Analysis and Numerical Simulation of Hydrofracture Crack Propagation in Coal-Rock Bed

Yiyu Lu,Chenpeng Song,2,Yunzhong Jia,Binwei Xia,Zhaolong Ge,Jiren Tangand Qian Li

Analysis and Numerical Simulation of Hydrofracture Crack Propagation in Coal-Rock Bed

Yiyu Lu1,Chenpeng Song1,2,Yunzhong Jia1,Binwei Xia1,Zhaolong Ge1,Jiren Tang1and Qian Li1

In underground coal mines,hydrofracture can cause the increase of breathability in the fractured coal bed.When the hydrofracture crack propagates to the interface between the coal bed and the roof-floor stratum,the crack may enter roof-floor lithology,thus posing a limit on the scope of breathability increase and making it difficult to support the roof and floor board for subsequent coal mining.In this work,a two-dimensional model of coal rock bed that contains hydrofracture crack was constructed.Then an investigation that combines the fracture mechanics and the system of flow and solid in rock failure process analysis(RFPA2D-Flow)were carried out to study the failure mechanism at the interface between rocks and coals,and critical water pressure that hydrofracture crack propagates.The results indicated that the main factors that affect the direction of hydrofracture crack propagation are the angle of intersection between coal-rock interface and horizontal section,horizontal crustal stress difference,tension-shear mixed crack fracture toughness in coal-rock interface and differences in elasticity modulus of coal-rock bed.The possibility of crack directly entering coal-rock interface would increase with the increase in angle of intersection or horizontal crustal stress difference.The trend that crack propagates along the coal-rock interface will become stronger with the decrease of the fracture toughness at the coal-rock interface and the increase of the elasticity modulus difference between the coal bed and the roof strata.The results of this study was to put forward a method of controlling hydrofracture crack,optimize the fracturing well location provides a certain theoretical basis.

Hydrofracture,crack propagation,coal-rock interface,coal mine.

1 Introduction

China is rich in coalbed methane(CBM),with a located quantity of geological resource in coal bed reaching 36.81 trillion m3.The effective extraction of CMB is of great importance to the safety of coal mine production and the development of China energy strategy[Chen Zhu,Wang,Li,and Wang(2011)].Nonetheless,the storage conditions for CBM are quite complicated,particularly in southwest of China where the coal bed permeability(<0.001mD)and thickness is low,because this region is primarily mountainous with a fluctuating surface and the ground technology for CBM extraction is powerless[Li(2001);Li,and Hua(2006)].Currently,the major techniques used for CBM extraction are permeability-increasing technologies such as the underground intensive drilling,and high-pressure pulsed water jet,etc[Li,Lu,Zhou,Kang,and Zhou(2008)].These technologies would lead to large drilling workload,low efficiency in extraction and long time of gas extraction due to the limited ability in increasing permeability,and the occurrence of gas-related accidents in coal mines.

In recent years,Chinese scholars proposed a method to increase the permeability in underground coal mine refering to hydrofracture principle in the field of oil and natural gas.This method aims to crush the coal bed by using the high pressure water pumped into coal bed through the drilling holes(from tunnels to coal seams),so as to expand and connect the existing cracks,form effective gas transport pathways,and thus improving the permeability in coal bed.Micro-seismic monitoring in field hydrofracture in the coal mines indicates that the expansion of hydrofracture crack in its initial phase could effectively handle coal bed fracutre.However,when the crack propogates to the interface between the coal-rock bed,the crack will enter the stratum through the interface.As a result,the scope of permeability-increasing will be limited and it is difficult to support the roof and floor stratum for coal mining in the later phase.It should be noted that the oil and gas layer is horizontal layer which is dozens of times thicker than that of the coal bed.This basically indicates that no sign of hydraulic fracture horizontally expanding into the interlayer.Therefore,the conventional oil gas fracture method cannot be applied directly to the complicated geological conditions in underground coal mines.The fracturing technology must be improved to adapt to the complicated underground fracturing.In this work,the expansion problem of hydrofracture crack at the coal-rock interface was studied so as to provide some theoretical information for development of a new method to control the crack in underground hydrofracutre cracks in later period.

Study on underground coal mine fracture started quite late, which is primarily about relevant principles of petroleum system fracturing.However,none is reported on the study of the impact coal-rock interface has on crack horizontal extension.Some scholars studied the impact of sand lens in mudstone layer on the horizontal extension of hydraulic fracture.Heuz(1990)reported that that the discrepancy between the horizontal stress difference and the elasticity modulus of discontinuity surfaces would deflect the direction of crack propagation.Hanson,and Shaffer(1980;1981)peformed experimental studies and found that the difference between the fracture toughness in multilayers is a major contributor to the crack arrest in hydraulic fracture.Anderson(1981)reported that whether the hydraulic fracture can traverse lens or not is determined by the pressure stress intensity on lens normal direction.The hydraulic fracture will traverse lens and continue its customary propagation when the pressure stress along the normal direction increases to 4 MPa.However,the fracture will propagate along the interface or even bypass the lens under a small pressure stress along normal direction.Many scholars conducted related studies and believed that the major factor that determines whether hydraulic fracture can traverse lens or not is the horizontal stress difference,discrepancy in mechanical properties between layer and sandstone lens.

The difference between the present study and the research performed by other researchers are as follows:

(1)All the above mentioned research assumed that sandstone lens are perpendicular to hydraulic fracture propagation.However,the object of this study is the ubiquitous coal-rock layer in which there is an intersection angle between hydraulic fracture and coal-rock interface,and this is probably the main factor that affects the direction of hydraulic fracture propagation.

(2)Mechanical strength exists at the coal-rock interface.The impact of the mechanical property at the on the hydraulic fracture propagation was not studied before.Therefore,the purpose of this work is study the coal-rock bed mechanics parameters how to effect the direction of hydrofracture crack propagation.Firstly,based on the geologic characteristics of coal-rock layer,a two-dimensional model of coal rock bed that contains hydrofracture crack was constructed.And then an investigation that combines the fracture mechanics and the system of flow and solid in rock failure process analysis(RFPA2D-Flow)were carried out to study the failure mechanism at the interface between rocks and coals,and critical water pressure that hydrofracture crack propagates.

2 Hydraulic Fracture Model in the Coal-rock Bed

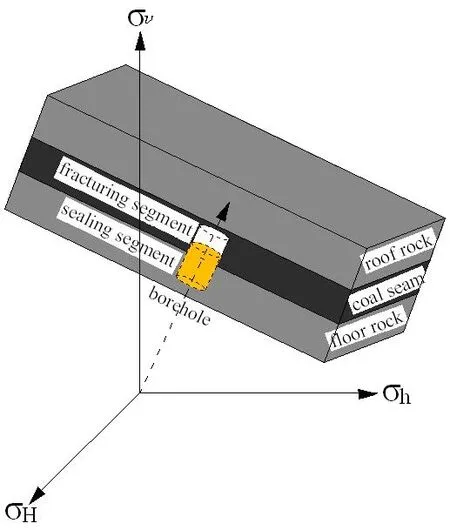

It is found that the coal bed drilling hole in the gas extraction tunnel in coal floor stratum is crushed by the underground hydraulic fracture Firstly,a three dimensional fracture model is established.As shown in Fig.1,σvis the vertical crustal stress σHis the horizontal maximum crustal stress,and σhis the horizontal mini-mum crustal stress.

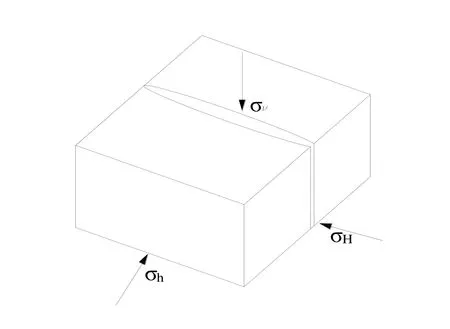

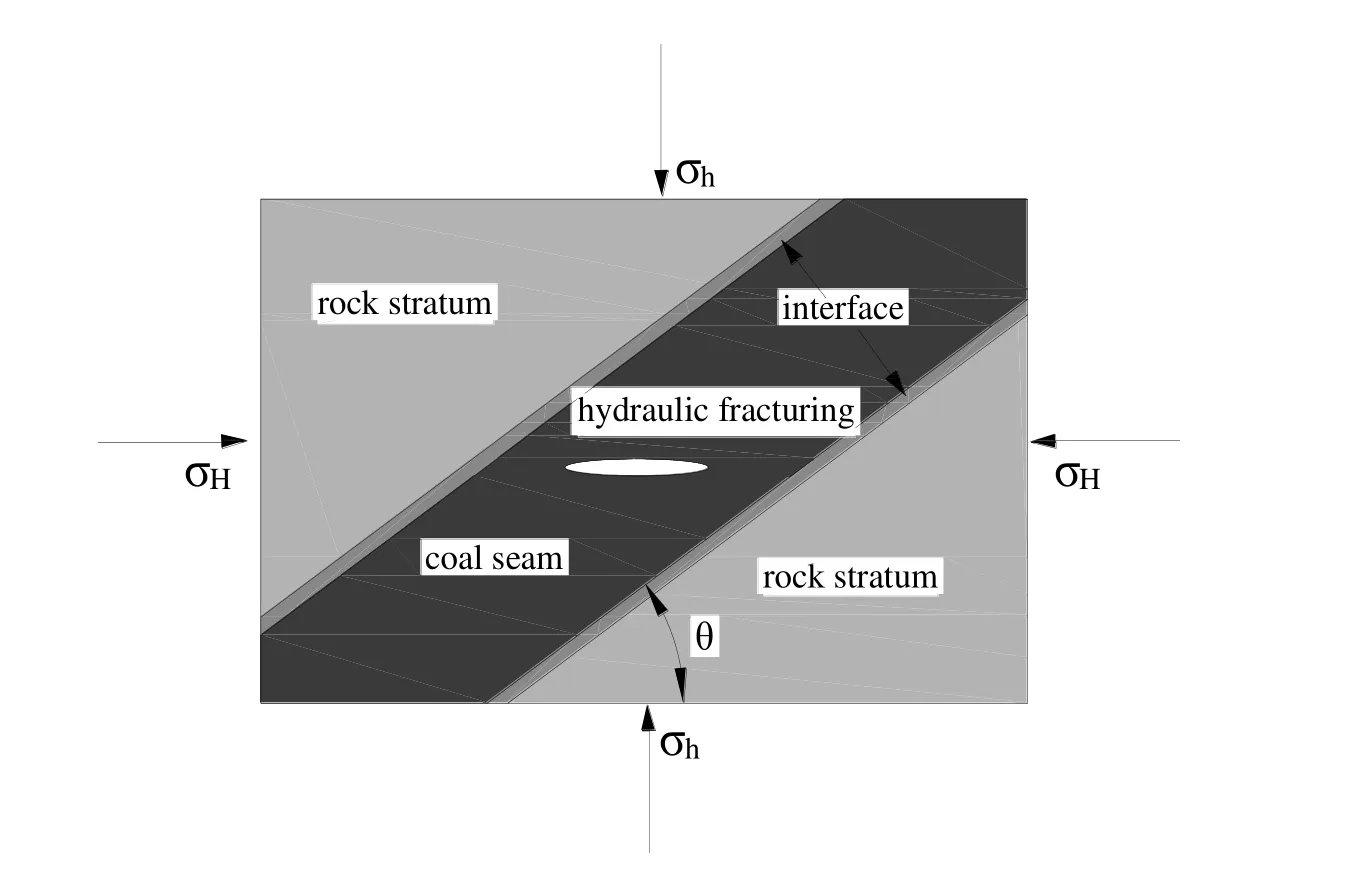

At present,the depth of coal bed where the underground hydraulic fracture technology is used generally exceeds 500m.According to the field practice of the hydraulic fracture in the oil and gas layer,the hydraulic fractureperformed in the range of(300~600)m underground usually forms a vertical crack perpendicular to horizontal minimum crustal stress direction,as shown in Fig.2[Chen,Jin,and Zhang(2008)].To study the crack propagation rules,the three dimensional model is usually converted to a two dimensional model because too many influence factors are involved in the three dimensional model.Compared with the 3-D model,the two dimensional model is more pertinent to study the impact of certain parameters and conditions on the crack propagation.Accordingly,a horizontal crack cutting is shown in Fig,3,which gives the following cutting plane and its stress condition.As seen in the figure,θ is the intersection angle between the coal-rock interface and the horizontal section.

Figure 1:The 3-D model of hydraulic fracture.

Figure 2:Schematic diagram of the vertical fracture.

Figure 3:A 2-D model of the coal-rock interface in hydraulic fracturing.

3 Analysis of the Crack Propagation

3.1 Critical Water Pressure of Hydraulic Fracture Propagation

As shown in Fig.3,the hydraulic fracture propagates under the combined action of far-field horizontal maximum crustal stress σH,horizontal minimum crustal stress σhand water pressure p within the crack.The normal stress σnand shearing strength τnare given as follows:

In the process of hydraulic fracture moving along the direction of horizontal maximum crustal stress σH,the fracture is only affected by the normal stress σnwhile the shearing strength τnremains zero.Based on the relative theory of fracture mechanics,the instability of hydraulic fracture propagation belongs to the category of Mode I crack problem.

At present,the Irwin crack propagation criterion is employed for the analysis of hydrofracture crack propagation.According to Irwin fracture mechanics theory,for Mode I crackthe fracture will propagate when the stress intensity factor KIreaches critical value KIC:

where KIis the stress intensity factor of Mode I crack,and KICis the critical stress intensity factor(fracture toughness).KIis calculated as follows:

where σnis the normal stress on fracture plane,and a the half-length of crack.For the problem discussed in this work,KIcan be determined through incorporating the expression of σnEq.1 into Eq.3:

KICis related to the rock’s elasticity modulus,poisson ratio and unit area surface energy:

where E is the elasticity modulus of rock;γ is the surface energy per unit area;v is the Poisson ratio

Combining Eqs. 4-5 and with Eq. 2, the critical water pressure of crack propagation can be expressed in Eq.6

where pm1and pm2is defined as the critical water pressure of crack propagation in the coal bed and in the rock layer,respectively.E1,γ1,v1are the elasticity modulus,unit area surface energy,Poisson’s ratio of the coal;E2,γ2,v2are elasticity modulus,unit area surface energy,Poisson’s ratio of the rock.Because KIC,the ability of coal bed’s to resist crack,is significantly smaller than the roof-floor rock stratum,which can be used to explain why pm1is always smaller than pm2.

3.2 Failure Mechanism at the Coal-rock Interface

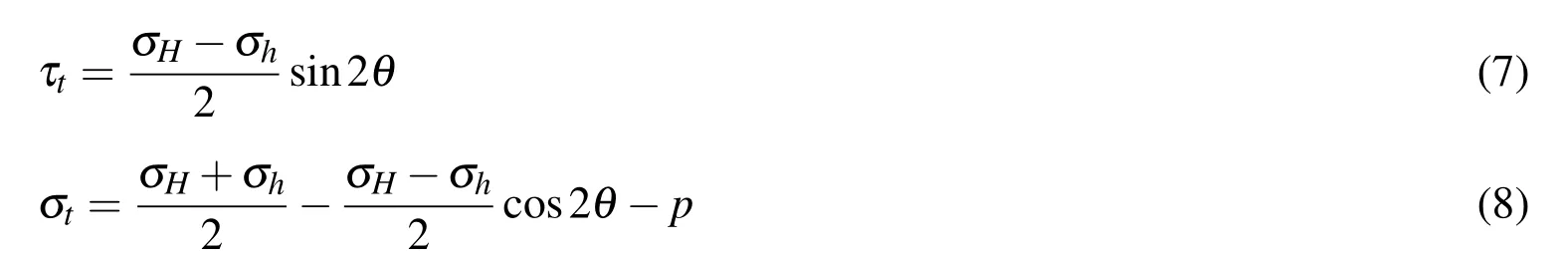

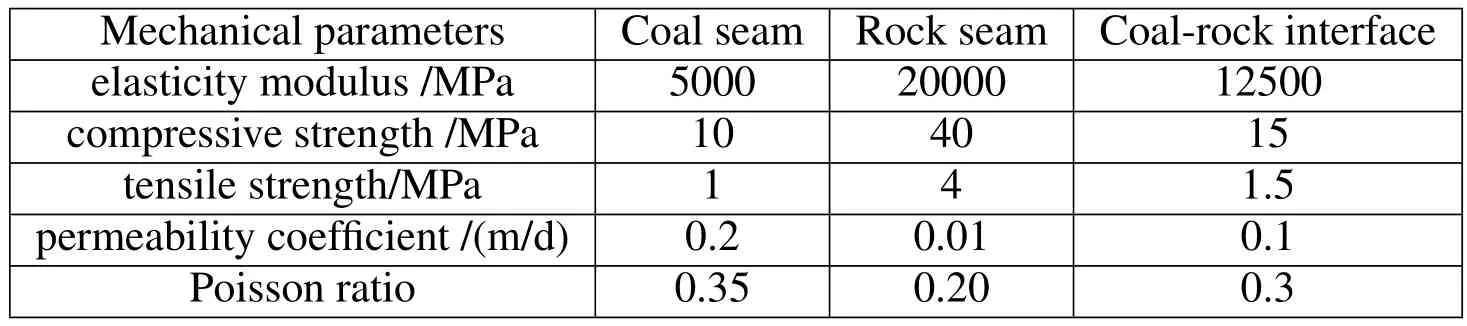

Using fracture mechanics theory,the problem of the hydrofracture propagation along formation interface can be simplified as tension-shear mixed mode crack.When the fracture propagates to the coal-rock interface,the shear stress σtand normal stress σtat the interface can be expressed as:

According to fracture mechanics theory,Mode I and II crack tip stress intensity factors are:

where l is the half-length of crack.

In fracture criterion of tension-shear mixed mode crack are maximum circumferential stress theory,strain energy density factor theory and energy release rate theory.Since complicated calculation is required in these theoriesit is difficult to obtain the formula of critical water pressure.From the perspective of engineering application,the approximate fracture criterion that is usually adopted in the area of engineering is employed in this study.Therefore,tension-shear mixed mode crack instability criterion can be expressed as[Li,Zhang,Ren,and Wang(2005)]:

where KICis mode I crack fracture toughness.

When the propagation instability occurs as the crack moves along the coal-rock interface,the interior pore water pressure is the critical water pressure.Combining Eqs.7-9 and with Eq.10 the critical water pressure of crack propagation in the coal-rock interface can be expressed in Eq.11.

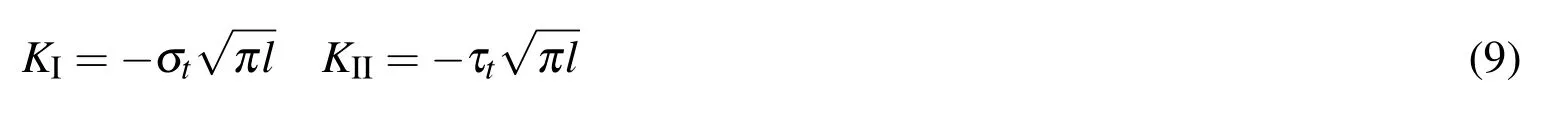

As seen in Eq.11,the factors that affect the critical propagation water pressure at the coal-rock interface are mode I crack fracture toughness,horizontal crustal stress difference,the minimum horizontal crustal stress as well as the intersection angle between interface and horizontal section.To analyze the impact of intersection angle and the horizontal crustal stress difference on the critical water pressure at the coal-rock interfaceis defined and the following equation is obtained:

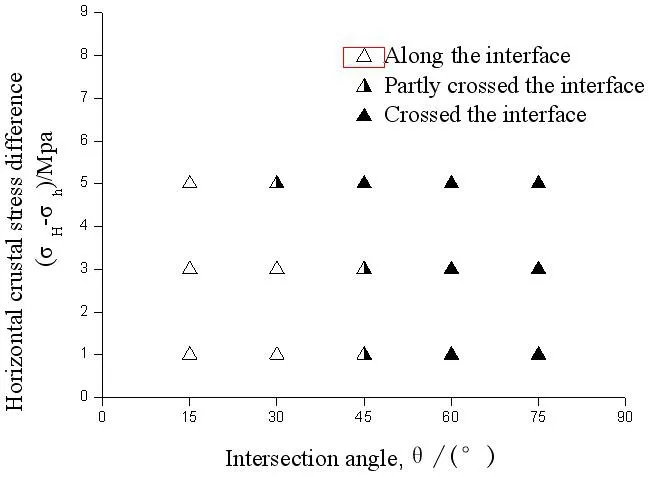

Fig.4 shows the impact of the intersection angle and horizontal crustal stress difference on the critical water pressure at the coal-rock interface As a whole the critical water pressure increases with the in increase intersection angle and horizontal crustal stress difference.This means that the crack tends to propagate along with the coal-rock interface and then enter the rock layer.Meanwhile,the critical water pressure will decrease slightly as it reaches the peak at θ =67°.The declining speed becomes larger with the increase of the horizontal crustal stress difference.

3.3 Determination of the crack propagation direction

(1)If pm3<epm1<pm2,the hydrofracture crack will propagate along the coal-rock interface.

(2)If min(pm1,pm2,pm3)=pm1,the water pressure will increase in the hydrofracture crack and then extend along the direction where critical internal water pressure is smaller between pm2and pm3.If the difference between pm2and pm3is slight,it is highly possible that the hydrofracture crack partially crosses and extends along coal-rock interface at the same time.

The propagation direction when intersection of hydrofracture and coal-rock interface is determined by relative sizes of critical water pressure of crack propagationHowever,according to analysis results from Eq.6 and Eq.7,their relative sizes are virtually determined by coal-rock interface mechanical parameters which mainly influenced by horizontal stress difference,intersection angle differences in elasticity modulus of coal-rock bed and tension-shear mixed crack fracture toughness in coal-rock interface.Because of the minimal horizontal stress σhincluded in Eq.6 and Eq.11,its influences is counteracted.

Figure 4:The impact of the intersection angle ad horizontal crustal stress difference on critical water pressure in coal-rock interface.

4 Numerical simulation

In this section,the coupling system of flow&solid in rock failure process analysis(RFPA2D-Flow)will be used for numerical simulation studies on crack propagation influenced by horizontal stress difference,intersection angle,differences in elasticity modulus of coal-rock bed and tension-shear mixed fracture toughness in coal-rock interface,which aims at verifying the theoretical result validity and qualitatively obtaining their influence rules on hydrofracture propagation.

4.1 Simulation method.

The coupling system of fl ow&solid in rock failure process analysis(RFPA2DFlow)is a numerical simulation method developed by professor Tang C.A.(1997,1998)on the basis of nonlinearity,heterogeneity and anisotropy in rock fracturing.Its computing method is based on the finite element theory and statistical damage theory which the heterogeneity of material property and the randomness of fl aw distribution are taken into consideration.Besides,the statistical distributional hypothesis for material property is applied to numerical computation method( finite element method)by damaging the element which meets the given strength criterion so that the numerical simulation of heterogeneity in material damaging process will be realized.Because RFPA software has unique computing and analyzing method,it is able to solve many problems that can not be solved by other simulation software in geotechnical engineering.

RFPA2D-Flow is based on the following hypotheses:(1)The fluid in rock medium follows Biot Seepage Theory;(2)The rock medium is an elasto-brittle material with residual strength that its loading and unloading process meets elastic damage theory;(3)The maximum tensile strength criterion and Mohr-Coulomb criterion are used as damage threshold to judge element damage;(4)Under elastic state,the stress-permeability coefficient relationship for material is described by negative exponential function and the permeability coefficient will be increased dramatically after material damaged;(5)The mechanical parameter of material mesostructure is assigned according to Weibull distribution with the purpose of bringing in material heterogeneity.

In classic coupled seepage theory,the change of rock permeability caused by stress is out of consideration,which does not meet momentum conservation.After taking the influence of stress into consideration,the coupled seepage and stress equation shall be provided.Therefore,the RFPA2D-Flow model with damage is as follows:

In those equations:ρ is physical density;σijis the sum of normal stress;εvand εijrepresent volumetric strain and normal strain respectively;Q represents Biot constant;G and λ represent shear modulus and Lame coefficient;∇2means Laplace operator;K0and K represent initial-value of seepage coefficient and seepage coefficient respectively;P is pore water pressure.ξα and β represent mutation ratio of seepage coefficient,pore water pressure coefficient and coupling coefficient(stress sensitivity factor)separately which are determined through experiment.

When stress state or strain state of element meet some given damage thresholds,the element will start to damage.The elasticity modulus of damage element is:E=(1−D)E0,of which D represents damage variable,E and E represent the elasticity moduli of damage element and non-damage element respectively.Those parameters are assumed to be scalars.

Through the analysis mentioned above,this shows that damage parameter was added in RFPA2D-Flow and continuum mechanics was used to analyze non-continuum medium.For that reason,this software is competent at analyzing the crack propagation of coal-rock interface.

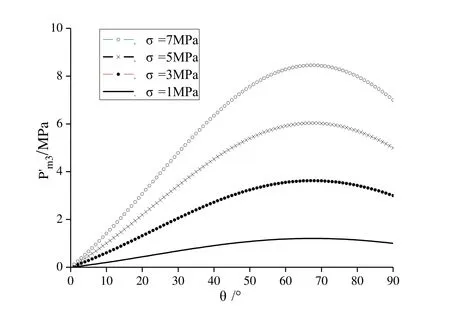

In regard to this issue,a 15m×9m rectangular region with 500×300=120000 elements shall be built.An ellipse(long axis:1.0m;short axis:0.2m)is made to represent the propagated crack(as shown in fig.5).The upper-lower section represents roof-floor stratum and the middle section represents coal layer.Under displacement boundary condition,horizontal crustal stress is exerted on both sides of the model.Because the principle direction of crack propagation is perpendicular to the direction of minimal horizontal principal stress,so that the maximum horizontal principal stress σHwill be exerted on the left and right side of the model and the minimal horizontal principal stress σhon top and bottom.The effect of injecting water pressure is acted on the internal edge of propagating crack with water pressure increased by the step of 0.2Mpa.Initial water pressure will be determined by initial boundary conditions of the model

Figure 5:The model of the coal-rock interface in hydraulic fracturing.

4.2 The influence of horizontal principal stress and intersecting angle

According to the analysis results from Eq.6 and Eq.11,if the horizontal differential principal stress or intersecting angle increases,the critical internal water pressure of hydrofracture propagating in strata remains unchanged while that of tensionshear damaged coal-rock interface will increase,which points out that under the condition of low intersecting angle and low horizontal differential principal stress the hydrofracture,because of the low critical internal water pressure when shearing damage happens in coal-rock interface,will propagate along coal-rock interface.Furthermore,due to the increased intersecting angle or horizontal differential principal stress,the critical internal water pressure in coal-rock interface will go up as well.Thus,while hydrofracture propagates along the coal-rock interface in original direction it may also go through at the same time.When intersecting angle and horizontal differential principal stress increase to a certain degree,hydrofracture crack will cross the interface in original direction and continue to propagate.

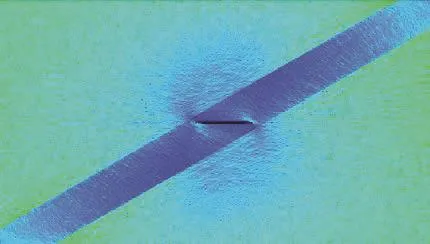

In this section,15 groups of the simulation experiments were conducted.Tab1 shows the parameters for horizontal principal stress and intersection angleand Tab2 shows the mechanical parameters for the coal-rock interface

Table 1:Parameters for the horizontal principal stress and the intersection angle.

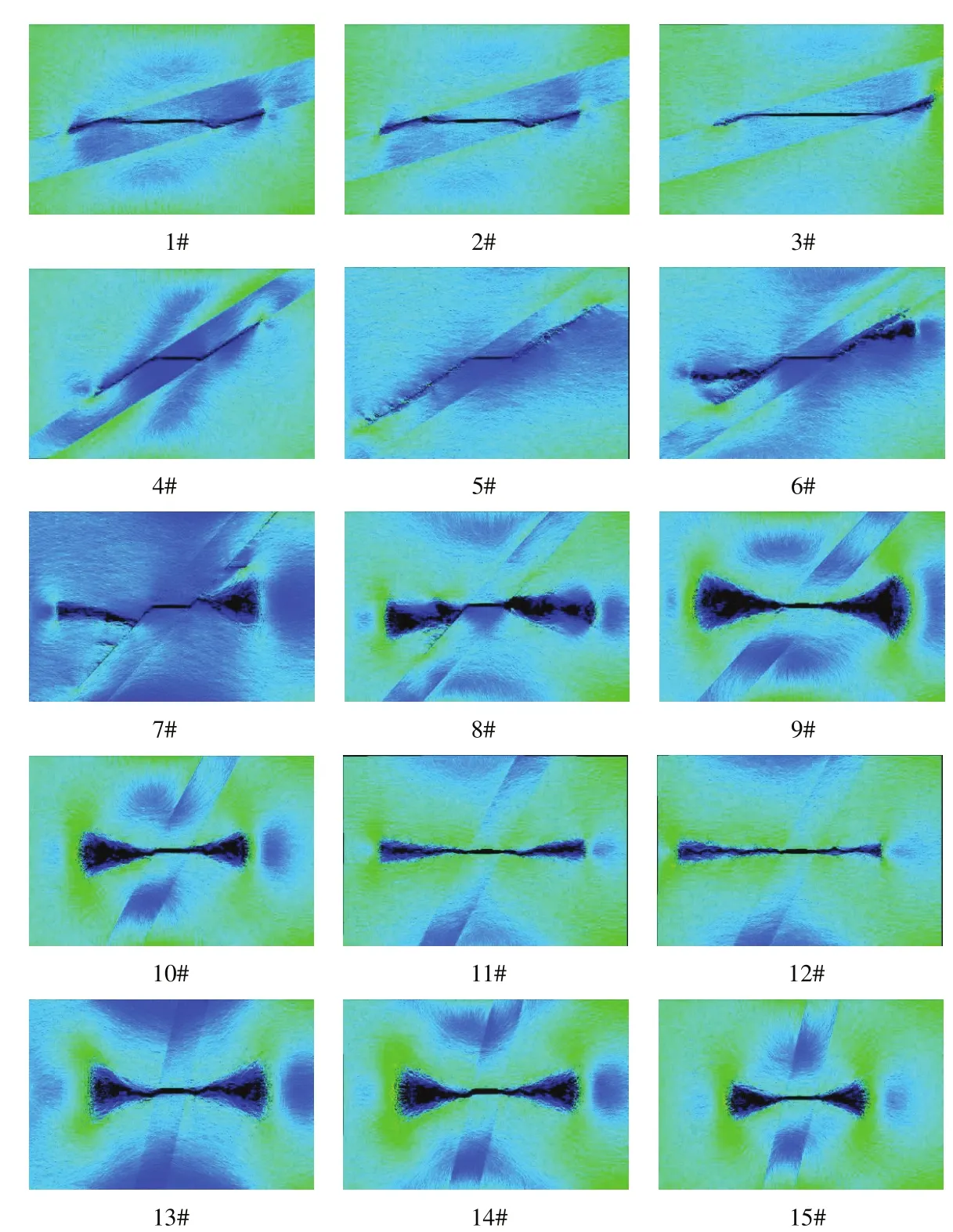

Fig.6 shows the simulation results.In the three simulating groups with intersecting anglesofθ =15°,the extending cracks extends along the coal-rock interface. In the 4#~9#simulating groups with intersecting angles of θ =30°and θ =45°,with the increase in the horizontal crustal stress difference,the hydrofracture extends along the maximal crustal stress direction after it extended certain distance along the coalrock interface,suggesting that,the hydrofracture crack tends to extend across the coal-rock interface with the increase in the horizontal stress difference or the intersecting angles.For the 10#~15#simulating groups with intersecting angles ofθ =60°and θ =75°,all cracks extends along the original directions through the interfaces.Boundary lines exist in the above simulating groups.Hydrofracture cracks are able to cross the interfaces easily at the upper side of the boundary line.hydrofracture cracks extend along the interfaces at the lower side of the boundary line.Around the boundary line exit these two kinds of extensions.

Table 2:Mechanical parameters for the coal-rock interface.

4.3 The influence of differential coal-rock bed elasticity modulus

As is known from Eq.6,the larger the elasticity modulus in rock bed is the higher the critical water pressure needed for crack propagation within.In that case,hydrofracture crack may easily change its original direction and propagate along coal-rock interface;otherwise,it may propagate through the interface.Next,we will change,based on the crack propagation conditions of group 6#and 7#in section 4.2,the elasticity modulus of rock bed so as to investigate its influence on crack propagation.Other parameters are the same as in section 4.2.

Table 3:Elasticity modulus of coal-rock bed.

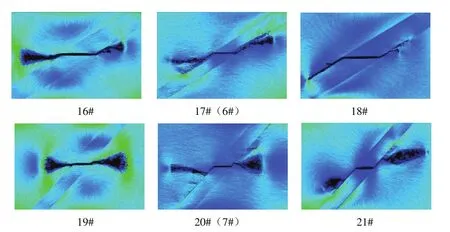

Simulation results shall be seen in Fig.7.When compare them with the crack propagations of group 6#and 7#,it is found that,under the condition of changed rock bed elasticity modulus and unchanged parameters mentioned above,the larger the elasticity modulus in rock bed is,the easier the hydrofracture propagates towards coal-rock interface.Otherwise,it may propagate through the interface.

Figure 6:The simulation results of hydrofracture crack propagation.

Figure 7:The simulation results of hydrofracture crack propagation.

4.4 The impact of tension-shear mixed crack fracture toughness of the coalrock interface

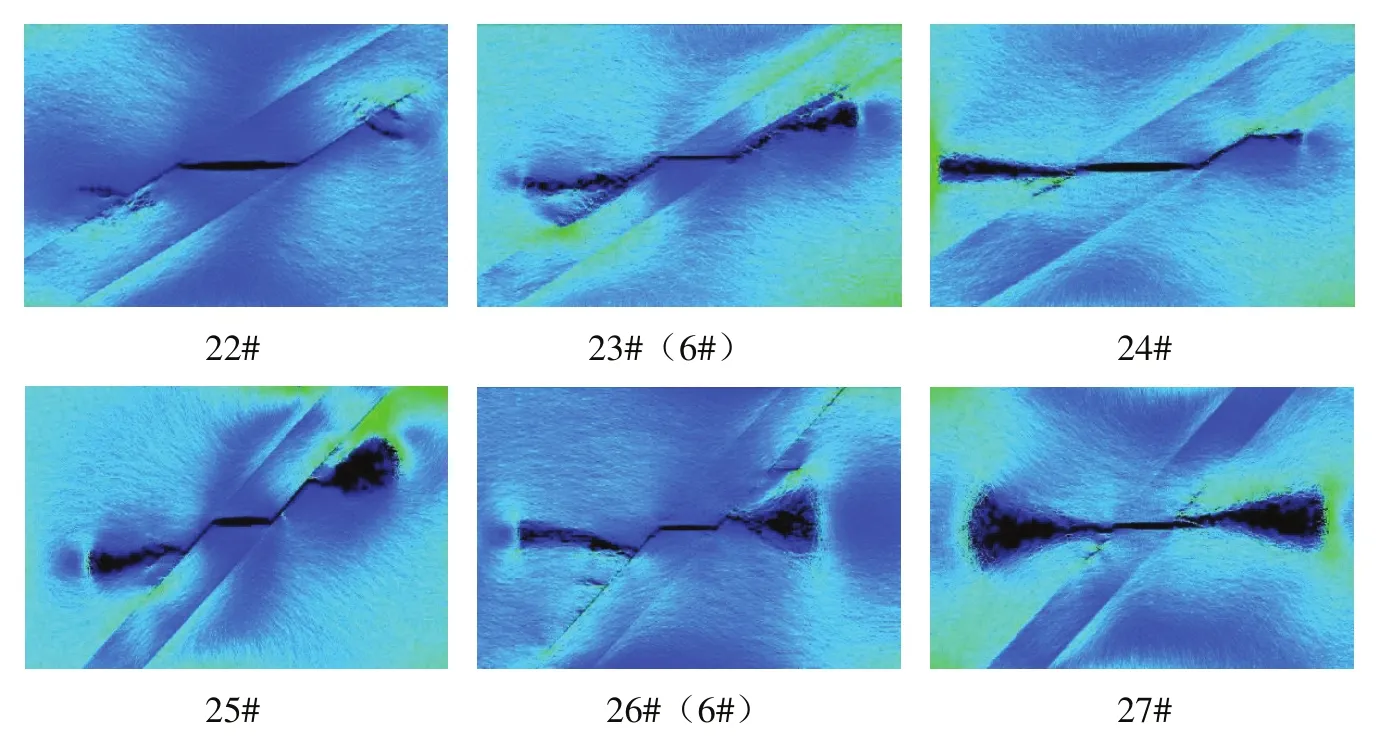

As fracture toughness can not be directly set in the RFPA2D-Flow software,and based on the analysis in Section 3, the I-II tension-shear mixed crack fracture toughness of the coal-rock interface mainly depends on the elastic modulus of the coalrock interface,the surface energy of the unit surface and the Poisson’s ratio,with the elastic modulus parameters bringing the most evident difference.Thus,as for the extensions of groups 6#,7#in Section 4.1,we altered the elastic modulus of the coal-rock interface and reflected the impact of tension-shear mixed crack fracture toughness of the coal-rock interface on the extension of the hydrofracture cracks,with other parameters being the same as their counterparts in Section 4.2 These two simulation results are as shown in Fig.8.With the increase in the elastic modulus,the extension distance of the hydrofracture cracks in the coal-rock interface will decrease,with the hydrofracture cracks extending across the coal-rock interface.When the toughness of the coal-rock interface increase to a certain degree,the hydrofracture cracks extend through the coal-rock interface directly.But as the extension of the hydrofracture crack is impacted by various factors,it cannot quantitatively indicate the specific impact of interface toughness on the hydrofracture cracks.

Table 4:Elasticity modulus of the coal-rock interface.

Figure 8:The simulation results of hydrofracture crack propagation.

5 Conclusions

(1)As the hydrofracture cracks extend to the coal-rock interface,it will be under the comprehensive impact of various forces,which may divert its extension direction.The main factors affecting the extension direction of hydrofracture cracks are the intersecting angles between coal-rock interface and the horizontal section,horizontal crustal stress difference,elasticity modulus of rooffloor stratum and tensionshear mixed crack fracture toughness in coal-rock interface.

(2)The tension-shear damage critical water pressure of the coal-rock interface increases with the degree of intersecting angles or the horizontal crustal stress difference.That is,under the condition of small intersecting angles and low horizontal crustal stress difference,the hydrofracture crack extends along coal-rock interface,whereas with the increase of intersecting angles or the horizontal crustal stress dif-ference,the cracks are more likely to extend along its original direction through the coal-rock interface.

(3)The extension critical water pressure of the hydrofracture cracks in the roof and fl oor stratum increases with the growth of elastic modulus in the rock layer.The stronger the elastic modulus in the rock layer,the more likely that hydrofracture cracks extend along coal-rock interface.

(4)We adopt tension-shear mixed crack fracture toughness to indicate the impact of coal-rock interface toughness on the hydrofracture cracks extension.The weaker the fracture toughness indicates a lower critical water pressure is needed when the hydrofracture cracks extends along the coal-rock interface and the higher possibility of the hydrofracture cracks extending along the coal-rock interface.

Acknowledgement: This paper is jointly supported by 973 Program(NO.2014 CB239206),PCSIRT(NO.IRT13043),the National Science Foundation of China(NO.51374258;NO.51474158)and the Open Projects of State Key Laboratory of Coal Mine Disaster Dynamics and Control(Chongqing University2011 DA105287-FW201412).The authors would like to thank the State Key Laboratory of Coal Mine Disaster Dynamics and National&Local Joint Engineering Laboratory of Gas Drainage in Complex Coal Seam.

Anderson,G.D.(1981):Effects of Friction on Hydraulic Fracture Growth Near Unbonded Interfaces in Rocks.Society of Petroleum Engineers Journal.,8347-PA.

Chen,M.;Jin,Y.;Zhang,G.Q.(2008):Petroleum engineering rock mechanics.Science Press.

Chen,S.B.;Zhu,Y.M.;Wang,M.;Li,W.;Wang,H.M.(2011):Prospect Conceiving of Joint Research and Development of Shale Gas and Coalbed Methane in China.Energy and Power Engineering.,vol.3,no.3,pp.348–354.

Dong,L.;Atluri,S.N.(2011):Development of T-Trefftz four-node quadrilateral and Voronoi cell finite elements for macro-µmechanical modeling of solids.CMES:Computer Modeling in Engineering&Sciences,vol.81,no.1,pp.69–118.

Dong,L.;Atluri,S.N.(2012):A Simple Multi-Source-Point Trefftz Method for Solving Direct/Inverse SHM Problems of Plane Elasticity in Arbitrary Multiply-Connected Domains.CMES:Computer Modeling in Engineering&Sciences,vol.85,no.1,pp.1–43.

Hanson,M.E.;Shaffer,R.J.;Anderson,G.D.(1981):Effects of Various Parameters on Hydraulic Fracturing Geometry.Society of Petroleum Engineers Journal.,8942-PA.

Hanson,M.E.;Shaffer,R.J.(1980):Some Results from Continuum Mechanics Analyses of the Hydraulic Fracturing Process.Society of Petroleum Engineers Journla.,7942-PA.

Han,Z.D.;Atluri,S.N.(2014):Eshelby Stress Tensor T:a Variety of Conservation Laws for T in Finite Deformation Anisotropic Hyperelastic Solid&Defect Mechanics,and the MLPG-Eshelby Method in Computational Finite Deformation Solid Mechanics-Part I.CMES:Computer Modeling in Engineering&Sciences,vol.97,no.1,pp.1–34.

Han,Z.D.;Atluri,S.N.(2014):Onthe(Meshless Local Petrov-Galerkin)MLPGEshelby Method in Computational Finite Deformation Solid Mechanics-Part II.CMES:Computer Modeling in Engineering&Sciences,vol.97,no.3,pp.199–237.

Li,H.(2001):Major and Minor Structural Features of a Bedding Shear Zonealong a Coal Seam and Related Gas Outburst,Pingdingshan Coalfield,Northern China.International Journal of Coal Geology.,vol.47,pp.101–113.

Li,X.H.;Lu,Y.Y.;Zhou,Y.;Kang,Y.;Zhou,D.P.(2008):Study on Improving the Permeability of Soft Coal Seam with High Pressure Pulsed Water Jet.Journal of China Coal Society.,vol.33,no.12,pp.1386-1390.

Li,X.Z.;Hua,A.Z.(2006):Prediction and Prevention of Sandstone-gas Outbursts in Coal Mines.International Journal of Rock Mechanics and Mining Sciences.,vol.43,pp.2–18.

Li,Z.L.;Zhang,H.C.;Ren,Q.W.;Wang,Y.H.(2005):Analysis of Hydraulic Fracturing and Calculation of Critical Internal Water Pressure of Rock Fracture.Rock and Soil Mechanics,vol.26,no.8,pp.1216-1220.

Tang,C.A.;Kaiser,P.K.(1998):Numerical Simulation of Cumulative Ddamage and Seismic Energy Release during Brittle Rock Failure–Part I:Fundamentals.International Journal of Rock Mechanics&Mining Sciences,vol.35,no.2,pp.113–121.

Tang,C.A.(1997):Numerical Simulation of Progressive Rock Failure and Associated Seismicity.International Journal of Rock Mechanics&Mining Sciences,vol.34,pp.249–261.

Tang,C.A.(1998):A New Approach to Numerical Method of Modelling Geological.Processes and Rock Engineering Pproblems.Engineering Geology,vol.49,pp.207–214.

1State Key Laboratory of Coal Mine Disaster Dynamics and Control,Chongqing University,Chongqing 400030,China.

2Corresponding author.Tel.:+86 023 65106640;fax:+86 023 65106640.

E-mail:songchenpeng@163.com(C.Song)

Computer Modeling In Engineering&Sciences2015年7期

Computer Modeling In Engineering&Sciences2015年7期

- Computer Modeling In Engineering&Sciences的其它文章

- The Use of High-Performance Fatigue Mechanics and the Extended Kalman/Particle Filters,for Diagnostics andPrognostics of Aircraft Structures

- A 3-D Visco-Hyperelastic Constitutive Model for Rubber with Damage for Finite Element Simulation

- Optimal Adaptive Genetic Algorithm Based Hybrid Signcryption Algorithm for Information Security