mm、秸秆为10%时,预测育苗块尺寸稳定性为80%。

2.3 综合优化及验证试验

以育苗块的抗破坏强度和尺寸稳定性为响应值,利用Design-Expert8.0.6软件中的优化程序设定抗破坏强度和尺寸稳定性的目标(Goal)参数均为maximize,权重(Weight)参数均为0.5,得到育苗块成型的最优工艺参数:含水率为20.78%,压力为4.5 kN,秸秆长度为10 mm,秸秆质量分数为11.55%,模型的预测值抗破坏强度为22.82 N,尺寸稳定性为83.13%。考虑到试验的操作性,对优化条件进行调整:优化条件为含水率为21%,压力为4.5 kN,秸秆长度为10 mm,秸秆质量分数为12%。试验重复3次,育苗块抗破坏强度分别为23.12、22.91、23.06 N,结果取平均值23.03 N,与预测值22.82 N相接近;育苗尺寸稳定性分别为82.8%、83.1%、82.6%,结果取平均值82.83%,与预测值83.13%相接近。两者误差分别为0.9%和0.4%,说明二项式优化的区域与设计目的相符,响应面模型与试验设计具有可靠性和重现性。

在抗破坏强度和尺寸稳定性权重均为0.5时,优化后的育苗块抗破坏强度达到最大;育苗基质与育苗块的体积之比为3.01,接近目标值3,误差仅为0.3%。其参数符合黄瓜育苗要求,同时具有较好的机械强度[18-19]。

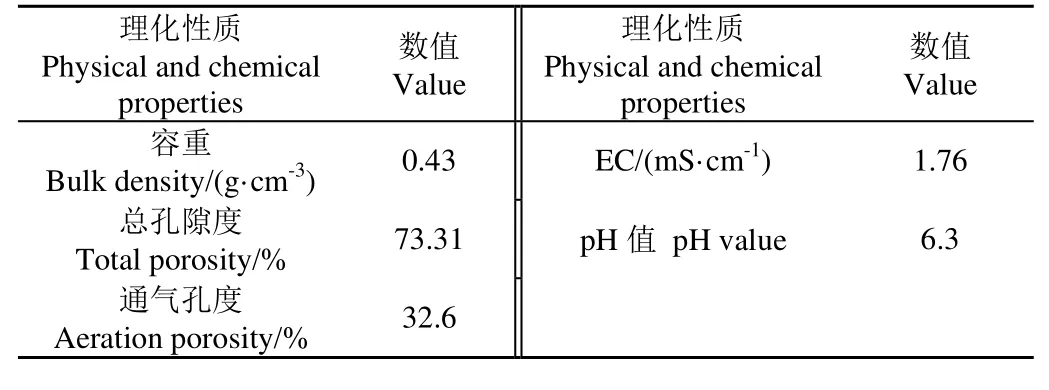

2.4 优化后育苗块理化特性分析

基质的理化性状(容重、孔隙度、通气孔隙、pH值、EC值等)与黄瓜幼苗的生长发育和幼苗质量密切相关,并影响到后期的长势和产量,本试验最佳成型工艺条件下育苗块的理化特性如表5所示。

表5 育苗块理化特性Table 5 Physical and chemical properties of seedling nursery block

育苗块的物理性质由固液气三相决定,容重和孔隙度常用于衡量育苗块物理结构的好坏。育苗块的容重影响其机械性能,容重越大,机械性能越好,但通透性变差,从而抑制水、肥、热、气的输运,不利于幼苗的生长发育;总孔隙度影响土壤的通透性,总孔隙度大,有利于作物根系生长,但固定作用差;通气孔隙影响保水性能,通气孔隙过大,保水性能差。艾冬冬等[19,24-25]认为黄瓜育苗基质的容重应在0.1~0.85 g/cm3,总孔隙度应60%以上,通气孔隙度在15%以上,持水孔隙度在45%以上,通气孔隙与持水孔隙比应接近1。由表5可知,优化后育苗块容重为0.43 g/cm3,总孔隙度为73.31%,通气孔度为32.6%,通气孔隙与持水孔隙比为1:1.25,均符合黄瓜育苗要求,适宜黄瓜出苗和幼苗的生长。

基质pH值影响幼苗对水分和矿质元素的吸收;电导率(EC)的高低是制约有机废弃物用于育苗或栽培基质的主要因子[26]。崔秀敏等[27-29]认为育苗基质的pH值的最优范围为5.8~7.0。方金等[30]认为黄瓜育苗基质的EC值最好小于2.6 ms/cm;李谦盛等[23]认为使用饱和浸提法测得的EC值在0.76~2 mS/cm范围内适合作物育苗。由表5可知,优化后育苗块的pH值为6.3,EC值为1.76 mS/cm,两者均在合理的范围内,适合于黄瓜种子萌发和幼苗生长。

上述分析结果表明,优化后育苗块的理化特性符合黄瓜育苗的农艺要求。

3 结 论

1)进行了二次通用旋转组合试验,建立了蔬菜育苗块成型特性的2个回归方程,并通过方差分析,对各回归模型进行了拟合度和显著性检验。

2)各因素对蔬菜育苗块抗破坏强度的影响主次顺序为:压力>秸秆长度>含水率=秸秆含量,在交互作用中,含水率与秸秆含量、压力与秸秆长度、秸秆长度与秸秆含量对抗破坏强度的影响显著(P<0.05);对蔬菜育苗块尺寸稳定性的影响主次顺序为:秸秆含量>含水率>压力>秸秆长度,含水率与秸秆长度的交互作用对尺寸稳定性的影响较显著(P<0.05)。

3)利用Design-Expert8.0.6软件得出最优工艺条件,并考虑试验的可操作性,调整最佳工艺条件并进行试验验证,得到最佳工艺参数:含水率为21%,压力为4.5 kN,秸秆长度为10 mm,秸秆质量分数为12%,育苗块抗破坏强度为23.03 N,尺寸稳定性为82.83%。根据讨论分析,优化后育苗块的理化特性符合黄瓜育苗的农艺要求。

[1] 闸建文,孙鹏,宋景玲,等. 机械化制营养钵工艺的研究[J].农业工程学报,1999,15(1):105-108. Zha Jianwen, Sun Peng, Song Jingling, et al. Study on technology of mechanized bowl-making[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1999, 15(1): 105-108. (in Chinese with English abstract)

[2] 郭孟报,杨明金,刘斌,等. 我国蔬菜育苗产业现状及发展动态[J]. 农机化研究,2015(1):250-253. Gu Mengbao, Yang Mingjin, Liu Bin, et al. Status and development trend of vegetable seedling industry in China[J]. Journal of Agriculture Mechanization, 2015(1): 250-253. (in Chinese with English abstract)

[3] 赵瑞. 营养环境对果菜育苗质量和生理变化的影响[D].沈阳: 沈阳农业大学,2001. Zhao Rui. Study on Quality of Fruit Vegetable Seedling and Physiological Variation Treated with Nutrient Environment[D]. Shenyang: Shenyang Agricultural University, 2001. (in Chinese with English abstract)

[4] Kristensen E F, Kristensen J K. Development and test of small scale batch fired straw boilers in Denmark[J]. Biomass and Bioenergy, 2004, 26: 561-569.

[5] Woc S, Wiltshire C W, Langdon J E, et al. Effects of cultivation techniques and methods of straw disposal on predation by Pterostichusmelanarius (Coleoptera: Carabidae) upon slugs (Gastropoda:Pulmonata) in an arable field[J]. Journal of Applied Ecology, 1996, 33(4): 741-753.

[6] Baniya B K,Tiwari R K,Chaudhary P, et al. Planting Materials seed systems of finger millet, rice and taro in Jumla, Kaski and Bara districts of Nepal[J]. Nepal Agric Res J, 2005(6): 39-48.

[7] 王君玲,高玉芝,尹维达. 秸秆类型对秸秆育苗钵成型质量的影响[J]. 沈阳农业大学学报,2010,41(3):357-359. Wang Junling, Gao Yuzhi, Yin Weida, et al. Experimental study on extrusion moulding quality of nursingcontainer made from different kinds of straw[J]. Journal of Shenyang Agricultural University, 2010,41(3):357-359.(in Chinese with English abstract)

[8] 徐永刚,马强,周桦,等. 秸秆还田与深松对土壤理化性状和玉米产量的影响[J]. 土壤通报,2015(2):428-432. Xu Yonggang, Ma Qiang, Zhou Hua, et al. Effects of straw returning and deep loosening on soil physical and chemical properties and maize yields[J]. Chinese Journal of Soil Science, 2015(2): 428-432. (in Chinese with English abstract)

[9] 白晓虎,李芳,张祖立,等. 农作物秸秆挤压成型育苗容器的研究进展[J]. 农机化研究,2007(5):225-227. Bai Xiaohu, Li Fang, Zhang Zuli, et al. Review of research on the corp straw-extruded seedling container[J]. Journal of Agriculture Mechanization, 2007(5): 225-227. (in Chinese with English abstract)

[10] 陈中玉. 秸秆原料热压成型育苗钵试验研究[D]. 沈阳:沈阳农业大学,2007. Chen Zhongyu. Experiments of Extrusion Hot Moulding With Straw[D]. Shenyang: Shenyang Agricultural University, 2007. (in Chinese with English abstract)

[11] 张志军,王慧杰,李会珍. 秸秆育苗钵质量和性能影响因素及成本分析[J]. 农业工程学报,2011,27(10):83-87. Zhang Zhijun, Wang Huijie, Li Huizhen, et al. Influence factors on quality and properties of straw blocks and cost analyses[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(10): 428-432. (in Chinese with English abstract)

[12] 时连辉,韩国华,张志国, 等. 秸秆腐解物覆盖对园林土壤理化性质的影响[J]. 农业工程学报,2010,26(1): 113-117. Shi Lianhui, Han Guohua, Zhang Zhiguo, et al. Effect of mulching with straw composts on soil properties of landscape[J]. Transaction of the Chinese Society of Agriculture Engineering (Transactions of the CSAE), 2010,26(1): 113-117.(in Chinese with English abstract)

[13] 孙容国,韦武思,王定勇. 秸秆-膨润土-PAM改良材料对砂质土壤饱和导水率的影响[J]. 农业工程学报,2011,27(1): 89-93. Sun Rongguo, Wei Wusi, Wang Dingyong. Effect of straw-bentonite-PAM improved material on the saturated hydraulic conductivity of sandy soil[J]. Transaction of the Chinese Society of Agriculture Engineering (Transactions of the CSAE), 2011, 27(1): 89-93.(in Chinese with English abstract)

[14] 苏丽影. 玉米秸秆混合基质在蔬菜穴盘鱼苗中应用研究[D].长春: 吉林农业大学,2013. Su Liying. Study on the Application of Corn Stalk Compand Subtract in Vegetable Seeding[D]. Changchun: Jiling Agricultural University, 2007. (in Chinese with English abstract)

[15] 范如芹,罗佳,严少,等. 农作物秸秆基质化利用技术研究进展[J]. 生态与农村环境学报,2016,32(3):410-416. Fan Ruqin, Luo Jia, Yan Shao, et al. Progress in study on utilization of crop straw in soilless culture[J]. Journal of Ecology and rural environment, 2016, 32(3): 410-416. (in Chinese with English abstract)

[16] 曹红亮,杨龙元,袁巧霞,等. 稻草、玉米芯调理牛粪堆肥成型育苗基质试验[J]. 农业机械学报,2015,46(3):197-202. Cao Hongliang, Yang Longyuan,Yuan Qiaoxia, et al. Experimental research of seedling substrate compressed of cattle manures[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(3): 197-202. (in Chinese with English abstract)

[17] 刘洋,樊涛,曲振兴,等. 泥炭营养块压制成型的试验研究[J]. 林业机械与木工设备,2014,42(5):10-12. Liu Yang, Fan Tao, Qu Zhenxing, et al. Experimental study on nutritious peat block press molding[J]. Forestry Machinery &Woodworking Equipment, 2014, 42(5):10-12. (in Chinese with English abstract)

[18] 赵瑞,韩旭,辛明金,等. 蔬菜育苗块成型工艺及成型机的研制[J]. 农机化研究,2010,32(4):78-80. Zhao Rui, Han Xu, Xin Mingjin, et al. The manufacture of vegetable seedling block formation technology & formation machine[J]. Journal of Agriculture Mechanization, 2010, 32(4): 78-80. (in Chinese with English abstract)

[19] 艾冬冬,赵瑞,陈俊琴,等. 不同压缩比对育苗块物理性质及黄瓜幼苗质量的影响[J]. 河南农业大学学报,2009,43(4):382-384. Ai Dongdong, Zhao Rui, Chen Junqin, et al. Effect of different compression ratio on the physical character of the seedling block and seedling quality of cucumber[J]. Journal of Henan Agricultural University, 2009, 43(4): 382-384. (in Chinese with English abstract)

[20] 陈天佑,孟军,辛明金,等. 玉米秸秆生物炭成型特性研究[J]. 沈阳农业大学学报,2016,47(6):728-733. Chen Tianyou, Meng Jun, Xin Mingjin, et al. Compaction behavior of biochar from corn stalk[J]. Journal of Shenyang Agricultural University, 2016, 47(6): 728-733. (in Chinese with English abstract)

[21] 王晖,陈丽,陈垦,等. 多指标综合评价方法及权重系数的选择[J]. 广东药学院学报,2007,23(5):583-589. Wang Hui, Chen Li, Chen Ken, et al. Multi-index evaluation method and the choice of weight coefficient[J]. Journal of Guang Dong College of Pharmacy, 2007, 23(5): 583-589. (in Chinese with English abstract)

[22] 郭世荣. 无土栽培学[M]. 北京:中国农业出版社,2003.

[23] 李谦盛,郭世荣,李式军. 基质EC值与作物生长的关系及测定方法比较[J]. 中国蔬菜,2004(1):70-71.Li Qianshen, Guo Shirong, Li Shijun. The relationship between EC value of substrate and crop growth and the comparison of measured methods[J]. Chinese Vegetables, 2004(1): 70-71. (in Chinese with English abstract)

[24] Abad M, Noguera P, Bures S. National inventory of organic wastes for use as growing media for ornamental potted plant production: A case study in Spain[J]. Bio-resource Technology, 2001, 77(2): 197-200.

[25] 程斐,张文静,孙令强. 棉籽壳菇渣复配基质理化性质分析及其对黄瓜幼苗的影响[J]. 中国瓜菜,2016,29(12):41-44. Cheng Fei, Zhang Wenjing, Sun Lingqiang. Chemical and physical property of compounded substrate by cottonseedhull mushroom residue and its effects on cucumber seedlings[J]. Chinese Cucurbits and Vegetables, 2016, 29(12): 41-44. (in Chinese with English abstract)

[26] Garcia G A, Bernal M P, Roig A.Growth of ornamental plants in two composts prepared from agroindustrial wastes[J]. Bioresource Technology, 2002, 83: 81-87.

[27] 崔秀敏,王秀峰. 蔬菜育苗基质及其研究进展[J]. 天津农业科学,2001,7(1):37-42. Cui Xiumin, Wang Xiufeng. Vegetable seedling substrates and their research progress[J]. Tianjin Agricultural Sciences, 2001, 7(1): 37-42. (in Chinese with English abstract)

[28] Kaudal B B, Chen Deli, Madhavan D B. An examination of physical and chemical properties of urban biochar for use as growing media substrate[J]. Biomass & Bioenergy, 2016, 84: 49-58.

[29] Garcia-gomez A, Bernal M P, Roig A. Growth of ornamental plants in two composts prepared from agroindustrial wastes[J]. Bioresource Technology, 2002, 83(1): 81-87.

[30] 方金,王斌,郭世荣. 黄瓜育苗海藻渣基质配方研究[J].沈阳农业大学学报,2013,44(5):622-627. Fang Jin, Wang Bin, Guo Shirong. Use of seaweed slag as growing media for cucumber seedlings[J]. Journal of Shenyang Agricultural University, 2013, 44(5): 622-627. (in Chinese with English abstract)

Parameters optimization for molding of vegetable seedling substrate nursery block with rice straw

Xin Mingjin1, Chen Tianyou1, Zhang Qiang1, Jiao Jinkang1, Bai Xuewei1, Song Yuqiu1※, Zhao Rui2, Wei Chen3

(1. College of Engineering, Shenyang Agricultural University, Shenyang 110866, China; 2. College of Horticulture, Shenyang Agricultural University, Shenyang 110866, China; 3. Kodenshi Sy Corp., Shenyang 110027, China)

Raising vegetable seedling with growing substrate nursery block is an effective way to utilize agricultural byproduct, reduce use of plastic pot which may pollute the environment and realize the optimal treatment of the growing media favorable for the growth of the seedlings. For the technology, the growing media is compacted and molded into nursery blocks; seeds are planted into the block in greenhouse; and seedlings with blocks are transplanted without the process of removing the plastic pot of traditional seedling raising at transplanting. Breaking strength and dimensional stability of the molded block are critical for the delivery and seedling production process and they affect the mechanical properties of the block as well, such as the density, and the porosity. And the parameters will affect the germination, emergence and growth of the crop seedlings. The compression ratio was determined as 3:1 according to previous studies. A mold was developed and equipped on a WDW-200 type computer-controlled electrical testing machine to compress the block according to horticultural requirement. The tested materials was the mixture of rice straw and growing substrate whose principal components were peat, vermiculite and other nutrients demanded for plant growing, which was produced by Shenyang Fannong Horticultural Materials Co. Ltd. and supervised by Seedling Developing Room of Horticulture College, Shenyang Agricultural University. Quadratic regression general rotary combined experiments of 4 factors were carried out, and by means of surface response methodology, the effects of moisture content, pressure, straw length and straw content on breaking strength and dimensional stability of the manufactured substrate block were investigated, and the regression models were set up. The fitting degree and significance of the regression model were tested through the analysis of variance. The results showed that the significance of the factors for breaking strength of the block was: pressure > straw length > moisture content = straw content; the interactions between moisture content and straw content, between pressure and straw length, and between straw length and straw content on breaking strength of the block were all significant (P<0.05); the influence of the factors on dimensional stability of the seedling nursery blocks was: content of straw > moisture content > pressure > straw length; the interaction of moisture content and straw length was significant for dimensional stability of the block (P<0.05). The optimal theoretical process parameters were obtained with Design-Expert 8.0.6. The optimal values of the factors were adjusted according to the operability and verification experiment results. The final optimal process parameters were determined as follows: moisture content of 21%, pressure of 4.5 N, straw length of 10 mm and straw content of 12%. The corresponding breaking strength and dimension stability of the block were 23.03 N and 82.83% respectively. The parameters of physical and chemical properties of the optimized seedling block were determined as follows: bulk density of 0.43 g/cm3, total porosity of 73.31%, aeration porosity of 32.6%, EC value of 1.76 mS/cm and pH value of 6.3. The analysis showed that the optimized parameters could meet the demand of physical and chemical requirement of vegetable seedling raising according to the relevant literature. The study may provide theoretical basis for process parameters optimization and machine development of vegetable seedling nursery block molding.

substrate; models; straws; seedling nursery block; breaking strength; dimensional stability; surface response methodology

10.11975/j.issn.1002-6819.2017.16.029

文献标志码:A 文章编号:1002-6819(2017)-16-0219-07

2017-03-21

2017-06-05

国家自然科学基金项目(51405311)

辛明金,教授,硕士生导师,主要从事水稻生产机械化技术及装备研究。沈阳 沈阳农业大学工程学院,110866。Email:xinmj2005@163.com※通信作者:宋玉秋,副教授,硕士生导师,主要从事水稻生产机械化技术及装备研究。沈阳 沈阳农业大学工程学院,110866。

Email:songyuqiusyau@sina.com