The Use of High-Performance Fatigue Mechanics and the Extended Kalman/Particle Filters,for Diagnostics andPrognostics of Aircraft Structures

Hai-Kun Wang,Robert Haynes,Hong-Zhong Huang,Leiting Dong,Satya N.Atluri

The Use of High-Performance Fatigue Mechanics and the Extended Kalman/Particle Filters,for Diagnostics and

Prognostics of Aircraft Structures

Hai-Kun Wang1,2,Robert Haynes3,Hong-Zhong Huang1,Leiting Dong2,4,Satya N.Atluri2

In this paper,we propose an approach for diagnostics and prognostics of damaged aircraft structures,by combing high-performance fatigue mechanics with filtering theories.Fast&accurate deterministic analyses of fatigue crack propagations are carried out,by using the Finite Element Alternating Method(FEAM)for computing SIFs,and by using the newly developed Moving Least Squares(MLS)law for computing fatigue crack growth rates.Such algorithms for simulating fatigue crack propagations are embedded in the computer program Safe-Flaw,which is called upon as a subroutine within the probabilistic framework of filter theories.Both the extended Kalman as well as particle filters are applied in this study,to obtain the statistically optimal and semi-optimal estimates of crack lengths,from a series of noisy measurements of crack-lengths over time.For the specific problem,a simple modification to the particle filter,which can drastically reduce the computational burden,is also proposed.Based on the results of such diagnostic analyses,the prognostics of aerospace structures are thereafter achieved,to estimate the probabilistic distribution of the remaining useful life.By using a simple example of a single-crack near a fastener hole,we demonstrate the concept and effectiveness of the proposed framework.This paper thus forms the scientific foundation for the recently proposed concepts of VRAMS(Virtual Risk-Informed Agile Maneuver Sustainment)and Digital Twins of aerospace vehicles.

Diagnostics and prognostics,fatigue mechanics,extended Kalmanfilter,particle filter

1 Introduction

Diagnostics of the system state and prognostics of the remaining useful life(RUL)for aircrafts have gained some momentum in the past few decades.This is because of the growing demand for having such an information in near real-time,to plan the maintenance and retirement,and to increase the safety-level of the aircraft structures.

Methods of diagnostics and prognostics in the literature can be generally classified into data-driven methods and model based methods[Baraldi,Cadini,Mangili,Zio(2013)].Data-driven methods can be used if sufficient failure data or condition monitoring data are available for similar structures,assuming that all of them degrade in a similar path.These methods are based on statistical models that learn trends from the available failure data:see the review of[Si,Wang,Hu,Zhou(2011)].Their applications in predicting the remaining fatigue life of aircrafts are however hindered by the lack of sufficient data for structural failure.

On the other hand, model-based estimation methods utilize the physics of the degradation process,to estimate the degradation state and the RUL.Since the available measurements are mostly contaminated by noise and disturbances,model-based methods mostly rely on Bayesian approaches such as Kalman and particle filters,to track the probabilistic distributions of system-states over time,see[Saha,Goebel,and Christophersen(2009);Baraldi, Mangili, and Zio(2012);Zaidan,Harrison,Mills,Fleming(2015)].These studies commonly require an explicit mathematical description of the degradation process.However,in order to predict the remaining fatigue life of aircrafts,such an explicit mathematical model may be unavailable.For example,even if a simple fatigue law which relates the crack growth rate to the stress intensity factor(SIF)can be postulated,the SIFs for growing cracks in complex aircrafts structures would have to be numerically and most efficiently computed.

Therefore,for the purposes of diagnostics and prognostics of complex aircraft structures,it is necessary to have a highly efficient algorithm for simulating fatigue crack propagations,which can be repeatedly called upon within the probabilistic frameworks of the filter theories.Finite element based methods,including the extended finite element methods with enriched basis functions,would fail in serving this purpose,because of their computational inefficiency for fracture mechanics,and their complex procedures of remeshing for crack growth:see the extensive documentation[Dong and Aluri(2013a,2013b)].

In contrast,the Finite Element Alternating Methods(FEAM)developed by Atluri and co-workers over many years have enabled the highly accurate computations of fracture mechanics parameters of cracks,and efficient automatic simulations of non-collinear and non-planar mixed-mode crack growth in complex 2D&3D structures,see[Nishioka and Atluri(1983);Wang and Atluri(1996);Park and Atluri(1998);Nikishkov,Park and Atluri(2001);Han and Atluri(2002);Dong and Aluri(2013a,2013b)].A Moving Least Squares(MLS)fatigue law was also proposed and combined with FEAM,to have better computations of fatigue crack growth rates[Dong,Haynes and Atluri(2015)].Such algorithms have been embedded by the authors in a computer program named SafeFlaw.

It is thus proposed in this study,to combine the high-performance computational fatigue mechanics using SafeFlaw,along with the probabilistic framework of filters,for performing the diagnostics and prognostics of aircraft structures.Fast&accurate deterministic analyses of fatigue crack propagations are carried out,by using the FEAM for computing SIFs and by using the MLS fatigue law for computing crack growth rates.Such algorithms for simulating fatigue crack propagations are called upon as subroutines within the probabilistic framework of filter theories.Both the extended Kalman and particle filters are employed,to obtain statistically optimal estimates of crack lengths,from a series of noisy measurements of cracklengths over time.A simple modification to the particle filter is also proposed for this specific problem,which can drastically reduce the computational burden.By using a simple example of a single-crack near a fastener hole,we demonstrate that near real-time diagnostics of the crack length,and prognostics of the RUL,can be achieved very efficiently,by using the proposed novel method.

This paper is organized as follows.In section 2,the basics of the FEAM for computing SIFs,and the MLS law for fatigue crack growths[da/dn versus K],are brie fl y reviewed.In section 3,the frameworks of the extended Kalman and particlefilters,as well as their applications are discussed in conjunction with the highperformance fatigue mechanics by using SafeFlaw.Section 4 presents a case study to demonstrate the effectiveness of the proposed method with a simple example of single crack near a fastener hole.Section 5 completes this paper with some concluding remarks.

2 High-performance fatigue mechanics by using the FEAM and the MLS fatigue law

As discussed in[Dong and Atluri(2013a,b)],in spite of its wide-spread popularity,the traditional finite element method,including the extended finite element method,with simple polynomial interpolations,is unsuitable for modeling cracks and their propagation.This is due to:(a)the inefficiency of approximating stress&strain-singularities using polynomial FEM shape functions;(b)the complexity of remeshing for crack propagations.On the other hand,although Dual Boundary Elements and Symmetric Galerkin Boundary Elements[Portela,Aliabadi,Rooke(1992);Li,Mear,Xiao(1998);Han and Atluri(2003)]are efficient in computing crack-front stress singularities,their computational burden drastically increases for models with a large number of degrees of freedom.

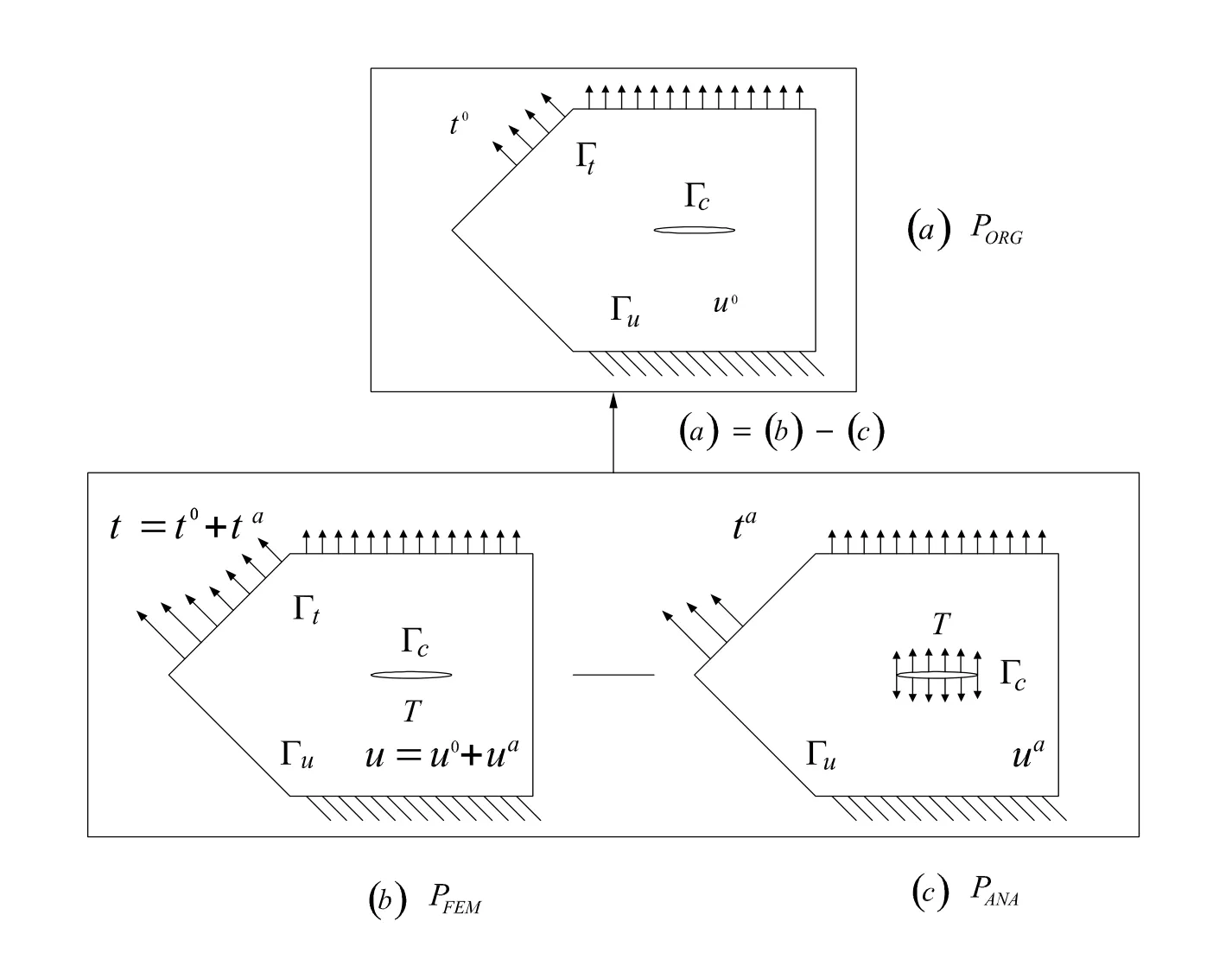

Figure 1:Superposition principle for the finite element alternating method(FEAM)

In a fundamentally different way,the FEAM uses the Schwartz-Neumann alternation between a crude and simple finite element solution for an uncracked structure,and the analytical/BIE solution for an infinite body containing the crack[Nishioka and Atluri(1983);Wang and Atluri(1996);Park and Atluri(1998);Nikishkov,Park and Atluri(2001);Han and Atluri(2002)].The motivation for this series of works,by Atluri and many of his collaborators since the 1980s,is to explore the advantageous features of each computational method:the advantages of FEMs in modeling large-scale&complicated structures,and the advantages of the integral equation based methods for modeling cracks and their propagations.

In this study,the two-dimensional FEAM is used,in which boundary integral equations are used to find the solution of the embedded crack in an infinite domain.Detailed procedures are described as follows.

1.Solve the FEM model with given loads and constraints on the boundary Γ.Denote the solution as,find the tractions at the crack surfaces Γc.

2.Reverse the crack surface tractions obtained in the previous step and apply it as the load.Solve the problem of the embedded crack in an infinite domain using BIE.Denote the solution asfind the tractions on the boundary Γtand the displacements on the boundary.

3.Reverse the tractions and displacement obtained in the previous step,as the load for the FEM model.Find the solutionand resulting crack surface tractions.

4.Repeat step 2 and 3 until the residual load is small enough to be ignored.The solution of the original problem is obtained by superposition of the FEM solution and the BIE solution,as shown in Fig.1.

It has been shown that very accurate solutions of fracture parameters such as SIFs can be obtained,in a very efficient manner,by using the alternating methods,see[Dong and Atluri(2013a,b)].However,the predicted fatigue life can differ in a large amount,if only a crude power-fatigue-law of the Paris type is adapted,such as da/dn=CΔKn.In[Dong,Haynes and Atluri(2015)],an improved Moving Least Squares fatigue law was proposed,to have better predictions of crack growth rates for given SIFs.As shown in Fig.2,very accurate predictions of crack-growth rates are obtained by using the newly developed MLS law,in contrast to the simple construction of the Paris’Law from experimental results.

In the present paper,the “fatigue engine”based on the MLS law,and the “fracture engine”based on the FEAM,are embedded in the computer program SafeFlaw,which is used for deterministic analyses of the total life of cracked structures.In this way,the governing equation for the fatigue crack growth can be written as:

where g[·]represents the MLS fatigue law,and ΔK −a relation is numerically computed by using FEAM,employing the computer program SafeFlaw.

3 Diagnostics and prognostics of fatigue crack growth by using filter theories

We consider the state transition model and the observation model:

where xkis the state vector of the system at the kthtime step,zkis the observation vector,ωkand vkare the process noise and measurement noise respectively.Externally applied control forces are neglected here as they are not applicable for the fatigue crack growth problem of this study.

In this study,only a single mode-1 crack is considered.From Eq.(1),one can obtain that:

which can be considered as the state transition model in analogy to Eq.(2).Thus,akis the state of the system(crack length)in fatigue crack growth,and the process noise is neglected in this study.Similarly,the measurement of the crack size,which is contaminated by noise vk,can be modeled by:

Figure 2:Approximating the da/dn−ΔK relation using Paris’Law as well as the Moving Least Squares(MLS),for the experiments of 7075-T6 aluminum sheets by[Forth,Wright,and Johnson(2005)]

Most filter theories are developed based on the probabilistic framework of Bayesian approaches,which have a prediction step and a correction step.Considering a sequence of observations/measurements z1,z2,...,zk−1,we use p(xk−1|z1:k−1)to denote the conditional probability density function of the state vector xk−1at step k−1,given all the measurements from step 1 to step k−1.Thus,in the prediction step,the prior probability p(xk|z1:k−1)can be determined by the total probability theorem:

where p(xk|z1:k−1)is the predicted conditional probability density function of the state vector xkat step k,given all the measurements from step 1 to step k−1.

In the correction step,when the kthstep measurement is given,the probability density function of the state vector xkcan be updated by taking advantage of the Bayes’rule:

Depending on the different assumptions of the transition and observation models,and the different methods of evaluating Eqs.(6)and(7),a large number of filter theories can be found in the literature.The classical Kalman filter by[Kalman(1960)]may be the most widely used.It assumes that both f(·)and h(·)in Eqs.(2)and(3)are linear functions,and noises ωk,vkare subjected to zero-mean Gaussian distributions.It also assumes that the initial state vector x0is subjected to Gaussian distribution.Under these assumptions,explicit expressions of the prior and posterior probabilities in Eqs.(6)and(7)can be established.However,in spite of the linear elastic structural and fracture mechanics theories considered in this study,the formulation of fatigue mechanics is a nonlinear dynamic equation of the crack length a.As shown in Eq.(1),both the fatigue law and the K−a relation are generally nonlinear functions.For these reasons,in this study,the extended Kalman filter is used,which directly takes advantage of the explicit expressions of the Kalman filter,with linearized state-transition and observation models at each time step.Particles filters,which are more general as compared to the Kalman filter,is also used here.The formulation and the application of these filter theories in the context of diagnostics and prognostics of aircraft structures are discussed in the next two subsections.

3.1 The extended Kalman filter

The extended Kalman filter (EKF) relaxes the assumption of the linearity of models,as in the classical Kalman filter.Both f(·)and h(·)in Eqs.(2)and(3)respectively may be nonlinear and differentiable functions.ωk,vkshould be zero-mean Gaussian noises with covariance matrices Qk,Rkrespectively.Similar to the Kalman if lter,EKF assumes that the state functions are subjected to Gaussian distributions centered atxˆkand with covariance Pk.In the prediction step,it linearizes the transition model atxˆk−1|k−1,giving the Jacobian matrix Fk−1:

The predicted state estimate and the covariance are given by:

In the correction step,the observation model is linearized atˆxk|k−1,giving the Jacobian matrix Hk:

Then the state estimate and covariance can be updated with the following 5 steps.

1.Compute the measurement residual

2.Compute the residual covariance

3.Compute the near-optimal Kalman gain

4.Update the state estimate

5.Update the covariance estimate

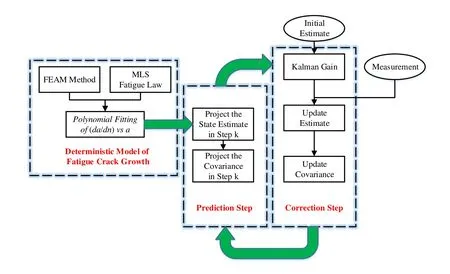

Figure 3:Flowchart of the extended Kalman filter for diagnostics of crack length

The assumption of Gaussian distributions makes the extended Kalman filter highly efficient in computation.However,an explicit formula for the transition model is needed to compute Jacobian matrices.In this study,we firstly compute many discrete da/dn−a data pairs by using SafeFlaw,and then fit a 5th-order polynomial,i.e.da/dn=The Jacobian matrix Fk−1of the transition model is thereafter computed using the fitted polynomial model.A detailed flowchart of the extended Kalman filter for diagnostics of fatigue crack growth is given in Fig.3.With the estimated crack length and covariance at the kthstep,the remaining useful life of the cracked structure can be easily determined by using SafeFlaw,with a given fracture toughness.The probabilistic distribution of the RUL,if of any interest,can also be determined,by various stochastic analysis methods such as Monte Carlo simulations.

The disadvantages of the extended Kalman filter are also obvious.Firstly,fitting an explicit formula of the fatigue crack growth is troublesome,which may be impractical for problems of multiple cracks.Moreover,unlike its linear counterpart,the extended Kalman filter in general is not an optimal estimator.If the initial estimate of the state is wrong,or if the process is modeled incorrectly,the filter may quickly diverge,owing to its linearization.For this reason,we also study particle filters for diagnostics and prognostics of cracked structures in this paper.As will be seen in section 5,the accuracy of particle filters is better than that of the extended Kalmanfilter.

3.2 The particle filter

Figure 4:Flowchart of the particle filter for diagnostics of crack length

Similar to the extended Kalman Filter,the particle filters also follow the two steps of prediction and correction(update),see[Zio and Peloni(2011)].However,no assumptions are placed on the distributions of the state vector.Instead,the posterior distribution pof the state vector at step k−1 is approximated by a set of samples(particles)i=1,2,...,N.The kthprediction step is accomplished by projecting the sample to a new set of particles,i=1,2,...,N,by using the state transition model Eq.(2).Then,the prior probability density of the state vector at step k can be approximated by:

And the correction step can thus be implemented by substituting Eq.(18)into Eq.(7).

As discussed in[Zio and Peloni(2011)],caution is necessary in the implementation of the particle filter,as degeneracy problems may be caused by the skewed distributions of weights.This can be avoided by a sequential resampling strategy,so that a new set of particles is generated which can represent the posterior distribution of the state vector,when the variance of the weights is larger than a certain value.Detailed discussions of sequential resampling methods can be found in[Doucet,de Freitas,Gordon(2001)].

In this study,the particle filter is applied to the problem of fatigue crack growth,by considering the state transition model Eq.(4)and the observation model Eq.(5).Unlike the extended Kalman filter,no curve fitting is necessary to have an explicit expression of the state transition model.Instead,the SafeFlaw computer code serves as a black box in the prediction step,which takes the particles(crack lengths)from the previous step as inputs,and gives a new set of particles in the next step,which can represent the prior probability distribution of crack lengths.A schematic plot of the algorithms is given in Fig.4.Similar to the extended Kalman filter,prognostics of the remaining life can be achieved based on the result of diagnostics,by using the computer code SafeFlaw.

3.3 A modified particle filter for fatigue mechanics

The major disadvantage of the particle filter lies in its high burden of computation.A large number of particles is needed to have a good approximation of the distribution of the state vector.For this specific problem,it is found that at least 1000 particles are needed,which means that the computer code SafeFlaw is being called upon a 1000 times for each step of prediction.Even for the highly-efficient Safe-Flaw,the consumed time for repeated computations cannot be neglected,and this hinders its real time application for diagnostics and prognostics of complex aircraft structures.

However,for this specific problem,it is found that the computational burden can be drastically reduced,by a simple modification of the prediction step of the particlefilter.This is based on the observation that,the state transition model of Eq.(4)is a monotonic projection fromThis means that ifthen we havefor a given load history.Therefore,the following property of the cumulative distribution function holds:

Figure 5:Flowchart of the modified prediction step of the particle filter

In contrast,p(ak|z1:k−1)=p(ak−1|z1:k−1)generally does not hold for the probability density function.Thus,instead of using a large number of particles to compute p(ak|z1:k−1),one can use only a small number of discrete points to project FAk−1|Z1:k−1(ak−1)to FAk|Z1:k−1(ak),and then compute p(ak−1|z1:k−1)by differentiation.

We thus propose the following procedures of the prediction step,while the correction step should remain the same as discussed in section 3.2.

1.By using the posterior probability density function)at the end of step k− 1,calculate the cumulative distribution function

3.Call SafeFlaw to projec?t th?e selected N points to the kthstep,we haveand,i=1,2,...,N.

4.Use the monotone Hermite cubic interpolation to perform the curve fitting of the predicted CDF

5.Compute the prior probability density functionby differentiating

6.Resample a set of particles based onfor the purpose of computing the posterior probability

It should be noted that,the monotone Hermite cubic interpolation[Fritsch and Carlson(1980)]is used here to preserve the monotone property of the CDF,and to avoid having negative values of p(ak|z1:k−1).A schematic plot of the proposed modified prediction step of the particle filter is given in Fig.5.

4 A simple case of a single crack near a fastener hole

4.1 Experimental set-up and a deterministic analysis

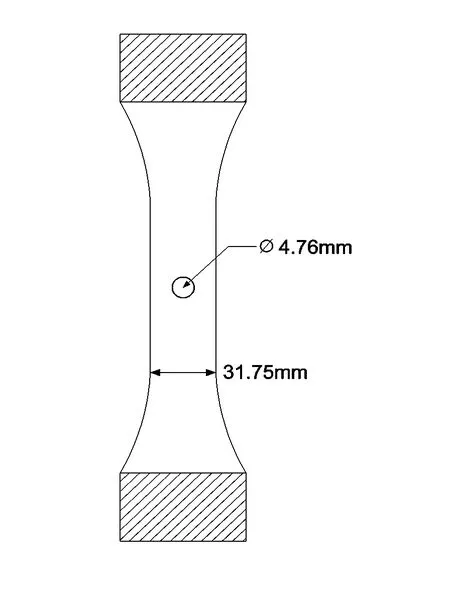

A Fatigue test for an aluminum 7075-T6 dogbone coupon was conducted in US Army Research Laboratory.The coupon is 1.60 mm in thickness.The gripped ends taper to a gage section(31.75 mm wide)with a centrally located 4.76 mm diameter hole.As shown in Fig.6,a small 1.3069 mm crack is created at the right side of the hole(including the notch and the pre-crack).

Figure 6:An aluminum 7075-T6 dogbone coupon with a single mode-1 crack at the right side of the hole

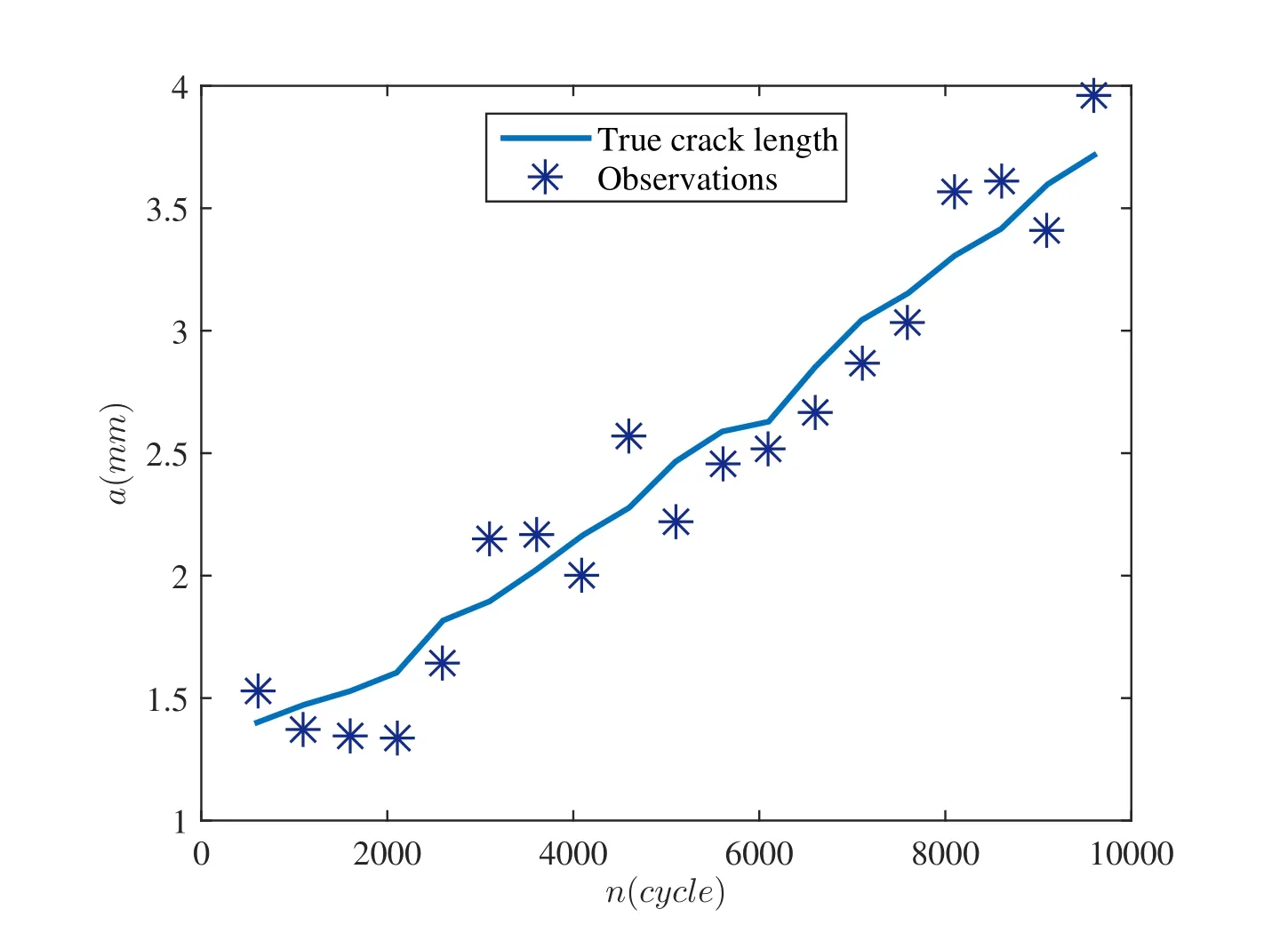

The dogbone coupon is subjected to a constant amplitude sinusoidal tensile load at the gripped ends at a frequency of 10 Hz,by using an MTS servo hydraulic testing machine.The maximum applied load is 5.00 kN with a stress ratio R=0.1.The cycling is paused every 100 cycles with the coupon held at maximum load to take a high-resolution photograph of the cracked area.A quite reliable measurement of the crack lengths is thus obtained by counting the pixels of the high-resolution photograph.In this study,these measurements are considered as“true crack lengths”as the measurement noises are relatively small.

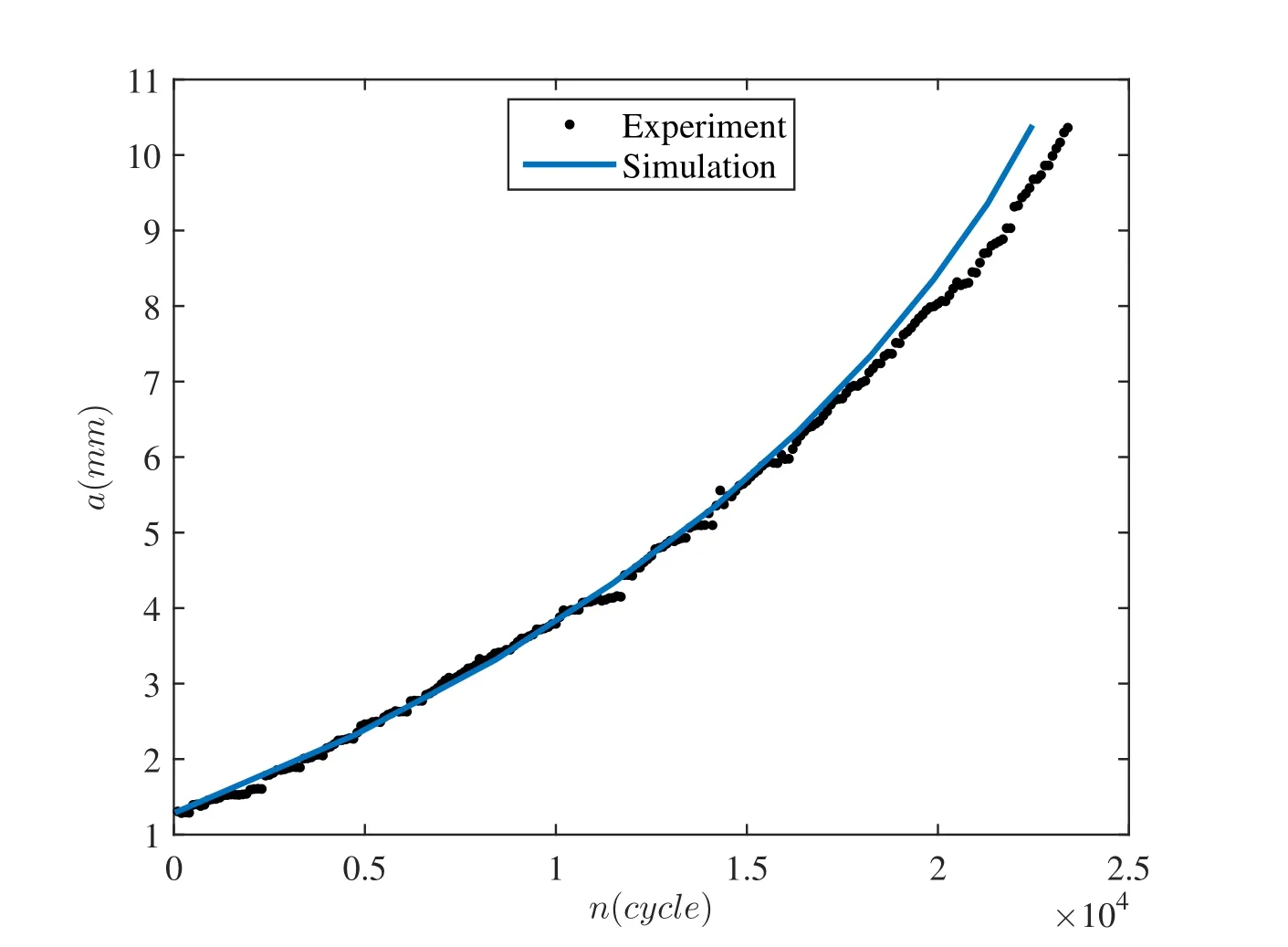

We firstly apply the FEAM with the MLS fatigue law to simulate the crack growth.The FEAM model consists of 218 finite elements for the uncracked structure and 20 boundary elements for the crack embedded in an infinite domain.The MLS fatigue law for Al 7075-T6 thin plate is formulated based on the fatigue test data of[Forth,Wright,and Johnson(2005)].The simulation is completed within 1.5 seconds on a standard PC equipped with i7 CPU.As shown in Fig.7,excellent agreements can be found between the ARL experimental results and the simulation by SafeFlaw.

Figure 7:Deterministic analysis of the fatigue crack growth by SafeFlaw

4.2 Diagnostics and Prognostics based on the simulated noisy measurements

In order to test the effectiveness of various filters for diagnostics and prognostics of the cracked specimen,we create a sequence of 20 artificial measurements by adding white noises to true crack lengths.The simulated noisy measurements of crack lengths are demonstrated in Fig.8.

The extended Kalman filters,the particle filter,and the modified particle filter are thereafter applied to give probabilistic optimal and semi-optimal estimates of the crack lengths.For each of the filters,the initial guess of the crack-length is centered at the first noisy measurement,with a very wide distribution.As shown in Figs.8-10,although the initial estimate departs from the true crack length,the error caused by measurement noises can be quickly removed by using any of the three filters.The extended Kalman filter is the most efficient among the three.However,as discussed in section 3.1,it requires a curving fitting to obtain the explicit expression of da/dn−a relation.Such a curve fitting is undesirable as its generalization to problems of multiple cracks is impractical.

Figure 8:Simulated noisy measurements of crack lengths

Figure 9:Diagnostics of crack lengths by the extended Kalman filter

Figure 10:Diagnostics of crack lengths by the particle filter

Figure 11:Diagnostics of crack lengths by the modified particle filter

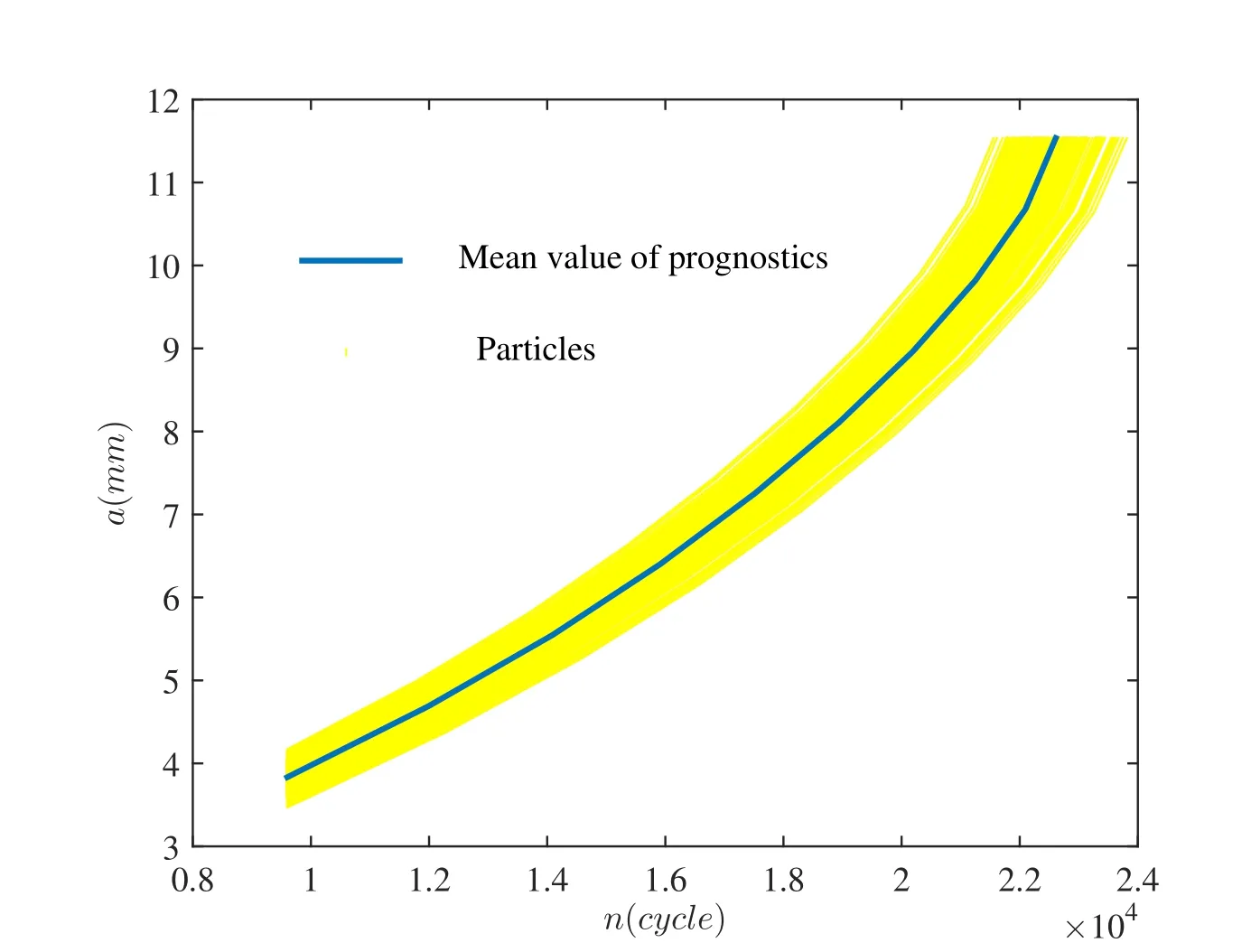

Figure 12:Prognostics of the remaining life by the extended Kalman filter

Figure 13:Prognostics of the remaining life by the particle filter

Figure 14:Prognostics of the remaining life by the modified particle filter

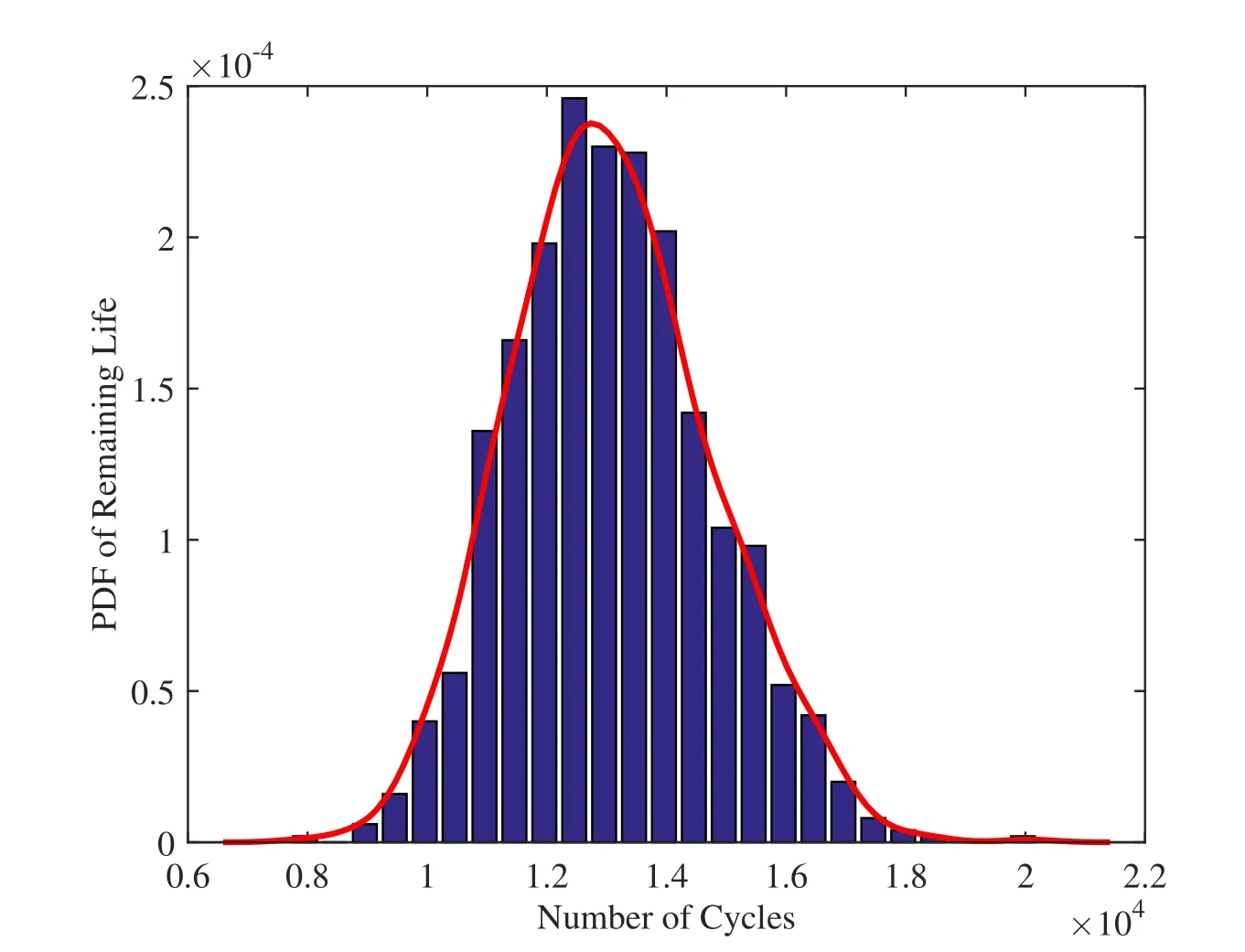

Figure 15:Distribution of the remaining life by the extended Kalman filter

Figure 16:Distribution of the remaining life by the particle filter

Figure 17:Distribution of the remaining life by the modified particle filter

Although the particle filter does not require such a curve fitting,it is however computationally very expensive.In this study,1000 particles are used.It costs around 10 minutes for each step of diagnostics.In order to reduce the computational cost,the modified prediction step use 6 uniformly distributed points(in percentiles)to compute the prior cumulative distribution function,following the procedure of Fig.5.It is found that the computational time is drastically reduced to 15 seconds for each step of diagnostics.

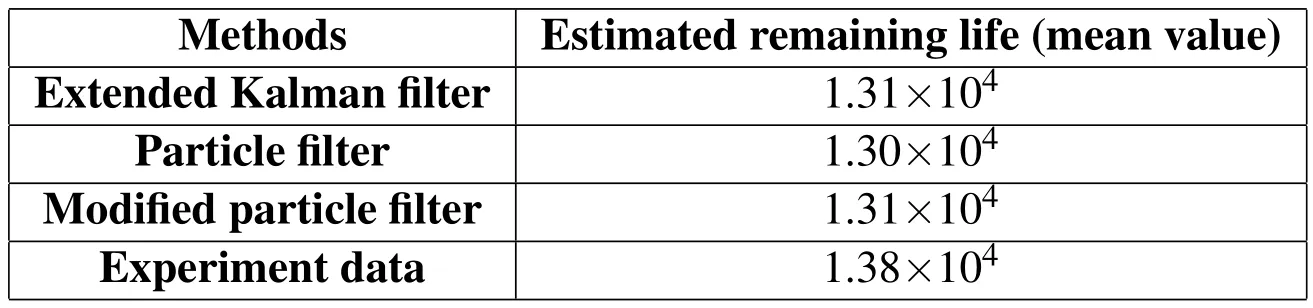

The extended Kalman and particle filters are also used for the prognostics of the remaining life.The diagnostics results obtained at n=9600 are used to estimate the remaining fatigue life of the specimen.It is assumed that the specimen fails at the fracture toughness Kc=27MpaFigs.12-14 give the trajectories of particles for various samples of crack growth paths.Figs.15-17 give the predicted probabilistic distributions of the fatigue lives,whose mean values are given in Tab.1.It can be clearly seen that,even though the estimated remaining lives are very close for the 3 methods,the extended Kalman filter is associated with a large uncertainty.This is due to the fact that the extended Kalman filter is not an optimal estimator for nonlinear systems.

Table 1:Prognostics of the remaining life by various methods

5 Conclusion

In this paper,an approach for the diagnostics and prognostics of aircraft structures is proposed,by combining high-performance fatigue mechanics along with filtering theories.Fast&accurate deterministic analyses of fatigue crack propagations are carried out by the computer program SafeFlaw,which is called upon as asubroutine within the probabilistic framework of filter theories.Both the extended Kalman and particle filters are applied in this study,to give statistical optimal and semi-optimal estimates of crack lengths,with a series of noisy measurements of crack-lengths over time.A simple modification to the particle filter is also proposed for this specific problem,to reduce the computational burden.Based on results of such diagnostic analyses,the mean value and probabilistic distribution of the remaining useful life can be thereafter computed.

By using a simple example of a single-crack near a fastener hole,we demonstrate the advantages and disadvantages of the various filters.It is concluded that the extended Kalman filter is not suitable for such an application,because:(1)it requires a curve fitting to obtain the explicit expression of da/dn−n relation;(2)it gives only semi-optimal estimates accompanied by a large uncertainty.The particle filter,on the other hand,has a better performance and does not require any curve fitting.Although it is computationally more expensive,the cost can be drastically reduced by the proposed modification of the prediction step.

Applications of the proposed methods of prognostics and diagnostics,with online measurements by NDE devices of complex aircraft structures,will be studied in our future works.The extension of the current approach to problems of multiple cracks,will also be pursued by the authors.

Acknowledgement: This work was supported by Vehicle Technology Division of the Army Research Labs.The support and encouragement of Dy Le and Jaret Riddick are thankfully acknowledged.

Baraldi,P.;Mangili,F.;Zio,E.(2012):A kalman filter-based ensemble approach with application to turbine creep prognostics.Reliability,IEEE Transactions on,vol.61,no.4,pp.966-977.

Baraldi,P.;Cadini,F.;Mangili,F;Zio,E.(2013):Model-based and data-driven prognostics under different available information.Probabilistic Engineering Mechanics,vol.32,pp.66-79.

Dong,L.;Atluri,S.N.(2013a):Fracture&fatigue analyses:SGBEM-FEM or XFEM?Part 1:2D structures.CMES:Computer Modeling in Engineering&Sciences,vol.90,no.2,pp.91-146.

Dong,L.;Atluri,S.N.(2013b):Fracture&fatigue analyses:SGBEM-FEM or XFEM?Part 2:3D solids.CMES:Computer Modeling in Engineering&Sciences,vol.90,no.5,pp.379-413.

Dong,L.;Haynes,R.;Atluri,S.N.(2015):On Improving the Celebrated Paris’Power Law for Fatigue,by Using Moving Least Squares.CMC:Computers,Materials&Continua,vol.45,no.1,pp.1-15.

Doucet,A.;De Freitas,N.;Gordon,N.(2001):An introduction to sequential Monte Carlo methods.Springer New York.

Forth,S.C.;Wright,C.W.;Johnston Jr,W.M.(2005):7075-T6 and 2024-T351 aluminum alloy fatigue crack growth rate data,NASA/TM-2005-213907.

Fritsch,F.N.;Carlson,R.E.(1980):Monotone Piecewise Cubic Interpolation.SIAM Journal on Numerical Analysis,vol.17,issue 2,pp.238–246.

Han,Z.D..;Atluri,S.N.(2002):SGBEM(for Cracked Local Subdomain)–FEM(for uncracked global Structure)Alternating Method for Analyzing 3D SurfaceCracks and Their Fatigue-Growth. CMES: Computer Modeling in Engineering&Sciences,vol.3,no.6,pp.699-716.

Han,Z.D.;Atluri,S.N.(2003):On Simple Formulations of Weakly-Singular Traction&Displacement BIE,and Their Solutions through Petrov-Galerkin Approaches.CMES:Computer Modeling in Engineering&Sciences,vol.4,no.1,pp.5-20.

Kalman,R.E.(1960):A new approach to linear filtering and prediction problems.Journal of Fluids Engineering,vol.82,issue 1,pp.35-45.

Li,S.;Mear,M.E.;Xiao,L.(1998):Symmetric weak-form integral equation method for three-dimensional fracture analysis.Computer Methods in Applied Mechanics and Engineering,vol,151,issue 3,pp.435-459.

Nishioka,T.;Atluri,S.N.(1982):Analytical solution for embedded elliptical cracks and finite element alternating method for elliptical surface cracks,subjected to arbitrary loadings.Engineering Fracture Mechanics,vol.17,pp.247-268.

Nikishkov,G.P..;Park,J.H.;Atluri,S.N.(2001):SGBEM-FEM alternating method for analyzing 3D non-planar cracks and their growth in structural components.CMES:Computer Modeling in Engineering&Sciences,vol.2,no.3,pp.401-422.

Park,J.H.;Atluri,S.N.(1998):Mixed mode fatigue growth of curved cracks emanating from fastener holes in aircraft lap joints.Computational Mechanics,vol.21,issue 6,pp.1333-1336.

Portela,A.;Aliabadi,M.H.;Rooke,D.P.(1992):The dual boundary element method:effective implementation for crack problems.International Journal for Numerical Methods in Engineering,vol.33,issue 6,pp.1269-1287.

Saha,B.,Goebel,K.;Christophersen,J.(2009):Comparison of prognostic algorithms for estimating remaining useful life of batteries.Transactions of the Institute of Measurement and Control,vol.31,no.3-4,pp.293-308.

Si,X.-S.;Wang,W.;Hu,C.-H.;Zhou,D.-H.(2011):Remaining useful life estimation–A review on the statistical data driven approaches.European Journal of Operational Research,vol.213,no.1,pp.1-14.

Wang,L.;Atluri,S.N.(1996):Recent advances in the alternating method for elastic and inelastic fracture analyses.Computer methods in applied mechanics and engineering,vol.137,issue 1,pp.1-58.

Zio,E.;Peloni,G.(2011):Particle filtering prognostic estimation of the remaining useful life of nonlinear components.Reliability Engineering&System Safety,vol.96,no.3,pp.403-409.

1School of Mechanical,Electronic,and Industrial Engineering,University of Electronic Science and Technology of China

2Center for Aerospace Research&Education,University of California,Irvine

3Vehicle Technology Directorate,US Army Research Laboratory

4Corresponding Author,Email:dong.leiting@gmail.com.Department of Hohai University,China

Computer Modeling In Engineering&Sciences2015年7期

Computer Modeling In Engineering&Sciences2015年7期

- Computer Modeling In Engineering&Sciences的其它文章

- A 3-D Visco-Hyperelastic Constitutive Model for Rubber with Damage for Finite Element Simulation

- Optimal Adaptive Genetic Algorithm Based Hybrid Signcryption Algorithm for Information Security

- Analysis and Numerical Simulation of Hydrofracture Crack Propagation in Coal-Rock Bed