Effects of Planting Density on Yield and Mechanical Harvesting Loss Rate of Brassica napus L.

Huiming PU, Maolong HU, Weihua LONG, Jianqin GAO

Ministry of Agriculture’s Key Laboratory of Cotton and Rapeseed, Institute of Industrial Crops, Jiangsu Academy of Agricultural Sciences, Nanjing 210014, China

Rapeseed is one of the most important oil crops in China. It accounts for about 2/3 of total output of oil crops.Rapeseed plays an important role in agricultural production. The rapeseed production in China has long depended on manual labor. This will not only require a large amount of intensive labor but also require high production costs. According to statistics, 225 man-hours are required for planting each hectare of rapeseed. The labor costs account for about 60% of the total production costs of rapeseed. So rapeseed production is still a labor-intensive industry[1-3].Mechanical harvesting is an effective way to reduce labor costs, re-duce labor intensity and improve production efficiency. In recent years,rice, wheat and other staple crops in China have generally realized mechanized production. The mechanized technologies for rapeseed production have been promoted and applied gradually, and they have attracted more and more attention in agricultural production.

Currently, the domestic rapeseed harvesting machinery is mostly improved from the full-feeding rice-wheat combine harvester. Based on the ricewheat combine harvester, the rapeseed harvesting machinery lengthens the header, increases vertical cutters,widens transporting trough, sets double threshing drums, replaces the size and shape of sieves and so on[4-10].The actual production shows the improved rapeseed harvesting machinery can basically meet the needs of rapeseed harvest. However, due to the large size of rapeseed plants, high yield of biomass, large amounts of branches,ununiformed maturity of pods, easy cracking of pods and small size of grains, the collision and pulling occurred during the mechanical harvesting may lead to the cracking of pods and breakage of stems,resulting in shattering losses. Harvesting loss rate is generally high. It can reach 10% and sometimes even more than 15%[10-11],restricting the application and promotion of rapeseed harvesting machinery. To reduce mechanical harvesting loss, not only harvesting machinery but also cultivar characteristics and agronomic measures of rapeseed are needed to be improved. Only the two aspects above are adapted to and integrated with each other can the rapeseed mechanized harvesting technology be applied and promoted widely[12].Therefore,the study on agronomical techniques in the mechanized production of rapeseed also has important practical significance.

In this study, two new hybrid rapeseed cultivars that are high-yield,disease-resistant and pod crackingresistant were used as the test material.The effects of different planting densities on yield and mechanical harvesting loss rate were investigated.The yield losses occurred during the cutting and screening of rapeseed were analyzed and compared. The aim is to explore the favorable factors to improve the regulating effect of planting density on plant type of rapeseed and reduce the mechanical harvesting loss so as to provide a scientific basis for the realization of fully mechanized production of rapeseed.

Material and Methods

Material and equipment

The double-low rapeseed cultivars, Ningza 19 and Ningza 21 are newly bred by Institute of Industrial Crops of Jiangsu Academy of Agricultural Sciences. The rapeseed cultivars are characterized by high yield, disease resistance and pod cracking resistance.They are mainly promoted by the Ministry of Agriculture in the downstream Yangtze River.The rapeseed harvesting machine (full-feeding track self-propelled combine harvester, Xingguangzhizun 4LL-1.5Y) is produced by the Xingguang Agricultural Machinery Limited (Huzhou,Zhejiang). The vertical cutters are installed additionally. The harvester parameters are as follows: width of header, 2 m; minimum ground clearance, 240 mm; feed rate, 1.5 kg/s;productivity,0.1-0.35 hm2/h.

Test design

The test was carried out in the rapeseed experimental fields located in the Institute of Industrial Crops of Jiangsu Academy of Agricultural Sciences. The test soil was Magan soil with uniform fertility. The two-factor split plot design and randomized block design were adopted.For the two-factor split plot design, the main plot was cultivar and the split plot was planting density. Each plot covered an area of 333.5 m2. There were 2 duplications for each treatment. A total of four density treatments(112 500(T1),225 000(T2), 337 500 (T3) and 450 000 (T4)plants/hm2)were designed.The planting density of 112 500 plants/hm2(low density treatment) is the transplanting density of rapeseed promoted widely in the middle and lower reaches of Yangtze River,and the planting densities of 225 000, 337 500 and 450 000 plants/hm2are the directly seeding densities commonly adopted in the large-scale directly-sowed rapeseed production. The sowing was carried out on September 28th, 2012. The row spacing was 40 cm. After the sowing,the fields were irrigated. After the young plants grew tidily and the young leaves were flattened, 3 times of seedling thinning were carried out during the cotyledon stage to the threeleaf stage according to the designed planting densities. The 4th thinning was carried out during the four-leaf stage.For different cultivars under different planting densities, the fertilization amount was same.The basal fertilizer was compound fertilizer(N∶P∶K=15 ∶15 ∶15, 750 kg/hm2); the seedling fertilizer was applied in the wintering period (46%of urea,225 kg/hm2);the spring fertilizer was 46% of urea with application amount of 225 kg/hm2.Other field management practices were as same as conventional management.

Determination methods

Seed test After the rapeseed was ripe, 30 plants were selected from each of the plots for seed test. The measured indexes included plant height,height of branching point, main stem length and pod number, primary branch number and pod number,secondary branch number and pod number, grain number per pod, kilo-grain weight, productivity per plant and biomass per plant. The pod number per plant was calculated based on the main-stem pod number, primary pod number and secondary pod number.The productivity per plant referred to the grain yield per plant. The biomass yield was calculated based on the grain yield, stem yield and husk yield per plant.

Yield The rapeseed was harvested on June 3th, 2013. On the harvesting day,the weather was sunny.No rapeseed stalks were lodged. The harvester operator is skilled and has many years of experience. The rapeseed in all the plots was harvested at the same harvesting speed in the same day by the same harvester operator. The rapeseed seeds were weighed once they were obtained.Then the seeds were dried at 105 ℃for 24 h to determine the moisture content. The yield per plot referred to the actual yield.

Loss rate The mechanical harvesting loss is accurately reflected by the sum of shattering loss, unharvestingloss and cleaning loss.During the harvesting, the harvester will undoubtedly collide with the rapeseed plants,resulting in the shattering of mature rapeseed seeds. In this study, the shattering loss included the naturally shattering loss and mechanically shattering loss. After the harvesting, the 3 cm surface soil of 5 points (0.09 m2/point)that were selected randomly from each plot was sampled and placed in 40 mesh nylon mesh bag. The soil samples were soaked in water and then rinsed with water repeatedly to remove sediment inside. Thus the pure rapeseed seeds were obtained.After dried,the seeds were weighed. Of course,the harvester may miss some rapeseed branches and pods. After the harvesting, the missed rapeseed branches and pods that were scattered in the plots were collected timely and used to calculate the unharvesting loss. The yield loss probably occurs in the threshing link. Some rapeseed grains may still exist in the wasted braches or pods discharged from the trash output of thresher. This part of yield loss is defined as cleaning loss.To determine the cleaning loss, a 40 mesh nylon bag was attached to the trash output of thresher to collect the unthreshed rapeseed branches and pods.Thus the three parts of yield loss during the mechanical harvesting were analyzed and compared.Based on the shattering yield loss, unharvesting yield loss and cleaning yield loss, the relative loss rates can be calculated.

Results and Analysis

Effects of planting density on yield and economic traits

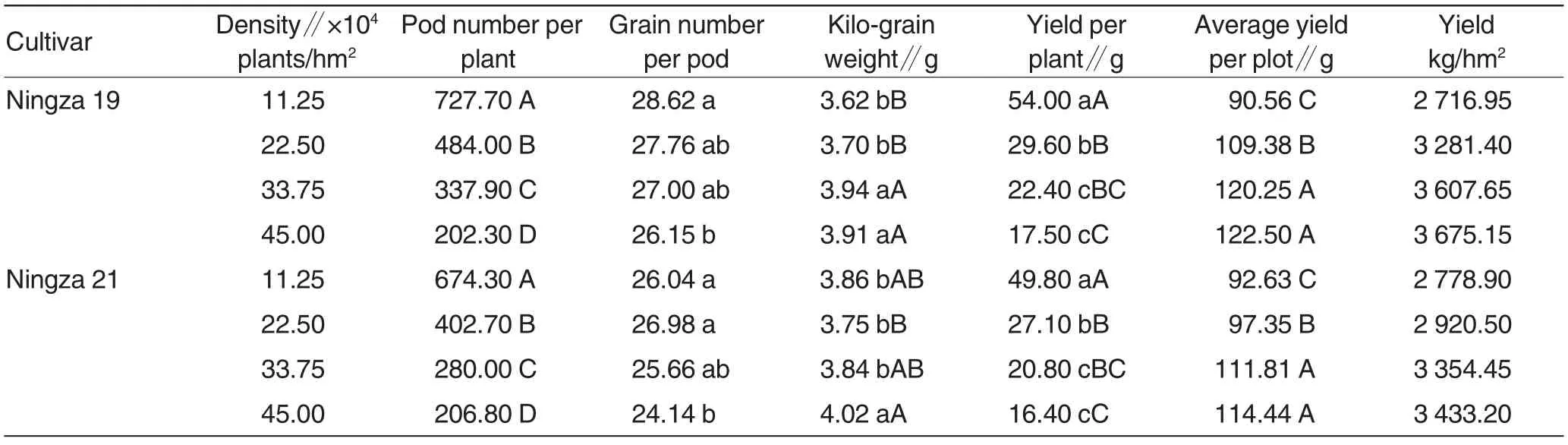

For the two rapeseed cultivars,when the planting density ranged from 112 500 to 450 000 plants/hm2,the yield was all increased with the increase of planting density. The yield of Ningza 19 was increased from 2 716.95 to 3 675.15 kg/hm2,and the yield of Ningza 21 was increased from 2 778.90 to 3 433.20 kg/hm2.The variance analysis showed the yields of Ningza 19 and Ningza 21 all showed no significant differences between cultivars (main plot), but showed significant differences among planting densities(split plot)(F=60.19,F0.05= 4.76, F0.01= 9.78). The yields of T3 and T4 were all significantly higher than those of T1 and T2 (P <0.01).However, there was no significant difference in yield between T3 and T4(P >0.05). The variation of yield among planting densities was same between the 2 cultivars. It is indicated to obtain a high yield,the planting density of Ningza 19 and Ningza 21 should not be lower than 337 500 plants/hm2.

The planting density also had great effects on economic traits of rapeseed plants.As shown in Table 1,the productivity per plant was decreased with the increase of planting density. The productivity per plant of Ningza 19 was decreased from 54.00 to 17.59 g, and of Ningza 21 was decreased from 49.80 to 16.40 g.Among the 3 yield components,there were no significant differences in the grain number per pod and the kilo-grain weight among planting densities. But the pod number per plant was decreased significantly with the increase of planting density(P <0.05).This was also the main reason for decreased productivity per plant. However, the decreased productivity per plant can be supplemented by population dominance. At an appropriate sowing time,the rapeseed directly sowed at a high density can still obtain a high yield.Compared to the transplanted rapeseed, the directly-sowed rapeseed is characterized by shorter growth period,fewer total leaves, deeper rooting,stronger lodging resistance, lower plant height and more obvious population dominance, which are all conducive to mechanical harvesting.

Table 1 Yield and yield components of rapeseed under different planting density

Effects of different planting density on mechanical harvesting loss

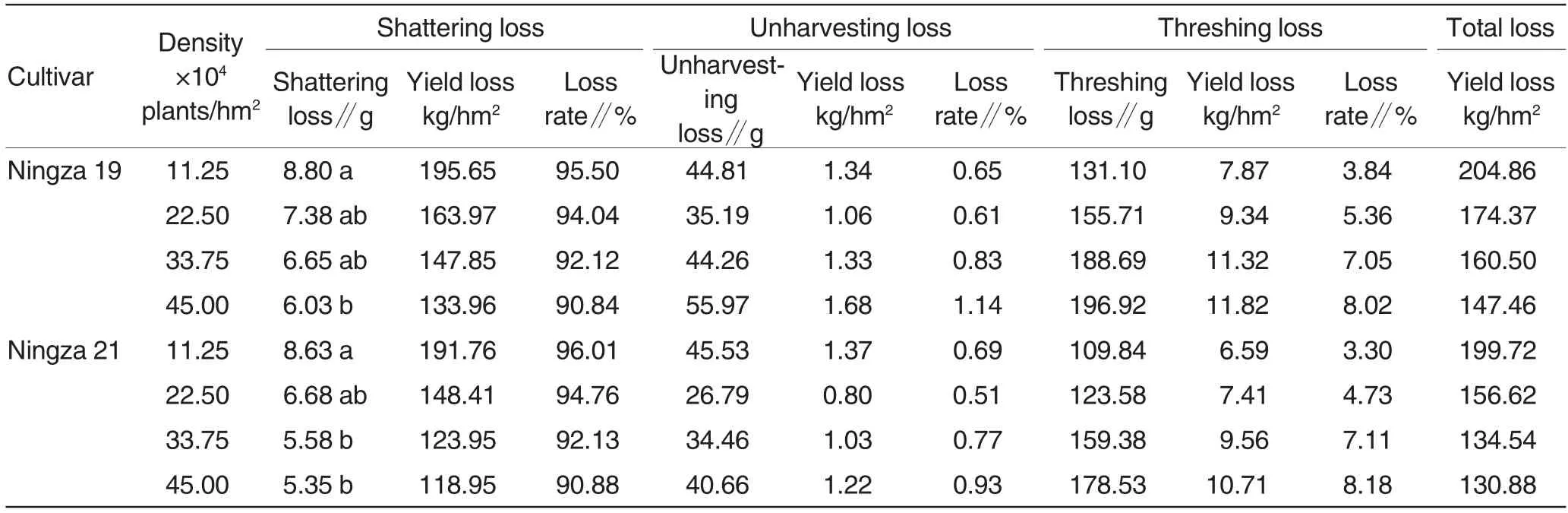

Effects of planting density on shattering loss in field Shattering loss is the main yield loss for the mechanical harvesting. For each plot, 0.45 m2of surface soil was sampled for estimating the shattering loss in field. The results showed the shattering loss differed significantly among different planting densities.With the increase of planting density, the shattering loss was decreased. The variation of shattering loss among planting densities was same between the 2 rapeseed cultivars. When the planting density was increased from 112 500 to 450 000 plants/hm2, the shattering yield loss of Ningza 19 was decreased from 195.65 to 133.96 kg/hm2with loss rate decreasing from 95.50% to 90.84%. The shattering yield loss of T1 was significantly higher than that of T4(P<0.05).With the increase of planting density,the shattering yield loss of Ningza 21 was decreased from 191.76 to 118.95 kg/hm2with loss rate decreasing from 96.01% to 90.88% . The shattering yield loss of T1 was significantly higher than those of T3 and T4 (P <0.05)(Table 2).

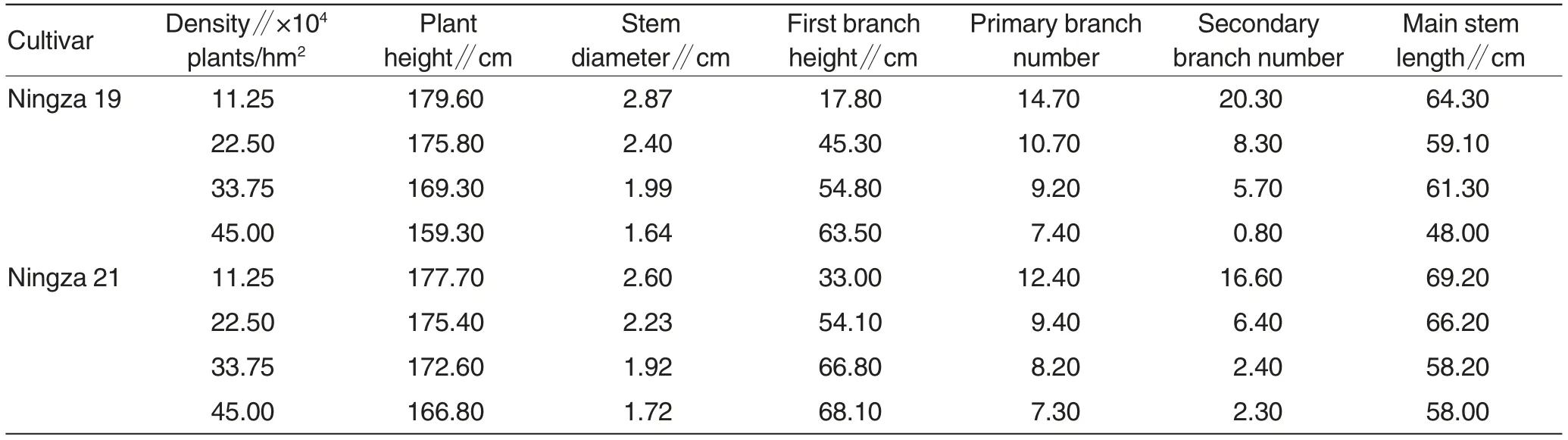

Under high planting density,sincethe plant height and productivity per plant were reduced greatly,the branch number was also reduced correspondingly, thereby reducing the crossing and tangling among branches and improving the maturity uniformity of pods.These changes of plant type are all conducive to reducing shattering loss during mechanical harvesting, which also contributes to reducing shattering loss under high planting density.In the large-scale production, the planting density should be increased appropriately in according to the cultivar characteristics and cultivation techniques,constructing plant type that is suitable for mechanical harvesting, thereby reducing shattering loss in field.

Table 2 Yield losses occurred in different links of mechanical harvesting under different planting densities

Effects of planting density on grain loss in wasted stems and pods

The field loss in wasted stems and pods (threshing loss and cleaning loss) is difficult to determine. The threshing wastes should be collected timely to collect the missed rapeseed seeds in wasted branches and pods.Since the biomass yield of rapeseed is extremely high, collecting waste is a hard work. Moreover, it needs a large amount of nylon mesh bags. In this study, 167 m2of field was selected for each plot.There were two duplications for each plot. The results showed with the increase of planting density, the rapeseed seeds missed in wasted branches and pods were increased.The field loss of Ningza 19 was increased from 7.87(T1)to 11.82 kg/hm2(T4) with loss rate increasing from 3.84% (T1) to 8.02% (T4). The field loss of Ningza 21 was increased from 6.59 (T1) to 10.71 (T4) kg/hm2with loss rate increasing from 3.30%(T1)to 8.18%(T4)(Table 2).In this study,the threshing and cleaning field loss was positively related to planting density.Generally, under low planting density,the plant height of rapeseed is low;the primary and secondary branches are more; the maturity of pods is ununiform;the crossing and tangling among branches are stronger. So the missed rapeseed seeds in wasted branches and pods are more. However, in this study, with the increase of planting density, the plant height, yield per plant and branch number of rapeseed were reduced; the occurrence of crossing and tangling among branches and pods was reduced. All the changes above are conducive to mechanical harvesting and reducing shattering loss during mechanical loss. However, with the increase of planting density, the biomass yield of rapeseed was increased. For example, the biomass yield of Ningza 19 was increased from 18 135.00 (T1)to 24 345.00 (T4) kg/hm2; the biomass yield of Ningza 21 was increased from 16 773.75(T1)to 23 535.00(T4)kg/hm2.The correlation analysis showed the threshing yield loss was positively related to biomass yield under different planting densities (Ningza 19: R =0.990, P <0.01 (R0.05= 0.950, R0.01=0.990);Ningza 21:R=0.987,P <0.05(R0.05=0.950,R0.01=0.990).Therefore,the high biomass yield may be the main reason for high yield loss in wasted branches and pods of rapeseed during mechanical harvesting.

Effects of planting density on grain loss in missed branches and pods

During the travelling of harvester,some rapeseed branches and pods may be missed in field due to the rolling of reel and cutting of vertical cutters, resulting in unharvesting loss.In this study, the unharvesting loss was calculated accurately. The results showed the unharvesting loss was relatively small with range of 0.80 to 1.68 kg/hm2.The loss rate was only 0.61%-1.14%. There were no significant differences in unharvesting loss among different cultivars or different planting densities (Table 2). It is suggested the unharvesting loss is random, and it is not significantly related to planting density or yield. This part of field loss is probably caused by mechanical characteristics of harvester and operating proficiency of operator.

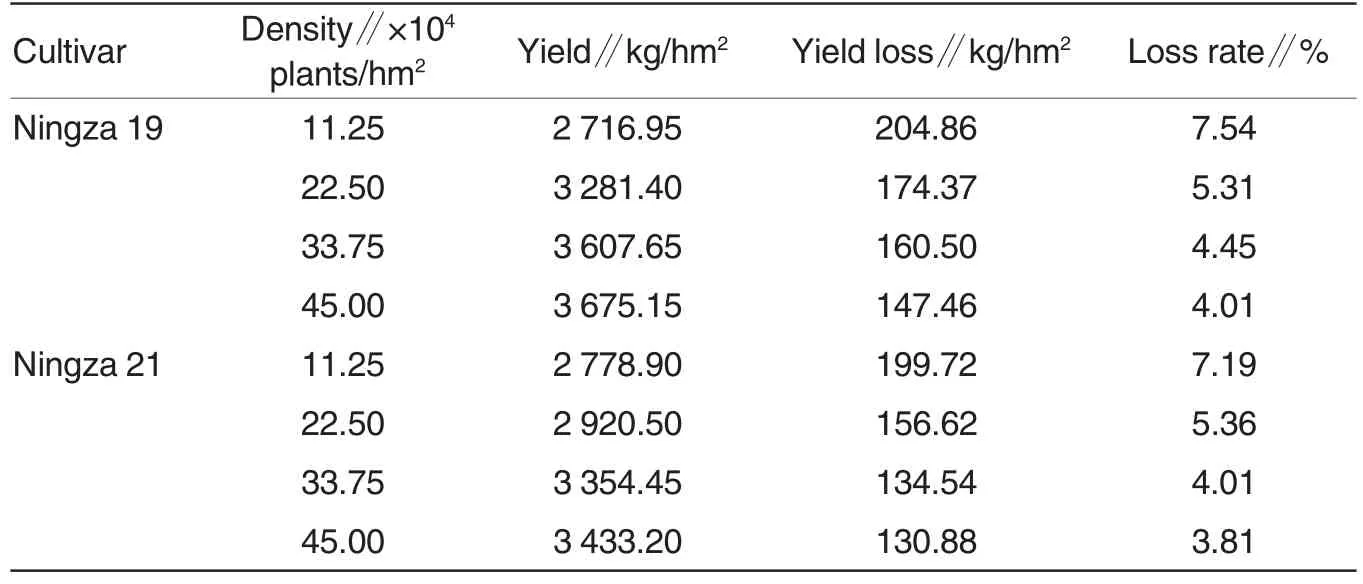

Comparison of mechanical harvesting loss rates among different planting densities Among the 3 parts of field loss, shattering loss was the main loss, and it accounted for more than 90% of the total field loss.The cleaning loss ranked second, and it accounted for 4%-8% of the total loss. The unharvesting loss was relatively small, and it only represented approximately 1%.The shattering loss,in this study, included both naturally and mechanically shattering losses.However, the naturally shattering loss was very small due to the larger pods,thicker husk and stronger pod cracking resistance of Ningza 19 and Ningza 21.So the shattering loss measured in this study mainly referred to the mechanically shattering loss. The test results showed the various yield losses and the total yield losses were related to the moisture content in rapeseed seeds. If the moisture content is high,the threshing loss and cleaning loss will be high,but the mechanically shattering loss will be low. If the moisture content is low, the threshing loss andcleaning loss will be relatively low, but the mechanically shattering loss will be relatively high. At the harvesting, the moisture content in rapeseed seeds was measured. The moisture content in Ningza 19 ranged from 11.31% to 11.55%among different planting densities with average of 11.43% . The moisture content in Ningza 21 ranged from 10.08% to 10.72% with average of 10.46%. So it can be concluded when the moisture content in seeds is about 11% , mechanically shattering loss will be the main part of mechanical harvesting field loss, but the cleaning loss will be relatively small. The test results also showed if the rapeseed is harvested till the rapeseed pods turn yellow and fully mature and the moisture content in rapeseed seeds declines to about 11%,the mechanical harvesting field loss and loss rate will all be decreased with the increase of planting density. The variation of mechanical harvesting field loss and loss rate was same between the 2 cultivars (Table 2). The average mechanical harvesting loss rate of Ningza 21 was 5.09% . The loss rates of Ningza 21 under planting densities of 337 500(4.45%)and 450 000(4.01%)plants/hm2were all below 5% (Table 3). In conclusion, the mechanical harvesting field loss can be effectively reduced if the pod cracking-resistant rapeseed cultivars are cultivated at the densities of 337 500 to 450 000 plants/hm2and harvested till the rapeseed pods turn yellow and fully mature and the moisture content in rapeseed seeds declines to about 11%.

Table 3 Comparison of yields and mechanical harvesting losses among different planting densities

Regulating effects of different planting densities on plant type of rapeseed

Planting density has certain regulating effects on plant height of rapeseed. The test results showed the plant height of rapeseed was decreased with the increase of planting density. The plant height of Ningza 19 was decreased from 179.6 (T1) to 159.3 cm (T4),and of Ningza 21 was decreased from 177.7 (T1) to 166.8 cm(T4).The decreased plant height is conducive to mechanical harvesting of rapeseed. With the decrease of plant height, the primary and secondary branches that were grown on the main stem were reduced significantly. The primary and secondary branches of Ningza 19 were decreased from 14.70 and 20.30 (T1)to 7.40 and 0.80 (T4),and of Ningza 21 were decreased from 12.40 and 16.60 (T1) to 7.30 and 2.30(T4).The decreased primary and secondary branches can avoid the crossing and tangling among branches of rapeseed, which is also conducive to mechanical harvesting (Table 4). In addition, although the productivity per plant was decreased when the planting density was increased,the population dominance brought by increased planting density supplemented the decreased productivity per plant. This is the root cause of high yield of rapeseed under high planting density.Therefore,the increased planting density of rapeseed will contribute to not only high yield but also low yield loss during mechanical harvesting.

Table 4 Effects of different planting densities on plant type of rapeseed

Discussion

The directly-sowed rapeseed can also obtain a high yield at appropriate seedling time and planting density.We ever investigated the relationship between planting density and yield of Ningyou 12 (double-low conventional rapeseed) and Qinyou 7 (double-low hybrid rapeseed). When the planting density ranges at 150 000, 300 000,450 000, 600 000 and 750 000 plants/hm2, the relationship between planting density and yield of Ningyou 12 accords with the curve of following quadratic equation:

y=-8.714 3x2+47.686x+157.4,r2=0.768 3.

The optimum planting density of Ningyou 12 is 411 000 plants/hm2.The relationship between planting density and yield of Qinyou 7 accords with the curve of following quadratic equation:

y = -11.214x2+ 61.586x + 155.8,r2=0.852 4.

The optimum planting density of Qinyou 7 is 412 700 plants/hm2.So the optimum planting density of directly-sowed rapeseed is 375 000-450 000 plants/hm2[13-14].Referring to the results above, the highest planting density of rapeseed is designed at 450 000 plants/hm2in this test.The experimental density is designed to range from 112 500 to 450 000 plants/hm2, which covers all the optimum planting densities of directly-sowed rapeseed and transplanted rapeseed. The test results show the optimum planting density of Ningza 19 and Ningza 21 is 337 500-450 000 plants/hm2to obtain a high yield. This conclusion is consistent with previous study results.Under high planting density, although the yield per plant of rapeseed is reduced, the population dominance is more obvious. The population dominance brought by increased planting density can supplement the decreased productivity per plant. This is the root cause of high yield of rapeseed under high planting density. The high planting density also has certain regulating effects on plant type of rapeseed plants, including increasing plant height, reducing biomass yield per plant,reducing branch number,reducing pod number per plant, improving maturity uniformity of pods and reducing occurrence of crossing and tangling among branches.All the changes above are all conducive to mechanical harvesting.However,the high planting density is also adverse to rapeseed production in some aspects. First, the high planting density may significantly increase the first branch height, lifting the center of gravity of pod-fruiting layer. Thus the lodging resistance of rapeseed will be reduced.Second,the high planting density will exacerbate the occurrence of Sclerotinia sclerotiorum in rapeseed in middle and lower reaches of Yangtze River in the year when precipitation is more, affecting the highly and stably yielding of rapeseed and increasing the shattering loss of early-dead pods in ill plants.Finally, the high planting density can effectively reduce plant height of rapeseed. However, the effects of planting density are different on different parts of rapeseed. High planting density will dwarf the shrinking stem and bolting stem, but elongate significantly elongating stem. The dwarfed shrinking stem can effectively avoid high rapeseed seedlings in rapeseed seedbeds, improving lodging resistance of plants.However,the elongated elongating stem is adverse to the improvement of lodging resistance of rapeseed plants[14]. Therefore, the planting density of rapeseed should be increased reasonably in according to different ecological characteristics of different regions to establish a reasonable high-density farming system. The yield of rapeseed will be improved significantly. Simultaneously, the rapeseed will also be suitable for being harvested by machine.

During the mechanical harvesting of rapeseed, the yield loss mainly occurs in the harvesting, threshing and cleaning links. The shattering loss is the major part of field loss. Since the rapeseed pods are easy to crack,naturally shattering loss may occur when the ripe rapeseed pods meet with wind,rain and other adverse weathers.During the mechanical harvesting, the rolling of reel and cutting of vertical cutters probably lead to the bursting and shattering of ripe rapeseed pods.This is the main reason for mechanical harvesting field loss[15-16].Some studies have shown the average mechanical harvesting yield loss is 8.54%, including 7.69% of mechanically shattering loss.The shattering of grains and pods is the main part of yield loss occurred in the mechanical harvesting of rapeseed. About 70% of the yield loss occurs before the harvesting[17]. Ningza 19 and Ningza 21 have larger pods,thicker husk and certain pod cracking resistance[18]. Large-scale production has also proved Ningza 21 has better pod cracking resistance and fewer shattering loss[19]. The shattering loss in field accounts for more than 90% of the mechanical harvesting field loss.The cleaning loss in wasted branches and pods accounts for 4%-8% of the total field loss. However, the unharvesting loss is relatively small, accounting for approximately 1% of total yield loss.In addition,the various yield loss and total yield losses are also related to moisture content in rapeseed seeds. If the moisture content is high,the threshing loss and cleaning loss will be high,but the mechanically shattering loss will be low. If the moisture content declines below 11%, the mechanically shattering loss will be increased gradually[16]. Therefore, the rapeseed should be harvested at an appropriate time. The appropriate harvesting time can be determined from the moisture content in rapeseed grains and color of pods.However,the moisture content in rapeseed seeds that is suitable for harvesting is controversial. The moisture content in rapeseed seeds varies for different harvesting patterns. The appropriate moisture contents in rapeseed seeds are 35%-40%, 12%-15% and 15%-20% for manual cutting, manual picking and mechanical harvesting. If the moisture content in rapeseed seeds is too low, the yield loss will be high for mechanical harvesting[17].There are also studies showing the appropriate moisture contents in rapeseed seeds are 10%and 12%for mechanical harvesting and section-divided harvesting.So if the harvester is sufficient,the rapeseed should be harvested 2-3 d later to minimize total yield loss[16]. In this study, the rapeseed is harvested by harvester when the rapeseed pods turn yellow and fully mature and the moisture content in rapeseed seeds declines to about 11%.The loss rate of mechanical harvesting of Ningza 21 is 5.09%. The loss rates of Ningza 21 under planting densities of 337 500(4.01%)and450 000 (3.81%)plants/hm2were all below 5%. The loss rate of mechanical harvesting of Ningza 19 is 5.33%. The loss rates of Ningza 19 under planting densities of 337 500(4.45%)and 450 000(4.01%)plants/hm2were all below 5%. The mechanical harvesting field loss can be effectively reduced if the pod cracking-resistant rapeseed cultivars are cultivated at the densities of 337 500 to 450 000 plants/hm2and harvested till the rapeseed pods turn yellow and fully mature and the moisture content in rapeseed seeds declines to about 11%.Thus the mechanical harvesting field loss rate can fully meet the relevant national agricultural machinery industry standards for full-feeding combine harvester(≤8%).

During the mechanical harvesting of rapeseed, the shattering loss is closely related to cultivar characteristics, planting density, production level,maturity degree of pods and otheragronomic factors. Except the factors above,the cleaning loss is also related to mechanical characteristics of harvester. The harvesting loss is determined by the mechanical characteristics of harvester and operating proficiency of operator. In order to reduce mechanical harvesting loss, the rapeseed production should be improved from the perspectives or agricultural machinery and agronomic measures.The agronomic production measures that are suitable for current harvesting machinery should be explored.In addition,the mechanized production model of rapeseed that combines closely the agronomic measures and agricultural machinery’s operation should also be developed.

[1]FU SZ (傅寿仲). Core competences of double-low rapeseed: analysis of costs and benefits of rapeseed cultivation (双低油菜核心竞争力研究—油菜栽培及其成本效益分析)[J]. Chinese Journal of Oil Crop Sciences (中国油料作物学报),2004,26(3):100-104.

[2]WU CY(吴崇友),JIN CQ(金诚谦),XIAO TQ (肖体琼), et al. Analysis on current status of fully mechanized production and technical influencing factors of rapeseed (我国油菜全程机械化现状与技术影响因素分析)[J].Journal of Agricultural Mechanization Research, 2007,12:207-210.

[3]WU CY(吴崇友),YI ZY(易中懿).Selection of technology roadmap of full mechanization of rapeseed in China(我国油菜全程机械化技术路线的选择)[J].Chinese Agricultural Mechanization,2009,2:3-6.

[4]CHEN CY(陈翠英),WANG XZ(王新忠),HE ZF (何增富). Design of header of grain combine harvester for rapeseed(谷物联合收获机油菜收获割台的设计)[J].Transactions of the Chinese Society for Agricultural Machinery (农业机械学报),2003,34(5):54-56.

[5]DONG YL(董月亮),LI YM(李耀明), XU LZ (徐立章), et al. Experimental research on influencing factors of header loss for rapeseed combine harvester(油菜联合收割机割台损失影响因素的试验研究)[J].Journal of Agricultural Mechanization Research, 2008, 30 (5): 109-112.

[6]WU ML (吴明亮),GUAN CY (官春云),TANG CZ (汤楚宙).Influencing factors of cutting force of rapeseed stalks(油菜茎秆切割力影响因素试验)[J].Transactions of the Chinese Society of Agricultural Engineering(农业工程学报),2009,25(6):141-144.

[7]LI YM(李耀明),WANG ZH(王智华),XU LZ (徐立章),et al. Motion analysis and experimental research of rapeseed extractions on vibration sieve(油菜脱出物振动筛分运动分析及试验研究)[J].Transactions of the Chinese Society of Agricultural Engineering(农业工程学报),2007,23(9):111-114.

[8]LI YM(李耀明),SUN T(孙韬),XU LZ(徐立章).Performance test and analysis of rapeseed multi-cylinder threshing and separating device(油菜多滚筒脱粒分离装置的性能试验与分析)[J]. Transactions of the Chinese Society of Agricultural Engineering(农业工程学报),2013,29(8):36-43.

[9]MA Z(马征),LI YM(李耀明),XU LZ(徐立章).Testing and analysis on floating velocity, friction and wettability characteristics of rapeseed extractions(油菜脱出物漂浮速度及摩擦与浸润特性的测定与分析)[J]. Transactions of the Chinese Society of Agricultural Engineering(农业工程学报),2011,27(9):13-17.

[10]HUANG XM(黄小毛),ZONG WY(宗望远).Research status and development trend of rapeseed combine harvester(油菜联合收获的研究现状及发展趋势)[J]. Agricultural Engineering (农业工程),2012,2(1):14-19.

[11]LUO HF(罗海峰), TANG CZ(汤楚宙),GUAN CY(官春云),et al.Research on characteristics of rapeseed plants suitable for mechanical harvesting(适应机械化收获的田间油菜植株特性研究)[J].Transactions of the Chinese Society of Agricultural Engineering (农业工程学报),2010,26(1):61-66.

[12]TANG CZ (汤楚宙),GUAN CY (官春云),WU ML(吴明亮),et al.Exploration and application of the integration of agronomy and agricultural machinery in mechanized rapeseed production(油菜机械化生产中农艺与农机相结合的探索与实践)[J]. Journal of Hunan Agricultural University (Natural Sciences)(湖南农业大学学报 (自然科学版)),2011,37(6):674-677.

[13]PU HM(浦惠明), LONG WH(龙卫华),GAO JQ(高建芹).Study on agronomical techniques for mechanized production of rapeseed I. Effects of sowing time and planting density on yield and economic traits of directly-sowed rapeseed(油菜全程机械化生产配套农艺技术研究I. 不同播期和密度对直播油菜产量和经济性状的影响)[J].Jiangsu Agricultural Sciences (江苏农业科学),2009,3:48-51.

[14]PU HM(浦惠明), LONG WH(龙卫华),GAO JQ(高建芹).Study on agronomical techniques for mechanized production of rapeseed II. Effect of different planting modes on plant type and economic traits of rapeseed(油菜全程机械化生产配套农艺技术研究II. 不同种植方式对油菜株型结构及经济性状的影响)[J]. Jiangsu Agricultural Sciences(江苏农业科学),2009,4:79-81.

[15]SHI JF (石剑飞),LENG SH (冷锁虎),ZUO QS (左青松), et al. Mechanical harvesting techniques in rapeseed(Brassica napus L.): harvesting loss of different rapeseed cultivars (油菜机械收获配套农艺技术研究I. 不同油菜品种机械收获损失的差异)[J]. Chinese Journal of Oil Crop Sciences(中国油料作物学报),2009,31(4):470-473.

[16]LIU DJ (刘德军),ZHAO XR (赵秀荣),GAO LX (高连兴), et al. Effects of moisture contents under different harvesting patterns on logistics loss of rapeseed(不同收获方式含水率对油菜收获物流损失的影响)[J].Transactions of the Chinese Society of Agricultural Engineering (农业工程学报),2011,27(10):339-342.

[17]JIN CQ(金诚谦),WU CY(吴崇友).Research status and prospect of rapeseed harvesting techniques (油菜收获技术基础研究现状与展望)[J]. Journal of Agricultural Mechanization Research(农机化研究),2010,1(1):5-9.

[18]PU HM(浦惠明), LONG WH(龙卫华),GAO JQ(高建芹),et al.Pod crackingresistance and correlation analysis of pods of Brassica napus(甘蓝型油菜角果的抗裂角特性及其相关分析)[J].Chinese Journal of Oil Crop Sciences(中国油料作物学报), 2013, 35(5):469-475.

[19]LIU CL(刘翠莲),LIU WH(刘维红),LIU XJ(刘雪基),et al.High-yield cultivation technology of rapeseed (Ningza 21) -broccoli interplanting (油菜宁杂21号与西兰花套种高产栽培技术)[J].Jiangsu Agricultural Sciences (江苏农业科学),2012,40(4):99-100.

[20]Ministry of Machinery Industry (机械工业部). JB/T 51190-1997 Cereal combine harvester quality grading (谷物联合收割机产品质量分等)[S]. Beijing:Mechanical Engineering Research Institute(北京: 机械科学研究院),1997.

Agricultural Science & Technology2015年1期

Agricultural Science & Technology2015年1期

- Agricultural Science & Technology的其它文章

- Analysis on Resistance of Rice Cultivar Lianjing 7 to Rice Black-streaked Dwarf Disease

- Seed Morphology and Seedling Variation of Four Ornamental Lupin Pedigrees

- Influences of Various Environmental Factors on the Degradation of Deoxynivalenol in Wheat Grains

- Reduction of Cd,Cu,Ni and Pb Mobility by Active Si

- Effect of Maize Sowing Time and Density on Stem and Leaf Morphological Characters of Soybean in Relay-cropping System

- Effects of Anti-wind Erosion with Peanut Stubbles in Sandy Lands during Fallow Period