3D Printing: New Darling of China’s Manufacturers

Additive manufacturing(AM), or 3D printing as its called more often today, is catching on in China compared to the rest of the world, as the countrys manufacturers hope to take the advantage of 3D print- ing technology to slash labor costs and bring previous glories back.

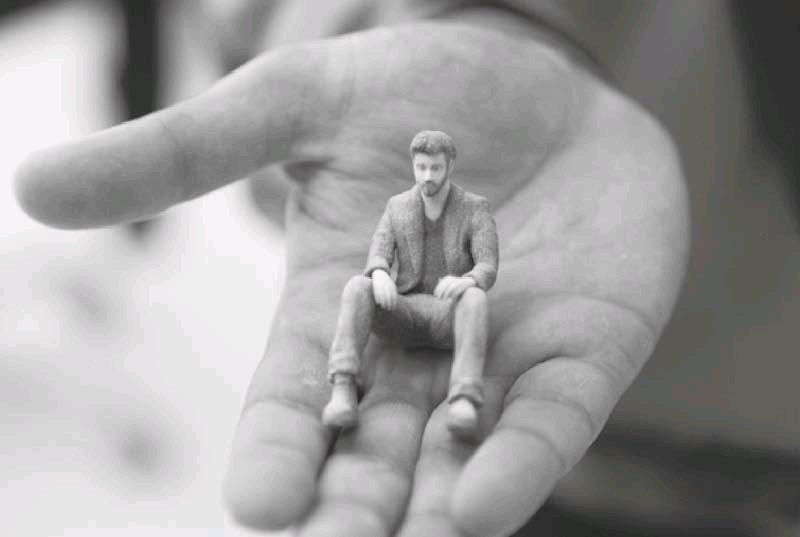

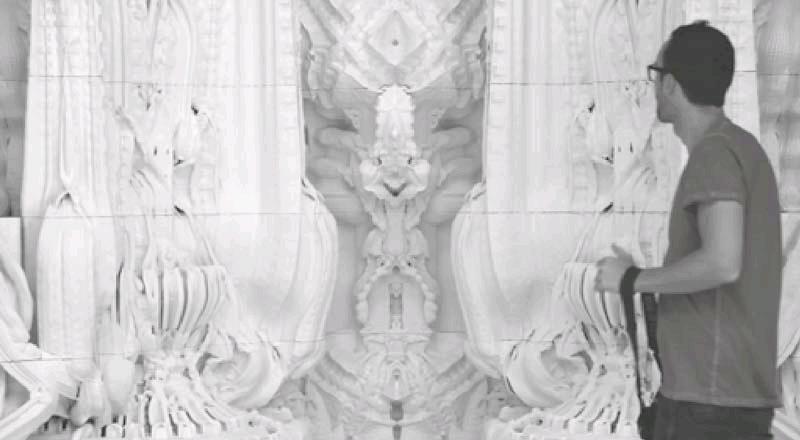

As a process of making three dimensional solid objects with plastic, metal, and composite materials, 3D printing is taking the world by storm. It uses computer-aided design to create three dimensional objects such as physical models, prototypes, patterns, tooling components, and production parts.

3D Printing Reshapes the World

Many believe that 3D printing is the closest thing that humans have to magic, as a click of the printing button on a 3D printer will automatically produce a solid product based on the pre-set three dimensional data.

In fact, the amazing technology has been around for over 20 years already, although it did not see widespread use and advertisement until just a few years ago. Early iterations of 3D printing equipment and materials were developed in the 1980s and were used solely for making rapid prototyping (RP) models.

However, those RP models had very limited strength and would often deform or degrade just within weeks or even days of manufacture. But given that early RP models were used to assess a products shape or form, those defects were acceptable at the time.

With the technology rapidly maturing, the range of materials available has increased greatly and mechanical properties and longevity also have improved. Over the past two decades, 3D printing has seen exponential growth which can arguably be described as unparalleled when compared with other fields of technology.

As its ability to create quality, costeffective three-dimensional solid objects improved in recent years, the technology caught the publics attention and became the new darling of the tech world.

More and more people are find-ing different uses and applications for 3D printing: doctors, engineers, artists, designers, even teachers, and the police. They are using 3D printers to make surgical tools and medical implants, as well as certain parts in airplanes, cars and other machines, and so on. Entrepreneurs and hobbyists are also snapping up inexpensive “personal” 3D printers to make jewelry, toys and other trinkets.

Currently, the United States, which has applied the technology to manufacturing in considerable scale, leads the world in the 3D printing industry with a 38% market share. Next is Japan with 9.7%, followed by Germany with 9.4%, China with 8.7%, the United Kingdom with 4.2%, Italy with 3.8%, France with 3.2% and South Korea with 2.3%. The remaining figure is shared by other countries where the emerging industry is still in relative infancy.

Big Room for Growth

Hailed as an industrial revolution for the digital age and the future of manufacturing, 3D printing can yield significant reductions in labor costs. With the astonishing technology, cutting, bending, pressing, molding and assembling will no longer be necessary in the manufacturing. Just a few employees oversee dozens of automatic printers, matching the production of several hundred or thousands of workers in standard factories.

3D printers also cut waste, reduce lead times for product rollouts and are better than conventional factory machines at customizing objects. With so many advantages, 3D printers are gaining popularity across the world. But theyre expensive and not adept at mass production, making them most suitable for limited runs of niche products.

In 2014, a total of 106,761 3D printers were sold worldwide, an increase of 68% on an annual basis. In a research report issued in September 2015, Gartner, a leading information technology research and advisory company, said that worldwide shipments of 3D printers will reach 496,475 sets in 2016, up 103% from the predicted 244,533 sets in 2015.

Gartner added that 3D printer shipments are forecast to more than double every year between 2016 and 2019, by which time worldwide shipments are expected to reach more than 5.6 million.

According to Pete Basiliere, research vice president at Gartner, rapid quality and performance innovations across all 3D printer technologies are driving both enterprise and consumer demand, with unit shipment growth rates for 3D printers increasing significantly.

He said: “The 3D printer market is continuing its transformation from a niche market to broad-based, global market of enterprises and consumers.”The consumer market is growing fastest, as 3D printer prices have continued to fall and the technology has rapidly improved. Currently, the primary market drivers for consumer 3D printers priced fewer than 2,500 dollars are not household purchases but acquisitions of low-cost devices by schools and universities.

Compared with low-cost consumer 3D printers, enterprise 3D printersfunction is multifaceted. They can not only prototype new products and produce tools and fixtures that are used to make other items, but also print highquality, short-run finished goods. The primary enterprise 3D printer market drivers are the finished-piece quality and material advances.

Last year, HP announced that it would enter 3D printer market and launch its first HP-branded 3D printer by 2016, which has created a huge buzz. The company is just one of the big companies that jumped on the 3D printing train in recent years.

China Chasing U.S. Lead

U.S. manufactures has largely used 3D printers to make prototypes and quirky objects since 1980s. Compared with the U.S.s market share of 38%, Chinas 3D printer market share is meager, only 8.7%.

Yet China is trying to narrow the gap. Since 1992, China has been investing in 3D printing and additive manufacturing research and development. The countrys sales of 3D printers have surged over the past decade.

In 2012, Chinas 3D printing revenue reached around 1 billion Yuan, or 163 million dollars, while total market revenues outside China hit 10 billion Yuan, according to figures from Beijingbased Asian Manufacturing Association(AMA).

Luo Jun, CEO of AMA, said:“China is the market with the greatest potential and demand for this new technology.”

In 2014, Chinas 3D printing market size approximated 4.65 billion. Luo Jun expected that starting 2015, the market will double yearly in the country.

Many Chinese companies, including car makers and aerospace companies, as well as real estate developers, already employed 3D printing. As the State introduced policies incentive to the development of 3D printing industry in recent years, more and more listed companies have entered the industry, a situation that helped integrate and develop Chinas 3D printing industry.

According to Engineering.com, revenues from Chinas 3D printing companies are expected to reach 10 billion Yuan within the next two years.

China hopes to overtake the United States as the global leader in the 3D printing industry. But it still needs to do more. In 2014, the number of enterprises involved was close to 100, but mostly small-sized.

According to Terry Wohlers, president of consulting firm Wohlers Associates, China has about 17,000 sets of 3D printers in operation and mostly are for personal use, while the U.S. has about 47,000 and nearly half are for industrial use.

Moreover, apart from artificial teeth and dental implants, the countrys 3D printers lag in end-user part production. Thats the more critical sector that has the potential to transform manufacturing.

The Chinese government has stepped up effort to beef up the 3D printing industry, with an aim to use the technology to make high-tech parts and high-value finished products.

With Chinese labor costs rising sharply the past few years, the country has been losing production to factories in Vietnam and Bangladesh that pay lower wages. The average monthly wage of factory workers was 2,832 Yuan, or 457 dollars in 2014, up 11.6% year-overyear, according to official data.

3D printing can help preserve Chinas reputation as "the factory of the world" while expanding beyond laborintensive assembly lines. Therefore, China is encouraging a wider usage of 3D printing in manufacturing.

Graham Tromans, chairman of the United Kingdom-based Additive Manufacturing Association, also predicted that the creation of larger industrial devices for major and business use will propel China to No 1 in the global market, most likely within the next five years.

New Driver for “Made in China”

Earlier this year, China unveiled an ambitious plan to enhance the competitiveness of its manufacturing sector by encouraging innovation and raising efficiency in an effort to boost economic growth.

The blueprint, titled “Made in China 2025,” comes as Chinas factories are struggling with sluggish demand, increasing competition from other developing economies and a slowing domestic economy.

Chinas manufacturing sector is challenged by bigger constraints from the environment and resources, rising labor costs and a notable slowdown in investment and exports. According to the State Council, Chinas cabinet, the key to creating a new driver of eco- nomic growth lies in the manufacturing sector. Therefore, the country calls for more new and revolution technologies to transform its traditional manufacturing.

It was inevitable that the home of the worlds biggest manufacturing industry would sooner or later turn their eye to 3D printing, a more cost-efficient way of production. China currently has only 8% of the 3D printing industry but that might soon change.

Shi Yusheng, vice-president of the school of materials science and engineering at Huazhong University of Science and Technology, said: “The country needs new technologies such as 3D printing to retain its position as the worlds largest manufacturer.”

Undoubtedly, the market is still in its early stage in the worlds second largest economy but there is huge potential to grow.