利用相变释能的农产品冷藏设备主动防除冰方法

丛 茜,陈廷坤,李 杨,孙成彬,金敬福

利用相变释能的农产品冷藏设备主动防除冰方法

丛 茜1,2,陈廷坤1,李 杨1,孙成彬1,金敬福1※

(1. 吉林大学生物与农业工程学院,长春 130022; 2. 吉林大学汽车仿真与控制国家重点实验室,长春 130022)

为减小农副产品冷藏设备表面的结冰危害,提高部件表面的抗结冰能力和设备运转效率,该文提出利用相变释能的主动防除冰方法。试验以带有不同凹坑尺寸的聚甲基丙烯酸甲酯(polymethyl methacrylate,PMMA)和6061铝合金作为基体材料,凹坑内填充气体或不同冰点的介质,表面覆盖双向拉伸聚丙烯薄膜(biaxially oriented polypropylene,BOPP)。试验采用水杯制冰法,测量表面结冰附着强度,结合剥离界面的形态,分析相变时差对界面附着强度的影响机理。结果表明:相对于光滑PMMA试样的表面附着强度169.81 kPa,试样(凹坑内分别填充纯净水和体积分数为6%乙醇溶液)表面的附着强度分别降低了100%和82%;对比无凹坑铝合金试样表面的附着强度,凹坑内填充体积分数为15%乙醇溶液低冰点溶液的试样表面附着强度可减小76.52%。因此利用不同水溶液的相变时间差和膨胀释能可减小试样表面的附着强度,并且试验表明试样材料、凹坑尺寸对附着强度的降低作用影响较小。利用相变时差和相变膨胀释能破坏冰在弹性冻结界面的接触稳定性,达到降低结冰表面附着强度的目的,并且水溶液中水的体积分数越大,试样结冰表面的附着强度的越小。研究结果为农产品冷藏领域中的防、除冰方法研究和开发提供参考。

制冷;冻结;界面;弹性膜;相变;膨胀;附着强度

0 引 言

随着中国冷冻、冷藏行业的迅速发展,农副产品、果蔬等食品对冷库、冷藏机械的需求逐年增加,如微型冷库在未来20年的保有量将达到50万左右台[1],而且保鲜冷库的制冷效率可影响储藏物的品质[2-3]。因此,制冷设备高效节能的运转一直是该行业追求的目标,但使用过程中,由于表面温度低,空气中的水蒸气或雨水易附着在蒸发器、冷凝管、冷风机等制冷部件表面,发生结霜、结冰现象,降低了制冷器表面的热交换效率,造成设备运行不稳定,严重影响制冷设备的运转效率和制冷速度,增加了用电量和运行成本,经济性差[4-10]。但日常的除冰、除霜效果是影响冷库运转效率的关键,并且常规除冰方式效率低且成本高[11-14]。因此,提高制冷设备表面的防/除冰效果一直是制冷行业中的重要研究课题。

冰冻结过程中必然发生体积变化,对农业、南水北调等领域中的渡槽、沟渠容易造成膨胀损坏[15-19],能否可以将冰的冻胀力作为破坏力应用于有益方向,如作为除冰动力进行自主破冰、提升制冷设备表面的防/除冰能力。项目组前期进行表面宏观形态对结冰附着强度的影响试验[20-21]:改变材料表面宏观形态、利用冰的相变膨胀影响表面结冰附着强度,结果表明网格状、条纹状、点状凹坑等不同形态对表面结冰附着强度的降低效果具有不同程度的影响。根据项目组提出的“一种防结冰覆膜”[22]的除冰思路,本文将弹性冻结界面与冻结过程中的相变膨胀释能进行耦合,同时利用不同冻结介质的相变时间差异,破坏已冻结界面的稳定性。在耦合作用下,降低表面冰的粘附强度。同时利用试验方法验证相变释能进行除冰的可行性,并分析相变时差对冻结界面稳定性的影响机理,为开发新除冰技术提供试验数据和理论支撑。

1 材料与方法

试验测试冷表面冰的剥离强度来评价水溶液相变时差对附着强度的影响,通过剥离后界面的形状分析相变时差对附着强度的影响效应。试验测试前,界面需采用丙酮溶液擦干。

1.1 试样制备

待测试样的材料为聚甲基丙烯酸甲酯(polymethylmethacrylate,PMMA),采用激光雕刻加工直径30 mm、深3 mm的凹坑,如图1所示。

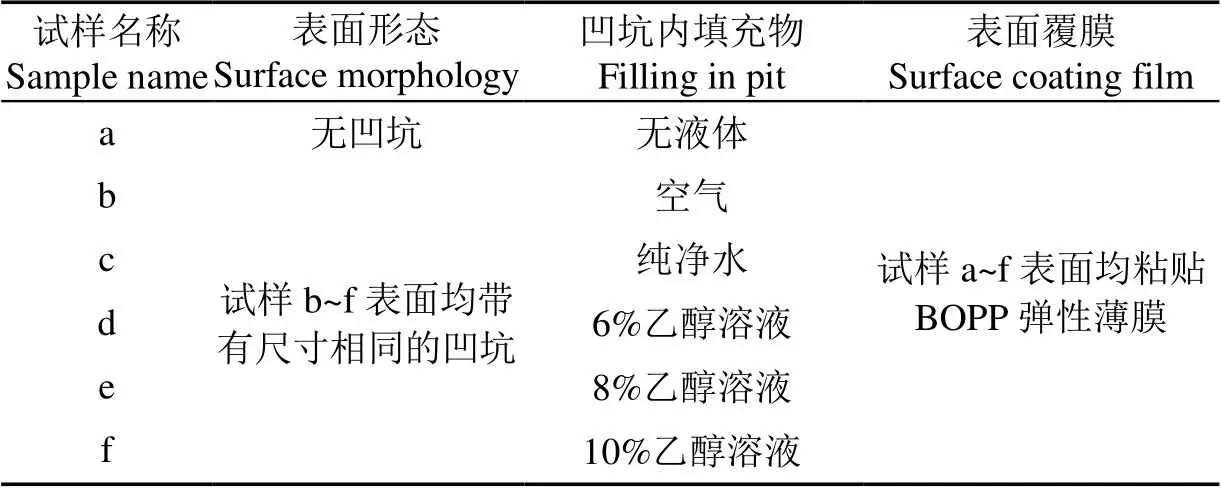

制备体积分数分别为6%、8%、10%的乙醇溶液,3种体积分数溶液的冰点分别为:−1.94、−2.6、−3.26 ℃。冻结介质填充凹坑后,表面粘贴双向拉伸聚丙烯薄膜(biaxially oriented polypropylene,BOPP),作为试样表面的弹性接触界面。制备6种待测试样,并分别命名为a、b、c、d、e、f,特征如表1所示。

表1 制备的6种PMMA试样特征

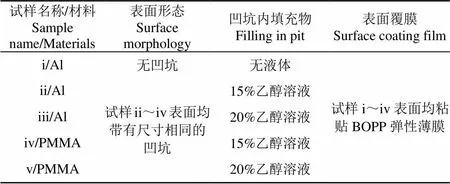

同时为验证该防除冰思路不受材料导热性、凹坑尺寸的影响,本文采用导热性差距较大的6061铝合金(237 W/(m·k))和PMMA(0.2 W/(m·k))作为试验材料,在材料表面制备直径30 mm、深3.5 mm的凹坑。凹坑内分别填充冰点为−6.8 、−10.4 ℃的15%、20%乙醇溶液,并分别命名为i~v,其具体特征如表2所示。

表2 制备的5种试样特征

1.2 试样制备

参考ASTM-D3528粘附剂测试标准及相关文献中结冰表面附着强度测试方法[23-26],搭建冰的切向附着强度测量装置,如图2所示。

试验中采用“水杯制冰法”,其中铝杯内径为32 mm、外径为39 mm、高度为41 mm,用水量为5 mL纯净水。采用东莞宏展仪器的LP-225U高低温环境箱控制−25 ℃的环境温度。制冷1 h以后,采用图2装置进行测量,每种试样测试5次。

2 结果与分析

2.1 结冰表面附着强度测试

2.1.1 试验数据

利用自制装置测试试样结冰的表面附着强度,并通过SPSS软件分析试验测试数据的显著性,如图3所示。

由试验结果可知,凹坑试样表面的附着强度明显低于光滑试样表面的附着强度。相对于光滑试样表面的附着强度平均值(169.81 kPa),带有凹坑的b~f试样表面附着强度分别降低了56%、100%、82%、65%、59%,其中试样b表面附着强度最大(75.51 kPa),试样c表面附着强度为0。d~f试样中,d试样(6%乙醇溶液)表面的附着强度最小,e和f试样表面的附着强度值相近。

相同试验条件下,分别测试i~v试样表面的附着强度,并利用SPSS软件分析试验测试结果的显著性,如图4所示。由试验数据可知,带有凹坑且填充低冰点乙醇溶液的ii~v试样表面的附着强度明显低于光滑的铝合金、PMMA试样表面的附着强度,其中无凹坑的铝合金试样i表面附着强度略小于PMMA试样a表面的附着强度。

相对于无凹坑铝合金试样i表面的附着强度,带有凹坑的ii、iii试样表面附着强度明显的降低了76.52%、74.91%。材质为PMMA的iv、v试样,其表面的凹坑尺寸及填充的介质不同于a~f试样表面的凹坑尺寸和填充的溶液,但其表面的附着强度值(分别为24.76 kPa、26.62 kPa)也显著减小,明显低于试样a、d、e、f表面的附着强度。ii、iii铝合金试样表面的附着强度略高于iv、v试样表面的附着强度。

Fig4. Surface adhesion strength of different thermal conductivity samples

综合图3、4的试验数据可见,试验材料采用导热性良好的铝合金和导热性差的PMMA作为冻粘基体,利用相变膨胀释能均明显的减小了试样表面的附着强度。基于防结冰模型中不同溶液的相变时间差,耦合利用凹坑内对表面附着强度的影响效果与模型中的凹坑尺寸无关。

2.1.2 结冰界面形态

图5为剥离后BOPP及结冰界面的表面形态,并参照剥离后的界面形态添加了BOPP膜变形示意图。表面未经任何处理的a试样,剥离后BOPP膜及冰的冻结界面未发生变化。具有凹坑且填充不同介质的b~f试样中,BOPP膜出现了不同程度的变形,如b试样的凹坑表面BOPP膜出现凹陷现象,c~f凹坑部位BOPP膜呈现膨胀凸起。剥离测试后,采用数显游标卡尺测量c~f表面膨胀凸起高度,平均值分别为3.34、1.25、1.13、1.04 mm,并且由图5可见,c试样(凹坑内填充纯净水)表面的膨胀凸起最为明显。

1.剥离后的BOPP膜 2.剥离后的结冰界面 3.BOPP膜 4.PMMA 5.冰

1.BOPP film after stripping 2.Freezing interface after stripping 3.BOPP film 4.PMMA 5.Ice

注:H、H、H、H、H分别为试样b~f表面BOPP覆膜的膨胀凸起高度。

Note:H,H,H,H,Hare the expansion deformation height of the BOPP film covered on the samples b-f, respectively.

图5 剥离后冻结界面的变形

Fig5. Deformation of freezing interface after stripping

2.2 结果分析与讨论

冷表面水滴的初始形态近似半球形,从冷表面开始冻结结冰,完成后顶端产生膨胀凸起、高度增加,形态类似于“桃”型[27-30],如图6所示。由于凹坑内水溶液的冰点,铝杯的导热系数大于PMMA的导热系数,延长了弹性覆膜上下水溶液与水之间的相变时间差。低温环境下,弹性覆膜表面上的水分首先开始冻结结冰,形成弹性冻结界面的同时,对凹坑内的水溶液形成弹性约束。随冻结时间的延长,凹坑内填充的液体开始相变结冰,水溶液短时间内释放相变膨胀能。

众所周知,水结冰产生会释放大量的能量,如冬季水箱内的水结冰引起水箱的破裂。防结冰模型中的凹坑只有表面粘贴的覆膜为弹性边界,释放的相变膨胀力只能加载于顶部的BOPP覆膜,引起冻结界面产生不规则的凹凸变形,破坏了试样表面的附着稳定性,如图7所示。

由试验结果及剥离后凹坑表面变形的BOPP覆膜可见,利用不同水溶液的相变时间差异以及膨胀释能,弹性冻结界面发生膨胀凸起,破坏结冰界面的连续性,降低表面的附着强度。试样凹坑内填充的低冰点溶液,水占据的比例越大,,相变膨胀能越大,对表面结冰附着强度的影响越大,如c试样(凹坑内填充纯净水,表面膨胀变形最大)表面附着强度为0 kPa。

实际环境中结冰的或结霜过程受诸多复杂因素的影响,不能仅仅是通过试验模拟冻结过程,需要结合理论分析开展研究,提出的防除冰方法仍需不断进行开发。该方法应用在工程领域中时,可采用诸多方式实现防结冰部件表面的相变时差,如表面粘贴容纳低冰点液体的覆膜,利用液体边界约束材料导热性差异等方式。

3 结 论

1)通过试验方法验证了采用弹性覆膜作为结冰界面,耦合冰自身产生的相变膨胀以及利用不同水溶液的相变时间差,破坏弹性冻结界面的稳定性,降低表面结冰附着强度的方法是可行的,并且防结冰模型中试样材料、凹坑尺寸对结冰附着强度的降低效果的影响较小。

2)试验中采用BOPP弹性覆膜作为冻结界面,利用不同水溶液的相变时差,将冻结过程中的相变膨胀能作为主动除冰动力,使弹性接触界面发生变形,与结冰界面之间产生间隙,破坏冻结界面的连续性,减小表面结冰附着强度。

3)冰在凹坑试样表面的附着强度明显(<0.05)低于在光滑试样表面的附着强度。相对于光滑试样a表面的附着强度,c试样(纯净水)对表面附着强度为0 kPa;凹坑填充不同体积分数乙醇溶液的试样中,6%乙醇体积分数表面的附着强度降低了82%。

由于显微观察、计算机模拟等技术手段的限制,目前本文仅停留在理论设想及采用工程材料进行试验验证的阶段。本文中采用的防、除冰模型对试样材料表面附着强度的降低作用显著,相对于常规除冰方式,该模型制备成本低,并为除冰方法的开发、升级提供了一种新的技术思路。

[1] 赵松松,杨昭,陈爱强,等. 微型冷库复合加热循环除霜系统的研制与试验[J]. 农业工程学报,2015,31(2):306-311.

Zhao Songsong, Yang Zhao, Chen Aiqiang, et al. Development and experiment about recombination heating circulation defrosting system of mini cold storage house[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(2): 306-311. (in Chinese with English abstract)

[2] 蔡琰,余美丽,刑宏杰,等. 低温预贮处理对冷藏水蜜桃冷害和品质的影响[J]. 农业工程学报,2010,26(6):334-338.

Cai Yan, Yu Meili, Xing Hongjie, et al. Effects of low temperature conditioning on chilling injury and quality of cold-stored juicy peach fruit[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(6): 334-338. (in Chinese with English abstract)

[3] 申江,王晓东,王素英,等. 冰温技术应用实验研究[J].制冷学报,2009,30(4):40-45.

Shen Jiang, Wang Xiaodong, Wang Suying, et al. Experimental study on application of hyo-on Technology [J]. Journal of Refrigeration, 2009, 30(4): 40-45. (in Chinese with English abstract)

[4] 郑传祥,卓传敏. 大型速冻设备不同结构蒸发器的传热性能比较[J]. 农业工程学报,2006,22(8):111-115.

Zheng Chuanxiang, Zhuo Chuanmin. Comparative research on the heat transfer efficiency of evaporators with different structures used in a large quick-freeze plant [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2006, 22(8): 111-115. (in Chinese with English abstract)

[5] 刘晓辉,鲁墨森,王淑贞,等. 小型冷库多效冷凝制冷机组的能耗及节能分析[J]. 农业工程学报,2010,26(6):103-108. Liu Xiaohui, Lu Mosen, Wang Shuzhen, et al. Analysis of energy consumption and energy conservation of multi-effect condensed refrigeration unit in small cold storage[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(6): 103-108. (in Chinese with English abstract)

[6] 刘耀民,刘中良,黄玲艳,等. 结霜对微型冷库性能影响的实验研究[J]. 工程热物理学报,2010,31(10):1755-1758.

Liu Yaomin, Liu Zhongliang, Huang Lingyan, et al. An experimental study of the influences of frost deposition on the performance of a small [J]. Journal of Engineering Thermophysics, 2010, 31(10): 1755-11758. (in Chinese with English abstract)

[7] 臧润清,陈春培,刘旭升,等. 冷却物冷藏间冷风机的空气除霜实验研究[J]. 低温与超导,2012,40(1):44-46.

Zang Runqing, Chen Chunpei, Liu Xusheng, et al. Experimental investigation on air defrosting of air cooler in cold storage[J]. Cryogenics & Superconductivity, 2012, 40(1): 44-46. (in Chinese with English abstract)

[8] Melo C, Knabben F T, Pereira P V. An experimental study on defrost heaters applied to frost-free household refrigerators[J]. Applied Thermal Engineering, 2013, 51(1): 239-245.

[9] 程建杰,陈汝东. 制冷装置的除霜研究[J]. 流体机械,2004,32(7):64-66.

Cheng Jianjie, Chen Rudong. Study on defrosting of refrigerating plant[J]. Fluid Machinery, 2004, 32(7): 64-66. (in Chinese with English abstract)

[10] 闫勤劳,朱琳,张密娥,等. 冷风机超声波除霜技术试验研究[J]. 农业机械学报,2003,34(4):83-85.

Yan Qinlao, Zhu Lin, Zhang Mie, et al. Study on ultrasonic defrost technology of refrigeration fan[J]. Transactions of the Chinese Society for Agricultural Machinery, 2003, 34(4): 83-85. (in Chinese with English abstract)

[11] 李辉,赵蕴慧,袁晓燕. 抗结冰涂层:从表面化学到功能化表面[J]. 化学进展,2012,24(11):2087-2096.

Li Hui, Zhao Yunhui, Yuan Xiaoyan. Anti-icing coatings: From surface chemistry to functional surfaces[J]. Progress in Chemistry, 2012, 24(11): 2087-2096. (in Chinese with English abstract)

[12] Lasse Makkonen. Ice adhesion-theory, measurements and countermeasures [J]. Journal of Adhesion Science and Technology, 2012(26): 413-445.

[13] Tang Yongqiang, Zhang Qinghua, Zhan Xiaoli, et al. Superhydrophobic and anti-icing properties at overcooled temperature of a fluorinated hybrid surface prepared via a sol–gel process[J]. Soft Matter, 2015(11): 4540-4550.

[14] Editorial. Anti-icing and deicing techniques[J]. Cold Regions Science and Technology, 2011(65): 1-4.

[15] 刘孟凯,王长德,冯晓波. 长距离控制渠系结冰期的水力响应分析[J]. 农业工程学报,2011,27(2):20-27.

Liu Mengkai, Wang Changde, Feng Xiaobo. Analysis on the hydraulic response of long distance canal control system during ice period [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(2): 20-27. (in Chinese with English abstract)

[16] 刘月,王正中,王羿. 考虑水分迁移及相变对温度场影响的渠道冻胀模型[J]. 农业工程学报,2016,32(17):83-88.

Liu Yue, Wang Zhengzhong, Wang Yi. Frost heave model of canal considering influence of moisture migration and phase transformation on temperature field [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(17): 83-88. (in Chinese with English abstract)

[17] 陈武,刘德仁,董元宏,等. 寒区封闭引水渡槽中水温变化预测分析[J]. 农业工程学报,2012,28(4):69-75.

Chen Wu, Liu Deren, Dong Yuanhong, et al. Prediction analysis on water temperature in closed aqueduct in cold regions[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(4): 69-75. (in Chinese with English abstract)

[18] 周庭正,赵新,黄炎. 南水北调中线工程渡槽结构冰盖温度膨胀力研究[J]. 南水北调与水利科技,2012,10(3):7-11.

Zhou Tingzheng, Zhao Xin, Huang Yan. Ice thermal expansive pressure acting on aqueduct structure of middle route scheme of SNWDP[J]. South-to-North Water Diversion and Water Science &Technology, 2012, 10(3): 7-11. (in Chinese with English abstract)

[19] 徐国宾,李大冉,黄炎,等. 南水北调中线输水工程若干冰力学问题试验研究[J]. 水科学进展,2010,21(6):808-815.

Xu Guobin, Li Daran, Huang Yan, et al. Laboratory study of problem in ice mechanics encountered in the middle route of South-to-North Water Transfer Project[J]. Advances in Water Science, 2010, 21(6): 808-815. (in Chinese with English abstract)

[20] 曹敏,陈廷坤,丛茜,等. 表面形态对结冰附着强度的影响[J]. 吉林大学学报:工学版,2013,43(5):1314-1319.

Cao Min, Chen Tingkun, Cong Qian, et al. Influence of PMMA surface morphology on ice adhesion strength[J]. Journal of Jilin University: Engineering and Technology Edition, 2013, 43(5): 1314-1319. (in Chinese with English abstract)

[21] 吉林大学. 一种降低材料表面结冰附着强度的方法:2013100115005.7 [P]. 2013-05-01.

[22] 吉林大学. 一种防结冰覆膜:201410456599.X[P]. 2014-12-10.

[23] Standard test and method for strength properties of double lap shear adhesive joints by tension loading: ASTM D3528-1996[S].

[24] 刘国敏,李建桥,田喜梅,等. 蚯蚓非光滑体表减粘降阻试验[J]. 农业机械学报,2008,39(9):138-143.

Liu Guomin, Li Jianqiao, Tian Ximei, et al. Experiment on reduction of soil adhesion force and sliding resistance of earthworm non-smooth surface[J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(9): 138-143. (in Chinese with English abstract)

[25] 丛茜,杨晓东,柴雄梁,等. 仿生柔性技术减少煤粘附的试验[J]. 农业机械学报,2007,38(3):209-210.

Cong Qian, Yang Xiaodong, Chai Xiongliang, et al. Experiment on reducing coal adhesion by bionic flexible technology[J]. Transactions of the Chinese Society for Agricultural Machinery, 2007, 38(3): 209-210. (in Chinese with English abstract)

[26] Jellinek H H G, Kacbi H, Kittaka S, et al. Ice releasing block-copolymer coatings[J]. Colloid & Polymer Sci, 1978, 256: 544-551.

[27] Snoeijer J H, Philippe B. Pointy ice-drops: How water freezes into a singular shape[J]. American Journal of Physics, 2012, 80(9): 764-771.

[28] Wang J T, Liu Z L, Gou Y J, et al. Deformation of freezing water droplets on a cold copper surfaces[J]. Science in China(Series E: Information Sciences), 2006, 49(5): 590-600.

[29] 金敬福,韩丽曼,曹敏,等. 水滴结冰相变体积膨胀规律[J].吉林大学学报:工学版,2016,46(5):1546-1551.

Jin Jingfu, Han Liman, Cao Min, et al. Volume expansion rule of water droplets during freezing process[J]. Journal of Jilin University: Engineering and Technology Edition, 2016, 46(5): 1546-1551. (in Chinese with English abstract)

[30] Gaurav Chaudhary, Ri Li. Freezing of water droplets on solid surfaces: An experimental and numerical study[J]. Experimental Thermal and Fluid Science, 2014(57): 86-93.

Active anti-icing method for agricultural product refrigerated equipment based on phase change energy release

Cong Qian1,2, Chen Tingkun1, Li Yang1, Sun Chengbin1, Jin Jingfu1※

(1.130022,;2.130022,)

The application of refrigeration in agricultural and sideline products preservation is getting more and more extensive. However, the surface of refrigeration equipment, such as evaporator, condenser and chiller, is prone to freeze, and ice and frost are easy to occur, which seriously affect the operation efficiency of refrigeration equipment and increase the cost. The formation of ice must be accompanied by the phase expansion. So, why not use the phase transition expansion as the deicing power, and make the refrigeration equipment surface own active control ability of ice? During the test, the polymethyl methacrylate (PMMA) with pit and the aluminum alloy were used as the matrix materials, which were bonded with the biaxially oriented polypropylene (BOPP) elastic film as the freezing interface. The pit of the PMMA was filled with gas or aqueous solution with different freezing point. The test adopted the cup method to make the ice under -25 ℃ temperature. With the same cup, the test directly adopted the measured peeling force as the icing adhesion strength. The experimental results showed that the influence of the freezing medium with different freezing point on the icing adhesion strength was different. Compared with icing adhesion strength on the smooth specimen surface 169.81 kPa, the icing adhesion strength of the sample filled with the pure water in the pit was 0 kPa, decreased by 100%. And the icing adhesion strength of the sample filled with 6% ethanol solution was declined by 82% compared with the smooth specimen. Compared with the aluminum alloy sample surface, the icing adhesion strength of the sample filled with the solution of low freezing point was reduced by 76.52%. The icing adhesion strength of the sample filled with 6% ethanol solution was the smallest among the samples with the pits filled with alcohol solution. After the test, it was found that the expansion bump with different height occurred on the surface of the BOPP film on the surface of the pits, and the maximum height (3.34 mm) was on the surface of the specimen filled with pure water, followed by the sample filled with 6%, 8% and 10% ethanol solution, whose swell bump heights were 1.25, 1.13 and 1.04 mm, respectively. The results showed that the icing adhesion strength would be reduced by the phase expansion energy owing to the time difference of phase change. What was more, the influence of sample material, size of pit and filled solution on the icing adhesion strength decrease was very small. During the test, BOPP elastic film was used as the icing interface, and the rigid freezing interface under normal conditions was transformed into a flexible freezing interface. Due to the different thermal conductivity, the moisture on the film was first frozen, and the water solution in the pit formed the boundary constraints. After the aqueous solution was frozen into ice, the swell was generated and the energy was released. The energy played a role on the BOPP elastic film, and it destroyed the contact stability of the interface and reduced the icing adhesion strength. Therefore, it is feasible to destroy the contact stability of the elastic freezing interface and reduce the surface icing strength by the phase transition expansion caused by the coupled effect of ice itself and time difference of the phase transition using different aqueous solutions. The experimental results could provide a reference for studying and developing of anti-icing during agricultural product refrigeration field.

refrigeration; freezing; interface; elastic film; phase transition; expansion; adhesion strength

10.11975/j.issn.1002-6819.2017.09.036

TB131

A

1002-6819(2017)-09-0276-06

2016-11-20

2017-04-10

吉林省教育厅“十二五”科学研究项目(2015-473,2015-417)和吉林大学研究生创新基金项目(2016167)联合资助。

丛 茜,女(汉族),吉林长春人,教授,博士,博士生导师,主要从事工程仿生学及低温防冻粘技术。长春吉林大学生物与农业工程学院 130022。Email: congqian@jlu.edu.cn

金敬福,男(朝鲜族),吉林长春人,副教授,博士,主要从事工程仿生学及表面与界面效应分析。长春吉林大学生物与农业工程学院 130022。Email: jinjingfu@jlu.edu.cn

丛 茜,陈廷坤,李 杨,孙成彬,金敬福. 利用相变释能的农产品冷藏设备主动防除冰方法[J]. 农业工程学报,2017,33(9):276-281. doi:10.11975/j.issn.1002-6819.2017.09.036 http://www.tcsae.org

Cong Qian, Chen Tingkun, Li Yang, Sun Chengbin, Jin Jingfu. Active anti-icing method for agricultural product refrigerated equipment based on phase change energy release[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(9): 276-281. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.09.036 http://www.tcsae.org