Evaluation of the effect of sodium silicate addition to mine backfill, Gelfill-Part 2:Effects of mixing time and curing temperature

M.Kermni,F.P.Hssni,*,E.Aflki,M.Benzzou,M.Nokken

aMining Engineering Department,McGill University,Montreal,Quebec,Canada

bAmirkabir University of Technology,Tehran,Iran

cUniversité du Québec en Abitibi Témiscamingue,Quebec,Canada

dDepartment of Building,Civil&Environmental Engineering,Concordia University,Montreal,Quebec,Canada

Evaluation of the effect of sodium silicate addition to mine backfill, Gelfill-Part 2:Effects of mixing time and curing temperature

M.Kermania,F.P.Hassania,*,E.Aflakib,M.Benzaazouac,M.Nokkend

aMining Engineering Department,McGill University,Montreal,Quebec,Canada

bAmirkabir University of Technology,Tehran,Iran

cUniversité du Québec en Abitibi Témiscamingue,Quebec,Canada

dDepartment of Building,Civil&Environmental Engineering,Concordia University,Montreal,Quebec,Canada

A R T I C L E I N F O

Article history:

in revised form

28 September 2015

Accepted 29 September 2015

Available online xxx

Gelfill

Cemented hydraulic fill(CHF)

Sodium silicate

Mercury intrusion porosimetry(MIP)

Drainage

A B S T R A C T

The effects of mixing time and curing temperature on the uniaxial compressive strength(UCS)and microstructure of cemented hydraulic fill(CHF)and sodium silicate-fortified backfill(Gelfill)were investigated in the laboratory.A series of CHF and Gelfill samples was mixed for time periods ranging from 5 min to 60 min and cured at temperatures ranging from 5°C to 50°C for 7 d,14 d or 28 d. Increasing the mixing time negatively influenced the UCS of Gelfill samples,but did not have a detectable effect on CHF samples.The curing temperature had a strong positive impact on the UCSs of both Gelfill and CHF.An elevated temperature caused rapid UCS development over the first 14 d of curing.Mercury intrusion porosimetry(MIP)indicated that the pore size distribution and total porosity of Gelfill were altered by curing temperature.

©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by

Elsevier B.V.All rights reserved.

1.Introduction

Mine backfill consists of tailings,binder and water.Gelfill is a new mine backfill material,in which the binder component includes an alkali activator,i.e.sodium silicate.Although sodium silicate has been used in concrete manufacturing,its use in mine backfill is relatively new.Until very recently,there have been only a few publications regarding Gelfill(Kermani and Hassani,2012;Kermani et al.,2014).This paper presents the second part of a comprehensive study of Gelfill.The first paper(Kermani et al., 2015),published in this journal,investigated the effects of sodium silicate concentration and binder dosage on the mechanical and microstructural properties of Gelfill and cemented hydraulic fill(CHF).It showed that Gelfill samples had higher mechanical strength than CHF samples.However,elevated sodium silicate concentrations(0.5 wt%,wt%is the percentage by total dry weight)detrimentally affected the mechanical strength of Gelfill.Pore structures and pore size distributions differed between Gelfill and CHF samples,which could have contributed to the enhanced mechanical properties of Gelfill.Finally,the addition of sodium silicate to CHF reduced the volume of water released from fill materials during curing.This paper expands upon the previous findings by investigating the effects of mixing time and curing temperature on the uniaxial compressive strength(UCS)and microstructure of Gelfill and CHF.

Mixing time and curing temperature are critical to mine backfill placing.Backfill materials must be mixed to produce a homogeneous cemented fill.Insufficient mixing leads to inconsistent distribution of cement and water,and reduces backfill strength. However,mixing consumes large amounts of energy and extended mixing is costly.Furthermore,overmixing inhibits gel formation during the hydration of cementitious materials.Therefore,it is essential to determine an optimal mixing time to reduce energy requirementsand ensurebackfill homogeneity.Curing temperature plays a key role in determining the mechanical characteristics of cemented materials.However,investigations on the influence of curing temperature on cemented backfill are very limited.Fall et al.(2010)conducted the uniaxial compression tests on paste backfill specimens cured at 0°C,20°C,35°C and 50°C.The strength development rate decreases with curing temperature due to the increasing hydration rate of the binders.Therefore,samples cured at lower temperatures had lower UCS.Moreover,the mode of strength development differed among binder types(Fall et al., 2010).

The objective of this research was to investigate the effects of various mixing times and curing temperatures on the mechanical strength of CHF and Gelfill.

2.Materials

2.1.Tailings

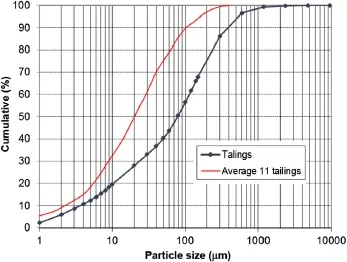

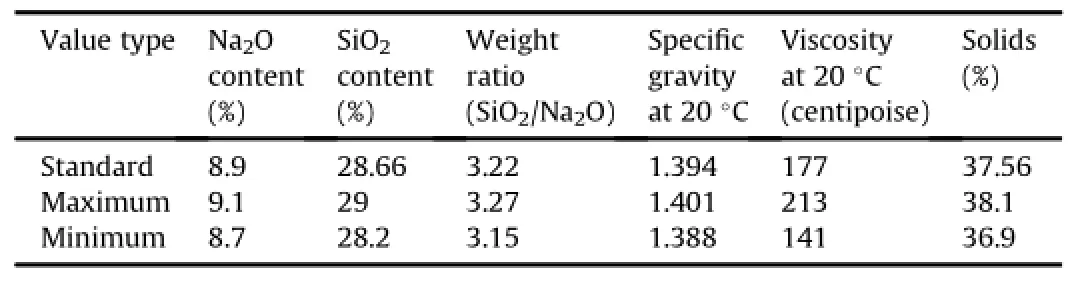

Tailings are waste products from ore processing plants,and primarily consist of fine ground host rock.When used as a component of mine backfill,the physicochemical properties of tailings significantly affect the mechanical performance of the backfill(Benzaazoua et al.,2004;Kesimal et al.,2004).In this research,the classified tailings from one of Vale's mines in Sudbury, Ontario,Canada,generally consist of quartz,albite and small quantities of calcite,muscovite,pyrrhotite,chalcopyrite,anorthite, and chlorite.The particle size distribution determined using laser diffraction(ASTM,1996)indicates that the Vale mine tailings are coarser than the average particle size of 11 mine tailings samples from the provinces of Quebec and Ontario(Ouellet et al.,2008)(Fig.1,Table 1).

2.2.Binder

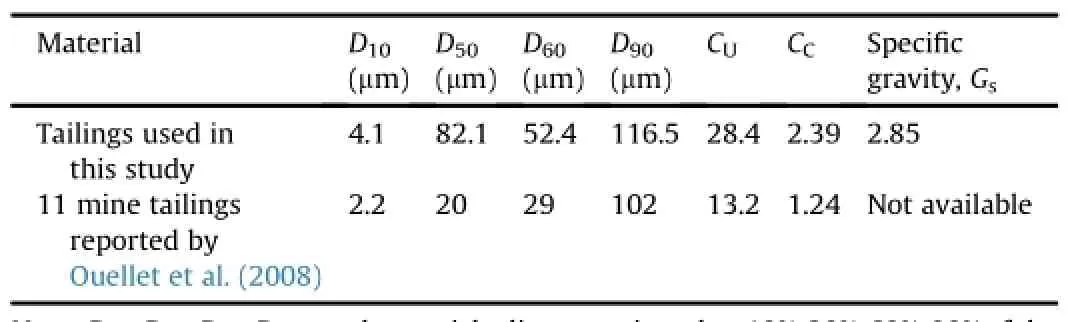

Binders are mainly used to increase the mechanical stability of fill materials.They are the most expensive component of mine backfill,representing up to 75%of backfill costs(Hassani and Archibald,1998).Normal Portland cement(NPC),fly ash and blast furnace slag(BFS)are commonly used for mine backfill.In this research,a combination of 10%type 10 NPC and 90%BFS,both provided byLafarge Canadawas used since its binder formulation is generally used in Vale mines in Ontario.The densities of the NPC and BFS were 3.07 g/cm3and 2.89 g/cm3,respectively.The Blaine specific surface areas of the NPC and BFS were 3710 cm2/g and 5998 cm2/g,respectively.The chemical compositions of the NPC and BFS are shown in Table 2.

For this application,BFS has generally been associated with three main limitations:(i)low hydration rate,(ii)low early strength,and(iii)relatively slow strength development.In order to overcome these limitations,BFS must be activated.Many studies have shown that BFS can be successfully activated by alkali activators such as sodium silicate(Anderson and Gram,1998;Bakhareva et al.,1999).

Fig.1.Particle size distributions of the Vale mine tailings and 11 mine tailings samples from Ontario and Quebec.

Table 1 Physical properties of the tailings.

Table 2 Chemical compositions of the NPC and BFS provided by Lafarge Canada.

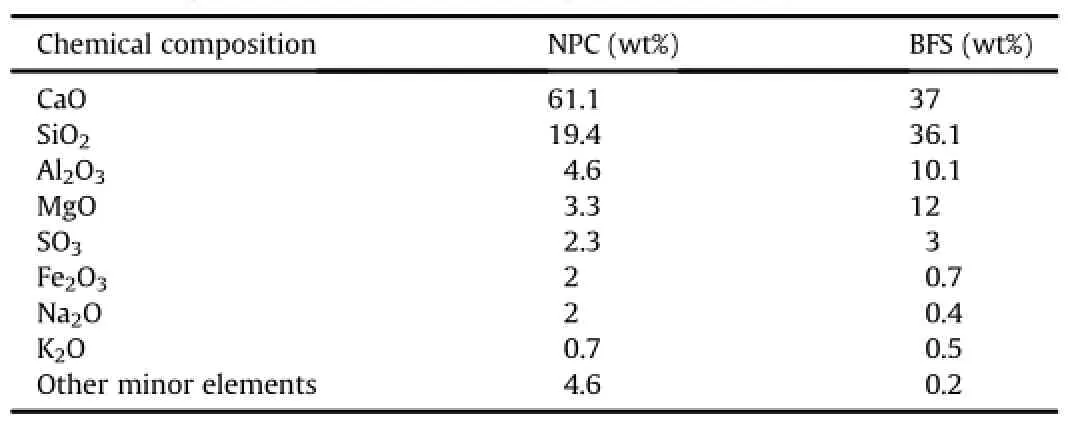

2.3.Sodium silicate

In addition to acting as an alkali activator of BFS and fly ash, sodium silicate has been used in glues,cements,paints,and detergents,and as a hardening agent for natural and artificial stones(Shi et al.,2006).It is manufactured from Na2CO3and SiO2by smelting silica with sodium carbonate at approximately 1100-1200°C.The general formula for sodium silicate is Na2O·nSiO2, with n ranging from 1.6 to 3.85 for most commercially available sodium silicate materials.Sodium silicate is the most effective alkali activator for most pozzolans,including BFS and fly ash(Anderson and Gram,1998;Bakhareva et al.,1999;Brough and Atkinson, 2002;Hilbig and Buchwald,2006;Chen and Brouwers,2007). Type N®sodium silicate,provided by the PQ National Silicate Company,was chosen because it is the most efficient activator for ground BFS(Table 3).

Table 3 The properties of sodium silicate(PQ National Silicate Company).

2.4.Sample preparation and curing

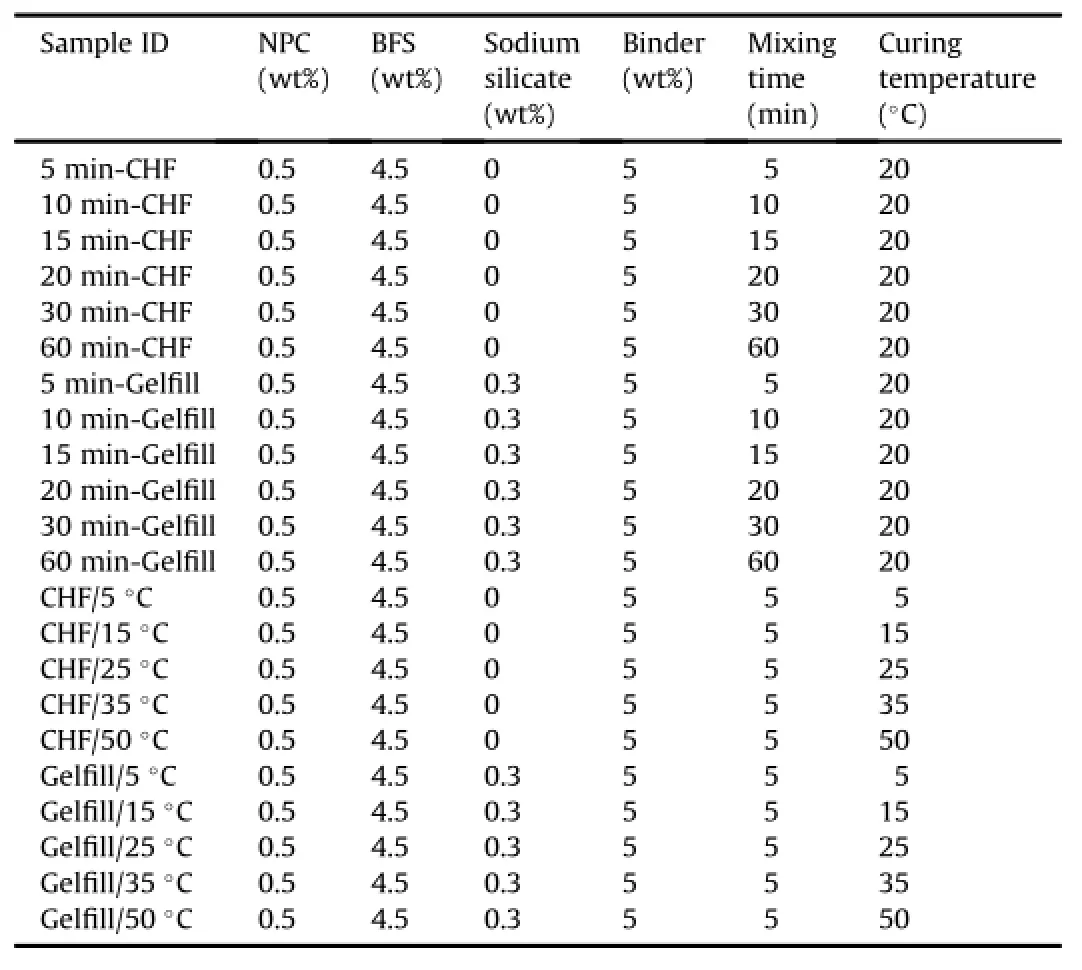

To investigate the effect of mixing time and curing temperature on CHF and Gelfill,198 CHF and Gelfill samples were prepared(Table 4).In both types of fill,the pulp density was kept constant at 70%,as is practiced in Vale mines in Sudbury.Also,the binder consisted of 5 wt%tailings.The binder for the Gelfill samples was a combination of NPC,BFS,and 0.3 wt%sodium silicate.CHF and Gelfill were mixed according to ASTM C305-14(ASTM,2014)in small batches in a 5-L stainless steel bowl for six mixing times(5 min,10 min,15 min,20 min,30 min and 60 min)using a mixerwith a stainless steel wire whip blade(Table 4).Mixtures were cast in cylindrical,polyvinyl molds 10 cm deep and 5 cm in diameter. The bottoms of the molds were perforated by 25 uniformly distributed holes to simulate drainage that occurs in the mines;a geotextile filter prevented the loss of fine particles.Specimens were cured in a curing chamber at constant(90±2)%relative humidity. In order to investigate the effect of curing temperature on CHF and Gelfill,samples were prepared according to the above-mentioned mixing design and cured at curing temperatures ranging from 5°C to 50°C(Table 4).

气瓶充装站中涉及的控制参数和预警信息主要包括场所液位、温度、压力、浓度、现场视频及事故预警信息等。根据《危险化学品重大危险源监督管理暂行规定》(国家安全生产监督管理总局令第40号)和《国家安全监管总局关于印发遏制危险化学品和烟花爆竹重特大事故工作意见的通知》(安监总管三〔2016〕62号)等文件要求,应对重点监管的危险化学品及重大危险源配备重点控制参数(温度、压力、液位、流量、组分等信息)不间断采集和监测系统,配备可燃气体和有毒气体泄漏检测报警装置以及火灾自动检测及报警系统,并具备信息远传、连续记录、事故预警、信息存储等功能。

Table 4 Binder mixtures characteristics of backfill samples.

3.Experimental setup

3.1.Uniaxial compression tests

The UCS of triplicate samples was measured after 7 d,14 d,and 28 d of curing with a“Wykeham Farrance 100 kN”pressure machine equipped with a 50 kN load cell(ASTM,2006).A linear variable displacement transducer sensor was used to measure the vertical deformation rate(strain).A data acquisition board and computerrecordedanddisplayedthedata.Sampleswere removed from the humidity room just prior to the uniaxial compression test.

3.2.Mercury intrusion porosimetry

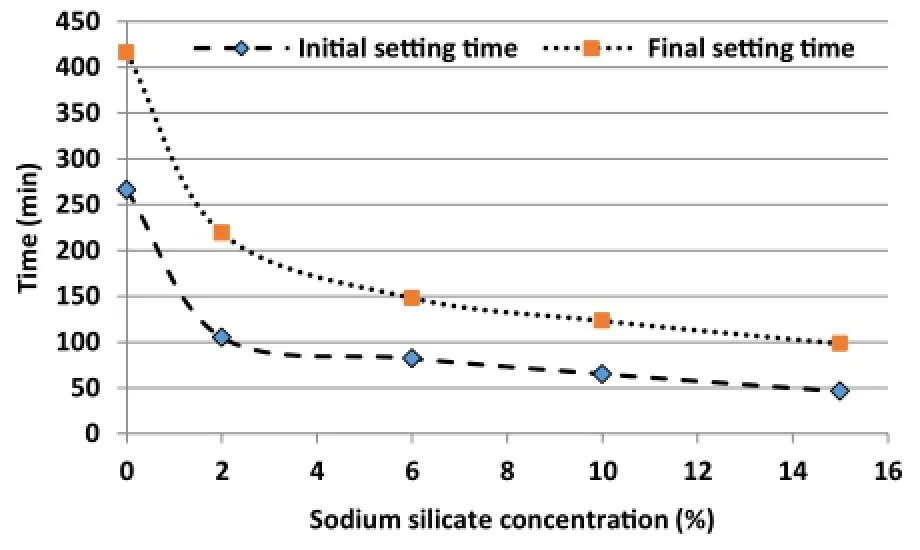

Mercury intrusion porosimetry(MIP)is a common technique to investigate the microstructure(pore size distribution and pore structure)of cemented materials(Aligizaki,2006;Ouellet et al., 2007).Evaluating microstructure is the key to understanding the mechanical properties and durability of cemented mine backfill(Belem et al.,2001).The MIP technique is based on the theoretical foundation of Washburn(1921),which states that a nonwetting liquid will only penetrate into pores under pressure,and that this penetration directly depends on the amount of applied pressure. Washburn developed a relationship between applied pressure and pore size as follows:

where r is the radius of the pore,γis the surface tension of the liquid(approximately 0.48 N/m for mercury),φis the wetting angle or contact angle between the liquid and solid material(approximately 140°for mercury),and P is the absolute applied pressure.

Six CHF and six Gelfill samples cured for 28 d and used for uniaxial compression test were subsequently subjected to MIP using a 9320-PoreSizer porosimeter(Micromeritics).Small particles(5-7 mm)were carefully removed from the center of samples,and then dried in a vacuum desiccator prior to porosimetry.

4.Results and discussion

4.1.Effect of mixing time on the Gelfill and CHF strengths

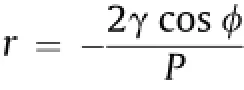

With increasing mixing time,the UCS of Gelfill samples decreased,whereas the UCS of CHF samples did not change(Fig.2).The UCS of Gelfill was almost 30%greater than that of CHF for the samples mixed for 5 min.However,the difference between Gelfill and CHF UCSs decreased with increasing mixing time.

Fig.2.Effects of mixing time on the UCSs of(a)Gelfill and(b)CHF samples after three curing periods.

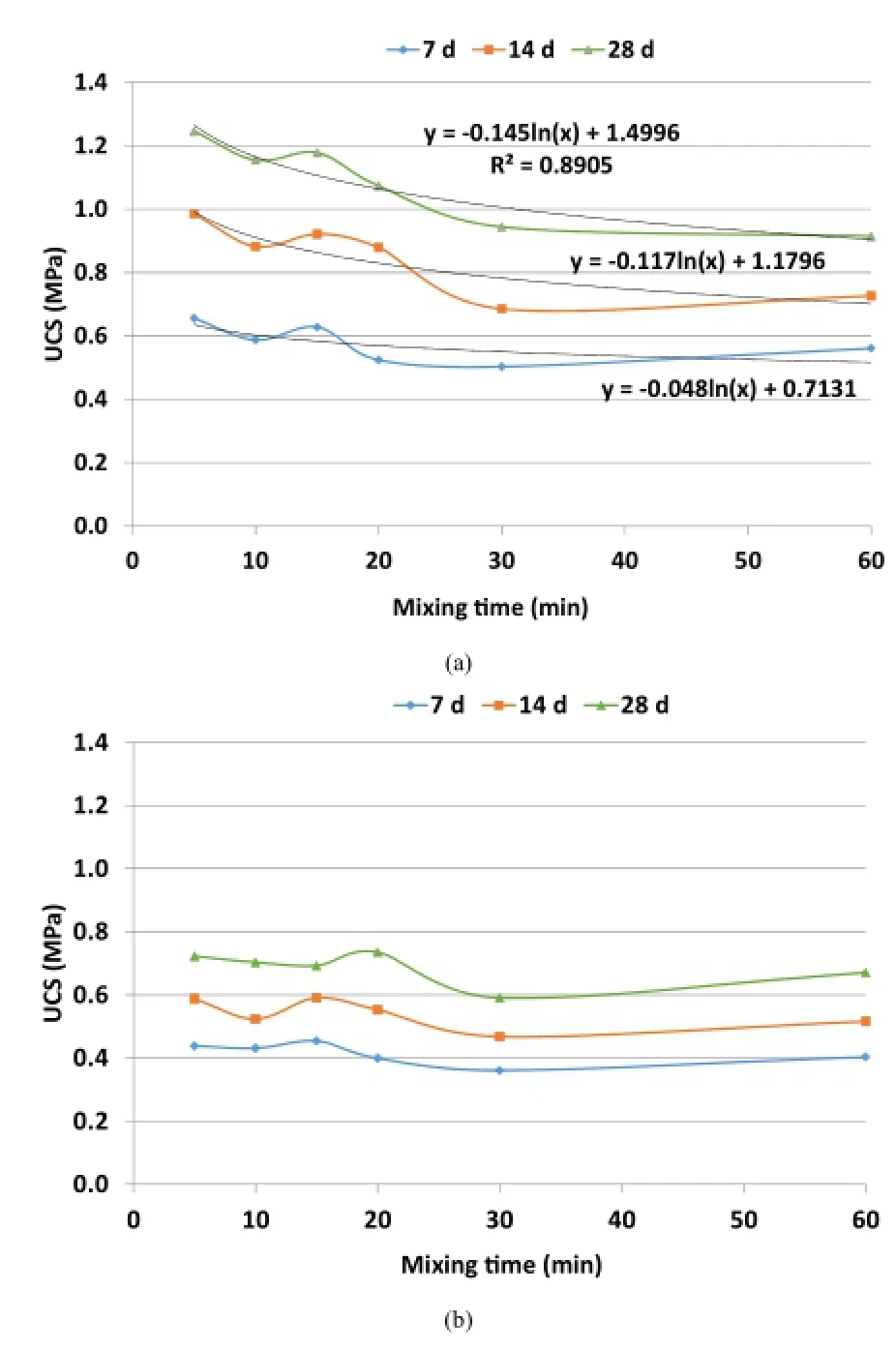

In order to explain the effect of mixing time,the initial and final setting times of the binder paste were determined by using a Vicat apparatus according to ASTM C191-13(ASTM,2013).The volume of distilled water required to reach the normal consistency of CHF was added to the binder.Consequently,five sodium silicateconcentrations(0 wt%,2 wt%,6 wt%,10 wt%and 15 wt%)were added to the Gelfill.The initial and final setting times of the NPC/ BFS paste decreased dramatically by the addition of sodium silicate(Fig.3),in agreement with the findings of Chang(2002).

Fig.3.Effects of sodium silicate concentration on the initial and final setting times of binder made with NPC and BFS at a ratio of 10:90.

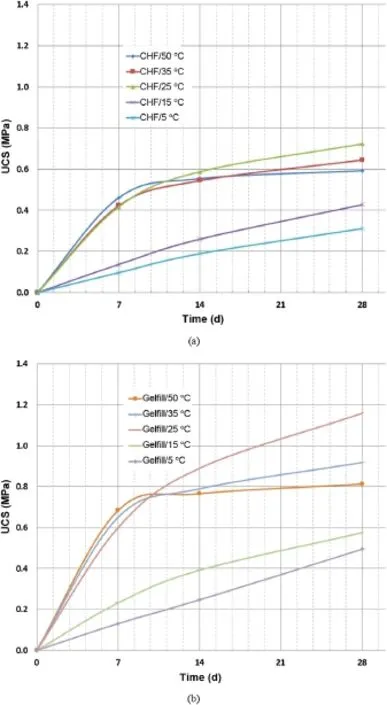

Fig.4.Effects of curing temperature on the UCS evolution of(a)CHF and(b)Gelfill.

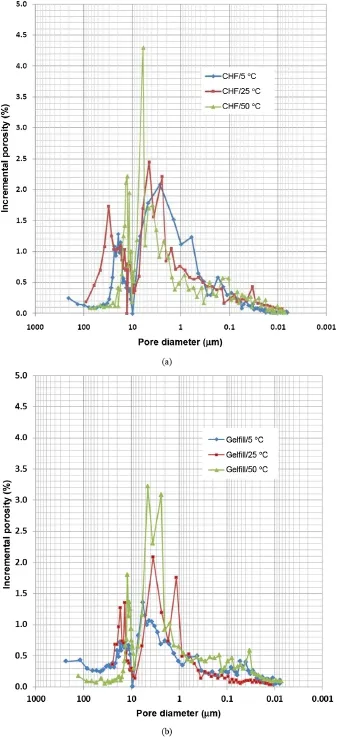

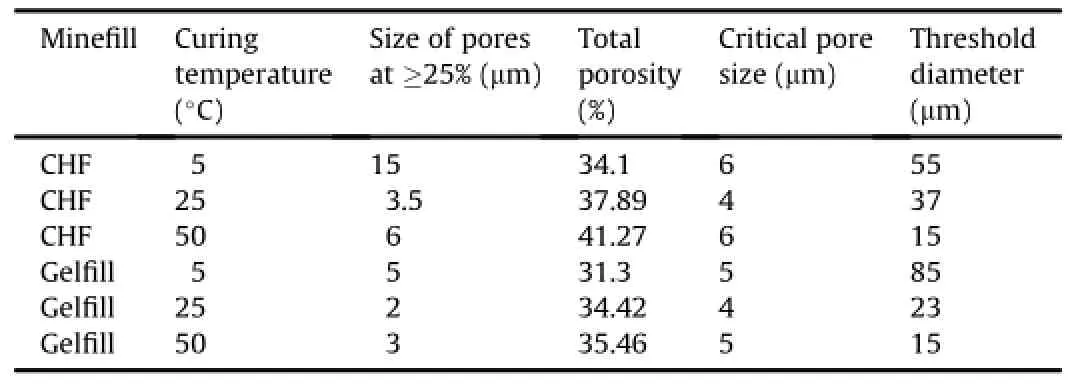

Fig.5.Incremental pore size distributions of(a)CHF samples and(b)Gelfill samples cured for 28 d.

4.2.Effect of curing temperature on the Gelfill and CHF strengths

In order to investigate the effect of curing temperature on the mechanical properties of CHF and Gelfill,Gelfill and CHF samples were prepared and cured at five curing temperatures(5°C,15°C, 25°C,35°C and 50°C).The CHF and Gelfill samples cured at 35°C and 50°C rapidly developed strength for the first 14 d of curing, and then plateaued(Fig.4).This might be due to the formation ofa solid C-S-H gel and ettringite layer around the binder particles, which could prevent moisture from reaching the inner parts of the binder.Therefore,the hydration would not be continuous.

Table 5 Summary of results of MIP tests conducted on CHF and Gelfill samples cured at 5°C, 25°C and 50°C.

The MIP results revealed that the pore size did not exceed 15μm(Fig.5,Table 5),which confirms the above hypothesis.After 14 d of curing,the UCS of the CHF and Gelfill samples cured at 25°C increased more rapidly than samples cured at 35°C and 50°C. Therefore,after 28 d the UCS of Gelfill samples cured at 25°C was 35%-90%higher than that of the other samples.The UCS values of samples cured at 50°C did not increase after 14 d,which could be explained by the driving out of moisture and hence cessation of hydration of BFS and NPC in the CHF and Gelfill.Moreover,the very low UCS values of samples cured at 5°C could be due to the low hydration rates of NPC and BFS at low temperature.This effect was clearly explained by Fall et al.(2010).Curing temperature altered the pore size distribution and pore structure of the CHF and Gelfill samples.Increasing the porosity decreased the UCS.The low UCS values for the samples cured at 5°C could be explained by the higher threshold and critical diameters.In fact,the pore size distribution of samples cured at 5°C was dominated by larger pores than those found in other samples.It can be concluded that the combination of lower total porosities and better pore size distribution contribute to the higher UCS values obtained from thee samples cured at 25°C.

5.Conclusions

An extended mixing time had a detrimental effect on the UCS of Gelfill,but no effect on CHF.Moreover,measuring the initial and final setting times of BFS and NPC paste showed that the addition of sodium silicate could strongly reduce the initial and final setting times.These results reveal that the addition of sodium silicate would be more effective if added at the close to the discharge rather than on the surface.Curing temperature strongly influenced the UCS of Gelfill samples.The results confirm that an elevated curing temperature could prevent the hydration of binders in CHF and Gelfill.Finally,a low curing temperature could cause low UCSs in CHF and Gelfill.In general and at the laboratory, the MIP conducted on the Gelfill samples cured in various curing temperatures showed that the curing temperature influenced the pore structures and pore size distributions,which could mainly contribute to the different mechanical properties of Gelfill samples.Use of Gelfill as mine backfill could contribute to reducing nonproductive time during the mining cycle and increase the mine production efficiency.Gelfill has the potential to improve the stability of underground mines and improve hydraulic fill economics.

Conflict of interest

The authors wish to confirm that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work that could have influenced its outcome.

Acknowledgments

The authors acknowledge the financial support given by Natural Sciences and Engineering Research Council of Canada(NSERC)and Vale.The authors are also grateful for the help and support of National Silicate Inc.,and the help and contributions of other graduate and undergraduate students at McGill and Concordia Universities.

References

Aligizaki KK.Pore structure of cemented-based materials.New York,USA:Taylor& Francis;2006.

American Society for Testing and Materials(ASTM).ASTM C136-96 standard test method for sieve analysis of fine and coarse aggregates.West Conshohocken, PA,USA:ASTM International;1996.

ASTM.ASTM D2166-06 standard test method for unconfined compressive strength of cohesive soil.West Conshohocken,PA,USA:ASTM International;2006.

ASTM.ASTM C191-13 standard test methods for time of setting of hydraulic cement by Vicat needle.West Conshohocken,PA,USA:ASTM International;2013.

ASTM.ASTM C305-14 standard practice for mechanical mixing of hydraulic cement pastes and mortars of plastic consistency.West Conshohocken,PA,USA:ASTM International;2014.

Anderson R,Gram H.Alkali-activated slag.Stockholm,Sweden:Swedish Cement and Concrete Research Institute;1998.

Bakhareva T,Sanjayana JG,Cheng YB.Effect of elevated temperature curing on properties of alkali-activated slag concrete.Cement and Concrete Research 1999;29(10):1619-25.

Belem T,Bussière B,Benzaazoua M.The effect of microstructural evolution on the physical properties of paste backfill.In:Tailings and mine waste'01.Rotterdam, Netherland:A.A.Balkema;2001.p.365-74.

Benzaazoua M,Fall M,Belem T.A contribution to understanding the hardening process of cemented paste backfill.Minerals Engineering 2004;17(2):141-52.

Brough AR,Atkinson A.Sodium silicate-based,alkali-activated slag mortars:part I. Strength,hydrationandmicrostructure.Cement andConcrete Research 2002;32(6):865-79.

Chang JJ.A study on the setting characteristics of sodium silicate-activated slag pastes.Cement and Concrete 2002;33(7):1005-11.

Chen W,Brouwers HJH.The hydration of slag,part 1:reaction models for alkaliactivated slag.Journal of Materials Science 2007;42:428-43.

Fall M,Célestin JC,Pokharel M,Touré M.A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill.Engineering Geology 2010;114(3):397-413.

Hassani F,Archibald JF.Mine backfill 1998.Montreal,Canada:Canadian Institute of Mining,Metallurgy and Petroleum;1998.

Hilbig H,Buchwald A.The effect of activator concentration on reaction degree and structure formation of alkali-activated ground granulated blast furnace slag. Material Science 2006;41(19):6488-91.

Kermani M,Hassani FP,Aflakib E,Benzaazouac M,Nokken M.Evaluation of the effect of sodium silicate addition to mine backfill,Gelfill-part 1.Journal of Rock Mechanics and Geotechnical Engineering 2015;7(3):266-72.

Kermani M,Hassani F,Nokken M,Aflaki E.An investigation into the addition of sodium silicate into mine backfill,Gelfill.In:International Symposium on Mining with Backfill(Mine Fill 2014),Perth,Australia;2014.p.271-80.

Kermani M,Hassani F.The mechanical properties of Gelfill.In:CIM Conference, Edmonton,Calgary,Canada;2012.

Kesimal A,Yilmaz E,Ercikdi B.Evaluation of paste backfill mixtures consisting of sulphide-rich mill tailings and varying cement contents.Cement and Concrete Research 2004;34(10):1817-22.

Ouellet S,Bussiere B,Aubertin M,Benzaazoua M.Characterization of cemented paste backfill pore structure using SEM and IA analysis.Bulletin of Engineering Geology and the Environment 2008;67(2):139-52.

Ouellet S,Bussière B,Aubertin M,Benzaazoua M.Microstructural evolution of cemented paste backfill:mercury intrusion porosimetry test results.Cement and Concrete Research 2007;37(12):1654-65.

Shi C,Krivenko P,Roy D.Alkali-activated cements and concretes.New York,USA:Taylor&Francis;2006.

Washburn EW.Note on a method of determining the distribution of pore sizes in a porous material.Proceedings of National Academy of Sciences of the United States of America 1921;7(4):115-6.

Mehrdad Kermani obtained a M.Sc.and a Ph.D.degree from McGill University,Canada.He is a research associate at the Mining Engineering Department of McGill University in Montreal.He is also a member of Professional Engineer of Ontario.He has been involved in mining and geotechnical as well as backfill research,consulting and education for more than 15 years.He is the author of more than 20 scientific papers.He is an executive committee member ofISRM2015congress andWorld Mining Congress 2014 in Montreal Canada.

Ferri Hassani obtained his Bachelor of Mining Engineering and Ph.D.from Nottingham University,Nottingham England in 1976 and 1981,respectively.Ferri Hassani is a Webster Chair Professor of Mining Engineering at McGill University and director of Geo-mechanics labs and Earth/ Mine Energy Research Group(EMERG),England.He was awarded a Fellow of the Canadian Institute of Mining and Metallurgy for his contribution to the mining industry in Canada.He has been at McGill University since 1983 and many years in a leadership role.His focus evolved from rock mechanics and mine design,to mining and energy and waste heat recovery from mining operation mine waste disposal,minefill and mining sustainability as well as microwave assisted rock breaking system.He was one of the pioneers of Pate backfill and he is the chairman of the International Mine Backfill Council.He was Co-founder and Chairman of the Canadian Mining innovation council(CMIC).He was given Canadian Rock Mechanics Award of Rock Engineering Society of CIM in 1992 and was also awarded Boleslaw Krupinski Gold Medal from the World Mining Organization of IOC 2013.He continues to maintain a strong interdisciplinary research and consulting activities with several million dollars of research and has graduated over 150 Ph.D.and MEng.Students,as well as research assistants,post-doctoral fellows,research associates and published over 160 scientific articles and reports.His research has led to obtaining several patents in the past 15 years.

Esmail Aflaki obtained his Bachelor of Engineering and his Masters of Engineering in Geological Engineering from McGill University in Canada in 1980 and a Ph.D.degree in Geotechnical engineering from the University of Newcastle Upon Tyne in 1996.He has worked in a leadership role in civil industry and conducted many geotechnical site investigations and consulting projects.He later joined the Amirikabir University in Tehran,Iran,as a lecturer and then assistant professor.He has published number of journal and conference articles in geotechnical engineering and is an author of two books.

Mostafa Benzaazoua obtained his Master degree in 1990(Lorraine University-Nancy,France),with specialization in applied mineralogy and metallogeny.He pursues his training with a Professional Master(DESS)in Mineral Processing(obtained in 1991);then in 1992 he obtained his geosciences Ph.D.around applied mineralogy and geochemistry applied to mine ores and others mine byproducts for beneficiation and/or management purposes. M.Benzaazoua joined the University of Quebec(UQAT)in 1996 beneficiating of a post-doctoral fellow.He became Professor in 1997 at UQAT.He obtained a Canada Research Chair in 2003 in the field of Integrated Mine Waste Management.In 2008 he obtained an International Research Chair funded by the IDRC jointly with the CRC in collaboration with Marrakech University(Morocco).Since UQAT appointment,he worked on several government funded and industry sponsored projects dealing with mineralogy and geochemistry for mine pollution control,waste management,mine site rehabilitation,mineral processing and waste reuse.Between 2010 and 2012,He took a leave and joined the National Institute of Applied Sciences at Lyon in France as Professor in the field of Industrial environment(treatment and reuse of industrial wastes).Now he is part of the young Mine and Environment Research Institute in UQAT.Dr.Benzaazoua's background is in geosciences with a specialization in applied mineralogy,geochemistry and mineral processing.He develops strong skills in mining environment,waste management,waste treatment and reuse;especially through the use of cemented mine backfill technology.

Michelle Nokken obtained her Bachelor of Applied Science and Doctorate in Civil Engineering at the University of Toronto.She is an Associate Professor in the Department of Building,Civil&Environmental Engineering at Concordia University,Montreal,QC.Dr.Nokken's research interests are durability of concrete,use of alternate cementing materials and non-destructive testing.Dr.Nokken is a member of ASCE,CSCE,ASTM.She is a Fellow of the American Concrete Institute.

11 August 2015

*Corresponding author.Tel.:+1 514 398 8060.

E-mail addresses:ferri.hassani@mcgill.ca,ferrihassani@hotmail.com(F.P.Hassani).

Peer review under responsibility of Institute of Rock and Soil Mechanics, Chinese Academy of Sciences.

1674-7755©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

http://dx.doi.org/10.1016/j.jrmge.2015.09.004

Journal of Rock Mechanics and Geotechnical Engineering2015年6期

Journal of Rock Mechanics and Geotechnical Engineering2015年6期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Characterizing the influence of stress-induced microcracks on the laboratory strength and fracture development in brittle rocks using a finite-discrete element method-micro discrete fracture network FDEM-μDFN approach

- Effects of fracture distribution and length scale on the equivalent continuum elastic compliance of fractured rock masses

- Shear strength behavior of geotextile/geomembrane interfaces Belén M.Bacasa,*,Jorge Cañizalb,Heinz Konietzkyc

- Engineering properties for high kitchen waste content municipal solid waste

- Effects of spatial variation in cohesion over the concrete-rock interface on dam sliding stability

- Studies on the key parameters in segmental lining design