Analysis and Numerical Simulation for Tunnelling Through Coal Seam Assisted by Water Jet

Dengfeng Su,Yong Kang,,∗,Xiaochuan Wang,andan Zheng,Dongyang Li,Binyuan Yan,Fuwen Yan

Analysis and Numerical Simulation for Tunnelling Through Coal Seam Assisted by Water Jet

Dengfeng Su1,Yong Kang1,2,∗,Xiaochuan Wang2,andan Zheng1,Dongyang Li1,Binyuan Yan1,Fuwen Yan1

Tunnel though coal seam is one of the most difficult tunnels since its risk of coal and gas outburst and the complex geological conditions.According to the directional cutting of water jet and the characteristic of the coal seam and rock mass,this paper presents a new method of tunnelling though coal seam assisted by water jet slotting,which can be divided into improving permeability of coal seam and directional cracking in the rock mass.The mechanism of improving permeability of coal seam was stated,and the crack criterion of rock during blasting was established based on fracture theory.Then,the evolution law of pressure wave and the crack propagation were simulated by FEM software ANSYS/LS-DYNA,the results show that the shape of the crush zone formed by stress wave is different between the normal borehole blasting and the slotted borehole blasting,and the tension is the main factor which let crack propagation.What is more,for normal borehole blasting,the tension concentration occurred along the direction of 45 degrees and let crack expand,while for slotted borehole blasting the tension concentration occurred along the direction of 0 degrees and 90 degrees,and the maximum tension along the direction of 0 degrees is larger than the maximum tension along the direction of 90 degrees,and the main crack expand along the direction of 0 degrees,which prove that the existence of the slot play a good role of orientation for directional cracking.

Tunnel though coal seam;Directional cracking;Water jet slotting;ANSYS/LS-DYNA.

1 Introduction

China western is known as a mountainous country which is rich in natural resources.With the deeply implementation of the western exploring strategy,there are more and more infrastructures have been put into the construction.Among these key projects,the number of the mountain tunnel through the coal seam is roaming.These tunnels,as one of the most complicated tunnels,have two typical characteristics.One is the risk of the coal and gas outburst when cutting through coal seam[Lin,Yan,and Zhu(2015);Tong,Liu,and Yu(2013)],the other is the inherent cracks and joints exist in the rock mass[Li,Jin,and Lu(2002);Ye,Huo,and Chang(2011);Kang,Yang,and He(2010);Li,Xie,and Wu(2013)].So,to get safe uncovering coal seam,the risk of coal and gas outburst must be eliminated firstly,and then cutting through coal seam,finally,excavation though the rock stratum.

To eliminate the risk of coal and gas outburst,common measures include concussion blasting,forepoling,multiple row drilling and hydraulic flushing[Zheng,Zhang,and Li(2000);Jiang,Liu,and Zhang(2005);Rafael and Cristobal(2010);Wang(2010)].However,the practice shows that these measures are usually timeconsuming and have a limited effect.On the other hand,smooth blasting and energy focusing blasting are the common measures to achieve the good blasting effect.As the most common measure of mountain tunnel excavation,smooth blasting has been widely applied[Xu and Zong(2000);Zong,2002;Kaushik(2012);Li,Xu,and Dong(2012);Zhang(2013)],but there are also many problems while tunnelling through the coal seam because of complex geological conditions.Surrounding rock outside the excavation area is often destructed upon the action of blasting vibration,which is leading to uneven contour and unexpected fractures,inevitably causing great damage to surrounding rock and influencing the stability of the tunnel[Sanchidrián(2008);Yong and Shen(2006);Nateghi,Kiany,and Gholipouri(2009)].

Figure 1:The typical uneven contour of tunneling.

Meanwhile,energy focusing effect,originated from energy adjusting and focusing,is a special form of explosive brisance,which just changes the brisance in one direction to a fierce level without changing the total energy of the kits.So,many scholars began using energy focusing effect theory to enhance the effect of directional control blasting,mainly there were two ways.One is the transformation of dynamite.Firstly a fusion slot is designed and produced at itself lateral symmetrical points,and experiment is done to find the appropriate size,then explosive slot will produce the phenomenon of energy concentration and make two adjacent boreholes through along this direction,and the blasting force in the other direction will be reduced effectively[He,Cao,and Shan(2003);Sanchidrián,López,and Segarra(2008);Liu,Liu,and Gao(2014)].This explosives roll can be used in the roadway trim holes blasting to form a smooth contour line,reduce the over-excavation in the vertical direction and improve the quality of tunnel section shape.But many technical problems have been encountered such as difficult to control charge orientation and too much time consuming.The other method is mechanical grooving between two adjacent boreholes and explosives,which can also produce energy focusing effect to improve the quality of smooth blasting[Xiao,Guo,and Zhang(1998);Zhang,Xiao,and Pu(2006);Cho,Nakamura,and Mohanty(2008);Mojtaba,Kamran,and Mostafa(2011);BRILL,Me-Bar,and Sadot(2012);Lu,Ming,and Xiang(2012);Yang,Zhang,and Yang(2013)].However,mechanical grooving is known as time-consuming and no safe.

So,to achieve safe and fast tunnelling though coal seam,according to the characteristic of the coal seam and rock mass and the directional cutting technology of water jet[Sheng(1998);Li,Lu,and Xiang(2007)],this paper presents a new method of tunneling through coal seam assisted by water jet.Certainly,it will be a promising method of tunneling.

2 Mechanism of safe and fast tunnelling through coal seam assisted by water jet slotting

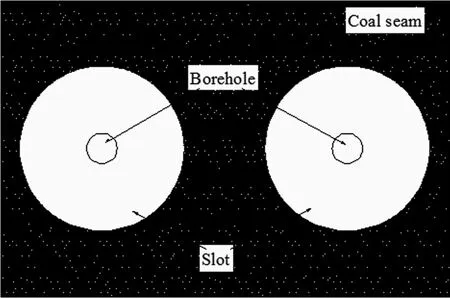

The procedure of this method is improving the permeability of the coal seam and achieves safe and quick tunneling by water jet slotting,which can be divide into two parts:one is slotting along the radial direction of the borehole in the coal seam by water jet to improve the permeability of the coal seam and eliminate the risk of coal and gas outburst fast and safe,another is slotting in the rock along the axial of the borehole to achieve the safe and quick driving,as shown in Figure 2.

Figure 2:Technical sketch of safe and fast tunnelling though coal seam.

Firstly,to eliminate the risk of coal and gas outburst,drilling the borehole though coal seam,then slotting along the radial direction of the borehole by water jet,as shown in Figure 3.The radius of the slot,confirmed by the experimental,can reach 1m.Slotting in the coal seam will form the slot and promote initial microfracture of coal propagation in the coal seam,which not only create the gas migration channel,but also relieve the pressure on the coal and improve the permeability,what is more,the sonic vibration of the water jet will further improve the permeability and promote gas desorption,which improve the gas drainage rate[Li,Lu,and Zhao(2008);Li and Zhou(2010);Lu,Liu,and Kang(2010);Lu,Song,and Liu(2011)].So as to quickly eliminate the risk of coal and gas outburst,and uncovering coal seam safe and fast.

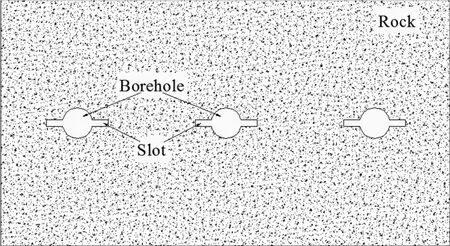

After uncovering the coal seam safely,drilling peripheral boreholes up to the specified depth along the tunnel outline in the rock,and then slotting the rock along the axial of the borehole by water jet.The depth of the slot depends mainly on the speed of the nozzle,so that a certain depth(usually 10~20 mm)two-way pre-cut slot can be formed in the borehole along the tunnel outline,as shown in Figure 4.

Figure 3:Profile of radial slotting in coal seam.

Figure 4:Profile of axial cutting in rock.

3 Analysis of the crack propagation under the blasting load

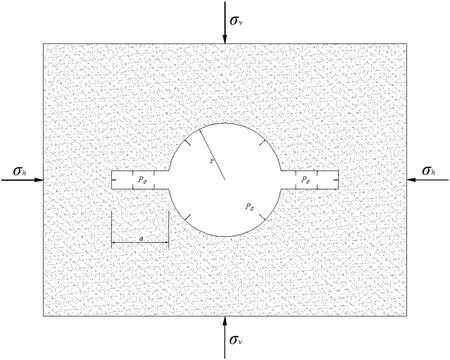

Assuming that boreholes wall was not crushed after blasting,the typical stress diagram of the borehole under the action of the quasi-static pressure was shown in Figure 5.Based on fracture mechanics,the instability of fracture propagation belongs to the category of Mode I crack problem,and according to the Irwin fracture mechanics theory[Atkinson(1987);Li,He,and Yin(2010)],for model 1 crack,the fracture will propagate when the stress intensity factorKIreaches critical valueKIC,otherwise it will stop.

Figure 5:Mechanical model of the borehole slotted.

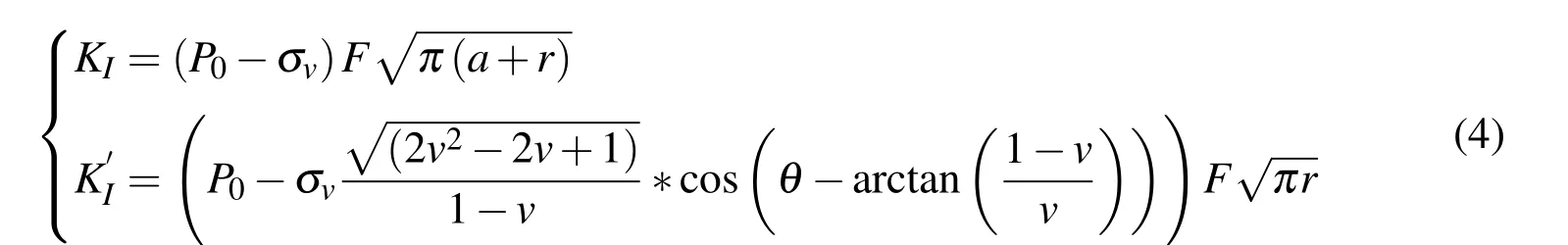

Where KIis the stress intensity factor of Mode I,and KICis the critical stress intensity factor(fracture toughness).KIand KICis calculated as follows:

Where P0is the quasi-static static pressure of explosion gas,σvis the vertical stress,v is the Poisson ratio,θ is the angle between σvand P0,F is the correction factor of stress intensity factor,which is a function of the hole radius and length of crack,r is radius of the borehole,and a is the length of the slot.

Combining Eqs.3–4 with Eq.2,the quasi-static static pressure of explosion gas of crack propagation can be expressed as:

4 Numerical simulation

To research the evolution law of pressure wave during blasting,a FEM software ANSYS/LS-DYNA was used to simulate the propagation of the pressure wave and the growth of crack in normal borehole,single-slotted borehole,dual–normal borehole and dual–slotted borehole.

4.1 Simulation model and parameters

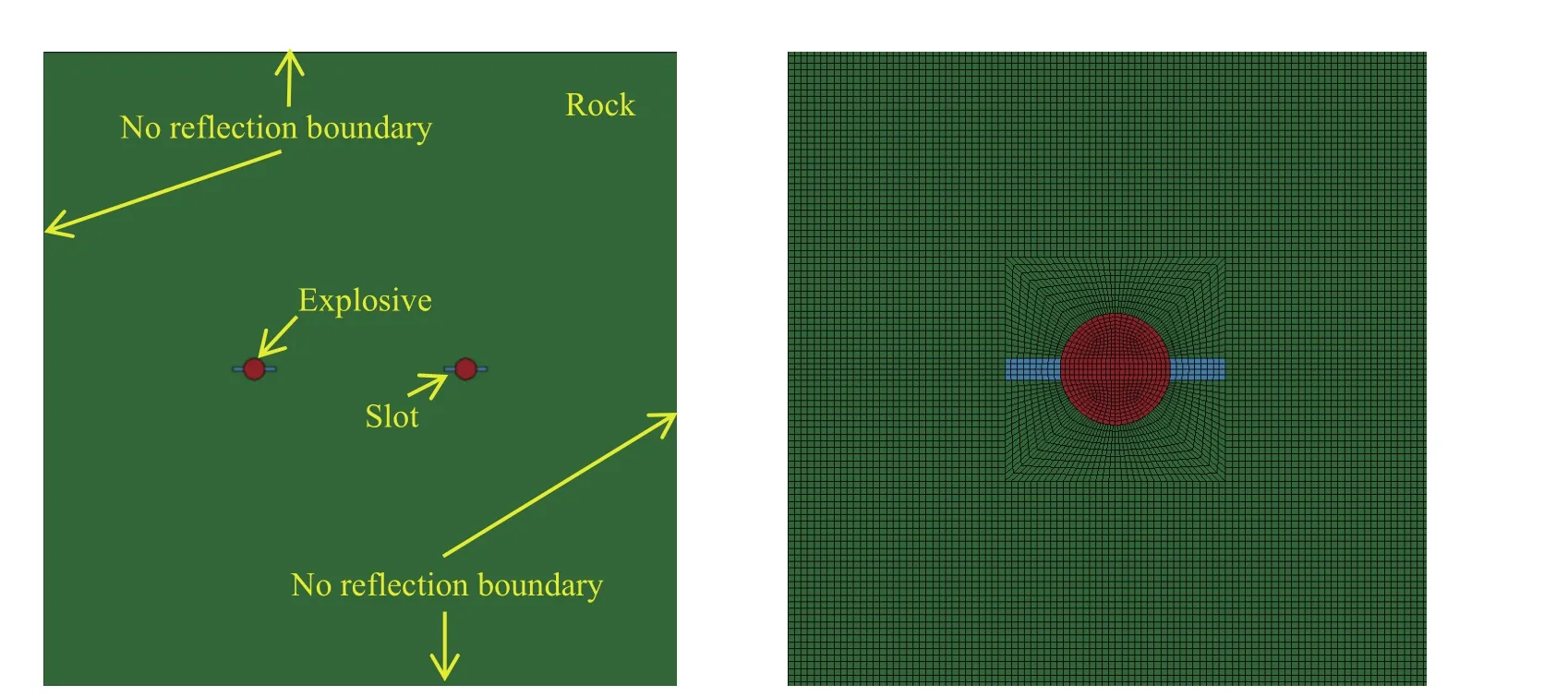

In this paper,quasi-2-d model was applied,the size of the rock is 150 cm×150 cm×3 cm,the diameter of borehole is 5 cm,and the size of the jet slot is 4 cm×0.3 cm×0.3 cm,and in the dual-slot borehole blasting,the distance between the two boreholes is 50 cm.the unit system is g-cm-µs,the model for dual-slot borehole and mesh distribution was shown as Figure6,and the parameters of explosive,rock,air and its state equation was shown in Table.1.

Figure 6:Numerical simulation model of dual-slotted borehole.

To simulate the dynamite explosion,keywords of MAT_HIGH_EXPLOSIVE_BURN and the state equation of JWL were adopted,in which,the pressure of the detonation products of the high explosive was defined as follows:

WhereP0is the pressure produced by the detonation products of high explosive,whereω,A,B,R1andR2are user defined input parameters,Vis relative volume,andEis the internal energy per initial volume.

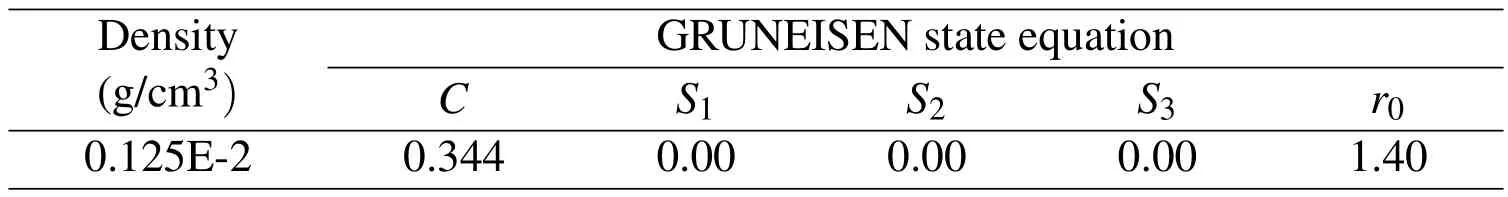

Table 1:Keywords of material type and its state equation.

Table 2:Parameters of the explosive and its state equation.

Table 3:Parameters of air and its state equation.

On the other hand,in order to avoid the large deformation problem of rock,fluidsolid coupling algorithm was adopted for the analysis of the explosive detonation.In which,ALE algorithm is used for explosive and air,and Lagrange algorithm for rock,meanwhile,meshes of explosive and the air were joined with common nodes,Then the fluid-solid coupling was defined between the meshes of the explosive,air and rock by the keyword of CONSTRAINED_LAGRANGE_IN_SOLID[Shi,Li,and Zhang(2005);Bai(2005)].According to the characteristics of high speed deformation of the material in blasting process,the time step of the simulation is 0.67.

4.2 Simulation results analysis

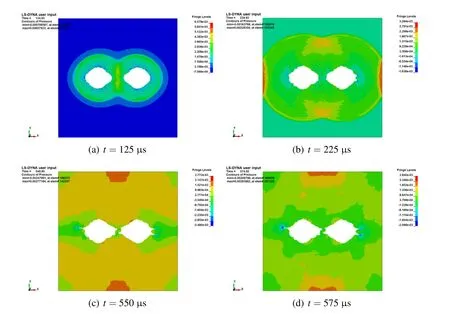

To describe the characteristic of pressure wave while it spread in rock of every condition,the post-processing software(LS-PREPOST)was used to draw graph,as shown below.

Figure 9:Monitoring points arrangement.

Figure 10:Pressure history curve of monitoring point at 0 degrees direction.

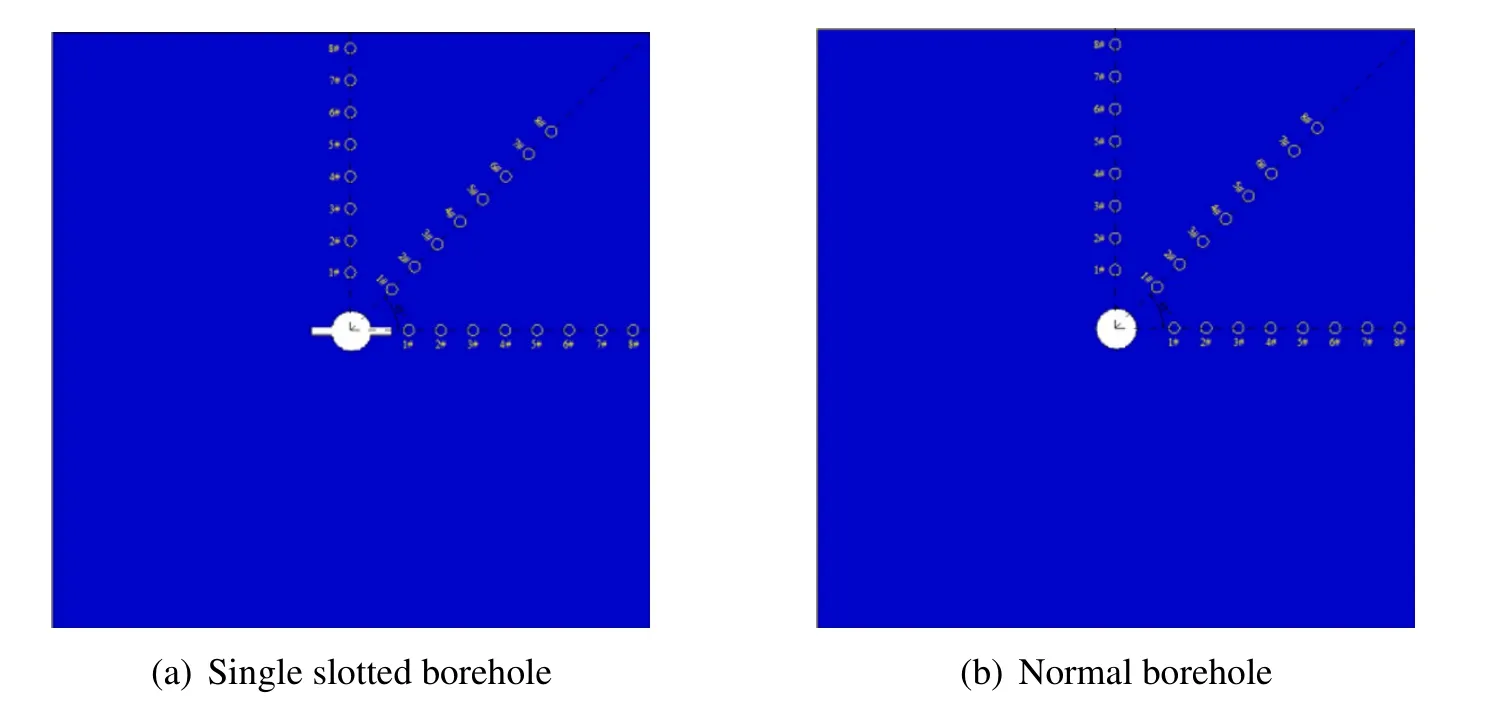

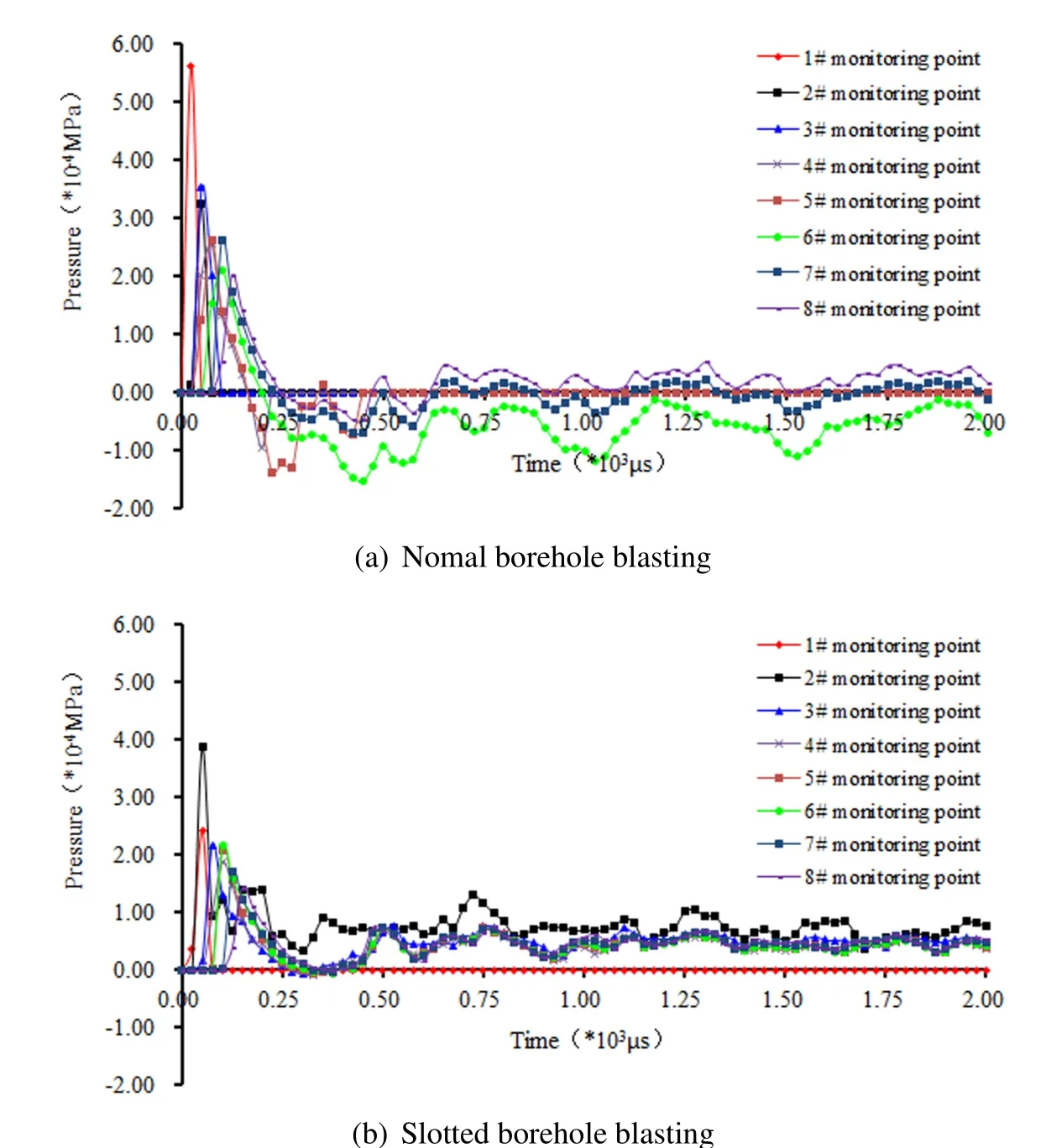

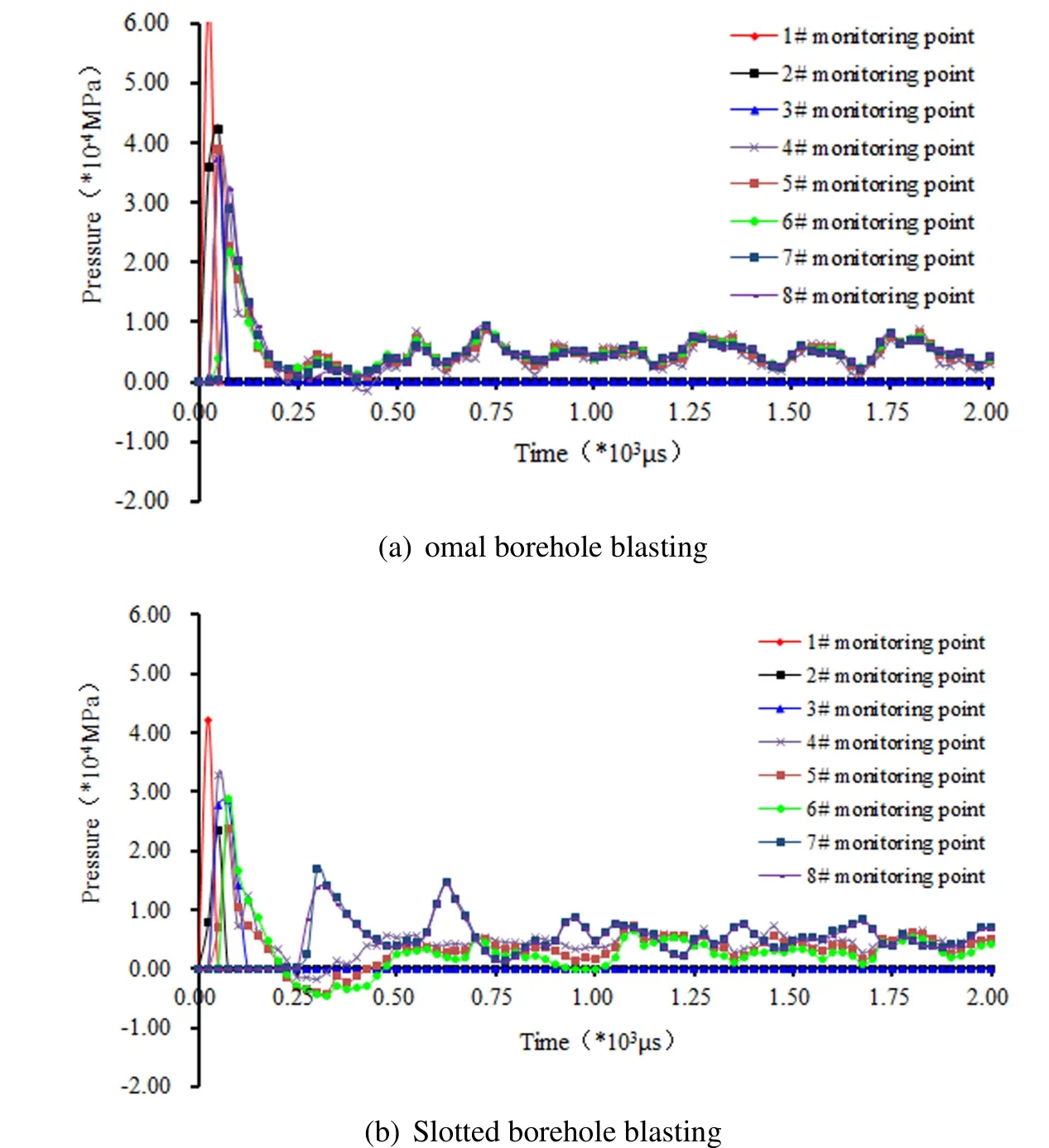

From Figures 7 and 8,the shape of the pressure wave is different between the single normal blasting and the single slot blasting at the beginning of the explosion.In the normal blasting,the stress wave effect evenly on the borehole wall and form the broken zone,the shape of the pressure wave is always a circle,and then the tensile stress concentration occurred at the 45 angle.However,for the slotted borehole blasting,the shape of the pressure wave likes an ellipse,and the tensile stress concentration is occurred at the 0 degrees direction and 90 degrees direction at the time of 200µs,and the final crack formed at the 0 degrees direction,which prove that the existence of the slot changes the shape of the pressure wave and the form of the broken zone,and also change the direction of the final main crack.

In addition,to further understand the distribution of the pressure during blasting,the pressure history curve was draw bellow,and the location of monitoring points was shown in Figure 9.

Figure 11:Pressure history curve of monitoring point at 45 degrees direction.

By comparing Figures 10–12,for normal borehole blasting,the maximum pressure of monitoring points is larger than the maximum pressure of monitoring points for slotted borehole blasting,but the tension concentration occurred at 45 degrees direction,and the maximum tension of the monitoring points is also larger than the maximum tension of monitoring points for slotted borehole blasting at the same location.

Meanwhile,for slotted borehole blasting,the tension concentration is occurred at 0 degrees direction and 90 degrees direction,and the maximum tension of the monitoring points at 0 degrees is nearly twice as large as maximal tension at 90 degrees direction.What is more,the action time of tension at 0 degrees direction is also longer than the action time of tension at 90 degrees direction,which proves that the explosion energy distribution is changed by the slot.

Figure 12:Pressure history curve of monitoring point at 90 degrees direction.

Figure 13:Propagation graph on pressure wave and crack in normal borehole blasting.

Figure 14:Propagation graph on pressure wave and crack in dual-slotted borehole blasting.

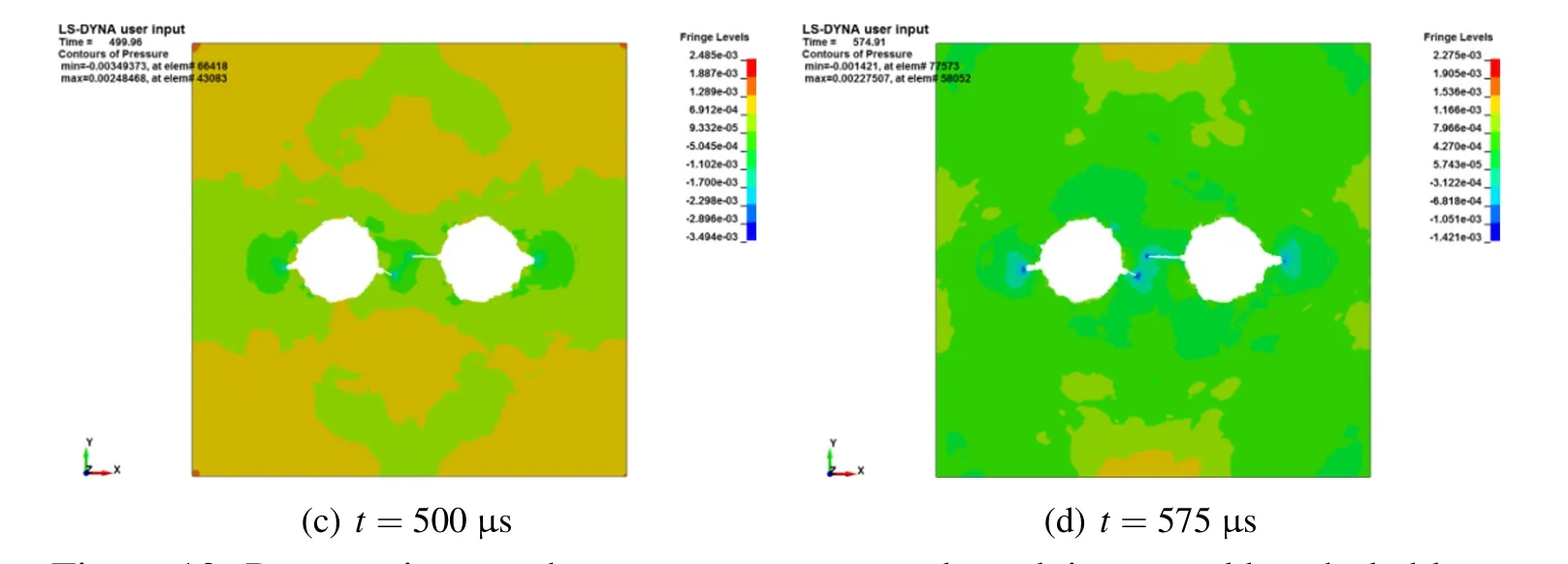

According to the simulation results,the crushing zone during explosion in rock is quite different between normal borehole blasting and slotted borehole blasting,for the normal borehole blasting,the shape of the crushing zone like a circle,while the shape of the crushing zone likes an ellipse in the slotted borehole blasting.Meanwhile,the explosion fracture of the borehole in the normal blasting expand along defiled line direction between the adjacent boreholes,and the fracture is very small and singleness.However,for the slotted borehole blasting,the shape of the crushing zone like an ellipse,the fracture expand along the direction of the slot,and then the adjacent slotted borehole connected with the development of the explosion fracture,which prove that the slot play a good role of orient let the explosion energy gather at the direction of slot.

5 Conclusions

Tunnel though coal seam,as one of the most complicated tunnels,has two typical characteristics,one is the risk of coal and gas outburst when cutting through coal seam,the other is the inherent cracks and joints exist in the rock mass.According to the character of the soft rock and the unique properties of water jet,the method of safe and fast tunnelling through coal seam assisted by water jet was put forward.Then,the mechanism for the technology of the safe and fast tunnelling through coal seam assisted by water jet was analysis,and the model of crack propagation is established based on the fracture mechanics,the stress condition for rock cracking on the different place was worked out.

What is more,the evolution law of pressure wave and the crack propagation were simulated,the results show that,the shape of the crush zone formed by stress wave is different between the normal borehole blasting and the slotted borehole blasting,which affect the distribution of stress,and the tension is the main factor which let main crack propagation.For normal borehole blasting,the tension concentrations occurred and crack propagation along the direction of 45 degrees,while for slotted borehole blasting,the tension concentration occurred along the direction of 0 degrees and 90 degrees,and the main crack also expand along the direction of 0 degrees.

Last but not least,the method of safe and fast tunnelling through the coal seam assisted by water jet will be an efficient approach in the tunnelling engineering.

Acknowledgement:Financial support for this work,provided by the National Basic Research of China(2014CB239203),the National Natural Science Foundation of China(51474158),and also supported by Program for New Century Excellent Talents in University(NCET-12-0424).The authors would like to thank the State Key Laboratory of Coal Mine Disaster Dynamics and Control and Hubei Key Laboratory of Waterjet Theory&New Technology.

Atkinson,B.K.(1987):Fracture Mechanics of Rock.Academic Press,London.Brill,A.;Me-Bar,Y.;Sadot,O.(2012):A method for measuring the impulse on structural foundations due to a blast wave.International Journal of Impact Engineering.vol.49,no.0,pp.214–221.

Bai,J.Z.(2005):Basis theoretical and instance analysis of LS-DYNA3D.Science Press.Beijing.

Cho,S.H.;Nakamura,Y.;Mohanty.B.(2008):Numerical study of fracture plane control in laboratory-scale blasting.Engineering Fracture Mechanics.vol.75,no.13,pp.398–3966.

Donzé,F.V.;Bouchez,J.;Magnier,S.A.(1997):Modeling fractures in rock blasting.International Journal of Rock Mechanics and Mining.vol.34,no.8,pp.1116–1153.

He,M.C.;Cao,W.F.;Shan,R.L.(2003):New blasting technology bilateral cumulative tensile explosion.Chinese Journal of Rock Mechanics and Engineering.vol.22,no.12,pp.2047–2051.

Jiang,D.Y.;Liu,C.;Zhang,A.Y.(2005):Technologies of whole cutting through coal seam and preventing collapse in highway tunnels Technologies of whole cutting through coal seam and preventing collapse in highway tunnels.Rock and Soil Mechanics.,vol.26,no.06,pp.906–909.

Kang,Y.;Yang,C.H.;He,Z.(2010):Stability analysis of surrounding rock structure of large—span tunnel passing through coal seams.Rock and Soil Mechanics.,vol.31,no.S1,pp.266–270.

Kaushik,D.;Murthy,V.M.S.R.(2012):Prediction of blast-induced overbreak from uncontrolled burn-cut blasting in tunnels driven through medium rock class.Tunnelling and Underground Space Technology.vol.28,no.0,pp.49–56.

Lin,B.Q.;Yan,F.Z.;Zhu,C.J.(2015):Cross-borehole hydraulic slotting technique for preventing and controlling coal and gas outbursts during coal roadway excavation.Journal of Natural Gas Science and Engineering.vol.26:pp.518–525.

Li,X.H.;Jin,X.G.;Lu,Y.Y.(2002):Study on deformation character of surrounding rock masses and numerical modeling of Xishanping tunnel through coal and working out area.Chinese Journal of Rock Mechanics and Engineering.,vol.21,no.05,pp.667–670.

Li,S.J.;Xie,Y.L.;Wu,D.Z.(2013):Research on mechanism of large deformation and countermeasures of surrounding rocks of tunnel through coal strata.Chinese Journal of Rock Mechanics and Engineering.,vol.32,no.S2,pp.3501–3508.

Li,Q.Y.;Xu,M.;Dong,L.J.(2012):Projection pursuit regression model and its application for predicting smooth blasting effect parameters.Journal of Central South University(Science and Technology).vol.43,no.10,pp.3976–3981.

Liu,J.;Liu,Z.G.;Gao,K.(2014):Experimental study and application of directional focused energy blasting in deep boreholes.Chinese Journal of Rock Mechanics and Engineering.vol.33,no.12,pp.2490–2496.

Lu,W.B.;Ming,C.;Xiang,G.(2012):A study of excavation sequence and contour blasting method for underground powerhouses of hydropower stations.Tunnelling and Underground Space Technology.vol.29,no.0,pp.31–39.

Li,X.H.;Lu,Y.Y.;Xiang,W.Y.(2007):Theory of water jet and its application in mining engineering.Chongqing University Press.Chongqing.

Li,X.H.;Lu,Y.Y.;Zhao,Y.(2008):Study on improving the permeability of soft coal seam with high pressure pulsed water jet.Journal of China Coal Society.vol.33,no.12,pp.1386–1390.

Li,X.H.;Feng,M.T.;Zhou,D.P.(2011):experimental analysis of coal bed methane desorption and seepage under sonic vibration of cavitation water jets.Journal of Chongqing University.vol.34,no.04,pp.1–5.

Lu,Y.Y.;Liu,Y.;Li,X.H.;Kang,Y.(2010):A new method of drilling long boreholes in low permeability coal by improving its permeability.International Journal of Coal Geology.vol.84,no.2,pp.94–102.

Lu,Y.Y.;Song,C.P.;Liu,Y.(2011):Mechanism analysis of permeability based on promoting coal matrix shrinkage by water jet.Journal of Chongqing University.vol.34,no.4,pp.20–23.

Li,S.Y.;He,T.M.;Yin,X.C.(2010):Introduction of rock fracture mechanics.University of Science and Technology of China Press.Hefei.

Mojtaba,G.;Kamran,G.;Mostafa,J.(2011):A multi-dimensional approach to the assessment of tunnel excavation methods.International Journal of Rock Mechanics and Mining.vol.48,no.7,pp.1077–1108.

Nateghi,R.;Kiany,M.;Gholipouri,O.(2009):Control negative effects of blasting waves on concrete of the structures by analyzing of parameters of ground vibration.Tunnelling and Underground Space Technology.vol.24,no.6,pp.608–616.

Ozgur,Y.;Tugrul,U.(2013):Three dimensional numerical rock damage analysis under blasting load.Tunnelling and Underground Space Technology.vol.38,pp.266–278.

Rafael Rodríguez.;Cristobal Lombardía.(2010):Analysis of methane emissions in a tunnel excavated through Carboniferous strata based on underground coal mining experience.Tunnelling and Underground Space Technology.vol.25,no.4,pp.456–468.

Sanchidrián,J.A.;López,L.M.;Segarra,P.(2008):The influence of some blasting techniques on the probability of ignition of firedamp by permissible explosives.Journal of Hazardous Materials.vol.155,no.3,pp.580–589.

Sheng,Z.H.(1998):Theory and technology of water jet.University of Petroleum press.Dongying.

Shi,D.Y.;Li,Y.C.;Zhang S.M.(2005):The Analysis of explicit explosion mechanics base on Ansys/Ls-dyna8.1.Singhua University Press.Beijing.

Tong,L.Y.;Liu,L.;Yu,Q.(2013):Tunneling in abandoned coal mine areas:Problems,impacts and protection measures.Tunnelling and Underground Space Technology.vol.38:pp.409–422.

Wang,Q.G.(2010):Discussions Oil Construction Techniques for Coal Mining in Gas Tunnel’s Coal Formation.Chongqing Architecture.vol.9,no.06,pp.53–55.

Xu,Y.;Zong,Q.(2000):Theoretical analysis on the parameters of smooth blasting soft mat layer charging construction.Journal of China Coal Society.vol.25,No.06,pp.610–613.

Xiao,Z.X.;Guo,X.B.;Zhang,Z.C.(1998):The mechanical effect of notched blasting under the explosive shock wave and explosive gas.Chinese Journal of Rock Mechanics and Engineering.vol.17,no.06,pp.650–654.

Ye,F.;Huo,S.S.;Chang,W.W.(2011):Construction Safety Control Technology in Highway Tunnel traversing Soft and Weak Coal Formation and Mined out Area.Highway.,vol.6,no.06,pp.199–205.

Yong,L.;Shen,Z.W.(2006):Study on orientation fracture blasting with shaped charge in rock.Journal of University of Science and Technology.vol.13,no.3,pp.193–198.

Yang,R.S.;Zhang,Z.R.;Yang,L.Y.(2013):Cumulative blasting experiment study of slotted cartridge based on hard-rock rapid driving technology.Chinese Journal of Rock Mechanics and Engineering.vol.32,no.02,pp.317–323.

Zheng,J.L.;Zhang,A.Y.;Li,X.H.(2000):The technology of cutting through coal seam and preventing collapse in the right line of Huayingshan highway tunnel.Chinese Journal of Geotechnical Engineering.,vol.22,no.05,pp.559–561.

Zhang,Z.Y.(2014):Detection and construction technology of coal in coal stratum of complex tunnel.Railway Construction Technology,no.05,pp.105–109.

Zong,Q.(2002):Study and application of smooth blasting technique in weak rock tunnel.Journal of China Coal Society.vol.27,no.1,pp.45–45.

Zhang,Z.C.(2013):Control in Blasting Engineering.Chinese Journal of Underground Space and Engineering.vol.9,no.0,5,pp.1208–1214.

Zhang,Z.C.;Xiao,Z.X.;Pu,C.J.(2006):Analyze of mechanism of rock directional fracture controlled blasting.Stone.vol.2,pp.16–20.

1State Key Laboratory of Coal Mine Disaster Dynamics and Control,Chongqing University,Chongqing 400030,China

2Hubei Key Laboratory of Waterjet Theory&New Technology,Wuhan University,Wuhan 430072,China.

∗Corresponding author:Yong Kang.Tel.:+027-68774906.

E-mail address:kangyong@whu.edu.cn

Computer Modeling In Engineering&Sciences2016年5期

Computer Modeling In Engineering&Sciences2016年5期

- Computer Modeling In Engineering&Sciences的其它文章

- The Numerical Accuracy Analysis of Asymptotic Homogenization Method and Multiscale Finite Element Method for Periodic Composite Materials

- A Homogenized Function to Recover Wave Source by Solving a Small Scale Linear System of Differencing Equations

- Simple Efficient Smart Finite Elements for the Analysis of Smart Composite Beams