China Nonferrous Metals Monthly

China Nonferrous Metals Monthly

The Making of the Glory of“China’s Capital of Molybdenum” –Part II

Li Chaochun, Chairm an of China Molybdenum, said that after th is acquis ition, the company would become the world’s biggest manufacturer of m olybdenum, tungsten, and cobalt, th e world’ s second biggest manufacturer of niobi um, and upgrade to the status of a world-cla ss le ading ente rprise specializing in rare metals. In 2013, China Molybdenum successfully acquired Australia NPM Copper & Gold Mine from mining giant Rio Tinto Group with about USD800 m illion. This mine operated stably over the past 3 years, which accumulated rich experience of overseas mine developm ent for China Molybdenum , meanwhile it also lay down foundation for China Molybdenum’s a cquisition of overseas assets.

Through integration, L uanchuan County lay down solid foundation for resource concentration, assisting the superior to become strong, and building m ore optimized scientific platform for uncompartmentalized prospecting, and deep-seated ore-prospecting.

China Molybdenum Group Sandaozhuang Mining Zone has 640,000 tonnes of associated white tungsten m etal reserve, whose average grade is 0.117%, m aking it China’s second biggest w hite tungsten m ineral deposit. Nevertheless, this white tungsten m ine which accounts f or 71.1% of China’s retained tungsten reserve has no con dition for independent exploitatio n, since th e average WO3 content of 90% above reserve is below 0.5%. For a long time in the past, in the mining and dressing process of Luanchuan molybdenum tungsten ore, each year nearly 8000 tonnes of tungsten m etal are piled up in tailing heap after mining, crushing and grinding processing steps.

For this reason, over the years China Molybdenum Group c ontributed 260 m illion yuan of investm ent, firs t it coop erated with scientific resea rch institu tes h eaded by Changsha Engineering a nd Resear ch Institu te of Nonferrous Metall urgy, adopted advanced technology of high benc h graded zone for processing large m ined-out area, recovered 81.88 million tonnes of residual ore resource; secondly, it introduced “autom ated large flotation colum n f ull-process jo int molybdenum dressing technology process”from the US-based EMC Technology Corporation, which improved molybdenum recovery rate by 2~6 percentage points, and concentrate grade by 5~4 percentage points, saved electricity by over 46%, this alone can add 100 million yuan of economic benefit each year; thirdly, it cooperated with the Nonferrous Metals Research ins titute of the Russian National Technology Center, re-started white tungsten recovery scientif ic research project, and success fully m astered Luanch uan white tungsten recovery technology, raised recovery rate to 72%, and rec overy ability to 30,000 tonne/day.

Yulu Mining Com pany is an ore dressing enterprise of the China Molybdenum Group focusing on molybdenum, tungsten, and iron in cooperation with Xiam en Tungsten Group, the white tungsten grade in its molybdenum dressing tailing is on ly about 0.06%, with complex ingredients. To this end, the com pany overcame difficulties, adopted large jetfloatation machine as crude grading equipm ent of the production line, set up cru de grad ing process system , adopted heating peeling concentration process technology, sewage treatment process technology, and white tungsten resource recove ry industrialization technology for molybdenum dressing tailing, increased comprehensive recovery rate of white tungsten from the past 46% to the current 62.4%, raised the concentrate grade from 19.32% to the current 28.9%, and comprehensive re covery ra te to 66%, whic h can increas e 9 m illion yuan of econom ic benefit each year.

In the 1.2073 sq km of the original Fuchuan Mining Company Shangfanggou m ining zone area, the exploitation m ethod is open-pit mining, it is both a large m ineral deposit with associated m inerals of m olybdenum & iron, and also a typical m ineral deposit of global high-talcose m olybdenum m ine. Through key technology test, the company im proved ore dressing recovery percentage of m olybdenum, iron and sulfur by 20.14, 20.38 and 80.93 percentage points respectively than the original technological proce ss. This technology upgrading not only increased incom e for the enterprise, but also so lved the d ifficulty of integrated utilization of domestic high-talcose molybdenum ore.

Owing to historical reasons, a certain num ber of enterprises lack sense of social responsibility, they emphasized resource development, and ignored environm ental protection, which brought bared rocks and disorderly stacking in the m ining zone, som e even resulted in dropping underground water level. Acco rding to statistics of Luanchuan County Geological and Mineral Resources Bureau, by the end of 2007 the whole county’s land area for m ineral developm ent is 26000 hectares, total land area da maged due to m ine production is 161.4 hectares.

In the aspect of m ine geological environm ent recovery and treatm ent, firstly, Luanchuan County strictly required 241 m ining right holders in the whole county to follow the guideline of “who brings dam age will be responsible for treatment”, m ake up for the debt in environm ental protection; secondly, it strictly im plemented m ine recovery treatm ent bond system, in the annual review of exploitation right, ente rprises failing to pay mine geological environm ent bond will be denied annual review; thir dly, it is required to compile tre atment plan in handlin g renewal, extension, alteration and transfer of exploitation license; fourthly, focused attention on key enterprises and leading enterp rises, adopted the approach of fanning out from a point to an area in m ine environment recovery and treatment. It has been learned that, since 2006 China Molybdenum Group invested over 55 m illion yuan to tr eat the “ar tificial p lain”with an area of 200,000 sqm in Sandaozhuang mining zone, planted over 30,000 cedars, junipers, common s moketrees, phoenix trees totaling 10 varie ties which are suitab le f or growth in alpine m ountainous areas at the slag discharge field. In 2012, China Molybdenum Group was identified as the second batch of national “Green Min e” pilo t u nits by th e Ministry of Land and Resources. Meanwhile, Luanchuan Zhongtian Mining Company used 102,000 cubic meters of mineral slag generated over the past years to carry out filling, land treatment, and road construction in 7 mined-out areas, reclaimed 23 mu land, and planted m ore than 500 trees. In 2013, Luanchuan Zhongtian Mining Company Central Niuxinduo Mining Zone was selected as one of the third batch of national “Green Mine” pilot units.

Driven by m ining order rectification, m ining resource integration, resource integrated utilization, m ine geological environm ent treatment and protection, Luanchuan County fulfilled the tr ansformation f rom black economy to green econom y, adde d luster to Luanchuan County’s “Rejuvenating the County through tourism” strategy.

Meanwhile, Luanchuan County went all out to find ore, aim ing to fulfill sustainable development of mining resources.

Over the past several years, Luanchuan County completed a tota l of 16 geological survey evaluation and key scientific problem tackling projects including th e land and resource comprehensive survey, the provincial-level cost of two rights project, and projects of the Ministry of Land and Resources and the Ministry of Science and Technology, whose total expense is 120 million yuan, subsequently it submitted 6 large an d medium sized newly discovered mineral deposits and one batch of molybdenum, tungsten, lead, zinc, and silver resources to the state government.

Currently, projects th at are und er way in Luanchuan County include: “Luanchuan Lead, Zinc Or efield D eep-seated Resourc e Prospecting Technology Integrated Research”, a subject of the Mini stry of Science and Technology “Twelfth Five Year” Support Plan;“Henan Nannihu-Sandaozhuang Porphyryskarn Type Molybdenum Mine Field Scientific Observation Base”, a special project for the industry of the Ministry of Land and Resources; “Study on Metallogenic Geological Background & Prospecting Model of Large Mineral Deposit”, “Key Basic Geological Research on Lead, Zinc, Silver, Molybdenum Uncompartmentalized Prospecting Zone in Luanchuan” etc. Over 40 m illion yuan of capital has been invested in relevant projects, key prospecting breakthroughs have been made in som e prospecting target areas, 6 large or ultra large lead, zinc, silve r m etal oref ields have been newly discovered, 1 large concealed molybdenum tungsten orefield has been discovered in the depth of mine, 7 A-grade, 5 B-grade, and 2 C-grade metallogenic prognosis zones have been defin ed, forecas t has been made for 3 molybdenum & tungsten m ines, 3 gold m ines, 7 lead and zinc mines, it is expected to newly add 2 m illion tonnes of molybdenum metal reserve, and 5 m illion tonnes of lead, zinc m etal reserve, whose potential value tops 500 billion yuan.

It has been lea rned th at in the th is coun ty’s GDP aggregate, m ining economy accounts for 80% above, wherein m olybdenum m ining economy ac counts for around 70%. In 2007, Luanchuan County’s overall economic strength jumped to third place in Henan Province. In 2015, even at a tim e when global molybdenum products rem ained in depression, Luanchuan County’s output of m olybdenum concentrate and tungsten concentrate reached 102,000 tonnes and 24,000 tonnes, accounting for 34% and 17% of dom estic total output respectively, making it the top-ranking tungsten & molybdenum production county nationwide.

The “Thirteenth Five Year”Development P lan of Hunan nonferrous metals industry: Poised to Reach One Trillion by 2020

Hunan is acclaim ed as the “Hom etown of nonferrous m etals”. Acco rding to statistics, there are 37 varieties of nonferrous metals with proven reserve in Hunan Province, wherein ensured reserve of nonfe rrous m etals such as tungsten, bism uth, and antim ony enjoy advantages in the national and even global context, reserves of tin, lead, zinc, vanadium , and rubidium rank top na tionwide. By relying on resource advantage a nd industry advantage, Hunan Province becam e an im portant nonferrous m etals production and processing base in the nation.

During the “Thirteenth Five Year Plan” period, Hunan Province nonferrous m etals industry planned grand target: By 2020, the whole province’s nonferrous m etals incom e from main business will reach 1 trillion yuan, industrial added value and total profit tax respectively will reach 300 billio n yuan and 150 billion yuan.

Nonferrous m etals industry is not only an important b asic raw mater ial industry, it also provides vital support for m anufacture industry to march toward m id to high-end position ing. During the “Thirteenth Five Year Plan” period,

Hunan Province m ust focus on high quality, high perform ance, high added value copper aluminum a nd titan ium products, vigorously develop deep processing, gradually extend toward high-end m anufacture industry such as new energ y vehicle, m achinery equipm ent, railway tran sport, air and space, shipbuild ing and m arine engineering. By 2020, the percentage of nonferrous m etals new m aterial and deep processing products m ust surpass 50%; industry concentration degree m ust be lifted to around 60%, it m ust cultiv ate 2 enterprises with sale s incom e topping 100 billion yuan, 3 enterpr ises with sales incom e topping 50 billion yuan, and 10 enterprises with sales income topping 10 billion yuan.

There are m ore than 3000 big or sm all nonferrous enterprises in Hunan Province, which are characterized by large number, small scale, scattered di stribution, serious homogenized development, high percentage of extensive processing products, and low percentage of deep processing products.

The “Plan” proposed that, revolving around the strategic ta rget of creating trillion grade nonferrous industry, in the “Thirteenth Five Year Plan” period it will newly build 8 featured park zones: Supporting Zhuzhou Sm elter Group’s relocation & tr ansition, plan the construction of lead zi nc production and deep processing park; based on enterprises headed by Changde Chuangyuan Alum inum, construct aluminum circu lar recycling indu strial park; based on enterprises headed by Yiyang Jintian New Material, construct air and space m aterial R&D production park; based on enterprises headed by Minmetals Rare Earth Jianghua Co., Ltd, construct Jianghua Rare Earth Industrial Park; based on enterprises headed by Jintian Aluminum, and Lantian Hi-tech, construct Luxi Nonferrous Metals Deep Processing Industrial Park; based on enterprises headed by Sunward Equipment Group, and Hunan Nonferrous Heavy Machinery, construct Changsha Nonferrous Equipment Manufacture Industrial Park; based on Xi kuangshan Shanxing Antimony Co., Ltd and Hunan Gold Group’s antimony product enterprise, construct antimony product deep processing park zone; based on deployment of functional divisions of headquarter econom y, construct nonferrous product trading and service park zone.

Propel 50 key projects including Changde highend industrial alum inum product deep processing, Zhuzhou Sm elter Group relocation & transition, Minm etals Shuikoushan gold copper, Zhuzhou hard prec ision tool, new lead acid battery energy storage power station, rare earth deep processing, antim ony deep processing, and air and space material R&D.

How to strike a balance between developm ent needs and environmental protection? The“Plan” proposed to vigorously develop nonferrous m etals circ ular economy, reduce consumption of m ineral resources and energy, change waste into tre asure, and turn harm into benefit.

In the “Th irteenth Fiv e Year Pla n” period, nonferrous m etals circular economy mainly covers: Resource integrat ed utilization of low grade, refractory ore and sm elting slag; recycling utilization of historically deposited mining was te rocks, a nd tailing after oredressing; large-scale ut ilization of secondary metals such as copper, alum inum, and lead, propel the construction of Hunan Province circular eco nomy “Bonded Zone” and “Dry Port”, join hands with m anufacturers, develop waste electromechanical product recycling and large waste m etal dism antling recyc ling industry.

In planning deploym ent, South Hunan will center on Chenzhou to construct resource development zone, ensure tiered developm ent and cir cular utiliza tion of m ineral resources; Central Hunan will ce nter on Changsha, Zhuzhou and Xiangtan to construct incubator for circu lar usage of advanced techno logy achievements, develop low-carbon and ecofriendly deep processing industrial circle; North Hunan will center on Miluo to construct nonferrous m etals secondary resourcesdistribution cente r integ rating recyc ling, dismantling, processing, R&D, and trading. During the “Thirteenth Five Year Plan” period, output of secondary nonferrous m etals m ust surpass 3 m illion ton nes, incom e f rom m ain business of circular econom y in dustry will reach 300 billion yuan.

The Plan dem anded t hat, by 2020, energy consumption per unit i ndustrial added value of nonferrous metals enterprises above designated size must drop by 18% than that at the end of 2015, energy consumption of major nonferrous metals products should approach w orld leading standard, residual heat and residual energy are fully utilized. Pollutant emission concentration and emission aggregate m ust both hit targets, industrial waste water will ach ieve zero discharge, integra ted utilization rate of industrial s olid waste will reach 75%, heavy metal pollution in key areas m ust decrease by 15%.

After entering the “Thirteenth Five Year Plan”, as important fundamental industry of national economy, meanwhile as Hunan Province’s key pillar industry, the nonferrous m etals industry has come to a c rucial period of transition and upgrading.

Hunan Province nonferrous metals industry is not small in terms of “size”: In 2015, provincewide nonferrous enterp rises above designated size fulfilled industrial added value of 96.204 billion yuan, incom e from main business was 382.702 billion yuan, total prof it tax was 19.385 billion yuan. Main econom ical indexes all ranked am ong top 6 in the nationwide nonferrous industry. Nonetheless, the industry’s developm ent is still facing m any problems.

Firstly, poor perform ance. Last year, nonferrous industry accounted for over 10% in whole province’s GDP, but accounted for under 5% in whole province financial income.

Secondly, high energy consum ption, and low output. In 2015, energy consumption of nonferrous metals industry accounts for 13.8% in whole province’s industrial en ergy consumption, but its adde d value of industrial output only accounts for 7.2% of the whole province.

Restraint of resou rces and environm ent has emerged evidently. Previously acclaimed as the“Hometown of nonferrous m etals”, due to excessive exploitation of resources, and low level of utilization, last year the self supply rate of Hunan Province’s m ajor nonferrous m etals mineral raw materials is 32.75%; heavy m etal pollution accum ulated from long-tim e mining & dressing of m ines and smelting production, plus historically left over m ine geological environmental problem s have gradually emerged……

According to Song Jianm in, Secretary of Party Leadership Group and Director of the Provincial Nonferrous Metals Ad ministration Bureau, most nonferrous enterprises walked the route of low-end duplication, which is the main reason leading to “big but not strong” condition of Hunan Province nonferrous metals industry.

Zhuzhou Sm elter Group, once a leading enterprise in China’s lead zin c sm elting industry, and today trappe d in predicam ent, is exactly a ty pical case in point. Over th e past years, though Zhuzhou Smelter Group’s annual capacity gradually grew from 150,000 tonnes to 650,000 tonnes, it never truly accom plished upgrading of product series. Driven by shortterm intere st, within the province othe r nonferrous enterprises one after another launched similar projects, and continued lowend duplication, provin ce-wide lead zinc capacity jumped from 600,000 - 700,000 tonnes to 6 million tonnes. In the past products were eagerly “snapped up” by custom ers, but later the situation turn ed into m utual price cut in order to grab the m arket. Results of m utual“slaughter” endangered existence and development for the entire industry.

“We cannot always follow others’ steps, we must have new vision, new thinking approach.”Song Jianmin said, on the one hand, against the global economic macro background, nonferrous metals industry is still trapped in a downturn, but its “re source a ttribute, m aterial attribu te, finance attribu te, an d social attribu te”determine vast space of future developm ent for the industry, enterprise s m ust have long-term vision; on the other hand, revolving around resources’ scien tific prospecting, inten sive exploitation, integrated recycling, deep processing, clean production, circular utilization, energy saving & environm ental protection steps, enterprises have an endless list of things to do.

According to Song Jianm in, Hunan Province nonferrous metals industry m ust make up for product inadequacies, fi rstly, starting from existing stock, strictly control newly added capacity, encourage enterprises with favorable conditions to voluntarily cut stock capacity, and connect with the natio nal “One Belt, One Road” strategy, relocate excess capacity; meanwhile, based on the development thinking of “i mproving lead zinc, expanding copper aluminum, strengthenin g tungsten, antim ony, bismuth, e xpanding rare earth”, support enterprises to implem ent technology renovation, speed up product upgrading.

Secondly, optim ize increm ent. W ith the implementation of key strategies including“Made in China 2025”, high-end m anufacture industry has created huge dem and for nonferrous strategic new materials. During the“Thirteenth Five Year Plan” period, Hunan Province nonferrous m etals industry m ust put through the channel linking up science & technology and industry development, by 2020, it is required to newly add 10 state-level innovation platform s, a nd 40 provincial-level innovation platform s. Strengthen extension & docking between nonferrous industry and downstream industries including new energy vehicle, m achinery equipm ent, railway transport, air and space, shipbuilding and marine engineering industries, continually expand co nsumption field and space for nonferrous metals, propel nonferrous em erging industry to m ake breakthrough and achieve development.

Liangshan Rare Earth Resources Reserve Ranks Second Nationwide

As early as on February 7, 2014, the National Development and Re form Comm ission reviewed and formally approved to set up Panxi Strategic Resource Innovation Developm ent Pilot Zone. Since its rare earth resource reserve ranked second nationwide, a num ber of counties and districts in Liangshan Prefecture are inco rporated into the Pilo t Zone, and become core components of this Pilot Zone.

According to relevant data, Sichuan Province has nearly 300 km rare earth resource belt stretching from Mi anning, Xichang to Dechang, wherein, two m ajor mines Mianning Maoniuping Rare Earth Mine, and Dechang Dalucao Rare Earth Mine rank among top three in the nation in terms of reserve, their reserves respectively have reached 2 million tonnes and 700,000 tonnes, boasting very high value for integrated utilization, making them China’s key Vanadium & Titanium, rare earth industry base and iron ore resource guarantee base.

According to staf f workers, f ollowing integration spanning over two years, Liangshan Prefecture has set up large rare earth group companies headed by Sichuan Jiangxi Copper Rare Earth Co., Ltd, this is regarded as a key measure in im plementing the construction of Panxi State-level St rategic Resources Innovation Developm ent Pilot Zone, it will propel integrated utilization and protection of Panxi strategic resources, and boost accelerated development in W est China and ethnic minority areas.

It has been learn ed that, acco rding to the Sichuan Province “Construction P lan of Panxi State-level Strategic Resources Innovation Development Pilot Zone (2013-2017)”, by 2017, Panxi rare earth m ine exploitation m ustdevelop from the existing 30000 tonnes to 50000 tonnes, rare earth smelting & separation will develop from the existing 10000 tonnes to 30000 tonnes. The developm ent of rare earth industry in Liangshan Prefecture is therefore considered as top priority.

By September 2015, S ichuan Jiangxi Copper Rare Earth Co., Ltd ha s completed 2.55 billion yuan of investm ent, total asset reached 3.099 billion yuan, it possessed the m ining right of Mianning County Maoniuping Rare Earth Mine, China’s second bi ggest light rare earth mine, and developed the annual production capacity of 20000 tonnes of rare earth concentrate, 16000 to nnes of s melting & separation, 2000 tonnes of m etal, 4000 tonnes of NdFeB strip, and initially developed mining, dressing, smelting, and deep process ing industrial chain, it has become one of China’s important rare ea rth enterprises. W hereas Dechang County Zhineng Rare Earth Co., Ltd is another important rare earth industry base in Liangshan Prefecture with represen tative feature, total production capacity of rare earth products has topped 20000 t/a, percentage of export products has reached 20%.

Copper tube of Hailiang Co., Ltd Will Utter the World’s “Loudest Voice”

On September 20, the Sixth Board of Directors of Zhejiang Hailiang C o., Ltd convened third meeting, which review ed and approved the“Proposal o n Accelerating Im plementation of Industrial Upgrading, Expanding Production Scale, Optimizing Production Layout, in Order to Meet th e Strategic Target of Becom ing the World’s Most Powerful Copper Tube Manufacturer at th e Earliest Possible Tim e“. This company plans to fu lly bring out its self advantages, firmly grasp industry developm ent opportunities, implement industrial upgrading, efficiency-increasing and production expansion project, so as to elim inate outdated capacity in the industry, adjust the com pany’s product structure, enhance pr oduct quality, expand production scale, optim ize production base deployment, incre ase m arket share, and m eet the strateg ic target of becom ing the world’s most powerful copper tube manufacturer at the earliest possible time.

Hailiang C o., Ltd plans to newly construct high-end copper tube production lines in production base in Guangdong, Anhui, Shanghai and Vietnam with self raised funds, expand production scale, further optim ize deployment of product structure and production base; meanwhile, the company plans to use self raised fund to acquire US copper tube manufacturer or invest and build new copper tube production lines in the U nited S tates, accelerate the p rogress of globa lization strategy, actively expand international m arket, and effectively avoid trade barrier risk.

Implementation of the above-m entioned projects will help enha nce Hailiang Co., Ltd’s overall co mpetitiveness, and m eet str ategic target a t th e ea rliest p ossible tim e. Af ter th e project is com pleted, it will q uicken th e company’s pace of copper tub e industrial upgrading, quickly rais e production equipm ent standard, continually im prove product quality, reduce production energy consumption and manufacture cost of products, further optim ize product structure, and enhance company core competitiveness. Meanwhile, Hailiang Co., Ltd will also further optim ize production b ase deployment, effectively rem ove international trade barrier, and rapidly increase market share.

Based on m arket development needs, actively constructing high-end copper tube production line is ve ry nec essary. In recent years, downstream industries especially the household electrical appliance industry experienced heightened dem and fo r energy saving & consumption reduction and co st con trol, downstream custom ers’ dem and for high precision and high perform ance c opper tube products g rew continu ally, som e trad itional equipment and production lines in the industry can no longer m eet the production needs of high precision and high perform ance products.

The Inte rnational Co pper Association once published “Copper Quality Household Electrical Appliance La bel”, aim ing to help consumers and enterprises to learn about safe quality of household electrical appliances, protect consumer rights, and im prove product competitiveness of Chinese househo ld electrical appliance brands. Hailian g Co., Ltd indicated that, after project im plementation, copper tube products will be able to completely meet custo mer needs in term s of precision, function, and production cost.

Furthermore, the above pr ojects can satisfy the needs of energy saving and emission reduction, and facilitate the indus try to achieve stable development. Through project execution, on the basis of analyzing energy consum ption structure of existing copper tube processing production process, Hailiang Co., Ltd intensified investment in crucial equipment and key energy-consum ing production steps, adopted the m ost advanced energy-saving and consumption reduction technologies and equipment, implemented optimized production process, and equipment upgrading measures, so as to m inimize energy con sumption in production steps; meanwhile, the project comprehensively promoted production control system (MES) and enterprise resources management system (SAP), changed traditionally hum an-centered m anufacture management m odel, and upgraded it to fully automatic infor matized high efficiency new manufacture m anagement model, which enhanced production m anagement standard, and effectively lo wered unit energy consumption of products. By leveraging its own leadin g status in the industry, Hailiang Co., Ltd will also rais e quality and energy consumption standard of the copper tube processing industry, o ccupy the height in energy consum ption standardization, and pioneer healthy development of the industry.

Judging from features of the c opper tube manufacture industry, construction of new production lines with curre ntly state-of the-art equipment and technologies can quickly lift the manufacturer to the industry summit, which can not only significantly enhance product quality, improve production efficiency, lower product cost, reduce energy consum ption, and improve environmental quality, it also can help phase out out-dated industry capacity, accelerate industrial upgrading, so as to create very favorable conditions for prom oting healthy development of the industry, and make positive contributions to the society’s energy saving and emission reduction. Furthermore, Hailiang Co., Ltd indicated that, new construction of production line dif fers from technology upgrading, since it will not b ring partial shutdown or production cut in the company, so as to m iss the chanc e of developm ent to quickly grasp the m arket, choosing new construction of producti on line to quicken the pace of industrial upgrading is both rational and feasible.

It has been learn ed that, after the ab ove actual investment project is launched into production, Hailiang’s copper tube production capacity will reach 600,000 t/a. On such basis, Hailiang Co., Ltd will a lso continu e to look f or new development opportunities, propel the enterprise’s rapid developm ent, and m eet the target of becom ing the world’s m ost powerful copper tube m anufacturer at the earliest possible tim e. As a par ticipant in the tide of industry transition and upgrading, Hailiang Co., Ltd holds reference value for other enterprises in the indu stry, all its actions f ollowed the“Guiding opinions on creating excellent market environment to prom ote nonferrous m etals industry to adjust structure, prom ote transition, and improve performance”, it strives to actively promote international cooperation, fully brings out advantages in China’s nonferrous m etals industry in technology and equipm ent, propels output in the entire industrial chain in advanced equipment, product, t echnology, standard, service, and im proves globalized operation ability. Through “walk out” as a Chinese enterprise and a nonfe rrous m etals, it will acquire industry influen ce in the global arena, and seek be tter development for itself, for the industry, and for the nation.

Baise Mining Group’s 300,000 t/a Aluminum Project Achieved Production Target, 10000 t/ a High Purity Aluminum Project Broke Ground

The 10000 t/a high purity alum inum engineering project in Baise Mining Group’s Coal-power-aluminum Integration Project started con struction a t Tianyang Xinshan Aluminum Industrial Park. Following the successful production launching of Baise Mining Group’s Coal-power-alum inum Integration Xinshan Project - Phase I 2×350MW coal-fired unit self supply power plant and 300,000 t/a Di rect Supply Liquid Aluminum Project, P hase II will develop toward refined alum inum, high purity aluminum, alum inum sheet, strip and foil projects.

At the end of 2013, fac ing mounting pressure of continual economic downturn, guided by the initiative “Building one more industrial Baise”proposed by the CPC Municipal Comm ittee and the Municipal Governm ent, with vigorous support and guidance f rom Tianyang County and Xinshan Park Zone, Baise Mining Group followed the developm ent m ainline of “coalpower-aluminum integration project construction”, despite absence of capital, professional talents, an d no experience in key project m anagement, it tackled problem s and overcame difficultie s, accom plished total completion and launching of coal-poweraluminum integration project ahead of schedule, and created the fastest s peed in the construction of sa me category dom estic projects. Up till now, the 2×350MW self power plant has successfully passed 168 hours fullload operation, the 300,000 t/a liquid aluminum project with a total of 268 electrolytic tanks has fully connected power and reach ed production capacity, all econom ic indicators in the operation surpassed design standard. In order to further ex tend aluminum industrial chain, promoted Baise alum inum i ndustry to develop toward high added value, high technology content, and low environm ental load directions, while vigorously propelling the construction of coal-power-alum inum integration project, Baise Mining Group actively prom oted and im plemented cooperation with S hanghai Jiao Tong University in the industrialization of refined aluminum & high purity aluminum purification technology, carried out early-stage work for the construction of the Refi ned Aluminum Project, established “Baise Mining Group—Shanghai Jiao Tong University Advanced Alum inum Alloy Material United Research Center”, carried ou t in-dep th research in high-end aluminum alloy aspects including high strength aluminum alloy for high-speed railway carriage body, aluminum alloy for new energy vehicle, high performance aluminum alloy for air and space, high performance and high so lderability aluminum a lloy for LNG ships, high voltage capacitor alum inum foil, high conductivity aluminum alloy etc.

The construction star t of 10000 t/a Refined Aluminum Projec t m arks a m ilestone in the development of in Baise’s alum inum industry, and a key m easure by Baise City in implementing and executing the “second business startup” of Guangxi alum inum industry developm ent, it signals that the construction of Baise’s eco-friendly aluminum industry demonstration base entered a brandnew developm ent stage. The construction of this project involves total investm ent of 77 million yuan, total lan d area of 2 8300 sqm, scheduled f or constructing 10000 t/a refined aluminum production line, with 18 m onths of construction period; after the project formally starts operation, it is es timated to fulfill 250 million yuan of annual sales in come, bring 34 million yuan of annual total profit, pay 24.55 million yuan of tax, and newly add 150 jobs. It features excellent econom ic benefit and social benefit.

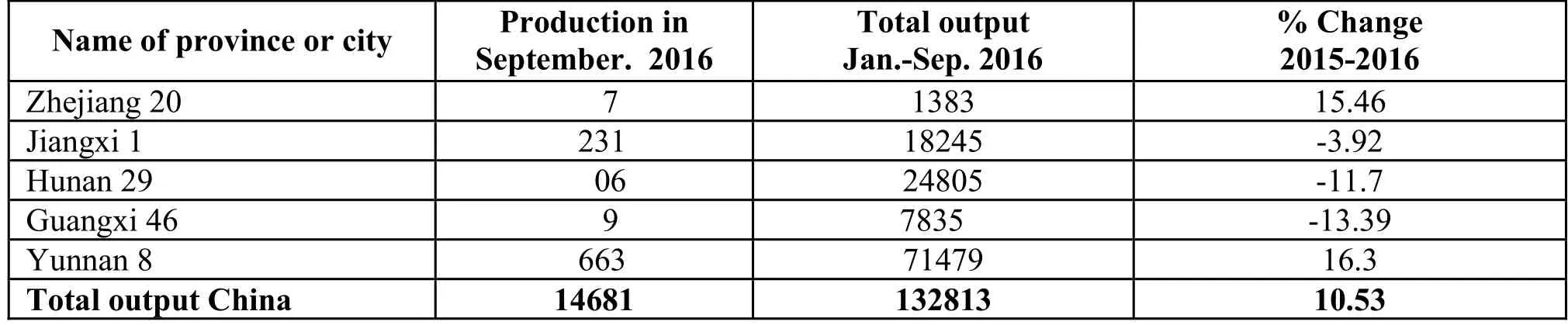

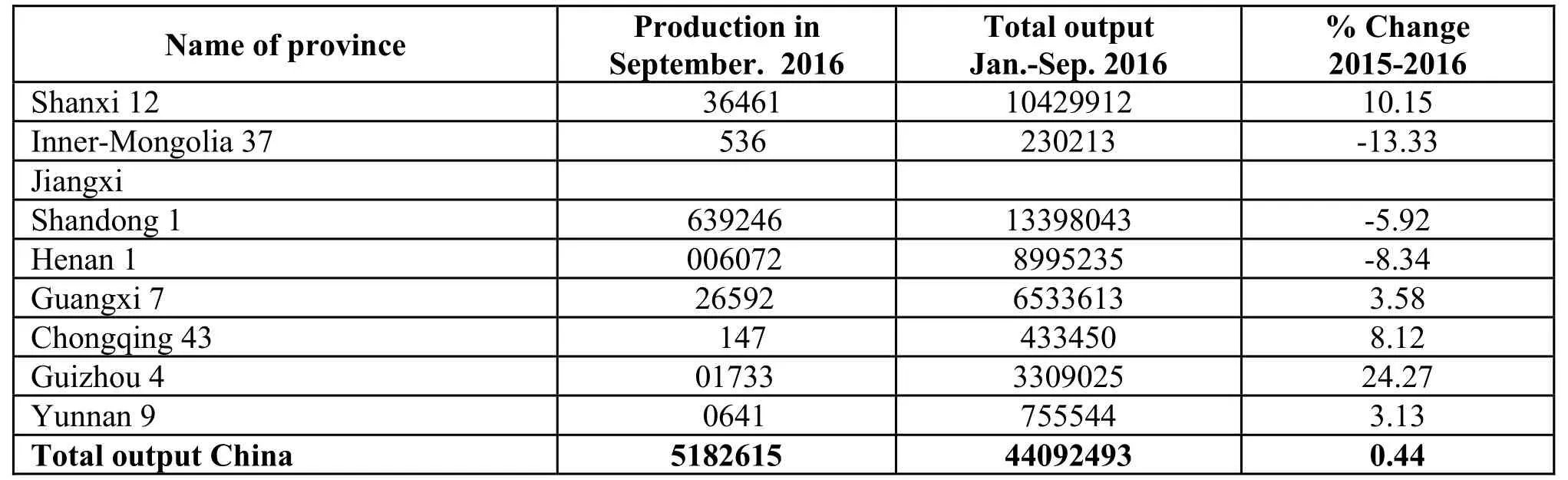

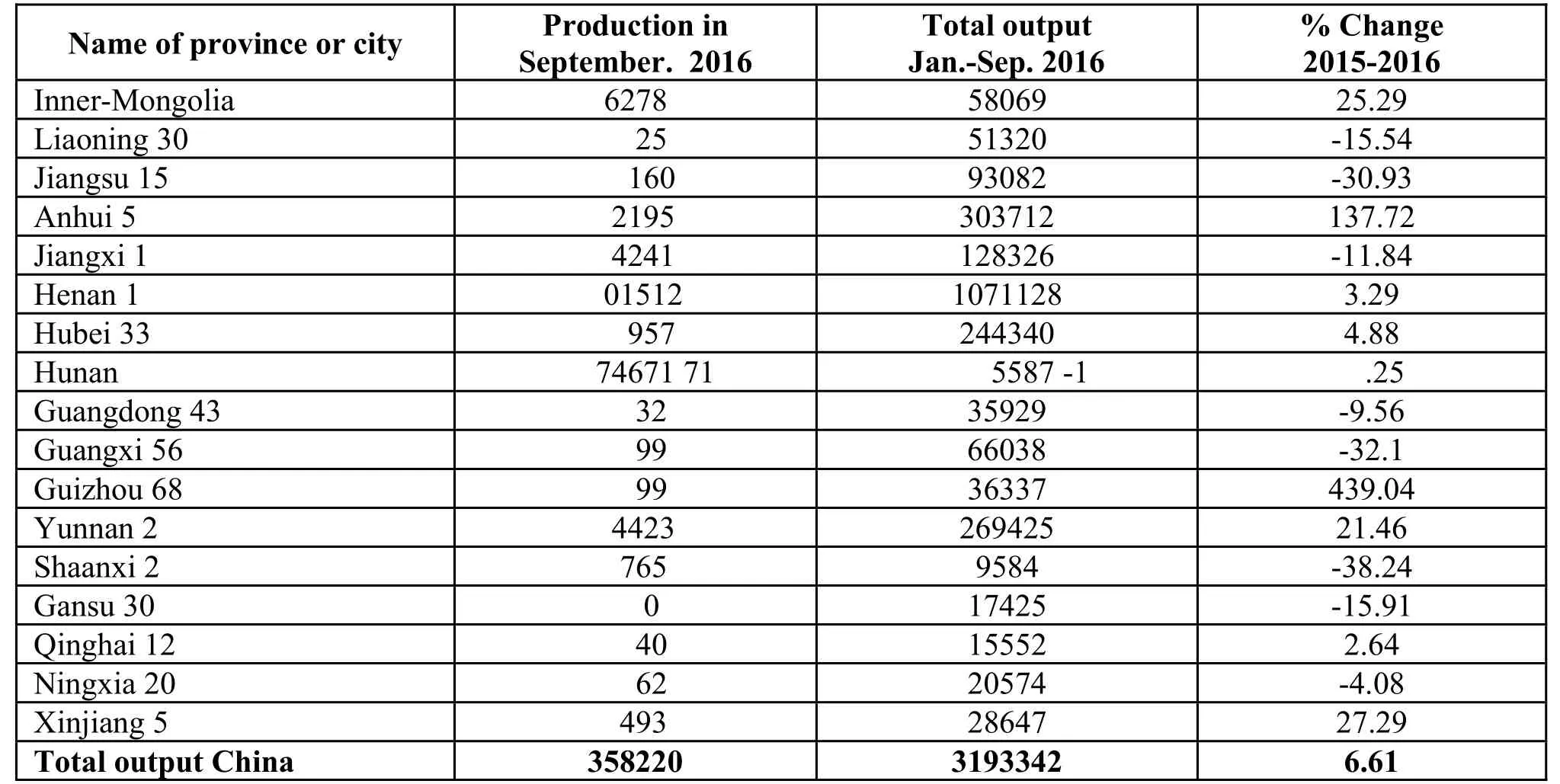

Tin Production by Province or City in 2016Unit: metric ton

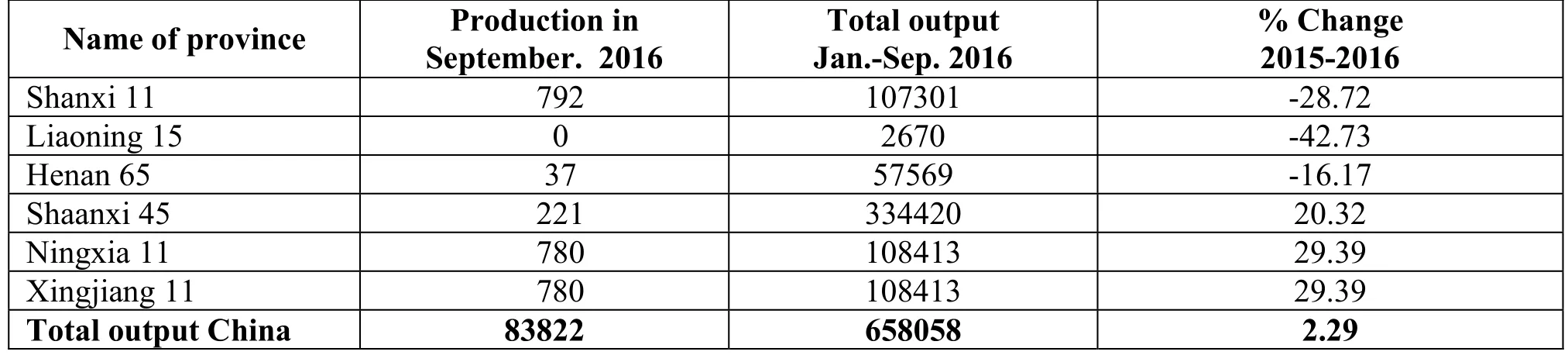

Magnesium Production by Province in 2016Unit: metric ton

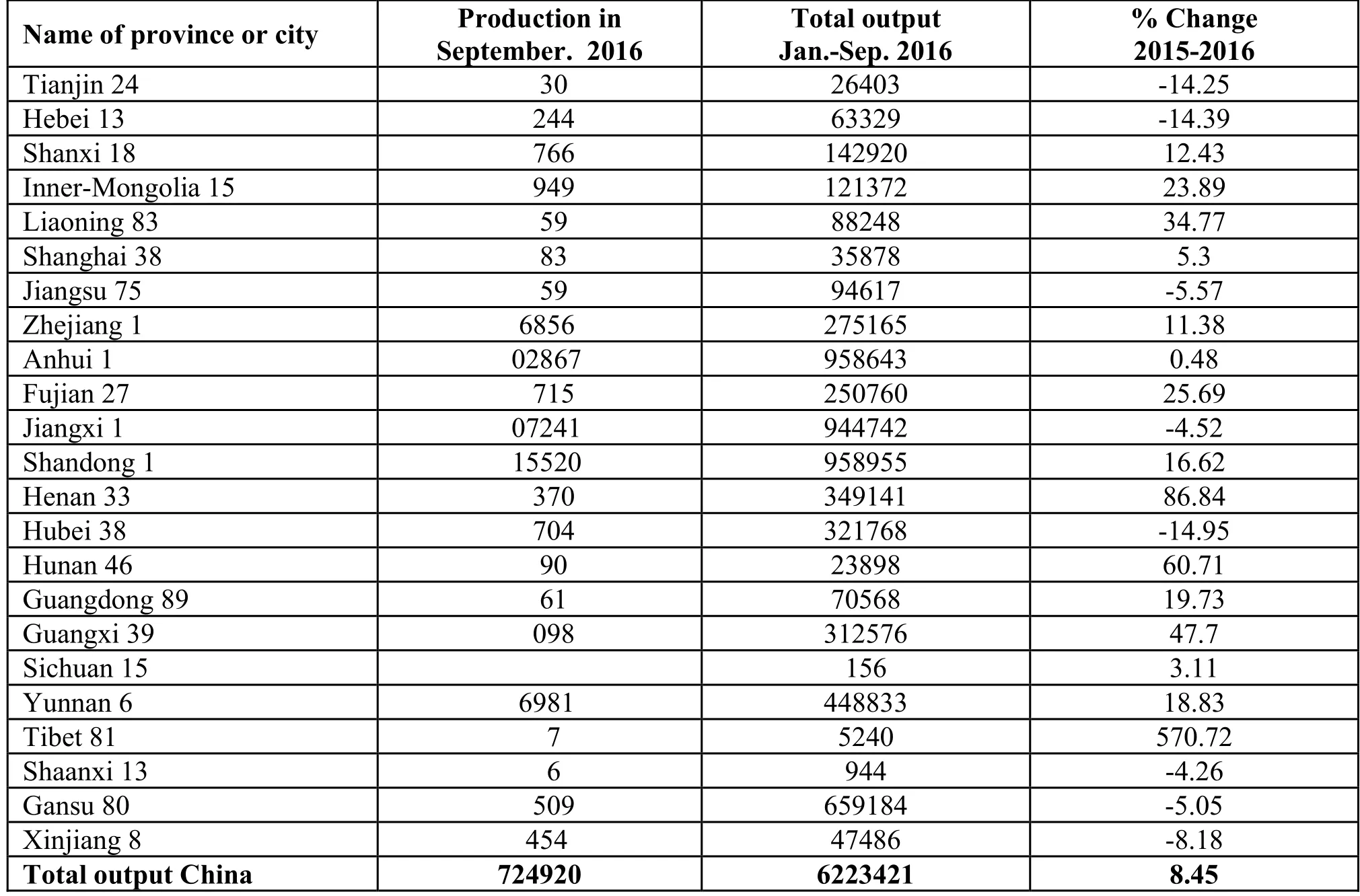

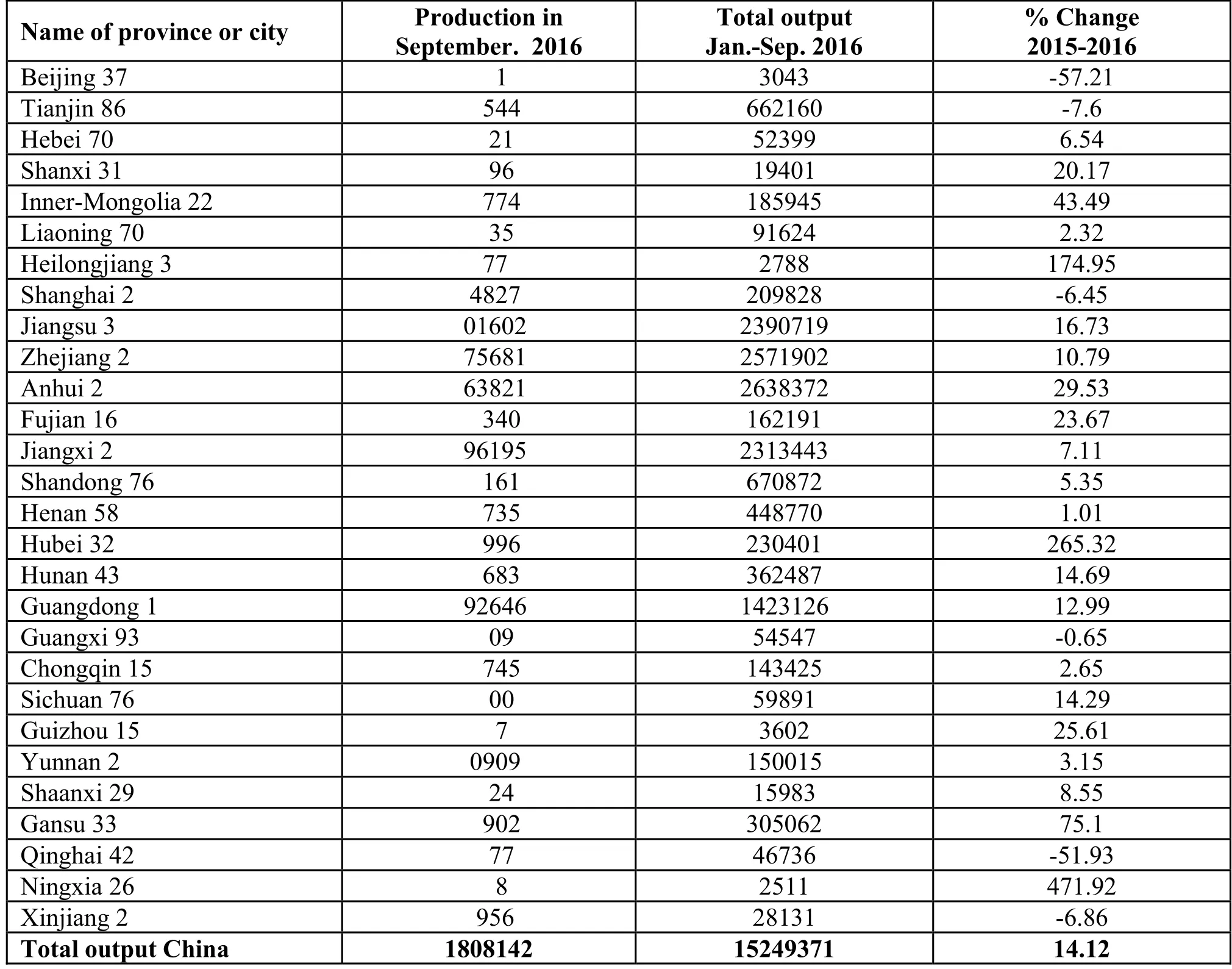

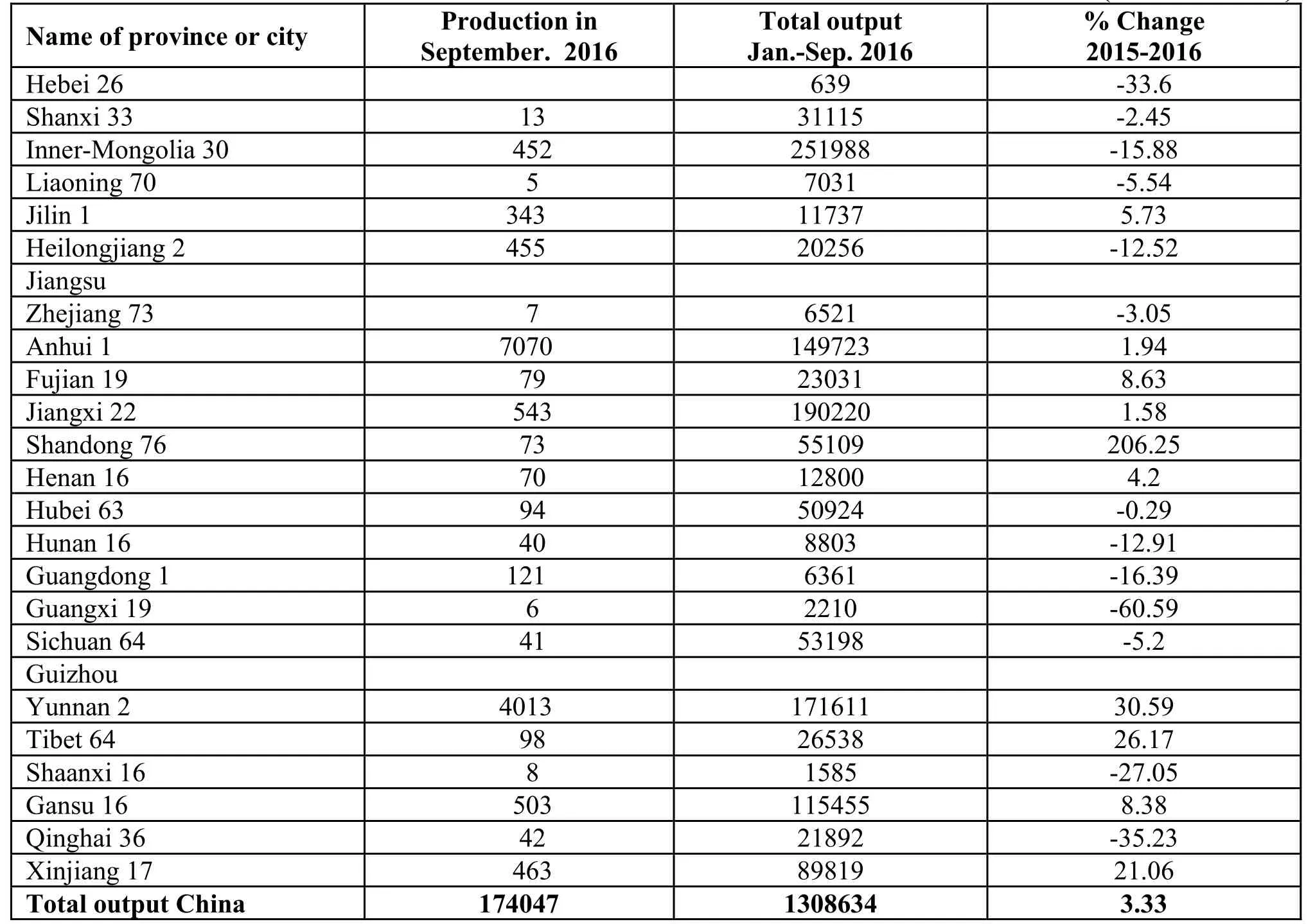

Refined Copper Production by Province or City in 2016Unit: metric ton

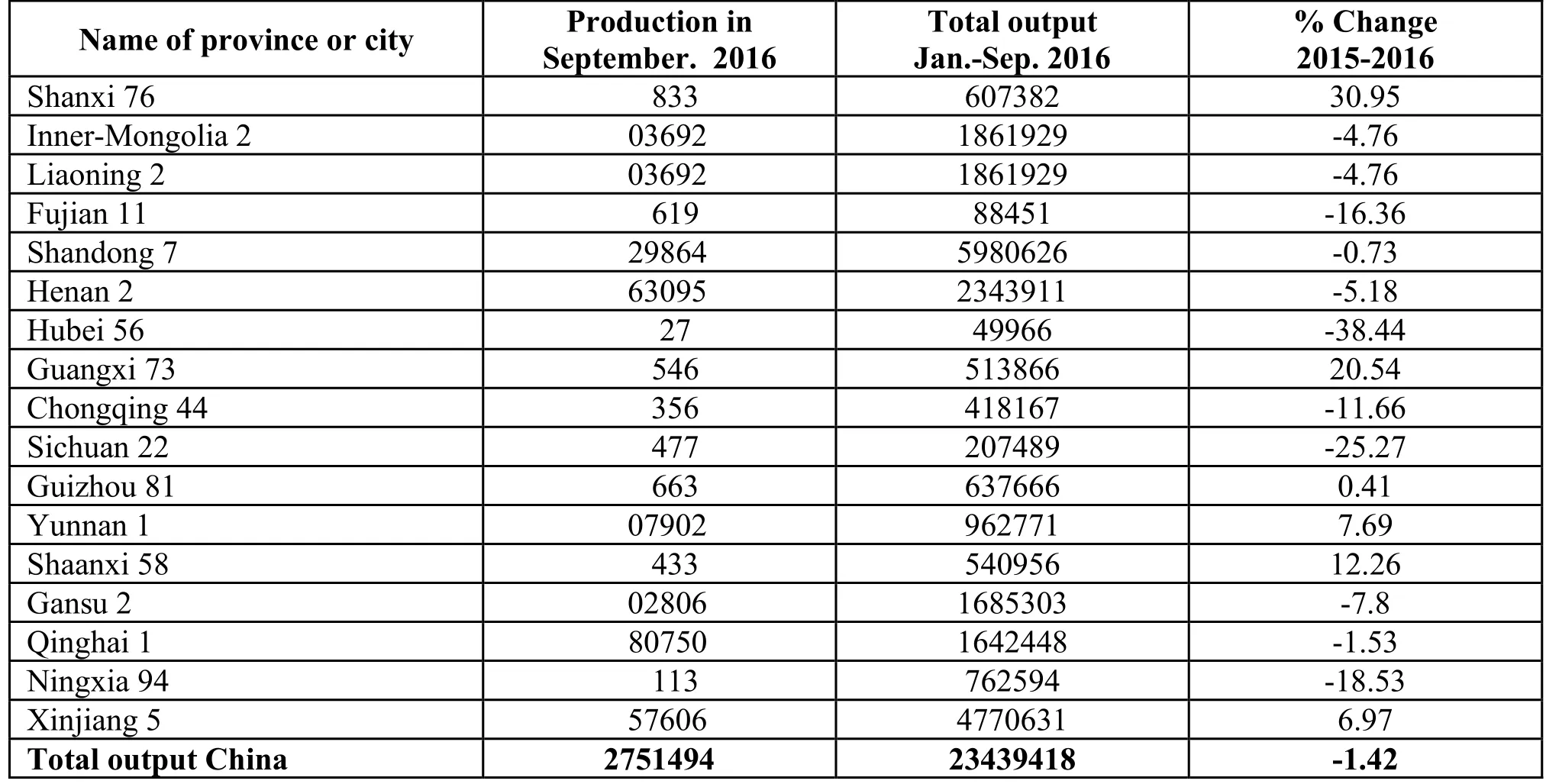

Aluminium Production by Province or City in 2016Unit: metric ton

Alumina Production by Province in 2016Unit: metric ton

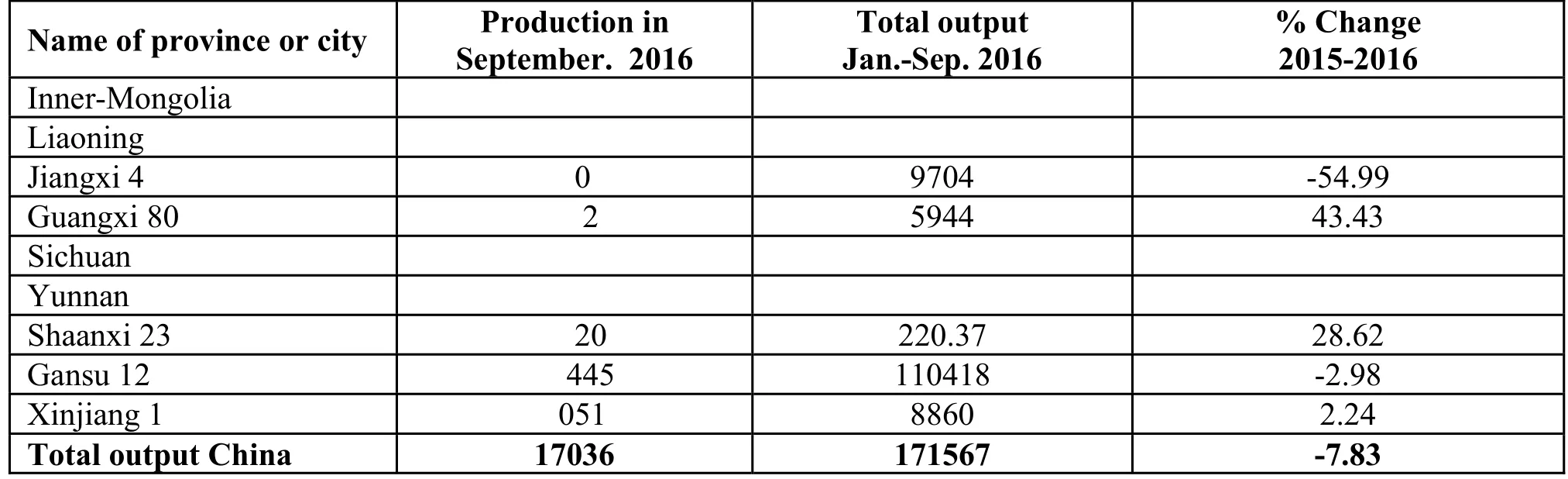

Nickel Production by Province or City in 2016Unit: metric ton

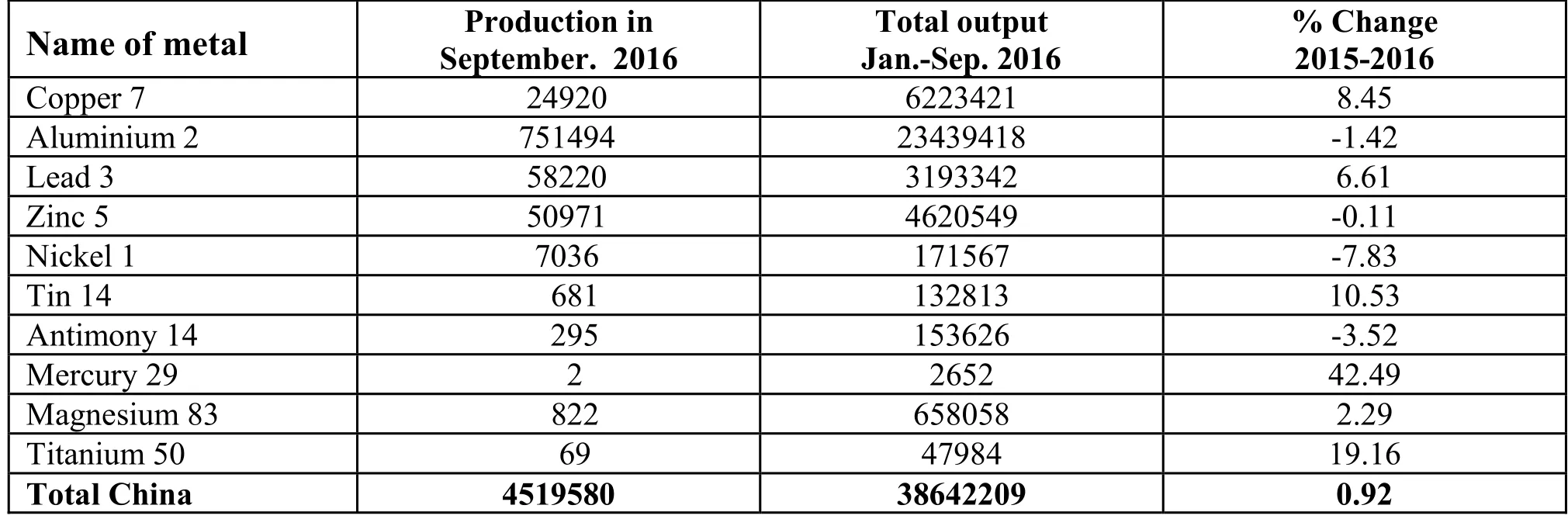

Production of the Ten Major Nonferrous Metals in 2016Unit: metric ton

Fabricated Copper Production by Province or City in 2016Unit: metric ton

Lead Production by Province or City in 2016Unit: metric ton

Copper Mine Production by Province or City in 2016Unit: metric ton(metal content)

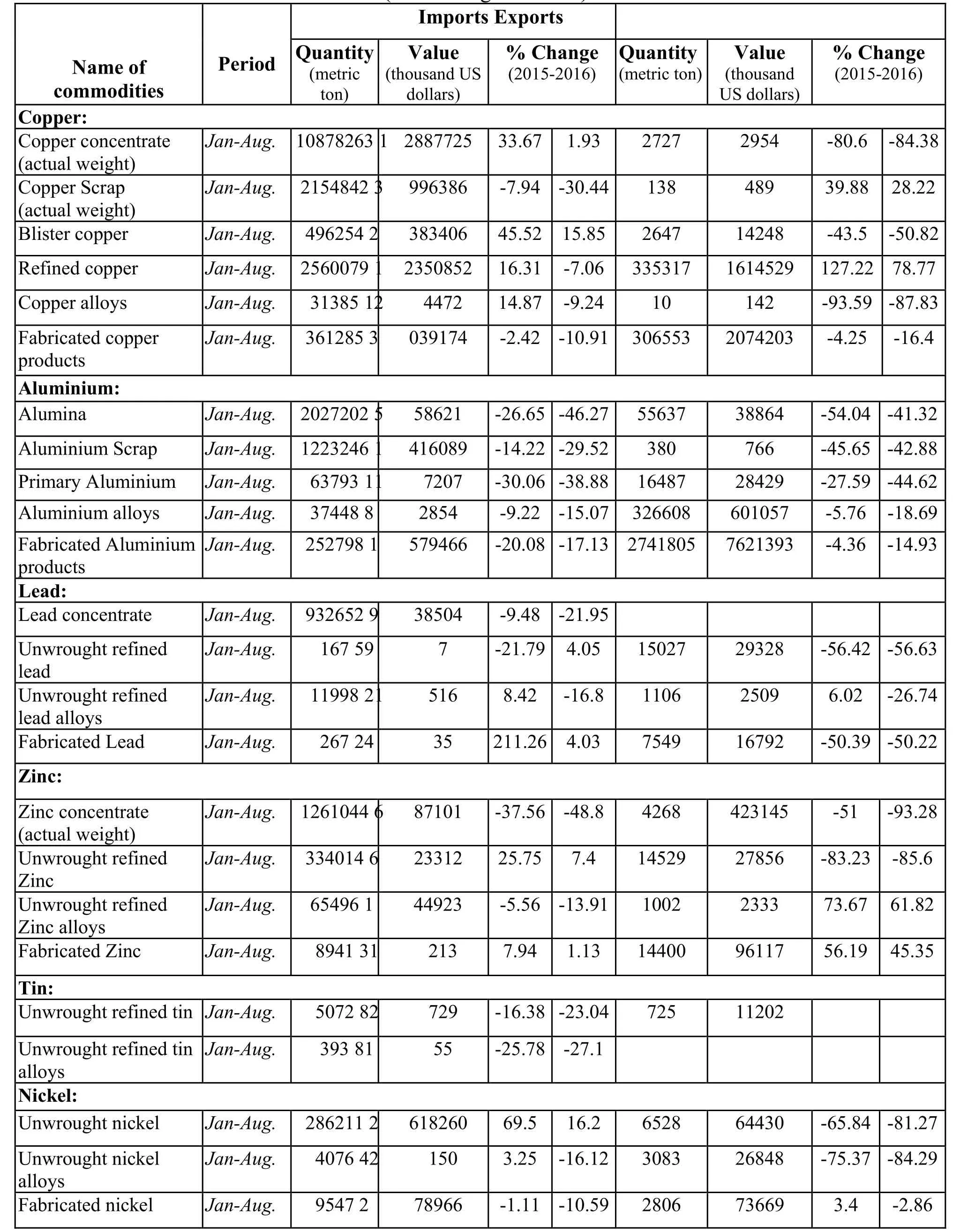

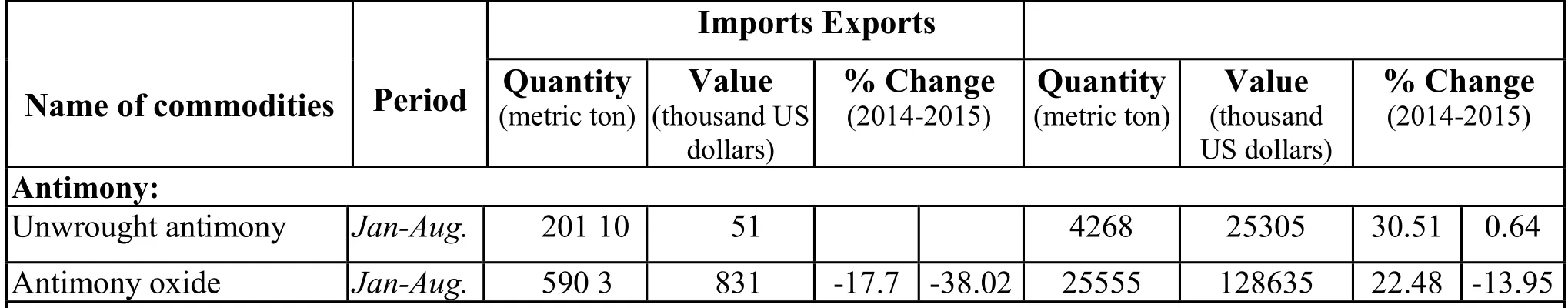

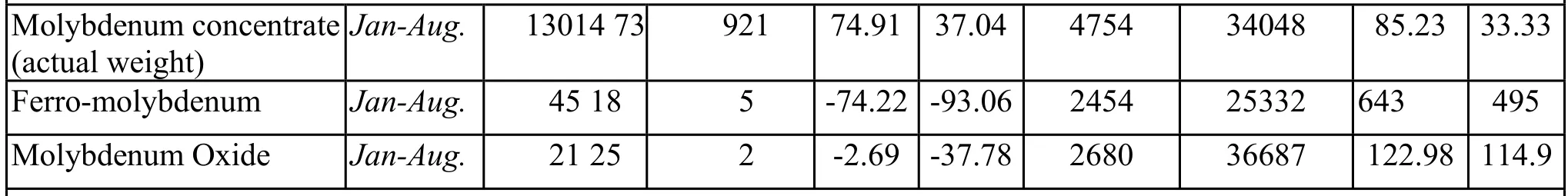

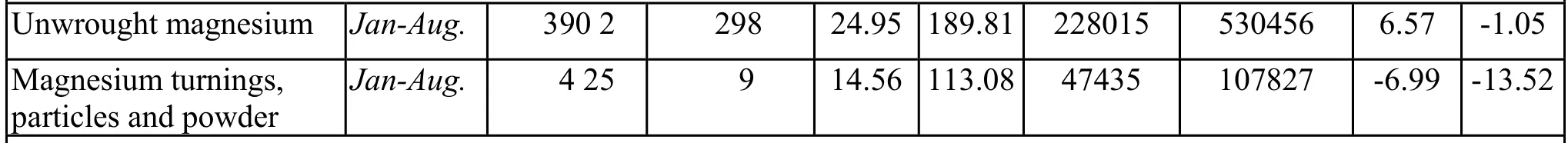

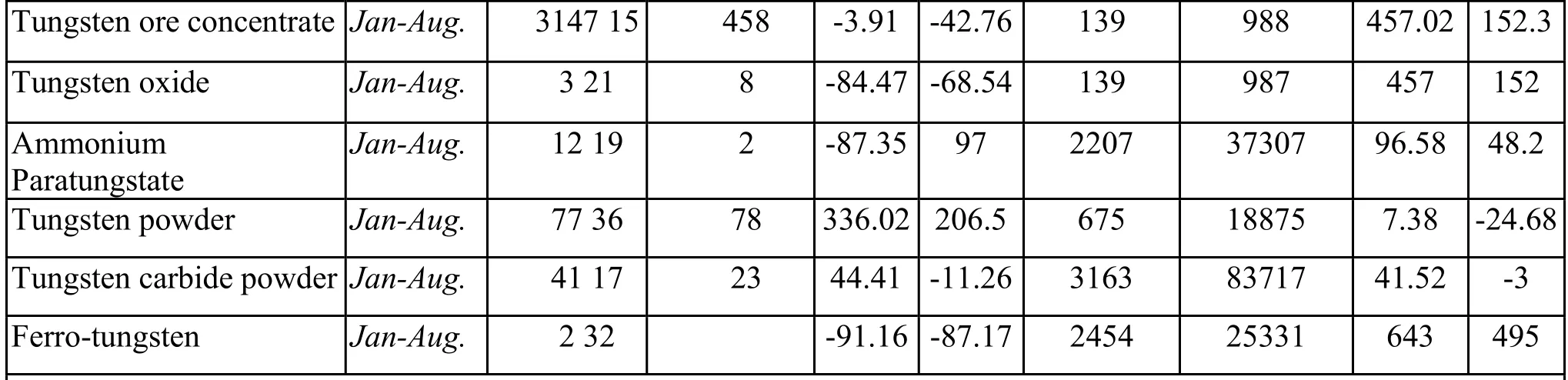

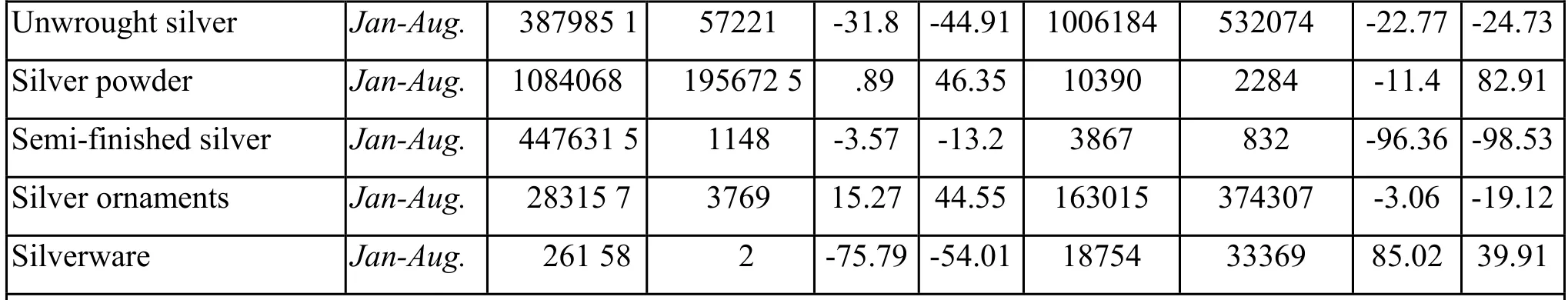

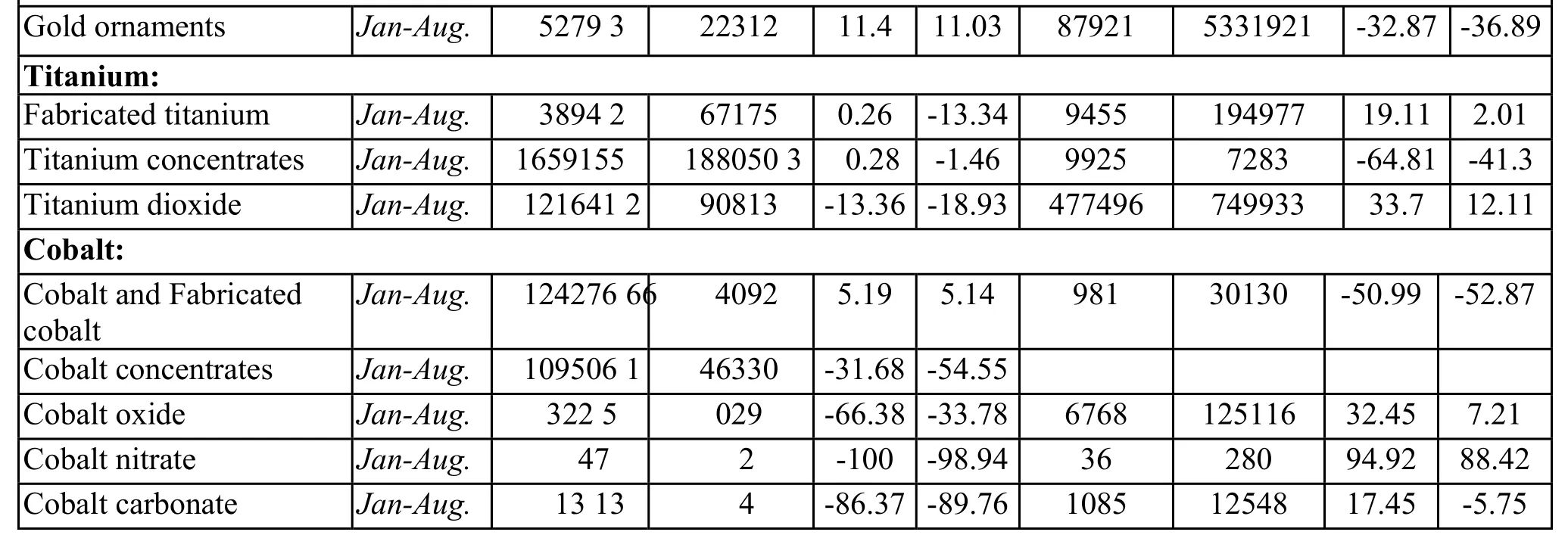

China’s Major Non-ferrous Metals Imports & Exports(End of August. 2016)

Continued from the previous page

Molybdenum:

Magnesium:

Tungsten:

Silver: (unit in kg)

Gold: (unit in kg)

Zinc Production by Province in 2016Unit: metric ton