蒸汽吞吐中汽窜控制体系配方设计与性能评价

吴丰豆 王 健 冯 天 余 恒 秦 山

西南石油大学油气藏地质及开发工程国家重点实验室, 四川 成都 610500

蒸汽吞吐中汽窜控制体系配方设计与性能评价

吴丰豆王健冯天余恒秦山

西南石油大学油气藏地质及开发工程国家重点实验室,四川成都610500

摘要:新疆风城油田稠油蒸汽吞吐作业区层间非均质性严重,导致开采过程中蒸汽窜流现象严重,热能利用率低,开发效果下降,为此本实验开展对蒸汽窜流控制体系的配方设计与性能评价,为有效改善吸汽剖面,提高蒸汽波及效率提供保障。针对注入蒸汽的窜流控制,以氮气为起泡气体,室内优选出在高温320 ℃下的配方为起泡剂(FA 2,0.1%)+ 起泡剂(FA 4,0.5%)+ 稳泡剂(FS 3,0.05%)+ 助剂(AS-1,0.1%),实验结果表明100 mL该体系起泡液起泡体积为605 mL,泡沫半衰期为135 min,泡沫干度为83.5%,表面张力为0.43 mN/m。对配方进行耐盐、耐油性评价,结果表明该配方对矿化度变化具有较好的适应性,同时较低的含油饱和度(蒸汽窜流带)对泡沫体系没有明显影响,可有效维持高渗层渗流阻力,从而抑制蒸汽窜流。

关键词:稠油;蒸汽吞吐;高温;窜流;泡沫

0前言

1)油井排液能力差,地层存水高;

2)水平段动用程度低;

3)地表汽窜造成储量、产能损失;

4)井间汽窜出砂严重[8-12]。

稠油蒸汽吞吐开发的主要矛盾是汽窜,汽窜导致蒸汽波及效率和热能利用率降低,蒸汽窜流带的无效吞吐是导致多轮次吞吐效果差的核心因素[13]。纵向上,由于层间非均质性致使蒸汽沿高渗层窜流,富集油的低渗层无法被有效动用;平面上,由于层内非均质性致使蒸汽沿高渗通道窜流,剩余油的远井带无法被有效动用[14-16]。因此,本文针对注入蒸汽的低利用率,以氮气为起泡气体,高温条件下采用泡沫调驱技术减少蒸汽指进、调整剖面矛盾,提高波及效率,为提高稠油油藏蒸汽吞吐开发效果提供保障[17-18]。

1实验部分

1.1主要材料和仪器

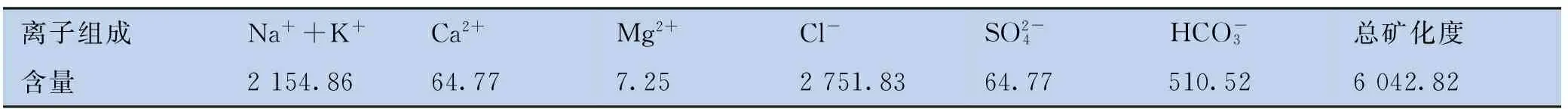

起泡剂:FA 1、FA 2、FA 3、FA 4、FA 5;稳泡剂:FS 1、FS 2、FS 3、FS 4;助剂:AS 1,均由新疆油田提供;重32井区模拟地层水离子组成见表1,化学剂组成见表2。无机盐:MgCl2·6 H2O、CaCl2、KCl、NaCl、Na2SO4、NaHCO3、NaOH;精密天平;烘箱;量筒;高温泡沫老化釜;氮气瓶;全自动表/界面张力仪HZ-800型;吴茵搅拌器,调速范围0~8 000 r/min。

由表4可知,硅-焓方程法计算得出的热储温度为182.36 ℃~274.58 ℃,冷水混合比例为39.47%~85.88%;硅-焓图解法计算的结果为172.58 ℃~258.23 ℃,冷水混入比例为39.19%~86.46%。对比发现由混合模型计算的热储温度与Na-K温标计算的温度较为接近,与其他温标及实测情况偏离较大。

表1重32井区模拟地层水离子组成

mg/L

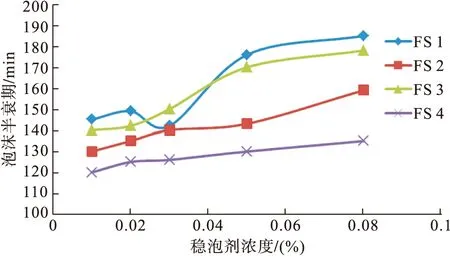

表2重32井区模拟地层水化学剂组成

g/L

1.2实验方法

2结果与讨论

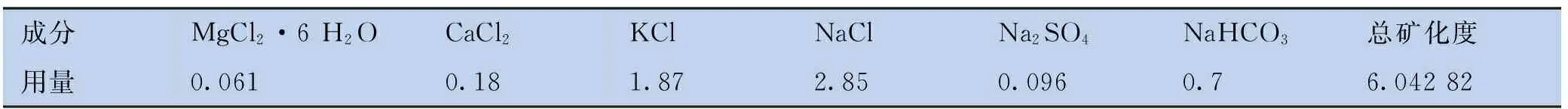

2.1起泡剂的确定

图1 起泡剂浓度对起泡体积的影响

图2 起泡剂浓度对泡沫半衰期的影响

表3起泡剂复配体系(FA 4+FA 2)不同浓度组合的起泡体积、泡沫干度、泡沫半衰期

浓度组合/(%)0.1+0.20.1+0.40.2+0.20.2+0.40.3+0.30.4+0.10.4+0.20.5+0.1㊞V㊣/mL375470500445460570600590㊞T㊣/min163143140132136137139143㊞G㊣/(%)73.378.780.077.578.382.583.383.1

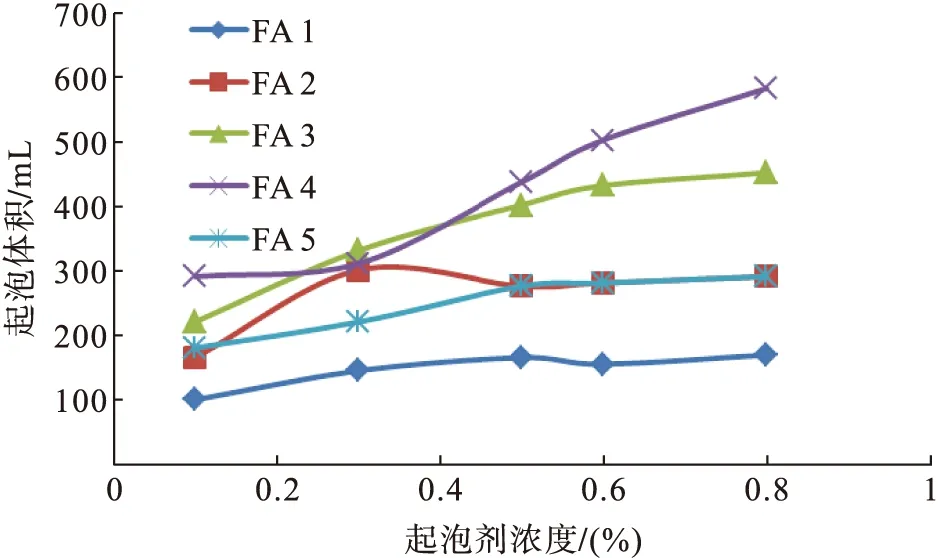

2.2稳泡剂的确定

图3 稳泡剂浓度对起泡体积的影响

图4 稳泡剂浓度对泡沫半衰期的影响

2.3助剂浓度的确定

表4助剂浓度对起泡体积、泡沫半衰期、表面张力的影响

浓度/(%)0.050.10.150.20.250.3㊞V㊣/mL600605590580578570㊞T㊣/min140135125116110108㊞σ㊣/(mN·m-1)1.730.430.0720.110.200.23

2.4性能评价

2.4.1耐盐性

在生产过程中,由于流体间的传质作用,矿化度不断发生变化,因此有必要对配方的耐盐性进行评价。测得的不同地层水矿化度倍数下的起泡体积、泡沫半衰期与矿化度关系见表5。由表5可知:随着矿化度的增加,地层水泡沫配方的各项参数均有所下降,但幅度很小。起泡体积大于500 mL,泡沫半衰期大于2 h;具有较好的耐盐性,可以满足施工要求。

表5矿化度对起泡体积、泡沫半衰期的影响

矿化度00.250.50.7511.25㊞V㊣/mL820785750665600515㊞T㊣/min190178165155138120

2.4.2耐油性

表6含油饱和度对起泡体积、泡沫半衰期的影响

含油饱和度/(%)5101520253035404550㊞V㊣/mL610585550415335285230205175155㊞T㊣/min1301261191141089075584538

3结论

2)将具有不同优点的起泡剂进行复配可同时兼顾起泡体积与泡沫半衰期;稳泡剂的加入在延长消泡时间的同时减小了起泡体积,助剂的加入对起泡能力影响较小,但对泡沫的稳定性和表面张力影响较大。

3)本文优选配方具有较好的耐盐性,能适应注入过程中矿化度的不断变化;较低的含油饱和度(蒸汽窜流带)对泡沫体系影响较小,即少量原油存在的情况下,泡沫稳定性比较好,能有效维持高渗层的渗流阻力,提高蒸汽吞吐开发效率。

参考文献:

[1] 霍进,吴运强,赵增义,等.准噶尔盆地风城地区稠油特征及其成因探讨[J].特种油气藏,2008,15(2):25-27.Huo Jin, Wu Yunqiang, Zhao Zengyi, et al. Heavy Oil Characteristics and Origin Discussion in Fengcheng of Junggar Basin [J]. Special Oil & Gas Reservoirs, 2008, 15 (2): 25-27.

[2] 朱婵.新疆油田蒸汽辅助重力泄油开采稠油研究[D].荆州:长江大学,2012.

Zhu Chan. The Research on Development of the Heavy Oil for Steam Assisted Gravity Drainage (SAGD) in Xinjiang Oilfield [D]. Jingzhou: Yangtze University, 2012.

[3] 李海燕,高阳,王延杰,等.辫状河储集层夹层发育模式及其对开发的影响——以准噶尔盆地风城油田为例[J].石油勘探与开发,2015,42(3):364-373.

Li Haiyan, Gao Yang, Wang Yanjie, et al. Intercalation Pattern and Its Impact on Development of Braided River Reservoirs: A Case of Fengcheng Oilfield, Junggar Basin, NW China [J]. Petroleum Exploration and Development, 2015, 42 (3): 364-373.

[4] 王伟伟.杜229块蒸汽驱窜流调控技术研究与应用[J].天然气与石油,2014,32(5):57-60.

Wang Weiwei. Research and Application of Control Technology in Du 229 Block Steam Flooding and Channeling [J]. Natural Gas and Oil, 2014, 32 (5): 57-60.

[5] 孙新革,马鸿,赵长虹,等.风城超稠油蒸汽吞吐后期转蒸汽驱开发方式研究[J].新疆石油地质,2015,36(1):61-64.Sun Xinge, Ma Hong, Zhao Changhong, et al. Research on Ultra-Heavy Oil Development by Steam Stimulation Converting into Steam Drive Combination Process in Fengcheng Oilfield [J]. Xinjiang Petroleum Geology, 2015, 36 (1): 61-64.

[6] Wu S H, Zhang Y T, Yang L Q, et al. Sequential Multi-Well Steam Huff and Puff in Heavy Oil Development [C]// Paper 97845 Presented at the SPE International Thermal Operations and Heavy Oil Symposium,1-3 Novembre 2005, Calgary, Alberta, Canada. New York:SPE,2005.

[7] Wu X H, Xu A Z, Fan Z F, et al. Superheated Steam Huff and Puff to Revivify a Marginal Pre-Salt Heavy Oil Reservoir [C].// Paper 134082 Presented at the SPE Asia Pacific Oil and Gas Conference and Exhibition,18-20 October 2010, Brisbane, Queensland, Australia. New York:SPE,2010.

[8] Jeong S, Chung S, Min B, et al. Optimal Operation of Fast-SAGD Process Considering Steam Channeling Among Vapor Chambers [C]// Paper I-13-186 Presented at the 23thInternational Offshore and Polar Engineering Conference,30 June-5 July 2013,Anchorage,Alaska,U S A.

[9] 孙德浩.氮气泡沫调剖技术改善汽驱效果研究[J].断块油气田,2008,15(6):92-93.

Sun Dehao. Application of Nitrogen Foam Profile Control Technique in Improving Steam Flood Effect [J]. Fault-Block Oil & Gas Field, 2008, 15 (6): 92-93.

[10] 朱明,姚凯,叶惠民,等.高温氮气泡沫调剖技术在Girasol油田的应用[J].特种油气藏,2015,22(2):137-139.

Zhu Ming, Yao Kai, Ye Huimin, et al. The Application of High Temperature Nitrogen Foam Profile Control Technology on Girasol Oilfield [J]. Special Oil & Gas Reservoirs, 2015, 22 (2): 137-139.

[11] 唐亮.稠油油藏化学复合蒸汽驱技术室内研究[J].油田化学,2014,31(1):65-67.

Tang Liang. Laboratory Study of Chemical Combination Steam Flooding for Heavy Oil Reservoir [J]. Oilfield Chemistry, 2014, 31 (1): 65-67.

[12] Wang C, Li H Z. Foam Stability of Solvent/ Surfactant/Heavy-Oil System Under Reservior Conditions [C]// Paper 172888 Presented at the SPE International Heavy Oil Conference and Exhibition,8-10 December 2014, Mangaf, Kuwait.New York:SPE, 2014.

[13] 高海涛,李雪峰,赵斌,等.ZY型耐温耐盐泡沫体系的研制及性能评价[J].断块油气田,2010,17(3):369-371.

Gao Haitao, Li Xuefeng, Zhao Bin, et al. Development and Performance Evaluation of ZY Type Temperature-resistant and Salt-resistant Foam System [J]. Fault-Block Oil and Gas Field, 2010, 17 (3): 369-371.

[14] 吕广忠,张建乔.稠油热采氮气泡沫调剖研究与应用[J].钻采工艺,2006,29(4):88-90.

Lü Guangzhong, Zhang Jianqiao. Study and Application of Nitrogen Foam Profile Control in Heavy Oil Thermal Production [J]. Drilling & Production Technology, 2006, 29 (4): 88-90.

[15] 赵江玉,蒲万芬,李一波,等.耐高温高盐泡沫体系筛选与性能评价[J].天然气与石油,2014,32(4):65-69.

Zhao Jiangyu, Pu Wanfen, Li Yibo, et al. Laboratory Selection and Performance Evaluation on High Temperature and High Salinity Resistant Foam System [J]. Natural Gas and Oil, 2014, 32 (4): 65-69.

[16] Tang G Q, Kovscek A R. Trapped Gas Fraction During Steady State Foam Flow [J]. Transport in Porous Media, 2006, 65 (2): 287-307.

[17] Huh C, Rossen W R. Approximate Pore Level Modeling for Apparent Viscosity of Polymer-Enhanced Foam in Porous Media [C]// Paper 99653 Presented at the SPEDOE Symposium on Improved Oil Recovery,22-26 April 2008, Tulsa, Oklahoma, USA. New York:SPE,2008.

[18] 曹献平,旷曦域,刘英波,等.泡沫欠平衡钻地热井井筒多相流特性研究[J].天然气与石油,2013,31(4):48-50.

Cao Xianping, Kuang Xiyu, Liu Yingbo, et al. Study on Characteristics of Multiphase Flow in Foam Underbalance Drilling Geothermal Well Wellbore [J]. Natural Gas and Oil, 2013, 31 (4): 48-50.

[19] 赖书敏,刘慧卿,庞占喜.高温氮气泡沫调驱发泡剂性能评价实验研究[J].科学技术与工程,2010,10(2):400-404.

Lai Shumin, Liu Huiqing, Pang Zhanxi. Laboratory Evaluation of High Temperature Nitrogen Foam Agents for Profile Control Technology [J]. Science Technology and Engineering, 2010, 10 (2): 400-404.

[20] 雷达.氮气泡沫剂性能评价及在大庆油田的应用[J].中外能源,2010,15(9):67-71.

Lei Da. Application and Stability Evaluation of Nitrogen Foaming Agent Used in Daqing Oilfield [J]. Sino-Global Energy, 2010, 15 (9): 67-71.

[21] 赵国玺.表面活性剂物理化学[M].北京:北京大学出版社,1984.

Zhao Guoxi. Physical Chemistry of Surfactant [M]. Beijing: Peking University Press, 1984.

收稿日期:2015-12-19

基金项目:国家自然科学基金项目“重力超覆下气体连续“剥蚀”稠油边界层的驱油机制研究”(51574200)

作者简介:吴丰豆(1991-),男,四川眉山人,硕士研究生,主要从事化学驱和化学调剖堵水方面的学习与研究。

DOI:10.3969/j.issn.1006-5539.2016.03.014