利用LNG冷能的海水淡化流程比较

林文胜,黄美斌,顾安忠

(上海交通大学制冷与低温工程研究所,上海200240)

Introduction

The use of liquefied natural gas (LNG)is increasing rapidly in today's world.At receiving terminals,LNG is delivered to consumers mostly in the form of gaseous natural gas,which means LNG must be regasified.Because of the large temperature difference between LNG and the heating source,usually seawater or air,great amount of cold energy,estimated about 850kJ·kg-1,will be released from LNG during its evaporation.So it is important and necessary to make use of the LNG cryogenic exergy.LNG cold energy has by far been used in power generation and related CO2recovery[1-3],in air separation[4-5],in light hydrocarbon separation[6-7],and so on.

In recent years,with the rapid economic development and population growth,the lack of fresh water has become a global problem.In the 21st century,fresh water will become an important strategic and economic resource.On the other hand,the earth has plenty of seawater resources,accounting for about 97%of the global total water,so seawater desalination technology has aroused more and more attention.

Desalination methods are classified into three categories:distillation,membrane and freezing method.The freezing desalination method needs refrigeration system that consumes electricity power.However,LNG will release cold energy during its vaporization,which can be used in freezing desalination system.The freezing desalination method with LNG cold energy utilization not only saves the cost of electric refrigeration equipment,but also achieves energysaving and emission reduction.Some scholars have done research work about this kind of desalination.

Cravalhoetal[8]proposed a zero-energy theoretic system recovering LNG cold energy for fresh water production in 1970s.The system includes a heat engine,a heat pump,an LNG heat exchanger and two seawater heat exchangers.The heat engine works between the LNG heat exchanger and one of the seawater heat exchanger.The power from the heat engine is used to drive the heat pump.Systematic theoretical maximum output of fresh water is about 6.7 (kg water)·(kg LNG)-1.

Antonelli[9]proposed a desalination method using organic Rankine cycle (ORC)and the secondary refrigerant freezing process (SRF)to obtain fresh water with LNG cold energy utilization at LNG receiving terminal.n-Butane is selected as the secondary refrigerant.The power generated from organic Rankine cycle (ORC)is used to drive the secondary refrigerant freezing process (SRF).

Chenetal[10-12]and Qinetal[13]studied solute inclusion in ice formed from falling film flows on a sub-cooled surface.The relationship between the average solute distribution coefficient,the average ice growth rate and the bulk concentration of solute at various solution velocities have been measured and correlated using an empirical equation.Songetal[14-17]established a population balance model to predict the volumetric heat transfer coefficient for direct-contact evaporation in a bubble.

In recent years,some processes were proposed to integrate the desalination process adopting LNG cold energy recovery with some other processes.Wangetal[18]combined freeze desalination with membrane distillation,while Xiaetal[19]integrated the desalination process with a solar-powered transcritical CO2power cycle.

This paper proposes and compares two kinds of seawater freezing desalination methods,which are the refrigerant/seawater direct-contact method[20]and the refrigerant/seawater indirect-contact method.The result shows that the indirect-contact method has some advantages over the direct-contact method.Then,two processes are presented with the indirect-contact method,which are the non-phasechange process and the phase-change process.Performances of the two processes at different running temperatures are analysed.The study shows that the phase-change process has some advantages.

Fig.1 Layout of refrigerant/seawater direct-contact freezing desalination system

1 Two freezing desalination methods

Freezing desalination is classified into directcontact method and indirect-contact method according to the way of heat transfer between seawater and refrigerant.These two methods are compared here to decide which is more suitable for actual experimental conditions.To simplify the comparison,it is assumed that the system operates at steady state.The mass flow of fresh water obtained from the freezing desalination systems is set as 150L·h-1.

1.1 Refrigerant/seawater direct-contact method

The layout of the direct-contact system is shown in Fig.1.The low temperature liquid secondary refrigerant goes into the crystallizer and mixes with pre-cooled seawater.The refrigerant absorbs heat from high temperature seawater and gasifies into gas.Afterwards,the refrigerant gas from the top of the crystallizer flows through the heat exchanger and is condensed by LNG.Then,the low temperature liquid refrigerant is drained out and sprayed into the crystallizer by apump.In the crystallizer,the seawater partially crystallizes to form ice.The ice is transported to a continuous convective washer and the salt attached on the surface of ice crystals is washed away.Then,the ice is collected and melts in a melter.The water from the melter is the fresh water product,which is partially used as washing water.

In order to know the characteristics of this kind of freezing seawater desalination,some calculations and simulations are carried out by HYSYS software.The temperatures at point 1,2and 3are set as-100,-5and-100℃,respectively.The mass flow rate of LNG required to supply cold energy is 82.7kg·h-1,and the volume of the crystallizer is 0.09m3.

1.2 Refrigerant/seawater indirect-contact method

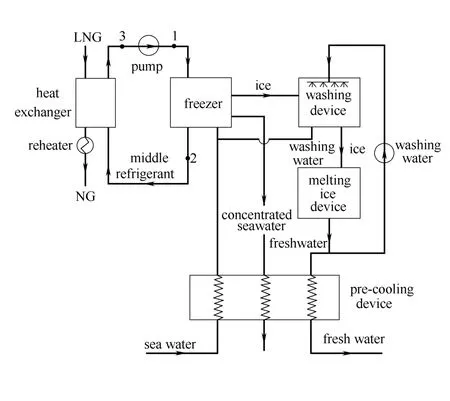

The layout of the indirect-contact system is shown in Fig.2.The low temperature liquid secondary refrigerant goes into the refrigerant side of the crystallizer,absorbs heat from high temperature seawater and gasifies.Then,the refrigerant gas from the crystallizer flows through the lowtemperature heat exchanger and is condensed by LNG.Afterwards,the low temperature liquid refrigerant is drained out and flows into the freezer by apump.In the freezer,the seawater partially crystallizes to form ice.The ice is transported to a continuous convective washing device and the salt attached on the surface of ice crystals is washed away.Then,the ice is collected and melts in an icemelting device.The water from the ice-melting device is the fresh water product,which is partially used as washing water.

Some calculations and simulations are also carried out for this system.The temperatures at point 1,2and 3are set as-40,-25and-40℃,respectively.The mass flow rate of LNG required to supply cold energy is 85.0kg·h-1,and the volume of the freezer is 3.60m3.

Fig.2 Layout of refrigerant/seawater indirect-contactfreezing desalination system

1.3 Comparison of two seawater desalination methods

Because the secondary refrigerant is sprayed into the seawater in the direct-contact system,the cold energy carried by the refrigerant is absorbed directly and almost completely by the seawater.Since the heat loss is reduced to minimum,the direct-contact freezing method has distinguishing features of high heat transfer efficiency and small size for the crystallizer.Theoretically speaking,the direct-contact method is almost perfect for seawater freezing desalination.

On the other hand,indirect-contact freezing method has some advantages in practice.The crystallizer (freezer)in the indirect-contact system is similar to an ice-making machine,which is commercially available.The ice produced in this kind of system is easily to be separated from the seawater.Furthermore,the ice may contains less salt because large size of ice block is produced,instead of little ice crystals in the direct-contact system.

2 Two processes of indirect-contact freezing

The indirect-contact method is then chosen for further study because it is simple and easy to be applied.Two processes are presented with different refrigerant conditions.In the non-phase-change process,the secondary refrigerant remains as subcooled liquid in the whole cycle.Sensible heat is transferred from seawater to the secondary refrigerant.In the phase-change process,however,the secondary refrigerant is vaporized when freezing the seawater,and then it is condensed when gasifying the LNG.Latent heat is transferred between seawater and the secondary refrigerant in the crystallizer.Performances of the two systems at different refrigerating temperatures are analysed here.

In order to understand the characteristics of these two processes,the refrigerant circulation loop is calculated and simulated through software HYSYS.R410Ais selected as the secondary refrigerant.The flow chart of non-phase-change process is the same as that of the phase-change process,shown in Fig.3.Fig.4is thep-hdiagram of the non-phase-change process and figure 5is for the phase-change process.

Fig.3 Flow chart of secondary refrigerant

In order to simplify analysis and comparison,the initial conditions are given.Taking into account the frictional drag and heat leakage of pipes,the temperature of LNG will rise a little before going into the cryogenic heat exchanger,so the initial state of LNG can be set at 0.15MPa and-160℃,at the state of subcooled liquid.The parameters of outlet natural gas are assumed as 0.1MPa and-160℃.Adiabatic efficiency of the pump in this system is 75%.The pressure drop of the secondary refrigerant is 20kPa in both of the crystallizer and the heat exchanger.The maximum pressure of the system is 0.5MPa,and the heat load of the crystallizer is 18.06kW,the temperature of R410Aat the inlet of crystallizer is-25℃,and the outlet temperature changes from-40to-30℃.

Fig.4 p-hdiagram of non-phase-change process

Fig.5 p-hdiagram of phase-change process

With these parameters set,simulations of the two processes are performed by HYSYS software.Fig.6and Fig.7show main differences between these two processes.

Fig.6 Mass flow of secondary refrigerant at different temperatures

Fig.7 Required pump power at different temperatures

From Fig.6and Fig.7,the main differences between these two processes are flow rate of the secondary refrigerant R410Aand pump power consumption under the same conditions.In the nonphase-change process,the mass flow rate of R410Ais very large,and the pump power consumption is a bit high.That is because there is only sensible heat transfer between seawater and the secondary refrigerant in the crystallizer.R410A's sensible heat from-25to-40℃or-30℃is much smaller than its latent heat.Therefore,when the heat load of the crystallizer is the same,mass flow rate will increase rapidly along with the increase of outlet temperature of R410Ain the non-phasechange process,which means that the secondary refrigerant flow velocity is very high or the diameter of pipeline is very large,which also leads to much larger pump power consumption.In the phase-change process,the cold energy is mainly transferred by vaporization latent heat,which results in smaller mass flow and lower pump power consumption than those of the non-phase-change process.

In summary,the non-phase-change process has the advantage of simple fluid state,and it is also easy to be controlled.Whereas,because of lager mass flow rate,the pipe diameter and pump power consumption is relatively large for the nonphase-change process.Considering its much lower pump power consumption,the phase-change process is more suitable for the seawater freezing desalination system utilizing LNG cold energy.

3 Conclusions

The conventional freezing desalination method needs cold energy from refrigeration system that consumes much electricity power.On the other hand,LNG will release a lot of cold energy during its vaporization process,which will be wasted if not recovered.This paper present a system integrating the two processes of LNG vaporization and seawater freezing,i.e.the freezing seawater desalination system with LNG cold energy utilization.Two kinds of seawater freezing desalination methods are proposed and compared,which are the refrigerant/seawater direct-contact method and the refrigerant/seawater indirect-contact method.

The indirect-contacting method is chosen for further study because the system is simple,because the ice is easily to be separated from the seawater,and also because the ice may contains less salt.Two processes,the non-phase-change process and the phase-change process,are presented with different refrigerant conditions for the indirect-contact method.In the two processes,the main differences are the mass flow of the secondary refrigerant and the pump power consumption.In this study,the flow rate of the refrigerant is about 300 kg·h-1and the pump power consumption is 0.02 kW for the phase-change process.But for the non-phase-change process,the refrigerant flow rate varies from about 3000kg·h-1to about 9000kg·h-1,while the pump power consumption varies from 0.15to 0.45kW.The study shows that the phase-change process of indirect-contact method is more suitable for the seawater freezing desalination system utilizing LNG cold energy,considering its much lower pump power consumption.

[1] Kim T S,Ro S T.Power augmentation of combined cycle power plants using cold energy of liquefied natural gas[J].Energy,2000,25:841-856.

[2] Lin Wensheng, Huang Meibin, He Hongming, Gu Anzhong.A transcritical CO2Rankine cycle with LNG cold energy utilization and liquefaction of CO2in gas turbine exhaust [J].JournalofEnergyResourcesTechnology-TransactionsoftheASME,2009,131 (4):042201.

[3] Wang Tao,Lin Wensheng,Gu Anzhong.Analysis of working fluid and variable working conditions of organic Rankine cycle utilizing LNG cold energy [J].CIESCJournal(化工学报),2010,61 (S2):107-111.

[4] Takashi N,Naohiko Y.Air separating method using external cold source[P]:US,5220798.1993-06-22.

[5] Rakesh A.Liquefied natural gas refrigeration transfer to a cryogenics air separation unit using high nitrogen stream[P]:US,5137558.1992-08-11.

[6] Gao Ting,Lin Wensheng,Gu Anzhong.Improved processes of light hydrocarbon separation from LNG with its cryogenic energy utilized[J].EnergyConversionandManagement,2011,52 (6):2401-2404.

[7] Gao Ting (高婷),Lin Wensheng (林文胜),Gu Anzhong(顾安忠).Light hydrocarbons separation at high pressure from liquefied natural gas with its cryogenic energy utilized[J].CIESCJournal(化工学报),2009,60 (S1):73-76.

[8] Cravalho E G,McGrath J J,Toscano W M.Thermodynamic analysis of the regasification of LNG for the desalination of sea water [J].Cryogenics,1977,17 (3):135-139.

[9] Antonelli A.Desalinated water production at LNG-terminals[J].Desalination,1983,45 (2):383-390.

[10] Chen Ping,Chen Xiaodong,Free K W.An experimental study on the spatial uniformity of solute inclusion in ice formed from falling film flows on a sub-cooled surface [J].JournalofFoodEngineering,1999,39 (1):101-105.

[11] Chen Ping,Chen Xiaodong,Free K W.Solute inclusion in ice formed from sucrose solutions on a sub-cooled surface-an experimental study [J].JournalofFoodEngineering,1998,38 (1):1-13.

[12] Chen Xiaodong,Chen Ping,Free K W.A note on the two models of ice growth velocity in aqueous solutions derived from an irreversible thermodynamics analysis and the conven-tional heat and mass transfer theory[J].JournalofFood Engineering,1997,37 (3):395-402.

[13] Qin F G F,Chen Xiaodong,Farid M M.Growth kinetics of ice films spreading on a subcooled solid surface[J].SeparationandPurificationTechnology,2004,39 (1/2):109-121.

[14] Song M,Steiff A,Weinspach P-M.Parametric analysis of direct contact evaporation process in a bubble column [J].InternationalJournalofHeatandMassTransfer,1998,41 (12):1749-1758.

[15] Song M,Steiff A, Weinspach P-M.Direct-contact heat transfer with change of phase:apopulation balance model[J].ChemicalEngineeringScience,1999,54 (17):3861-3871.

[16] Song M,Steiff A,Weinspach P-M.The analytical solution for a model of direct contact evaporation in spray columns[J].InternationalCommunicationsinHeatandMass Transfer,1996,23 (2):263-272.

[17] Song M,Steiff A,Weinspach P-M.A very effective new method to solve the population balance equation with particlesize growth[J].ChemicalEngineeringScience,1997,52(20):3493-3498.

[18] Wang Peng,Chung T S.A conceptual demonstration of freeze desalination-membrane distillation (FD-MD)hybrid desalination process utilizing liquefied natural gas (LNG)cold energy [J].WaterResearch,2012,46 (13):4037-4052.

[19] Xia Guanghui,Sun Qingxuan,Cao Xu,Wang Jiangfeng,Yu Yizhao,Wang Laisheng.Thermodynamic analysis and optimization of a solar-powered transcritical CO2(carbon dioxide)power cycle for reverse osmosis desalination based on the recovery of cryogenic energy of LNG(liquefied natural gas)[J].Energy,2014,66:643-653.

[20] Huang Meibin (黄美 斌),Lin Wensheng (林文胜),Gu Anzhong(顾安忠),Huang Jianmin(黄建民).Refrigerant direct-contact seawater desalination utilizing LNG cold energy[J].JournalofChemicalIndustryandEngineering(China)(化工学报),2008,59 (S2):204-209.