Liu Zhongjun: 3D Printing Reshapes Orthopedic Surgery

By staff reporter JIAO FENG

Liu Zhongjun: 3D Printing Reshapes Orthopedic Surgery

By staff reporter JIAO FENG

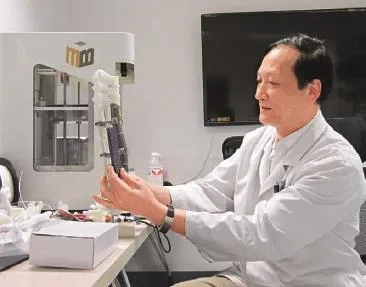

THERE is a 3D printing lab in the First Ward Zone of the Department of Orthopedics at Peking University Third Hospital (PUTH). Although not big,it’s where Professor Liu Zhongjun,director of the department, spends most of his time, when not dealing with patients and students. Entering the room, the China Today reporter saw a row of computers and printers on the table to the left, and also some 3D-printed bones and models. Liu pointed to the printer and said: “We just completed an operation to remove tumor-affected vertebrae and have successfully replaced them with 3D-printed replicas.”

On May 6, 2016, the metal 3D-printed vertebrae - the first of its kind in the world and co-developed by PUTH and Beijing AKEC Medical Co., Ltd. (AK Medical) - was approved by China Food and Drug Administration (CFDA). As project chief, Liu said it signifies that China is leading the world in the application of 3D-printed implants.

Professor Liu implants 3D printed artificial vertebrae into a patient’s spine.

Inspiration

In 2009, AK Medical introduced the functions of a newly-purchased metal 3D printer to PUTH doctors during a routine meeting. Upon hearing that it could make items in any shape or form,Liu suddenly got an inspiration - maybe it could be applied to making bone replacements to be implanted in human beings.

“We often need implants of various shapes and forms during surgery, and 3D printing technology precisely meets our needs,” said Liu. He went on to explain that vertebrae are normally of an irregular shape. For example, the atlas and axis feature complicated structures,so making replicas using traditional methods is difficult.

Titanium cylinders have been widely adopted to place inside the disc space. These cages allow the bone to grow from the vertebral body through the cage into the next vertebral body. However, titanium cages can’t closely match the human anatomical structure, which adversely affects the fixation. It also takes a long time for patients to recover, and they normally suffer a lot during the process. Now, 3D printer can make replicas that perfectly resemble the patient’s bone structures, so proving a better option.

Another advantage of the 3D printer is that the replica it makes is porous,which perfectly resembles human bones.“Those pores provide space for bone cells to grow,” said Liu. It took several years for him and his team to research the basic theories and application of 3D printing to making implants.

Now, surgeons no longer need to insert bone substance into titanium cylinders, instead allowing the human bone and the implant to achieve complete fusion, significantly enhancing the fixation of implants.

The 3D printed artificial vertebral body that received CFDA approval lastMay was listed in the third section of orthopedic implants. These can be directly implanted and are under the highest level of supervision in China. “The development of medical science is always about making innovations to meet the needs of patients,”Liu said.

Pioneering Operation

In May 2016, the Department of Orthopedics of PUTH received Mr. Yuan, a special patient suffering from chordoma, a rare cancer. Yuan’s situation was dire because up to 19 centimeters of his spine had to be completely removed, including thoracic vertebrae T10, T11, and T12 and lumbar vertebrae L1 and L2.

According to Liu, the surgery itself was an unprecedented challenge. They faced problems such as how the implants could be supported, and how the important spinal cord, nerves, and blood vessels in the spinal canal could be kept intact after removing such a large section. In the past it would have been impossible for Yuan to have such an operation because there was no titanium mesh large enough, or in a shape that matched the spine’s natural curve.

“3D printing technology provides a new option. We were able to use metal 3D printing technology, in accordance with the patient’s anatomical structure,to create an artificial vertebral body similar in shape and length to the five sections that needed to be removed,” Liu explained.

The surgery took place at 8 am on June 12. Over six hours later, it was successfully completed. Having lost little blood and his vital signs stable, Yuan didn’t need to stay in the ICU and was moved back to the general ward immediately. Two weeks later, he could stand unsupported and walk with help. By August 20, Yuan had recovered, and walked out of the hospital.

Yuan was the first beneficiary since the artificial vertebrae gained CFDA approval. Liu and his team have been at the world forefront in the application of 3D printing technology to treat bone diseases. On July 31, 2014, Liu and his team performed the first surgery ever to implant a 3D printed vertebrae replacement into a 12-year-old boy diagnosed with bone cancer that affected his axis. Another five patients implanted with such an artificial axis have all recovered well.

Professor Liu compares traditional titanium cylinders with the 3D printed artificial vertebrae.

3D PRINTING

Liu and his team have been at the world forefront in the application of 3D printing technology to treat bone diseases.

From Learning to Innovating

Recalling the initial stage of this scientific development, Liu told China Today that the first difficulty the team encountered was describing the shapes and forms of the implants they needed to 3D printing technicians.

At first, they couldn’t understand what Liu meant, because his description entailed many medical terms. Liu had a sudden inspiration. He used play dough to make a section of vertebrae and asked the technician to replicate it. The first standard model was so created after rounds of discussions and adjustments.

But now they no longer rely on 3D printing technicians. Liu’s student Li Zihe has mastered the technology. Models of various shapes can be printed out automatically after he inputs relevant data into a computer.

“Progress and development in the healthcare sector demands the increasing integration of multiple sciences and cross-curricular learning. It is no longer enough for a doctor to have medical knowledge. To achieve innovation, we need to conduct inter-disciplinary teaching and learning to cultivate talents that develop comprehensively in various areas,” said Liu.

So far there have been two 3D printed implants approved by the CFDA, and both were developed by the PUTH Department of Orthopedics. The artificial hip joint, approved by the CFDA in September 2015, was also the world’s first 3D-printed hip joint to be approved after clinical tests. Over a year since it went on the market, it has benefited over 1,000 patients.

The application of 3D printing technology not only enjoys advantages in spinal surgery, but also has bright prospects for eye socket repairs, skull repairs, and plastic surgery. Moreover,it is worth exploring the next frontier in 3D printing of human organs and tissues with biological materials.

“3D-printing technology provides a precious opportunity for China’s medical scientists to progress from learning to innovating,” Liu said. Years ago, countries around the world were at the same starting line in the application of metal 3D printing technology. It has matured in recent years. Now Chinese orthopedists, to a certain extent, have been at the forefront of medical applications of 3D printing in terms of clinical testing and relevant research and development.