第十六届中国国际高新技术成果交易会深圳职业技术学院参展成果简介

第十六届中国国际高新技术成果交易会深圳职业技术学院参展成果简介

第十六届中国国际高新技术成果交易会于2014年11月16日至21日在深圳会展中心隆重举行。本届高交会总展览面积达11.5万平方米,共有包括37个外国团组在内的3016家展商参展,带来的高新技术项目与产品数达3593项,涵盖了节能环保、新一代信息技术、生物、高端装备制造、新能源、新材料、新能源汽车和现代农业等领域。为加强创业与投资服务,支持小微企业发展,高交会设立科技创业型小微企业展区、个人技术创新展区,还全新设立了大学生创新创业专区,取得了较好效果。

本届高交会深圳职业技术学院携13个单项成果和17个科研平台参展,项目涉及农业、智能交通、自动化和先进制造、医疗器械、物联网等多个领域,眼镜堪比导盲犬,驾车危险能提醒,会议室里就能勘测施工现场……,主动服务地方产业经济与社会发展。本期学报对参展的部分成果进行简要介绍。

1 导盲眼镜

世界卫生组织估计全世界盲人有4000~4500万。中国约有盲人600~700万,占世界盲人总数的18%,另有双眼低视力患者1200万。盲人生活中最大的问题是行走不便,特别是缺少头部保护装置,很容易受到空中悬挂物的伤害。由医学技术与护理学院张艳明老师(E-mail:zymgzzj@163.com)主持研发的导盲眼镜,是根据视觉生理前沿理论设计的一种新型盲人行走辅助设备,它能帮助盲人感知周围环境,靠近障碍物时,报警器会根据不同距离报警,使盲人接收耳机接收到报警信号,成为盲人行走的好帮手,保证盲人的出行安全。该仪器体积小,方便携带和使用。目前本产品开发成本较低,已生产出初级产品,可以向各级盲校、社区卫生医疗机构及盲人个体推广,改变盲人行走易受到突出物伤害的现状。

World Health Organization estimated that there are 40 million to 45 million visually-impaired people all over the world, 600 to 700 million of whom live in China, accounting for 18% of the total, with 12 million with low vision. Walking is a great challenge for the visually-impaired. The smart glassed developed by Prof. Zhang Yanming will help the visually-impaired detect obstacles and avoid injuries. With obstacles around, the alarmalertsaccording to the distance, the headset receives the alarm signal. The instrument is characterized by small size, easy operation and low cost. Therefore, it can be widely used in health care centers and schools for the visually-impaired or by the visually-impaired.

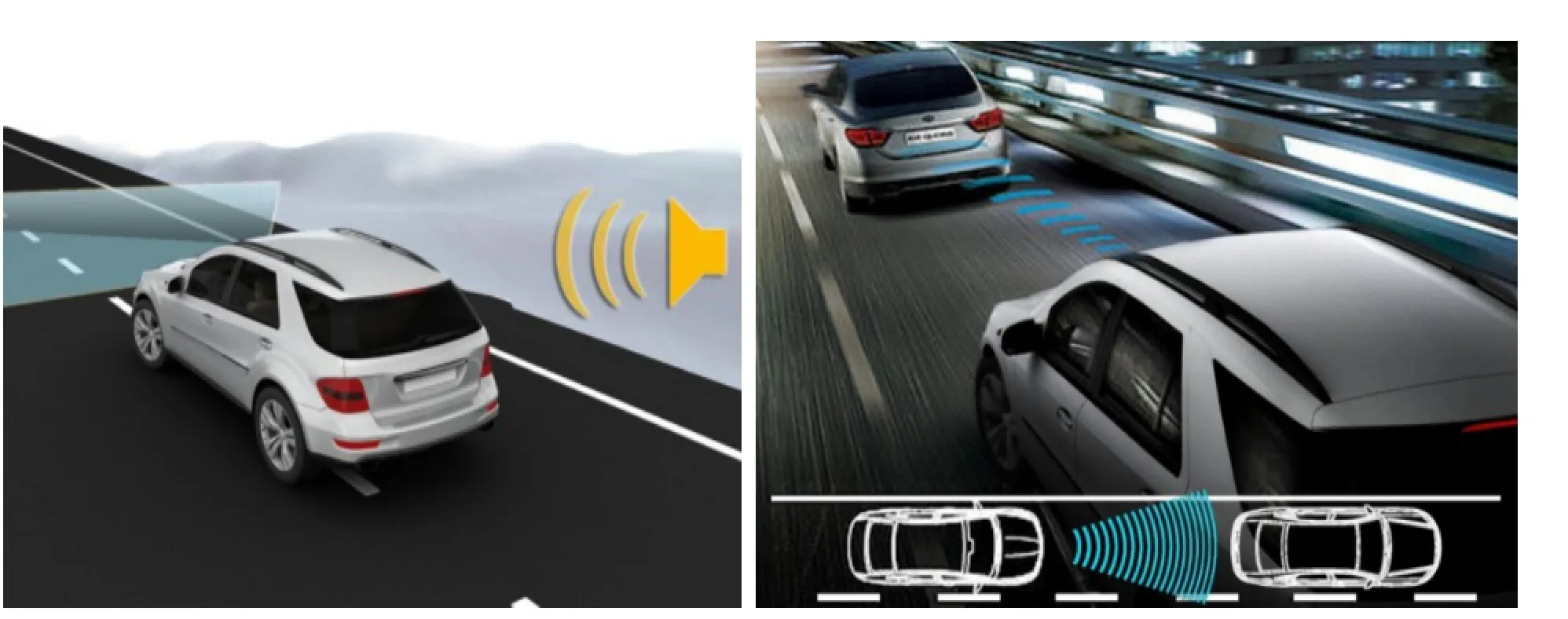

2 高级驾驶员辅助系统(ADAS)车载行车预警仪

汽车与交通学院梁伯栋高级工程师(E-mail:liangbodong@szpt.edu.cn)主持研发的ADAS车载行车预警仪,通过车载摄像头采样进行实时图像分析,并提供给驾驶员实时预警,主要具有以下功能:

1)车道偏离预警。车道偏离预警系统能够通过安装在挡风玻璃后的单目摄像头,实时检测地面上的车道线,并通过计算越线时间(TLC)去判断车辆是否即将越线。

2)前车避撞预警。前车避撞系统通过图像识别算法检测前方的车辆,并通过透视变换计算出前车离当前车辆的距离。再根据距离和相对速度,可以计算出虚拟碰撞时间(TLC),当TLC低于一定的阈值时,系统会发出声光报警以提醒驾驶员刹车减速。

3)行人避撞预警。当本车前方有行人接近时,预警仪会发出声光报警。

4)疲劳驾驶预警。通过安装在仪表盘上且正对着驾驶员脸部的摄像头,疲劳驾驶监测系统能够实时监测驾驶员的眼部状态,并通过算法分析眼部的睁闭状态来判定驾驶员是否处于疲劳状态。

5)开灯提醒。当驾驶环境光线不足时,例如进入隧道或地下室,系统会发出需要开灯的声光提醒。

6)前车起步提醒。在城市道路中跟车等红绿灯时,在此功能开启的状态下,当本车停驶5~10s后(具体可设置),系统开始检测前方车辆是否驶离,若是,系统会发出声音提醒。

With a single HD camera mounted behind the windshield, the ADAS Dashcam product can perform functions as follows:

1)Lane Departure Warning System (LDWS): The LDWS can detect the lane markings by using one singlecamera mounted on the windscreen behind the rearview mirror. Based on Time to Lane Crossing (TLC) calculation, the system can give a warning to the driver in case of unintentional lane departure.

2)Forward Collision Warning System (FCWS): The FCWS detects whether a crash is imminent by calculating the ‘Time to Contact’ (TTC) taking into account host vehicle speed, relative speed and relative acceleration. In case of emergency, a ‘critical’ warning is given to the driver.

3)Pedestrian Detection: by adopting advanced pattern recognition and classifiers with image processing and optic flow analysis, both static and moving pedestrians can be detected within the range of around 30m using VGA resolution imagers.

4)Fatigue Driving Detection System (FDDS): According to delicate changes of driver’s eyes, FDDS can detect fatigue driving.

5)Auto Light: Once the light environment is becoming dark, such as entering tunnel or basement, the system would alert driver to turn on the light.

6)Stop-Go: While waiting at the traffic light, after stopping for a predefined period (5 – 10s), the system would start to detect whether the frontal vehicle is leaving or not.

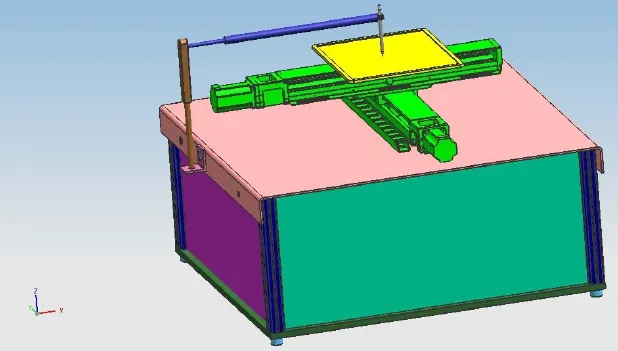

3 坐标式二轴机器人平台

机电工程学院刘先明高级工程师(E-mail:lxming@szpt.edu.cn)主持研发的“坐标式二轴机器人平台”,是工业自动化典型机械模组,采用精密机械,交互式控制软件,既可独立运动,也可镶入在其它自动设备中,构成不同功能的自动化设备。该系统利用光电、伺服及独特传动原理,充分考虑机电接口的协调性、匹配性和整体性,具有传动平稳、体积小、运动精度高、效率高、噪声低,以及较好的动态性能等优点,可应用于激光雕刻、机床进给系统、激光焊接、锂电池生产设备、新能源设备等领域。

Coordinate Biaxial Robot Platform is a typical mechanical module, which can not only function alone, butalso be inserted in other automatic equipment, performing different functions in automation equipment. The platform can be widely used in laser engraving, machine tool feeding, laser welding, the lithium battery production equipment, new energy equipment, etc. Based on photoelectric, servo and unique transmission principles, with coordination, matching and integrity of mechanical and electrical interface taken into consideration, the system is characterized by stable transmission, small size, high precision and efficiency, low noise and good dynamic performance.

4 超声声强测量仪

电子与通信工程学院李正中副教授(E-mail:lzz@szpt.edu.cn)主持研发的超声声强测量仪,属于专用超声声强传感器,采用便携式仪表结构,嵌入式操作系统,具有超声声强测量、频率测量、超声监控、数据存储、数据分析等功能。其技术指标如下:

测量声强量程:0 - 255 w/in2

测量频率:10 ~200 kHz;500 kHz~4MHz

数据显示:彩屏显示,时间与能量曲线、最大值、最小值、平均值、记录文件号

数据存储:时间、瞬时能量,连续记录24小时,180 k点数据(每点0.5秒)

电源:3.7V锂可充电电池;

探头材料:不锈钢密封管;

流体温度:0~200℃。

本测量仪可以应用于工业超声清洗设备生产厂、电子产品、汽车工业、机械零部件生产企业超声清洗现场、超声医疗设备生产企业、超声化学实验等行业。

Ultrasonic technology is widely used in industrial cleaning, chemical and medical beauty industry. Ultrasonic intensity is an important technical index in ultrasonic applications.

Ultrasonic sound intensity measuring instrument can be widely used in industrial ultrasonic cleaning equipment factories, electronic products, automobile industry, and mechanical parts manufacturing enterprises, ultrasonic medical equipment production enterprise, ultrasonic chemistry experiment and other industries. The Ultrasonic Sound Intensity Meter (USIM) is based on the portable instrument structure and embedded operatingsystem. It features functions such as ultrasonic sound intensity measurement, frequency measurement, ultrasonic monitoring, data storage, data analysis etc. Its specifications are as follows:

Sound intensity measurement range: 0 - 255 w/in2

Measuring frequency: 10 - 200 kHz; 500K~4MHz

Function: TFT display; Time and energy curve, Maximum value, Minimum value, Average value.

Data storage: time, instantaneous energy, continuous record of 24 hours, 180K point data (each 0.5 seconds)

Power supply: 3.7V lithium rechargeable battery;

Sensor Material: stainless steel sealed tube probe;

Fluid temperature: 0 - 200℃.

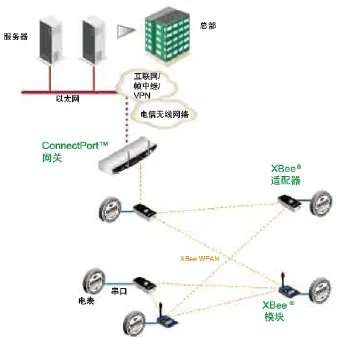

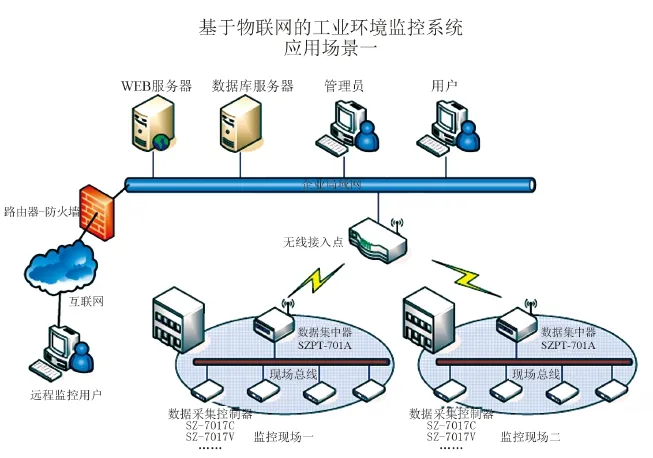

5 基于物联网的环境监测系统

由电子与通信工程学院岑宏杰老师(E-mail:chj@szpt.edu.cn)主持研发的环境监测系统包括:一套服务器端的上位机监控软件、数据采集器、无线传输模块、数据集中器,以及协议转换器等设备。利用这套软件和硬件,可以灵活快速地建立一个有线或无线的监控系统,对工业环境的室内温度、湿度、设备的压力、耗水、耗电等数据进行远程监控。系统可以对现场数据进行远程采集、存储和传输,用户通过上位机监控软件浏览、分析设备的实时或历史数据。本系统除了应用在工业环境中之外,还可应用于如写字楼办公室、酒店房间的温湿度监控、大型商场冷库的温度监控、员工宿舍的用水用电监控等需要数据采集、传输的场合。

The Monitoring and control system for industrial environment based on internet of things consists of WEB 2.0-based supervising software, data acquisition units, remote I/O units, wireless transmitters, data concentrators and protocol converters. With the software and

equipment,a wire or wireless system can be developed intelligently and

rapidly to monitor various industrial data such as temperature, pressure,

humidity, water and electricity consumption, etc. remotely. Real-time

data are delivered to and stored on server, and can be easily retrieved,

browsed and analyzed just with WEB browser. The system is widely

applicable in factories, buildings, hotels, dormitories, refrigeration

houses, etc.

网关

6 智能传感器自动在线标定系统

由电子与通信工程学院唐建东副教授(E-mail:jdtang@szpt.edu.cn)主持研发的智能传感器自动在线标定系统,由智能传感器和智能标定系统两部分构成。通过改进传统的传感器使之成为适合于自动标定的智能传感器,将传统传感器生产过程中的标定方法和工艺方法嵌入到智能传感器中,既能实现高精度的标定,也可以实现过程中的关键参量和数据记录在传感器芯片中。智能标定系统按照传感器标定的工艺要求建立自动控制标定测试系统,建立数据库对标定过程中的相关测试参数、多路待标定传感器技术参数和标定结果进行记录存储,对待标定的产品按照标定的工艺要求进行自动控制,实现多路传感器的自动标定。该标定系统适合应用于各类传感器的生产标定和维护,以及部分需要调试的采集电路和其他电子产品。本系统已应用于油中微量水分传感器、温湿度模块和温湿度变送器的批量生产中。本系统特别适用于中小型传感器制造企业、传感器销售和设计企业,能降低传感器制造对熟练技术员工的依赖,既容易将传感器的生产进行外包,也容易实现多种传感器的制造,从而降低传感器制造成本和公司的运营成本。

The discreteness of sensitive element and its conditioning circuit make sensor calibration complicated. Calibration of the traditional sensor is operated by skilled workers, characterized by high cost, human dependence, and difficulty in performance enhancement.

Intelligent sensor automatic on-line calibration system, developed by Prof. Tang Jiandong, is composed of two parts, intelligent sensor and intelligent calibration system. Based on the process of sensor calibration,intelligent calibration system relies on the development of automatic control of calibration and testing system, including a database on the calibration process-related test parameters, multiple calibrated sensor technology parameters and the calibration results in order to record, store, and process the calibration.

The project is applicable not only to all types of sensor calibration and maintenance, but also to circuit acquisition for debugging and other electronic products. This system has been applied in mass production of oil trace moisture sensor, temperature and humidity module, and temperature and humidity transmitter. The calibration system lessens the dependence on skilled workers in sensor manufacturing, making sensor production outsourcing and diversity possible, and reducing the cost of sensor manufacturing.

7 基于物联网技术的智能插座

由电子与通信工程学院王洋博士(E-mail:wyang@szpt.edu.cn)主持研发的基于zigbee技术的智能插座,采用高精度的电能计量IC和进口欧姆龙继电器,在精确采集用电器耗能的同时,又能通过继电器在定时模式及过流过载的情况下,及时关断保护好您的用电器。该插座的数据采集和控制都是通过无线zigbee技术和局域网通信技术,把相关的信息数据转载手机上,以及从手机端把相关的信息数据转载到基于zigbee技术的智能插座内进行相关的操作处理。基于zigbee技术的智能插座能够实现在手机APP上对220V市电进行手动控制通断、定时控制通断和过流过载关断控制等保护通电器及个人用电安全的智能操作。用户还可以在手机APP上查看当前用电器的耗能情况、负载功率和负载电流、负载电压以及耗电量大小等相关信息。手机APP还提供各项采集信息的历史曲线图给专业的用户对用电器的安全状况进行评定。该插座可用于家居、企事业单位及厂矿等。

With high-precision electric energy metering IC and OMRON relay, the intelligent socket based on ZigBee technology can protect your appliances in cases of energy flow overload in relay cases by timely cutoff. Intelligent socket collects data and control the relay through the wireless ZigBee technology and LAN communication technology,and the relevant information data will be transferred to mobile terminal by Wi-Fi. It can be applied in houses, companies and factories.

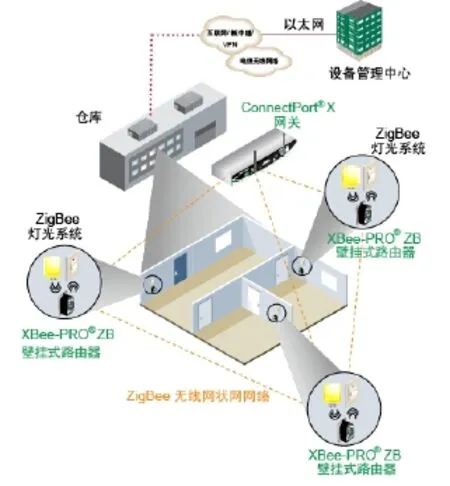

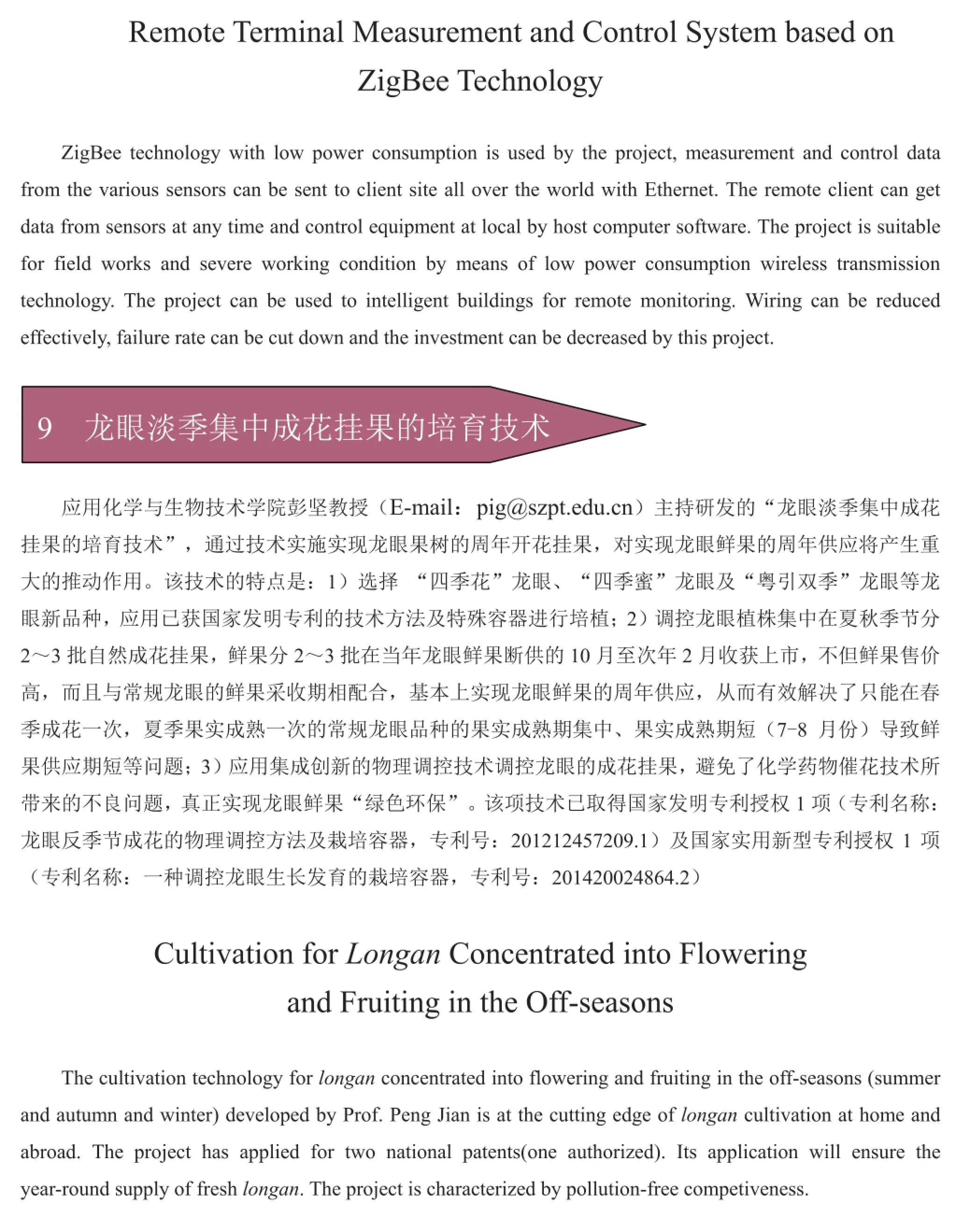

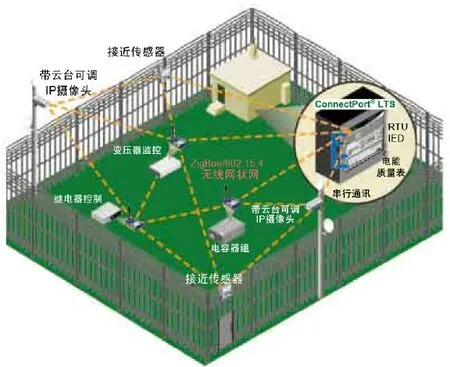

8 基于ZigBee无线物联网技术的远程终端测控系统

机电工程学院詹泽海老师(zhanzehai@szpt.edu.cn)主持研发的基于ZigBee无线物联网技术的远程终端测控系统,采用低功耗ZigBee无线物联网结合以太网技术,可以把测控现场的各种传感器数据,按需求发送到以太网履盖的全球任意远程客户端,远程客户端通过上位机软件随时获取测控现场的各种传感器数据,也可以通过上位机软件控制测控现场设备的工作状态。由于项目数据采集现场采用低功耗的无线传输技术,所以该系统既适用于野外供电困难、工作环境恶劣等场合的远程数据采集,也适用于智能楼宇等场合的设备远程监控,可有效减少现场布线,降低设备故障率,减少建设投入。

Brief Introduction to Research Achievements of Shenzhen Polytechnic Displayed on the Sixth China Hi-Tech Fair

Glasses for the Visually-impaired

Advanced Drive Assistance System

Coordinate Biaxial Robot Platform

Ultrasonic Sound Intensity Meter

Environment Monitoring and Control System Based on Internet of Things

Online Automatic Calibration System of Intelligent Sensors

Intelligent Socket Based on ZigBee Technology