Thermal Decomposition Reaction Kinetics of a HAN-based Gel Propellant

CHEN Yong-kang, CHEN Ye-hong, AN Zhen-tao, ZHANG Li, ZHANG Qian,LIU Jian-guo

(1. Ordnance Engineering College, Shijiazhuang 050003, China;2. Hebei University of Technology, Tianjin 300130, China)

陈永康1,陈也弘2,安振涛1,张 力1,张 倩1,刘建国1

(1.军械工程学院,河北 石家庄 050003; 2.河北工业大学,天津 300130)

Thermal Decomposition Reaction Kinetics of a HAN-based Gel Propellant

CHEN Yong-kang1, CHEN Ye-hong2, AN Zhen-tao1, ZHANG Li1, ZHANG Qian1,LIU Jian-guo1

(1. Ordnance Engineering College, Shijiazhuang 050003, China;2. Hebei University of Technology, Tianjin 300130, China)

In order to study the thermal decomposition characteristics of hydroxylamine nitrate(HAN) based gel propellant, the thermal decomposition of two kinds of HAN-based gel propellant samples containing polyvinyl alcohol(PVA) with different mass was tested by differential scanning calorimeter(DSC) and thermogravimetric analyzer(TGA). A double-base propellant was chosen to be compared with this propellant. The thermal decomposition process of HAN-based gel propellant and double-base propellant was analyzed and kinetic parameters of their thermal decomposition reaction were obtained. Activation energy was calculated by an isoconversional method. The critical temperature of thermal explosion and self accelerating decomposition temperature were calculated by Zhang-Hu-Xie-Li method. Malek method is used to infer the most probable mechanism function of thermal decomposition reaction. Results show that the thermal decomposition of HAN-based gel propellant is a continuous exothermic process and has a small amount of residue. The activation energy is about 100kJ/mol. The critical temperature of thermal explosion and self accelerating decomposition temperature increase when the content of PVA increases. HAN-based gel propellant has good thermal stability compared with thermal decomposition parameters of double-base propellant.

gel propellant; Malek method; decomposition reaction kinetics; thermal stability;HAN;polyvinyl alcohol

HAN-基凝胶推进剂的热分解反应动力学

陈永康1,陈也弘2,安振涛1,张力1,张倩1,刘建国1

(1.军械工程学院,河北 石家庄 050003; 2.河北工业大学,天津 300130)

Introduction

Gel propellant is a system with specific structure and performance.[1-2]The gelation of liquid fuel, the oxidant or the mixture of them needs a small amount of gels. The large amount of solid fuel uniformly suspend in the propellant system. Gel propellant combines the advantages of solid propellant and liquid propellant.

In 1970s, hydroxylamine nitrate (HAN)-based liquid propellant[3-5]developed rapidly because of high energy, low freezing point, safety and non-pollution. It was first used as liquid propellant by the US military[6-7]. But there are still some problems including combustion pressure oscillation, poor stability, easy spontaneous combustion and poor storage security. For this reason, liquid propellants are gelled to obtain good mechanical properties, stable combustion characteristics and good storage stability. Ma Zhongliang[8]prepared a HAN-based hydrogel propellant and tested its performance. Results show that the ignition of the propellant is difficult. But the combustion is clean. He Liming[9]found that the HAN hydrogel will precipitate liquid under long storage conditions. The storage temperature should not be higher than 313K.

In this study, a HAN-based gel propellant was prepared. Polyvinyl alcohol (PVA) was added as a gel. The main combustion product of this propellant is N2, CO2and H2O which are non-toxic and non-polluting. Thermal decomposition process of this propellant was tested by TGA and DSC. A double-base propellant which is commonly used and has good thermal stability was also chosen to be compared with this propellant. The activation energy and the most available mechanism function were obtained to evaluate the thermal stability of this kind of gel propellant comprehensively. The evaluation will provide an important basis for the gel propellant application in the future.

1 Experimental

1.1Samples

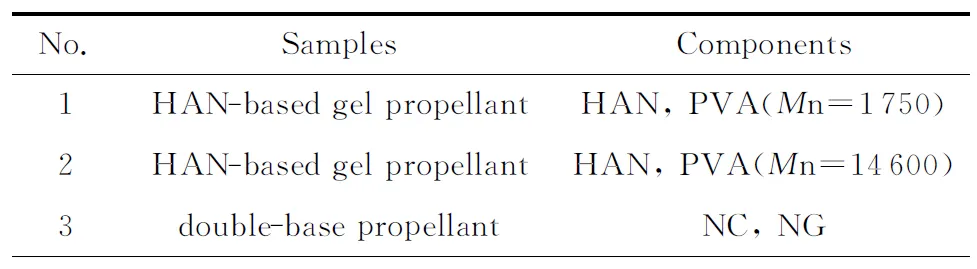

Table 1 shows the experimental samples. Two kinds of HAN-based gel propellant were prepared which differ in polyvinyl alcohol(PVA) content. A double-base propellant sample (sample 3) was prepared to be compared with HAN-based gel propellants.

The HP204 DSC employed in the experiment is from NETZCH Company of Germany, and the field emission scanning electron microscopy from FEI Company.Pyris-1 thermogravimetry and DSC 8000 differential scanning calorimeter from US PerkinElmer.

Table 1 Components of experiment samples

1.2Performance tests

Thermal decomposition processes of three samples were tested by TG and DSC. Experimental conditions: N2atmosphere(purity 99.999%), pressure is 0.2MPa, gas flow rate is 20mL/min, the mass of the sample is about 2mg.

2 Results and discussions

2.1Thermogravimetry test results

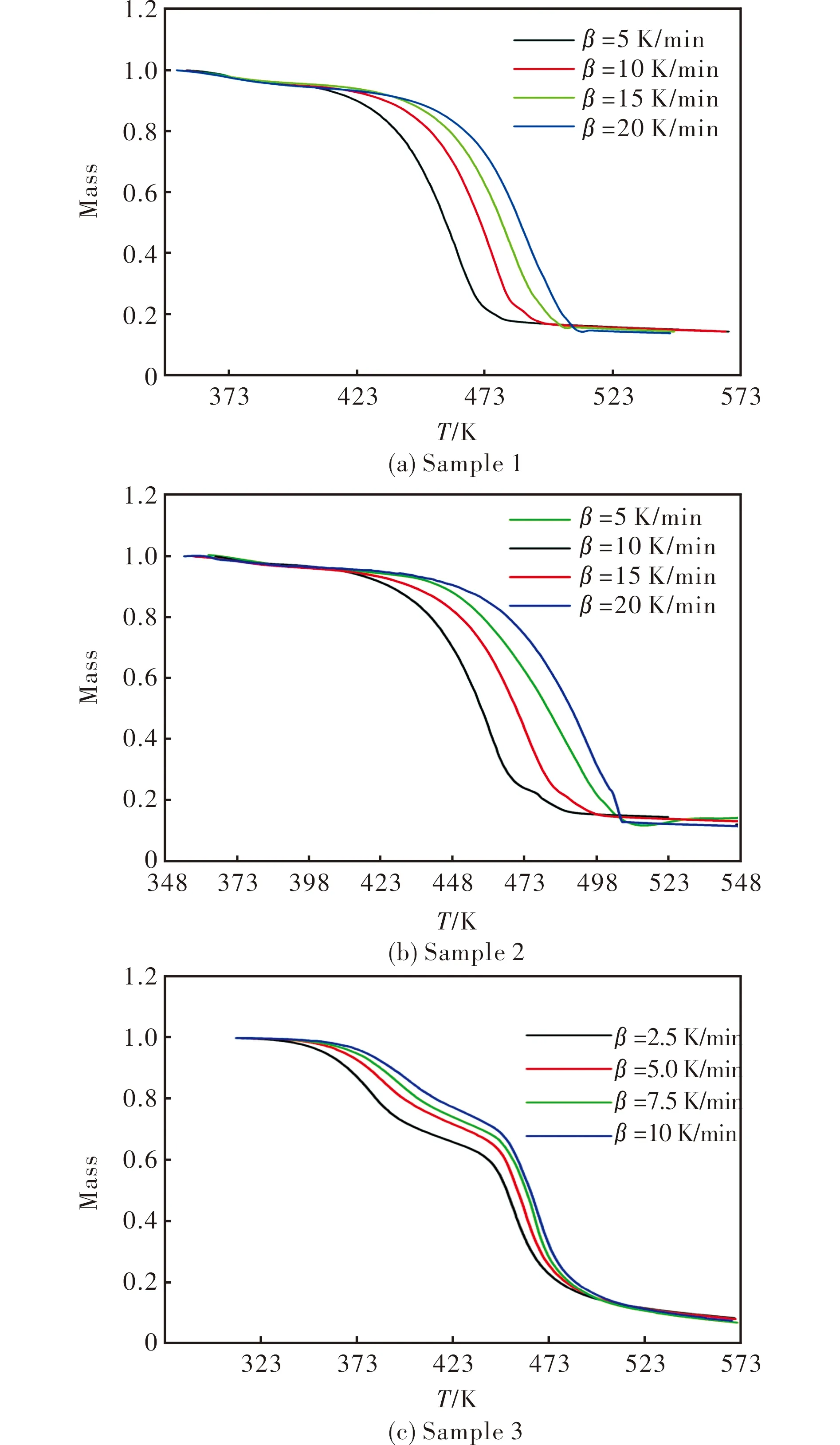

Fig.1 are TG curves of the three samples.

As can be seen from Fig.1, the decomposition of HAN-based gel propellant has a step of about 5% mass loss from beginning to about 400K, which is the loss of water in gel propellant samples. The next mass loss step from about 400-500K is the continuous thermal decomposition process. The final mass loss of sample1 is 86.1% and the residue is 13.9%. The final mass loss of sample2 is 87.3% and the residue is 12.7%. The results show that the thermal decomposition of gel propellant is comparatively thorough and only has a small amout of residue.

As can be seen in Fig.1(c), the decomposition of double-base propellant is divided into two steps. The first stage is the thermal decomposition of nitroglycerine(NG) from about 370-440K with 28.6% mass loss[10]. The nitrocotton(NC) has not yet reached the critical state of thermal decomposition in this stage. When the thermal decomposition of NG has almost reached the end, NC traps heat. In this reason, the decomposition rate of double-base propellant becomes slow. The second stage is the thermal decomposition stage of NC which probably from 440-525K[11-12]. As the temperature increases, the thermal decomposition accelerates. Mass loss step becomes steep. The mass loss of the second step is 54.54%. The final mass loss of double-base propellant is 83.17% and the residue is 16.83%. The decomposition of gel propellant is more thorough than double-base propellant and the residue is less.

Fig.1 TG curves of three samples at different heating rates

2.2DSC test results

Fig.2 are DSC curves of the three samples.

As can be seen from Fig.2, samples 1 and 2 have an exothermic decomposition peak. With the heating rate accelerating, the exothermic peak shifts to higher temperature. And the exothermic peaks of two samples are accompanied by a shoulder peak at slow heating rates. When the heating rate accelerates, shoulder peak has been gradually concealed. This peak is exothermic peak of PVA. Due to higher PVA content, the shoulder peak of sample 2 is more obvious.

The thermal decomposition of the double-base propellant sample has only one smooth and symmetry exothermic peak.

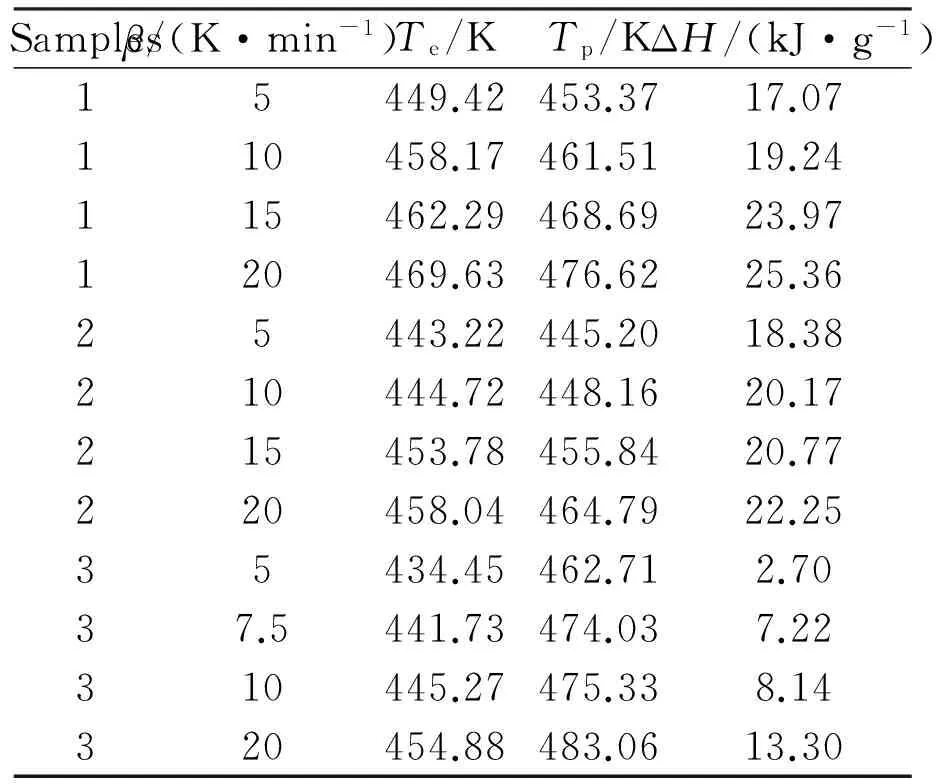

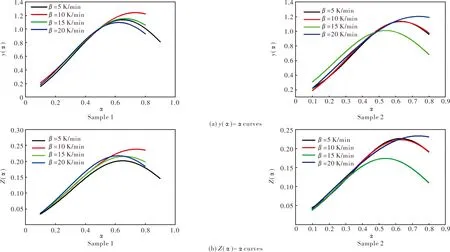

The thermal decomposition parameters calculated from DSC curves are shown in Table 2.

Table 2 DSC data of the three samples at different heating rates

Note:Teis initial decomposition temperature;Tpis peak temperature; ΔHis enthalpy change.

According to DSC datas, the kinetic parameters can be calculated by isoconversional method[13].

2.2.1Kinetic parameters calculation

The formula of Flym-Wall-Ozawa method[14-15]which is commonly used is

(1)

In formula (1):Ais frequency factor, s-1;Eis activation energy, J/mol;Ris molar gas constant, 8.31J/(mol·K);αis the depth of the reaction;G(α) is the integral form of mechanism function;Tis the reaction temperature, K.

Formula of Kissinger method[16]is

(2)

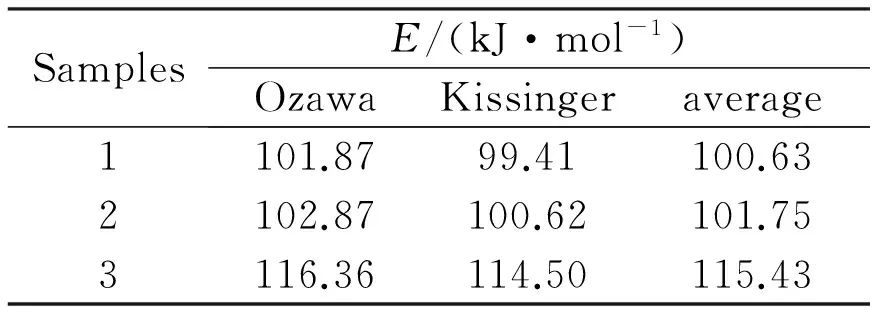

Calculation results are shown in Table 3. The results suggest that the activation energy of gel propellant is a bit lower than that of double-base propellant. The increase of PVA content can barely affect the activation energy of gel propellant.

Table 3 Activation energy of three samples calculated by

2.2.2Thermal safety parameters calculation

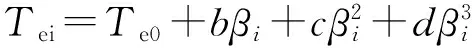

Critical temperature of thermal explosionTbcan be obtained according to Zhang-Hu-Xie-Li method[17]:

(3)

Table 4 Calculated results of thermal safety parameters

TbandTSADTof sample 2 are higer than sample 1.TbandTSADTof double-base propellant are a bit lower than sample 2. The results show that the increase of PVA content can raiseTbandTSADTof gel propellant.

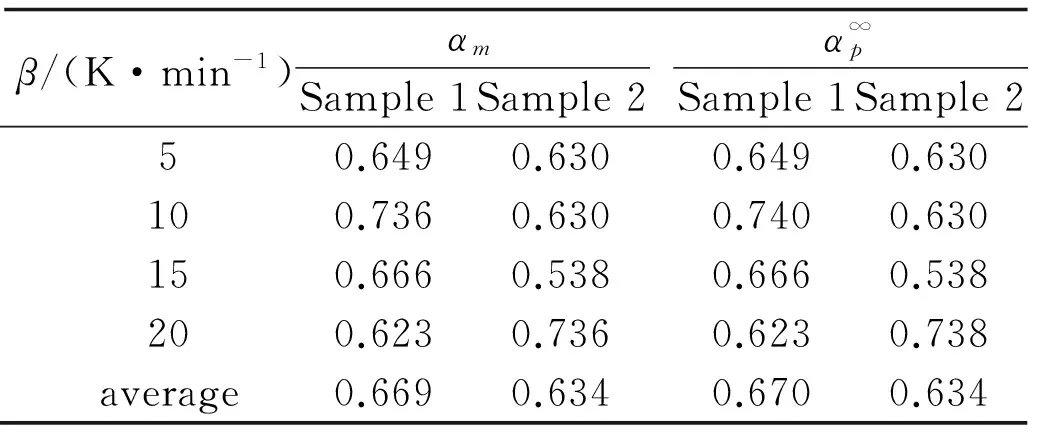

2.3Select mechanism function by Malek method

Malek method[18-19]is a new method for thermal kinetics analysis. This method starts from calculating activation energy by isoconversional method and gradually obtains kinetic results without any assumptions and approximations. Malek method selects reasonable mechanism functions logically and avoids trying mechanism functions one by one. Malek method calculates and infers a reasonable mechanism function by defining functiony(α)-αandZ(α)-αwhich are based on experimental data[20-21].

y(α)=(T/T0.5)2(dα/dt)(dα/dt)0.5

(4)

Z(α)=π(u)(dα/dt)T/β

(5)

In formulae (4) and (5),T0.5and (dα/dt)0.5are respectively the temperature and reaction rate whenα=0.5; π(u) is temperature integral using Luke approximation[22]π(u)=1/(u+2),u=E/RT.

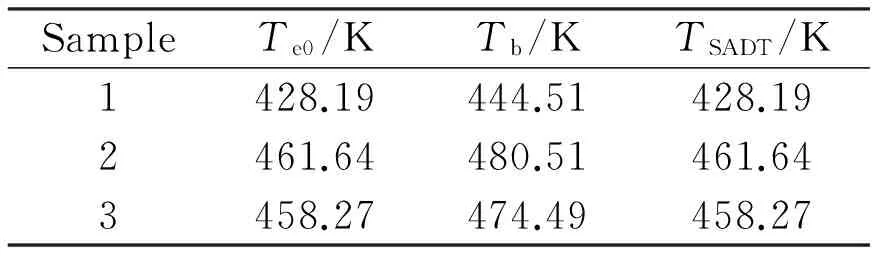

The experimental data is plugged into formulae (4) and (5) to obtainy(α)-αandZ(α)-αcurves which are shown in Fig.3.

Fig.3 y(α)-α and Z(α)-α curves for samples 1 and 2

Table 5 Characteristic parameters for two gel propellant samples

Using curves and characteristic parameters can infer the most probable mechanism functionf(α).

(6)

Linear fitting for ln[(dα/dt)eu] and ln[αS(1-α)] is used.nis obtained according to the slope.S=m/n,mis determined according toS. The mechanism functions of sample 1 isf(α)=α2.19(1-α)1.08.

(7)

In formula (7),f′(αp) is the differential value off(α) whenα=αp.

The average lgAof samples 1 and 2 are 15.32 and 16.18,respectively.

In this way, the rate equation describing the thermal decomposition reaction of gel propellant samples are obtained:

for sample 1:

dα/dt=1015.32exp(10063/RT)α2.19(1-α)1.08;

for sample 2:

dα/dt=1016.18exp(10175/RT)α2.11(1-α)1.22

3 Conclusions

(1) The decomposition of HAN-based gel propellant is a continuous exothermic reaction and is more thorough than double-base propellant. Gel propellant has good thermal stability.

(2) The rate equation describing the thermal decomposition reaction of gel propellant samples 1 and 2 are dα/dt=1015.32exp(10063/RT)α2.19(1-α)1.08and dα/dt=1016.18exp(10175/RT)α2.11(1-α)1.22, respectively.

(3) Increasing PVA content can raiseTbandTSADTof gel propellant.

References:

[1]Haeseler D, Bombelli V, Vuillermoz P, et al. Green propellant propulsion concepts for space transportation and technology development needs[C]∥Proceedings of the 2nd International Conference on Green Propellants for Space Propulsion. Cargliari: Esa Special Publication, 2004.

[2]Muller D C, Turns S R. Theoretical effects of aluminum gel propellant secondary atomization on rocket engine performance[J]. Journal of Propulsion and Power, 2012, 12(3): 591-597.

[3]Liu L, Papadaki M, Pontiki E. Isothermal decomposition of hydroxylamine and hydroxylamine nitrate in aqueous solutions in the temperature range 80-160 degree C[J]. Journal of Hazard Matter, 2009, 165(1/3): 573-578.

[4]Fokema M D, Torkeleson J E. Thermally stable catalysts and process for the decomposition liquid propellant: US, 20070184971[P].2007.

[5]CHEN Xin-qiang, ZHANG Zhi-yong, TENG Yi-gang, et al. Two kinds of green liquid monopropellants HAN, AND for replacing hydrazine[J]. Chemical Propellants & Polymeric Materials, 2011, 9(4): 63-66.

[6]Sachiem Robert L. Overview of United States space propulsion technology and associated space transportation systems[J]. Journal of Propulsion and Power, 2006, 22(6): 1310-1333.

[7]Meinhardt D, Breweter G, Christofferson S, et al. Development and testing of new HAN based mono-propellants in small rocket thrusters, 98-4006[R]. New York: AIAA, 1998.

[8]MA Zhong-liang, WU Hao, HE Li-ming, et al. Performance of HAN-based gel propellants[J]. Sichuan Defence Technology, 2007, 29(3): 3-5.

[9]HE Li-ming, XIAO Zhong-liang, LI You-ping, et al. Storage performance of HAN Hydrogel[J]. Chinese Journal of Energetic Materials, 2011,19(2): 226-228.

[10] WANG Xuan-jun, WANG Ze-shan. Thermal decomposition performance of energy increased and deterred single-base propellant[J]. Journal of Ballistics, 1999, 9(1): 22-26.

[11] Liu Y, Jiang Y T, Feng C G. Thermal kinetic performance and storage life analysis of a series of high-energy and green energetic materials[J]. Journal of Thermal Analysis & Calorimatry, 2015, 119(1): 659-670.

[12] YU Jin-yang, CHEN Li-ping, PEN Jin-hua. Thermal decomposition behavior of retired single-base propellant[J]. Chinese Journal of Explosives & Propellants(Huozhayao Xuebao), 2013, 36(1): 73-77.

[13] Dickinson C F, Heal G R. A review of the ICTAC kinetics project. Part 2. Non-isothermal results[J]. Thermochimica Acta, 2007, 494, 15-25.

[14] Koga N. Ozawa′s kinetic method for analyzing thermoanalytical curves[J]. Journal of Thermal Analysis & Calorimetry, 2013, 113(3): 1527-1541.

[15] HU Rong-zu, GAO Sheng-li, ZHAO Feng-qi, et al. Thermal Analysis Kinetics[M]. Beijing: Science Press, 2008.

[16] Ruben Ruiz-Femenia, Caballero J A. Analysis of the relative strength of the singular values obtained from the nonparametric kinetic method[J]. Journal of Thermal Analysis & Calorimatry, 2012, 107(2): 585-596.

[17] HU Rong-zu, SUN Li-xia, WU Shan-xiang, et al. Explosives Testing Methods GJB772A-97 Self-ignition Temperature, DTA and DSC Method[M]. Beijing:National Defense Standard Press, 1997, 181-183.

[18] Perez-Maqueda L A, Criado J M. Combined kinetic analysis for crystallization kinetics of non-crystalline solids[J]. Journal of Non-crystalline Solids, 2003,320(1): 84-91.

[19] Malek J. The application of Johnson-Mehl-Avrami model in the thermal analysis of the crystallization kinetics of glasses[J]. Thermochim Acta, 1995, 267: 61-73.

[20] WANG Shao-xu, ZHAO Zhe, TAN Zhi-cheng, et al. Thermal stability and kinetics of thermal decompositon for protionamide[J]. Acta Phys-Chim Sin, 2007, 23(9): 1459-1462.

[21] TANG Zhan, REN Yan, YANG Li, et al. A new way to estimate the thermal decomposition mechanism function and thermal safety of RDX[J]. Chinese Journal of Explosives & Propellants(Huozhayao Xuebao), 2011, 34(1), 19-22.

[22] Luke Y K. Mathematical Functions and their Approximations[M].New York: Academic Press, 1975.

[23] BAO Shi-long, CHEN Wang-hua, CHEN Li-ping, et al. Identification and thermokinetics of autocatalytics exothermic decomposition of 2, 4-Dinitrotoluene[J]. Acta Phys-Chim Sin, 2013, 29(3):479-485.

[24] Gotor F J, Criado J M. Kinetic analysis of solid-state reaction: the universality of master plots for analyzing isothermal and nonisothermal experiments[J].The Journal of Physical Chemistry A,2000,104(46): 10777-10782.

10.14077/j.issn.1007-7812.2016.04.015

为研究HAN-基凝胶推进剂的热分解特性,利用差示扫描量热仪(DSC)和热重分析仪(TGA)对两种含不同质量聚乙烯醇(PVA)的HAN-基凝胶推进剂样品进行热分析试验,并与一种双基推进剂进行对比。分析了HAN-基凝胶推进剂和双基推进剂的热分解过程,得到热分解反应的动力学参数;采用等转化率法计算了活化能,采用Zhang-Hu-Xie-Li等方法计算出热爆炸临界温度和自加速分解温度。采用Malek法推断出两种HAN-基凝胶推进剂样品的热分解反应的最可几机理函数。结果表明, HAN-基凝胶推进剂的热分解是一个连续的放热过程,热分解较为彻底,残渣较少,活化能约为100kJ/mol。当PVA含量增加时,其热爆炸临界温度和自加速分解温度升高。与双基推进剂相比,HAN-基凝胶推进剂具有较好的热安定性。

凝胶推进剂;Malek法;分解反应动力学;热安定性;HAN;聚乙烯醇

date:2016-01-11;Revised date:2016-03-17

TJ55;V512Document Code:AArticle ID:1007-7812(2016)04-0077-05

Biography:CHEN Yong-kang (1991-), male, research field: ammunition support and safety technology.E-mail:995019739@qq.com