基于正渗透技术的沼液浓缩工艺优化

许美兰,叶 茜※,李元高,宋燕清,肖 芬(.厦门理工学院厦门市膜技术研发及应用重点实验室,厦门 3604; .武汉市博天环境集团股份有限公司,武汉 430000)

基于正渗透技术的沼液浓缩工艺优化

许美兰1,叶茜1※,李元高1,宋燕清1,肖芬2

(1.厦门理工学院厦门市膜技术研发及应用重点实验室,厦门 361024;2.武汉市博天环境集团股份有限公司,武汉 430000)

摘要:为解决沼液体积过大,难以实际应用的问题,采用正渗透技术对沼液进行浓缩。通过对不同条件下沼液正渗透浓缩工艺运行性能的研究,发现较优的膜朝向为活性层朝向沼液;错流速度宜采用20.5 cm/s;汲取液宜选择浓度为2 mol/L 的MgCl2溶液。在上述优化条件下将沼液浓缩至5倍。浓缩后的沼液中溶解性有机物、总磷、总氮、氨氮和总钾浓度均显著提高。正渗透膜对上述物质的截留率均达到80%以上。该研究为沼液正渗透浓缩技术的广泛应用提供了一定的技术基础。

关键词:浓缩;优化;渗透;沼液;膜朝向;错流速度;汲取液

许美兰,叶茜,李元高,宋燕清,肖芬. 基于正渗透技术的沼液浓缩工艺优化[J]. 农业工程学报,2016,32(2):193-198.doi:10.11975/j.issn.1002-6819.2016.02.028http://www.tcsae.org

Xu Meilan, Ye Qian, Li Yuangao, Song Yanqing, Xiao Fen. Optimization of forward osmosis process for concentration of biogas slurry[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(2): 193-198. (in Chinese with English abstract)doi:10.11975/j.issn.1002-6819.2016.02.028http://www.tcsae.org

0 引 言

畜禽养殖废水经厌氧处理后产生的沼液富含有机质、腐殖酸以及农作物生长所需的氮、磷、钾等无机营养元素,是一种优质的有机液体肥料[1-4]。基于环境保护和资源回收的需要,将沼液还田成为了人们的首选[5]。但是,由于原始沼液营养元素浓度偏低,体积过大,就近农用消纳能力有限,在储存以及运输上存在较大困难[3],因此,进行沼液浓缩并循环回用是一种资源化利用的可选途径。

在沼液浓缩技术中,膜分离技术凭借其工艺简单、操作方便和不改变成分特性等特点成为沼液浓缩方法的理想选择。用于沼液浓缩的膜技术一般为超滤(ultrafiltration,UF)[4]、纳滤(nanofiltration,NF)[6-8]和反渗透(reverse osmosis,RO)技术[3,9-10],均需外界加压推动分离过程。近年来新兴的正渗透(forward osmosis,FO)技术无需外界加压,可利用渗透压差作为驱动力,使得水自发从渗透压较低的原料液一侧透过半渗透膜进入到渗透压较高的汲取液一侧,能耗低,污染小,对许多污染物的截留效果好[11-13]。但是,目前FO应用于沼液浓缩的研究相对较少。李红娜等曾对某海滨猪场的沼液进行正渗透浓缩,其试验结果表明了沼液正渗透浓缩技术的可行性[14]。但是,由于上述研究采用海水作为汲取液,受到了一定的地域限制。因此,沼液正渗透浓缩技术还需投入大量系统的研究工作,以扩大其应用范围。本研究将构建养猪废水厌氧发酵沼液的FO浓缩工艺,优化其操作方案和汲取液条件,并分析优化条件下FO对沼液中营养物质的浓缩效果,为沼液正渗透浓缩技术的广泛应用提供一定的技术基础。

1 材料与方法

1.1试验装置

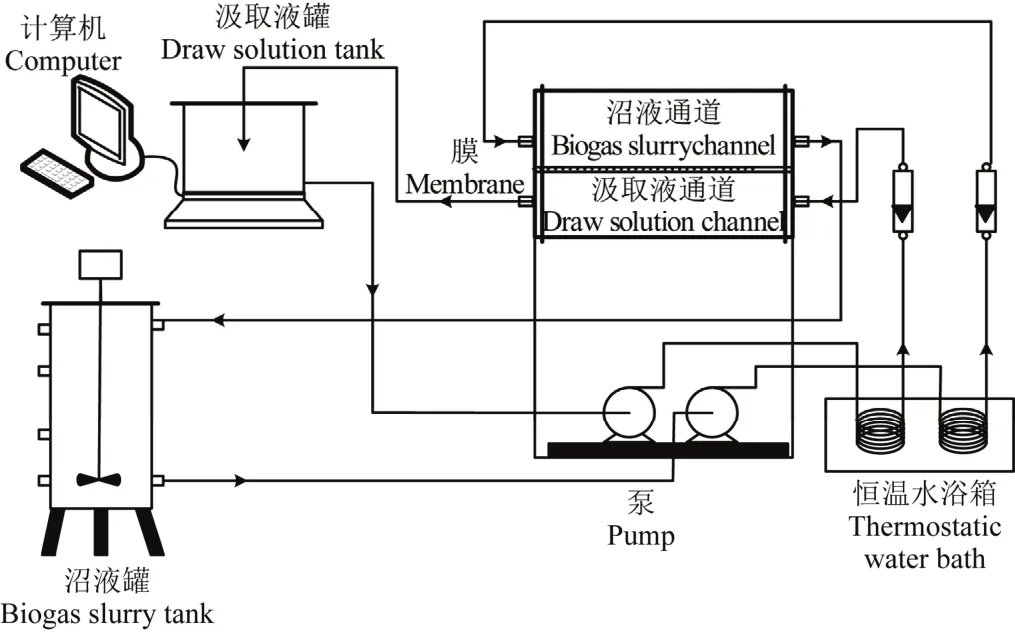

试验采用的沼液正渗透浓缩装置可见下图1。

图1 正渗透膜工艺流程示意图Fig.1 Schematic diagram of FO process

如图1所示,沼液和汲取液分别在泵的作用下从沼液罐和汲取液罐被输送至FO膜两侧的料液通道并进行循环流动。其中,汲取液罐置于电子天平上,通过计算机实时记录汲取液的质量变化情况。沼液罐配备电动搅拌器以保证料液混合均匀。此外,沼液和汲取液在各自的料液循环过程中通过恒温水浴箱将其温度控制在(23±1) ℃范围。试验中采用的FO膜为美国Hydration Technology Innovations (HTI)公司生产的三醋酸纤维素(cellulose triacetate,CTA)膜。该膜由醋酸纤维素活性膜层和聚酯网状支撑层组成,有效过滤面积为545 cm2。

1.2沼液来源及性质

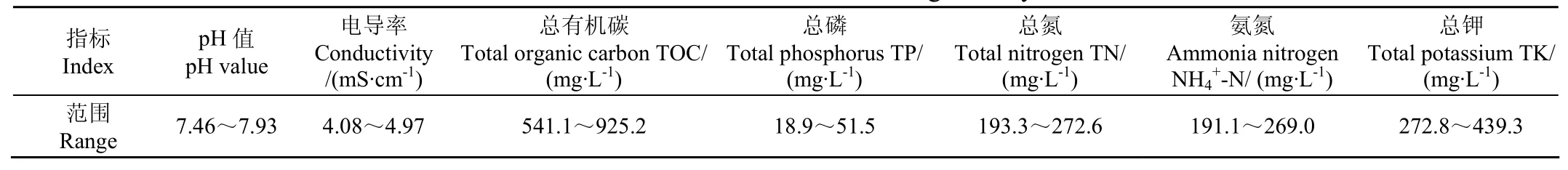

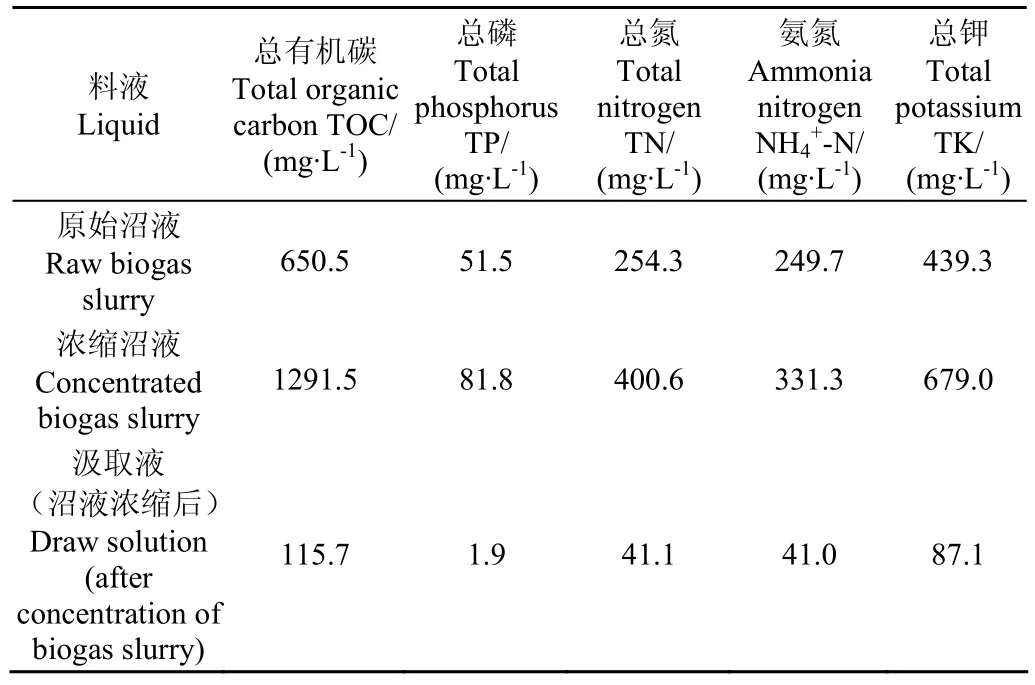

试验所使用的原始沼液为养猪废水经厌氧膜生物反应器厌氧发酵后产生的沼液,其成分如下表1所示。在每组单因素优化试验中所采用的沼液性质相同。

表1 原始沼液基本性质Table 1 Characteristics of raw biogas slurry

1.3试验方案

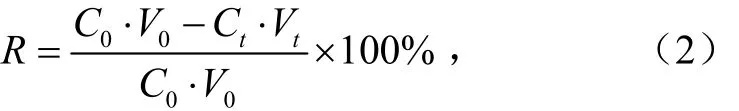

1)优化膜朝向:试验中采用的正渗透膜为非对称膜,由致密的活性层和多孔支撑层构成,其正渗透浓缩过程有2种运行模式,即活性层朝向沼液的FO模式和支撑层朝向沼液的PRO(pressure retarded osmosis)模式[15]。在错流速度为20.5 cm/s,汲取液为1和2 mol/L NaCl条件下,比较FO 和PRO模式下的正渗透膜水通量,获得较优的膜朝向。

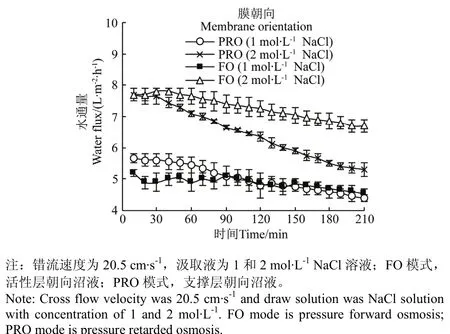

2)优化错流速度:在较优膜朝向下,以2 mol/L NaCl作为汲取液,比较错流速度为10.2、15.4、20.5、25.6和30.7 cm/s条件下的膜运行性能,从而获得较优的错流速度。

3)筛选汲取液种类:在较优膜朝向和错流速度下,分别选取2 mol/L的NaCl、MgCl2、Na2SO4和MgSO4溶液作为汲取液,并比较上述4种汲取液条件下的正渗透膜运行性能以筛选出理想的汲取液种类。

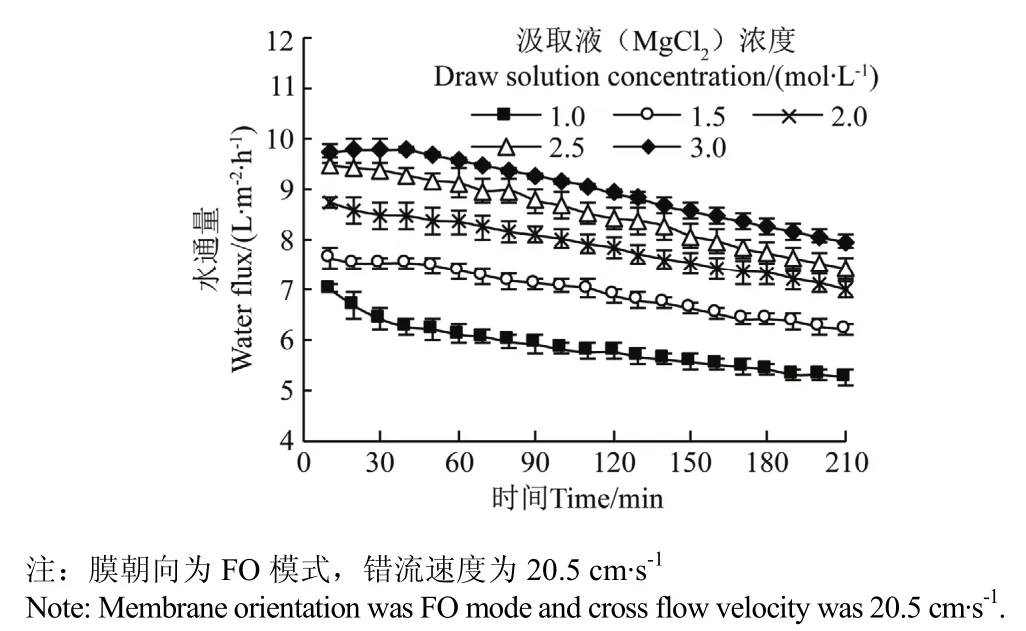

4)优化汲取液浓度:在筛选出理想的汲取液种类后,改变该汲取液浓度(1.0、1.5、2.0、2.5和3.0 mol/L),比较其正渗透膜运行性能以获得该汲取液的最佳浓度。

上述优化试验中,每个条件下均做2组重复运行试验。

1.4分析指标及方法

试验中料液的总有机碳(TOC)采用总有机碳分析仪(型号:TOC-VCPH)测定;TN的测定方法为过硫酸钾氧化紫外分光光度法;NH4+-N采用纳氏试剂分光光度法进行测定;TP采用总磷快速测定仪(型号:5B-6P)测定;TK采用电感耦合等离子体发射光谱仪(型号:Optima 7000DV)进行测定。

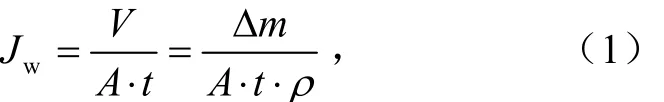

水通量是评价FO工艺运行性能的重要指标,可根据下式(1)进行计算。

式中Jw为水通量,L/(m2·h);V为通过FO膜的水量,L;A为有效膜面积,m2;t为运行时间,h;Δm为运行时间内汲取液质量的变化差值(通过电子天平及连接的计算机进行实时记录),g;ρ为水的密度,g/L。

FO膜对沼液中物质的截留率可根据下式(2)进行计算。

式中R为截留率,%;Ct为浓缩结束后汲取液某组分的浓度,mg/L;C0为原沼液某组分的浓度,mg/L;Vt为浓缩结束后汲取液体积,L;V0为原沼液体积,L。

2 结果与分析

2.1膜朝向对FO工艺运行性能的影响

对2种膜朝向条件下的膜运行性能进行了考察,获得的结果如图2所示。与FO模式相比,PRO模式下的水通量下降速率较快,这一现象在NaCl汲取液浓度为2 mol/L的条件下尤为显著。在NaCl汲取液浓度为1 mol/L的条件下,虽然PRO模式下的初始水通量较高,但由于水通量下降速率较快,工艺运行至150 min时的水通量已低于FO模式下的水通量。

图2 膜朝向对水通量的影响Fig.2 Effect of membrane orientation on water flux

正渗透膜的运行性能会受到浓差极化和膜污染的影响。其中,浓差极化包括在支撑层内部发生的内部浓差极化和在活性层表面发生的外部浓差极化。由于正渗透膜在FO模式下发生的内部浓差极化相比PRO模式更加显著,因此有效的渗透驱动力降低幅度更大,导致FO模式下的初始水通量较低[16-17]。而PRO模式下的水通量下降趋势较FO模式明显,这一现象可能与膜污染有关。在PRO模式下,沼液中的溶质易累积于多孔支撑层内部,而膜表面错流产生的水力剪切力无法直接作用于支撑层内部的污染物,使得膜污染加剧,水通量降低趋势明显。在FO模式下,错流产生的剪切力能够在一定程度上阻止沼液中的溶质沉积于致密活性层的表面,从而控制膜污染的发展,使水通量能够保持相对稳定[15,17-18]。Zhao等在其研究中发现正渗透膜朝向的选择取决于待浓缩料液的性质,易致膜污染的料液如废水、蛋白质溶液等应采用FO模式进行浓缩[18]。在本试验中,当采用正渗透膜对成分复杂,易受膜污染的沼液原料液进行浓缩时,基于控制膜污染的考虑,FO模式较优于PRO模式。

2.2错流速度对FO工艺运行性能的影响

在FO运行模式下,考察不同错流速度条件下的膜运行性能,其结果如图3所示。随着错流速度的提高,正渗透膜的初始水通量升高。当正渗透膜在FO模式下运行时,会发生浓缩的外部浓差极化和稀释的内部浓差极化。一些研究认为,内部浓差极化是影响水通量的关键[19-20]。但Suh等在对正渗透模型研究中发现,当浓缩浓度较高的料液时,浓缩的外部浓差极化对水通量的影响显著[21]。在本试验中,待浓缩的料液为浓度相对较高的沼液,浓缩的外部浓差极化不可忽视,而错流速度的提高在一定程度上抑制了正渗透膜的外部浓差极化[22],从而提高了初始水通量。

图3 错流速率对水通量的影响Fig.3 Effect of cross-flow velocity on membrane flux

虽然错流速度的提高能够增加初始水通量,但是根据图3中的运行数据可知,当错流速率提高至25.6和30.7 cm/s时,水通量的下降趋势更加显著。当沼液浓缩至150 min时,错流速度为25.6和30.7 cm/s下的水通量均已降低至7.2 L/(m2·h),接近于错流速度为20.5 cm/s下的水通量(7.1 L/(m2·h))。这一现象的出现可能存在两方面的原因:一方面是由于在上述2个错流速率条件下,初始水通量较高,单位时间内通过活性层进入支撑层内部的水量较大,加剧了稀释的内部浓差极化。由于错流速率的提高对内部浓差极化的作用不大[12],此时内部浓差极化的加剧在一定程度上抵消了错流速度提高对外部浓差极化的削弱作用,最终表现出水通量的下降趋势更加明显;另一方面可能是由于在较高的初始水通量下,在膜表面形成的污染层结构更加紧实,粘附性更强,从而加快了水通量下降速度[23]。根据各错流速度下的水通量及其在运行过程中的下降情况,本研究中沼液正渗透浓缩工艺的错流速度宜采用20.5 cm/s。

2.3汲取液种类对FO工艺运行性能的影响

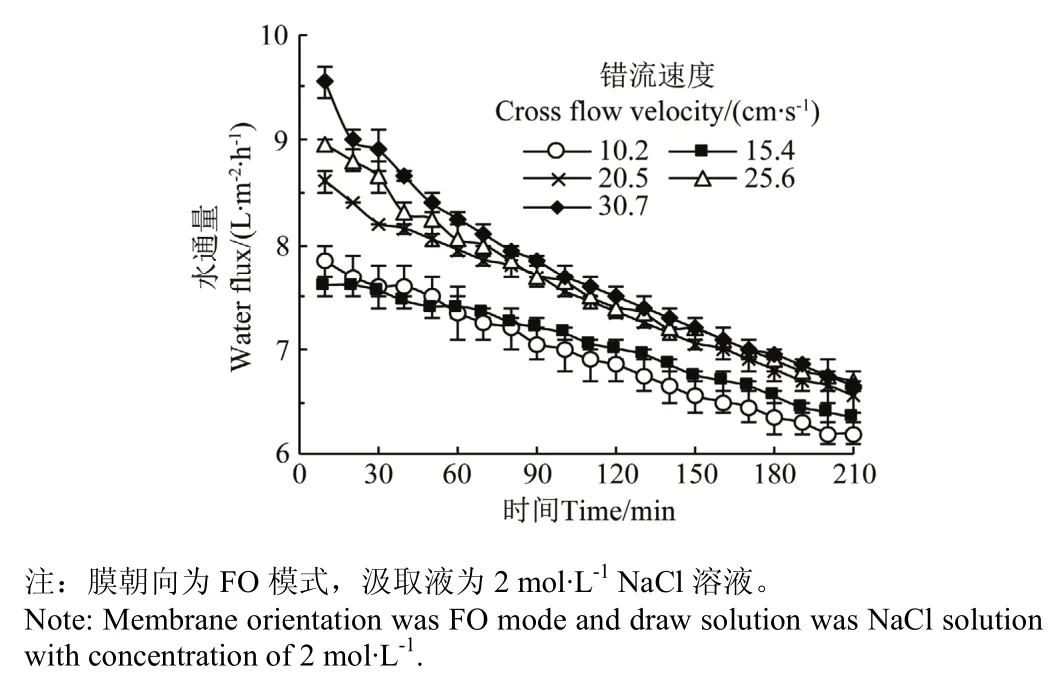

下图4为不同种类汲取液条件下的正渗透膜运行结果。

图4 采用不同种类汲取液的FO水通量Fig.4 Water flux of FO with different types of draw solution

根据图4中所示的运行数据,MgCl2汲取液的水通量最高。由于在相同浓度的4种汲取液中,MgCl2的渗透压最高[24],因此其正渗透驱动力最大,水通量最高[25]。由此可见,对于本研究中的沼液正渗透浓缩工艺,汲取液宜采用MgCl2溶液。王薇等在对上述4种汲取液的研究中也获得了类似的结果[26]。此外,Achilli等从运行性能、汲取液回收和经济成本等方面综合比较了14种无机汲取液(包括本研究中的4种汲取液)[27]。他们指出当采用正渗透膜处理废水时,在大多数情况下,MgCl2是最理想的汲取液。

2.4汲取液浓度对FO运行性能的影响

图5为不同浓度MgCl2汲取液条件下的水通量结果。随着MgCl2浓度的提高,水通量呈现上升的趋势。

图5 MgCl2汲取液浓度对水通量的影响Fig.5 Effect of draw solution (MgCl2) concentration on water flux

这主要是由于随着MgCl2浓度的提高,MgCl2汲取液的渗透压升高,渗透驱动力增加[25]。但是,MgCl2浓度与水通量并不成线性关系。如图5所示,当MgCl2浓度提高至2.5和3.0 mol/L时,水通量的上升幅度相对较小。当工艺运行至210 min时,MgCl2浓度为2.5 mol/L条件下的水通量已接近2.0 mol/L条件下的水通量。由此可见,此时MgCl2汲取液浓度的提高对于提高水通量的作用不显著。而另一方面,汲取液浓度的提高也意味着所需汲取液药剂量的增加,这将导致汲取液成本的上升。因此,综合考虑水通量及汲取液成本,MgCl2汲取液浓度应以2 mol/L为宜。

2.5FO对沼液的浓缩效果

在上述优化条件下将原始沼液浓缩5倍,并对原始沼液浓缩5倍后的浓缩沼液及汲取液主要成分进行分析,其结果见下表2。

表2 沼液和汲取液主要成分含量Table 2 Main substances contents in biogas slurry and draw solution

如表2所示,经正渗透膜浓缩后,沼液中各营养物质浓度均有显著地提高。其中,溶解性有机物(以TOC表征)、TP、TN、-N和TK浓度分别约为浓缩前的2.0倍、1.6倍、1.6倍、1.3倍和1.5倍,其浓缩效果与魏泉源等采用反渗透膜对沼液浓缩4~5倍的浓缩效果相当[2]。

此外,表2中沼液浓缩结束后汲取液各物质的浓度数据表明在浓缩过程中,沼液中部分物质仍会透过正渗透膜进入汲取液端。根据式(2)可计算正渗透膜对各营养物质的截留率,得出溶解性有机物、TP、TN、-N 和TK截留率依次为82.2%、96.4%、83.8%、83.6%和80.2%。正渗透膜对沼液中常规营养物质的截留率均超过80%,截留效果理想。

3 结 论

本研究优化了沼液正渗透浓缩工艺的运行方案,获得了以下主要结论:

1)本研究中的沼液正渗透浓缩工艺较理想操作方式是膜朝向为活性层朝向沼液的FO模式,错流速率则宜采用20.5 cm/s;

2)NaCl、MgCl2、Na2SO4和MgSO4这4种汲取液的对比试验结果表明,MgCl2作为汲取液时的水通量最高;此外,MgCl2汲取液最适宜的浓度为2 mol/L;

3)在优化条件下,当沼液浓缩至5倍时,溶解性有机物、TP、TN、-N和TK浓度均得到显著提高。正渗透膜对上述营养物质的截留率均在80%以上。

[参考文献]

[1] 靳红梅,常志州,叶小梅,等. 江苏省大型沼气工程沼液理化特性分析[J]. 农业工程学报,2011,27(1):291-296. Jin Hongmei, Chang Zhizhou, Ye Xiaomei, et al. Physical and chemical characteristics of anaerobically digested slurry from large-scale biogas project in Jiangsu Province[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(1): 291-296. (in Chinese with English abstract)

[2] 魏泉源,魏晓明,梁康强,等. 浓缩沼液在油菜上的应用效果研究[J]. 中国沼气,2011,29(5):50-54. Wei Quanyuan, Wei Xiaoming, Liang Kangqiang, et al. Effect of concentrated biogas slurry on rape[J]. China Biogas,2011, 29(5): 50-54. (in Chinese with English abstract)

[3] 宋成芳,单胜道,张妙仙,等. 畜禽养殖废弃物沼液的浓缩及其成分[J]. 农业工程学报,2011,27(12):256-259. Song Chengfang, Shan Shengdao, Zhang Miaoxian, et al. Concentration and determination of composition of biogas slurry[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2011, 27(12): 256-259. (in Chinese with English abstract)

[4] 余薇薇,张智,罗苏蓉,等. 沼液灌溉对紫色土菜地土壤特性的影响[J]. 农业工程学报,2012,28(16):178-184. Yu Weiwei, Zhang Zhi, Luo Surong, et al. Characteristics of purple vegetable soil under biogas slurry irrigation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(16): 178-184. (in Chinese with English abstract)

[5] 靳红梅,付广青,常志州,等. 猪、牛粪厌氧发酵中氮素形态转化及其在沼液和沼渣中的分布[J]. 农业工程学报,2012,28(21):208-214. Jin Hongmei, Fu Guangqing, Chang Zhizhou, et al. Distribution of nitrogen in liquid and solid fraction of pig and dairy manure in anaerobic digestion reactor[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(21): 208-214. (in Chinese with English abstract)

[6] 韩瑾. 沼液膜浓缩分离及其液肥混配技术研究[D]. 临安:浙江林学院,2009. Han Jin. Study on Biogas Slurry Concentration and Separation by Membrane and Liquid Fertilizer Preparation Technology[D]. Lin’an: Zhejiang Forestry College, 2009. (in Chinese with English abstract)

[7] 徐国锐. 沼液纳滤膜浓缩技术及其液体有机肥开发研究[D].杭州:浙江大学,2012. Xu Guorui. The Research on Concentration Technology for Biogas Slurry Using Nanofiltration Membrane and Subsequent Development of Concentrated Biogas Slurry asLiquid Organic Fertilizer[D]. Hangzhou: University of Zhejiang, 2012. (in Chinese with English abstract)

[8] 邓蓉. 畜禽养殖场沼液的负压浓缩与纳滤膜浓缩研究[D].重庆:西南大学,2014. Deng Rong. Vacuum Concentration and Nanofiltration Concentration of Livestock Biogas Slurry[D]. Chongqing: Southwest University, 2014. (in Chinese with English abstract)

[9] 梁康强,阎中,朱民,等. 沼气工程沼液反渗透膜浓缩应用研究[J]. 中国矿业大学学报,2011,40(3):470-475. Liang Kangqiang, Yan Zhong, Zhu Min, et al. Application research of reverse osmosis in concentrating biogas slurry from biogas projects[J]. Journal of China University of Mining & Technology, 2011, 40(3): 470-475. (in Chinese with English abstract)

[10] 梁康强,朱民,林秀军,等. 反渗透浓缩沼液预处理试验研究[J]. 中国沼气,2013,31(2):8-10. Liang Kangqiang, Zhu Min, Lin Xiujun, et al. Pretreatment of biogas slurry for its concentrating by reverse osmosis[J]. China Biogas, 2013, 31(2): 8-10. (in Chinese with English abstract)

[11] 林红军,陈建荣,陆晓峰,等. 正渗透膜技术在水处理中的应用进展[J]. 环境科学与技术,2010,33(12F):411-415. Lin Hongjun, Chen Jianrong, Lu Xiaofeng, et al. Application progresses of forward osmosis process in water treatment[J]. Environmental Science & Technology, 2010, 33(12F): 411-415. (in Chinese with English abstract)

[12] Zhao Shuaifei, Zou Linda, Tang Chuyang Y, et al. Recent developments in forward osmosis: Opportunities and challenges[J]. Journal of Membrane Science, 2012, 396: 1-21.

[13] Holloway Ryan W, Childress Amy E, Dennett Keith E, et al. Forward osmosis for concentration of anaerobic digester centrate[J]. Water Research, 2007, 41(17): 4005-4014.

[14] 李红娜,史志伟,朱昌雄. 利用海水汲取液的沼液正渗透浓缩技术[J]. 农业工程学报,2014,30(24):240-245. Li Hongna, Shi Zhiwei, Zhu Changxiong. Concentration of biogas slurry with forward osmosis technology[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(24): 240-245. (in Chinese with English abstract)

[15] McGovern Ronan K, Mizerak Jordan P, Zubair Syed M, et al. Three dimensionless parameters influencing the optimal membrane orientation for forward osmosis[J]. Journal of Membrane Science, 2014, 458: 104-110.

[16] Tang Chuyang Y, She Qianhong, Lay Winson C L, et al. Coupled effects of internal concentration polarization and fouling on flux behavior of forward osmosis membranes during humic acid filtration[J]. Journal of Membrane Science,2010, 354(1/2): 123-133.

[17] Mi Baoxia, Elimelech Menachem. Chemical and physical aspects of organic fouling of forward osmosis membranes[J]. Journal of Membrane Science, 2008, 320(1/2): 292-302.

[18] Zhao Shuaifei, Zou Linda, Mulcahy Dennis. Effects of membrane orientation on process performance in forward osmosis applications[J]. Journal of Membrane Science, 2011,382(1/2): 308-315.

[19] McCutcheon Jeffrey R, Elimelech Menachem. Influence of concentrative and dilutive internal concentration polarization on flux behavior in forward osmosis[J]. Journal of Membrane Science, 2006, 284(1/2): 237-247.

[20] Gray Gordon T, McCutcheon Jeffrey R, Elimelech Menachem. Internal concentration polarization in forward osmosis: Role of membrane orientation[J]. Desalination,2006, 197(1/2/3): 1-8.

[21] Suh Changwon, Lee Seockheon. Modeling reverse draw solute flux in forward osmosis with external concentration polarization in both sides of the draw and feed solution[J]. Journal of Membrane Science, 2013, 427: 365-374.

[22] Cath Tzahi Y, Childress Amy E, Elimelech Menachem. Forward osmosis: Principles, applications, and recent developments[J]. Journal of Membrane Science, 2006,281(1/2): 70-87.

[23] Xie Ming, Nghiem Long D, Price William E, et al. Impact of organic and colloidal fouling on trace organic contaminant rejection by forward osmosis: Role of initial permeate flux[J]. Desalination, 2014, 336: 146-152.

[24] 吴晴. 正渗透过程中驱动溶质反渗规律研究[D]. 哈尔滨:哈尔滨工业大学,2013. Wu Qing. Research on the Reverse Permeation of Draw Solute in Forward Osmosis[D]. Harbin: Harbin Institute of Technology, 2013. (in Chinese with English abstract)

[25] 刘彩虹. 正渗透工艺特性及膜污染特征研究[D]. 哈尔滨:哈尔滨工业大学,2013. Liu Caihong. Basic Principles of Forward Osmosis and Its Membrane Fouling Behavior[D]. Harbin: Harbin Institute of Technology, 2013. (in Chinese with English abstract)

[26] 王薇,孙静,王宝春. 正渗透过程参数对渗透性能的影响.高分子材料科学与工程[J]. 2012,28(1):86-88,92. Wang Wei, Sun Jing, Wang Baochun. Effect of process parameters on osmosis performance during forward osmosis[J]. Polymer Materials Science and Engineering,2012, 28(1): 86-88, 92. (in Chinese with English abstract)

[27] Achilli Andrea, Cath Tzahi Y, Childressa Amy E. Selection of inorganic-based draw solutions for forward osmosis applications[J]. Journal of Membrane Science, 2010, 364(1/2): 233-241.

Optimization of forward osmosis process for concentration of biogas slurry

Xu Meilan1, Ye Qian1※, Li Yuangao1, Song Yanqing1, Xiao Fen2

(1. Xiɑmen Key Lɑborɑtory of Membrɑne Reseɑrch ɑnd Applicɑtion, Xiɑmen University of Technology, Xiɑmen 361024, Chinɑ; 2. Wuhɑn Poten Environment Group Co., Ltd., Wuhɑn 430000, Chinɑ)

Abstract:Biogas slurry is one of the products of anaerobic fermentation of livestock wastewater, which contains substantial quantities of organic matter, nitrogen, phosphorus, potassium and other nutrients. For environmental protection and resources recycling, the biogas slurry could be used as a fertilizer. However, the biogas slurry could not be completely used for nearby farmland and it is difficult to transport such large volume of biogas slurry. Therefore, concentration becomes important for economic transportation and practical application of the biogas slurry as a fertilizer. In recent years, forward osmosis (FO)concentration technology has attracted growing interest. However, there were few researches concerning concentration of the biogas slurry with FO technology. To facilitate the extensive application of FO process for concentration of biogas slurry,further and comprehensive works should be carried out. In this study, a forward osmosis process was built for concentration of the biogas slurry and the performance of this process under different conditions was investigated. The results indicated that the membrane orientation should be set as FO model when the active layer was facing the feed solution. When the support layer was facing the feed solution (pressure retarded osmosis, PRO model), although the initial water flux was higher, the water flux declined quickly. Under the FO model, the hydraulic shear caused by the cross flow could prevent the deposition of the solutes of the biogas slurry over the active layer of the membrane, thereby alleviating the membrane fouling. By comparing the performance of the FO process under different cross flow velocities of 10.2, 15.4, 20.5, 25.6 and 30.7 cm/s, the cross flow velocity of 20.5 cm/s was considered to be preferred for this process. When the cross flow velocity was increased to be 25.6 and 30.7 cm/s, the water flux decline quickly, which was possibly due to the severer internal concentration polarization and membrane fouling caused by the higher initial water flux. To select the ideal draw solution, four inorganic draw solutions as NaCl, MgCl2, Na2SO4and MgSO4solutions with the same concentration were tested for this process. Due to the highest osmotic pressure of MgCl2, the highest water flux was obtained when MgCl2was used as the draw solute. To obtain the optimal concentration of MgCl2draw solution, the performance of the FO process with MgCl2solution concentrations of 1.0,1.5, 2.0, 2.5 and 3.0 mol/L was further evaluated. The results indicated that the increase of MgCl2solution concentration could heighten the water flux. However, when the concentration was increased to be 2.5 and 3 mol/L, the enhancement of the water flux was not significant. Therefore, comprehensively considering the water flux and the cost of draw solution, the MgCl2solution concentration of 2 mol/L was advised to be used for this FO process. Under the above optimal conditions, the volume of the biogas slurry was reduced to be 1/5 of the original volume by the FO process. Soluble organic substances, total phosphorus, total nitrogen, ammonia nitrogen and total potassium concentrations in the concentrated biogas slurry significantly increased. The rejection efficiencies of the above substances were 82.2%, 96.4%, 83.8%, 83.6% and 80.2%, respectively. The above results indicated the excellent performance of the FO process.

Keywords:concentration; optimization; osmosis; biogas slurry; membrane orientation; cross flow velocity; draw solution

作者简介:许美兰,女,福建惠安人,讲师,博士,主要研究方向为废弃物处理及资源化利用、膜技术研发及应用。厦门厦门理工学院环境科学与工程学院,厦门市膜技术研发及应用重点实验室,361024。Email:brooke@xmut.edu.cn※通信作者:叶茜,女,江西九江人,副教授,博士,主要研究方向为生物质资源回收及利用、膜技术研发及应用。厦门厦门理工学院环境科学与工程学院,厦门市膜技术研发及应用重点实验室,361024。Email:yeq@xmut.edu.cn

基金项目:福建省科技计划重点项目(2013N0035);福建省资助省属高校科研专项课题(2014JK0035)

收稿日期:2015-05-24

修订日期:2015-12-10

中图分类号:X71;S19

文献标志码:A

文章编号:1002-6819(2016)-02-0193-06

doi:10.11975/j.issn.1002-6819.2016.02.028