Influence of shear sensitivities of steel projectiles on their ballistic performances

WANG Lin(王琳), HU Xian-feng(胡贤风), CHENG Xing-wang(程兴旺)

(National Key Laboratory of Science and Technology on Materials under Shock and Impact, School of Materials Science and Engineering, Beijing Institute of Technology, Beijing 100081, China)

Influence of shear sensitivities of steel projectiles on their ballistic performances

WANG Lin(王琳), HU Xian-feng(胡贤风), CHENG Xing-wang(程兴旺)

(National Key Laboratory of Science and Technology on Materials under Shock and Impact, School of Materials Science and Engineering, Beijing Institute of Technology, Beijing 100081, China)

In ballistic penetration, a main failure mode for a projectile is adiabatic shear localization which results in macro cracks developing along ASBs which lead to the fracture of projectile. In this paper, the adiabatic shear sensitivity and ballistic performances of two high strength steels, 30CrMnSi and 35CrWMo, with similar static mechanical properties were investigated. Split Hopkinson Pressure Bar (SHPB) for compression loading and ballistic experiments above the velocity of 1 000 m/s against thick concrete targets were performed. The SHPB and ballistic experimental results showed that the 30CrMnSi steel exhibits more adiabatic shear sensitivity, compared with the 35CrWMo steel. Even though these two steels have similar static mechanical properties, the 35CrWMo steel projectile exhibits better penetration performance than the 30CrMnSi projectile due to different adiabatic shear sensitivities.

high strength steel; adiabatic shear sensitivity; penetration

During ballistic penetration, a main failure mode for projectile materials is adiabatic shear localization which can result in macrocracks developing along ASBs and lead to projectiles fracture[1-3]. In the conventional designations and selections of projectile materials, high strength and high toughness are two major considerations. Relatively few considerations have been given to the projectile materials’ sensitivity to adiabatic shear localization or the materials’ ability to resist adiabatic shear localization[4-5].

In this paper, two steels were chosen as projectile materials: one is a conventional projectile material 30CrMnSi, another is the 35CrWMo steel designed based on anti-adiabatic shear localization. The influence of adiabatic shear sensitivity of these steels on their ballistic performances was investigated. The dynamic properties and ballistic performance of the two high strength steels with similar static mechanical properties were investigated. Split Hopkinson Pressure Bar (SHPB) and ballistic gun were used to perform dynamic compression tests and terminal ballistic performances respectively.

1 Experimental procedures

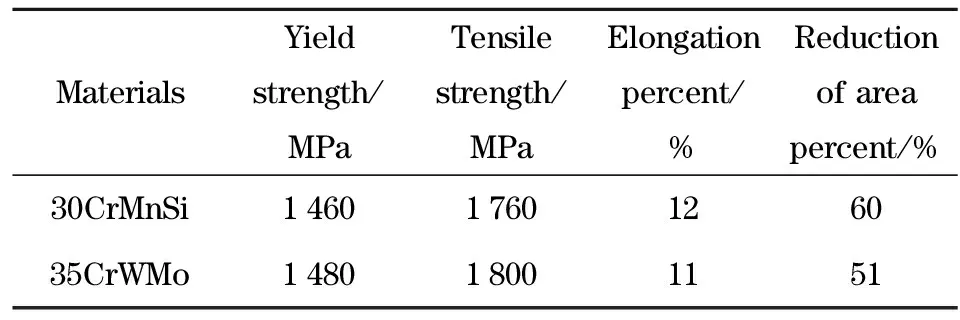

Two steels were chosen as projectile materials: one was the 30CrMnSi, a conventional projectile material with Cr, Mn and Si alloying; another was the 35CrWMo steel whose alloying principle was designed based on anti-adiabatic shear localization. The static mechanical properties of these two steels are list in Tab.1. The yield strength and tensile strength of the 30CrMnSi and the 35CrWMo are slightly different, with 20 MPa and 40 MPa lower for the 30CrMnSi than those of 35CrWMo. The ductile and toughness of both steels are similar.

Tab.1 Mechanical properties of two steels

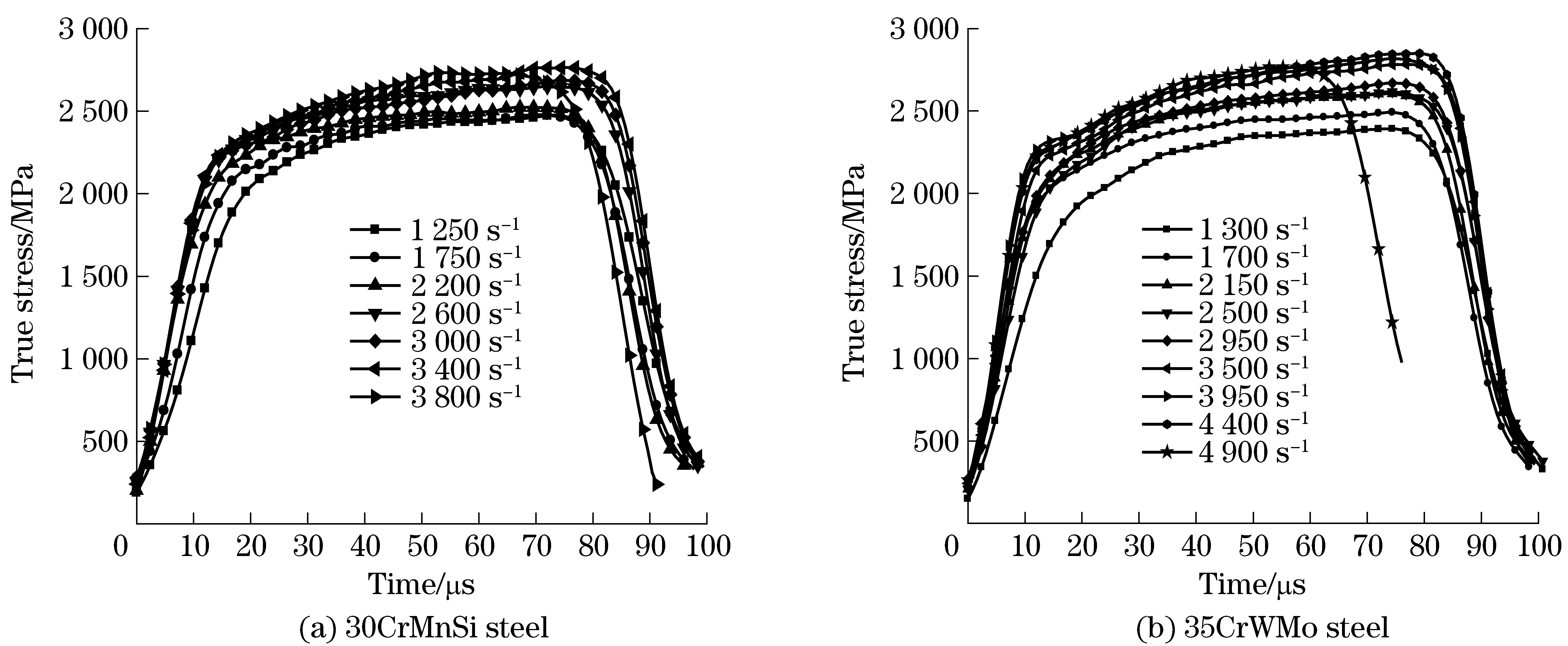

SHPB was used to carry out dynamic compression experiments to investigate the dynamic response of materials, including adiabatic shear localization. The chosen pressures ranged from 0.3 MPa to 1.1 MPa with step of 0.1 MPa and the corresponding strain rates ranged from 1 250 s-1to 4 900 s-1. The inner caliber of SHPB wasφ14.5 mm. The impact projectile bar was 80 mm length and the loading pulse was 80 μs. The cylindrical sample was ofφ5 mm×5 mm dimension. After the SHPB experiments, both stress-strain curves and stress-time curves were obtained. From stress-time curves, the loading and unloading conditions of cylinders could be fairly distinguished, which indicated the deformation and fracture of the materials[5-6].

Fig. 1 True stress-time curves of 30CrMnSi steel and 35CrWMo steel

A set of ballistic experiments were operated with aφ105 mm caliber gun. The velocities were adjusted by the weight of the detonator powder. The projectiles were 14.5 mm in diameter and 100 mm long, with a spherical nose shape and CRH of 2.5. The projectiles were accelerated to above 1 000 m/s and impact perpendicularly to the concrete targets. The velocities were measured by laser velocity meter and the impact angles of the projectiles were examined by paper targets located just before the targets. The concrete targets were ofφ360 mm×500 mm and confined by 5 mm thick steel plates. In each experiment, two targets are tightly put together to form a 1 000 mm semi infinite plate.

After SHPB and ballistic experiments, the recovered cylinders and the projectiles were sectioned along their axes. Standard metallographic samples were prepared through mounting, grinding, polishing and erosion. Microstructure characterizations were carried out by optical microscope (OM) and scanning electron microscope (SEM). The penetration depth were measured, the deformation or fracture of projectiles and the targets were analyzed.

2 Experimental results and discussion

2.1 SHPB experimental results

The true stress-time curves from SHPB experiments are shown in Fig.1. The strain rage ranges from 1 250 s-1to 4 900 s-1. True stress-time curves illustrate the loading history of the cylinder, which demonstrate whether the cylinder fails or not. The stress decrease after 80s means that the cylinder can stand the full loading and keep intact. While the stress decrease before 80 μs of full loading time indicates that the cylinder fails due to severe plastic deformation or fracture and cannot stand the full loading stage of 80 μs.

True stress-strain curves of the 30CrMnSi and the 35CrWMo steels show that two steels exhibit different dynamic behaviors. Under loading pressure from 0.3 MPa to 0.8 MPa or the strain rate from 1 250 s-1to 3 400 s-1, the 30CrMnSi steel does not fracture and still have the loading ability. But at 0.9 MPa compression pressure and strain rate of 3 800 s-1, the stress value fall suddenly at 71.2 μs. In this case, the pulse did not finish loading and the cylinder fracture, which indicates that the loading ability of the sample fail and shear fracture occur. For the 35CrWMo steel, the stress does not fall down until the strain rate of 4 900 s-1, under the loading pressure of 1.1 MPa, the stress collapse at 72.8 μs.

Compared with two sets of stress-time curves, one can see that the 30CrMnSi steel fracture at relatively lower pressure or relatively lower strain rate than the 35CrWMo steel. Under 0.9 MPa loading pressure, the 30CrMnSi steel cylinder fails and under 1.1 MPa loading pressure, the 35CrWMo steel fails. The combinations of macro and microstructure observation results show that the two steels fail due to adiabatic shear localization.

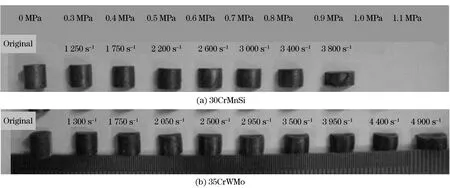

2.2 Macro and microstructure observation results from SHPB experiments

The macro observation results are shown in Fig. 2. It can be seen clearly that with the increasing loading pressure, the cylinder deform and then fracture. Under the same loading pressure, the deformation amounts of the 30CrMnSi steel are more than those of the 35CrWMo steel. At strain rate of 3 800 s-1, the 30CrMnSi steel cylinder fracture along 45° direction from the axis. At strain rate of 4 900 s-1, the 35CrWMo cylinder breaks into two parts. Therefore, the steels exhibit different critical conditions of deformation and fracture[7-8].

Fig.2 Macro observation results of the two steel cylinders after SHPB experiments

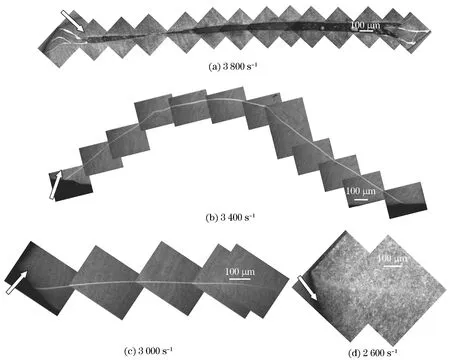

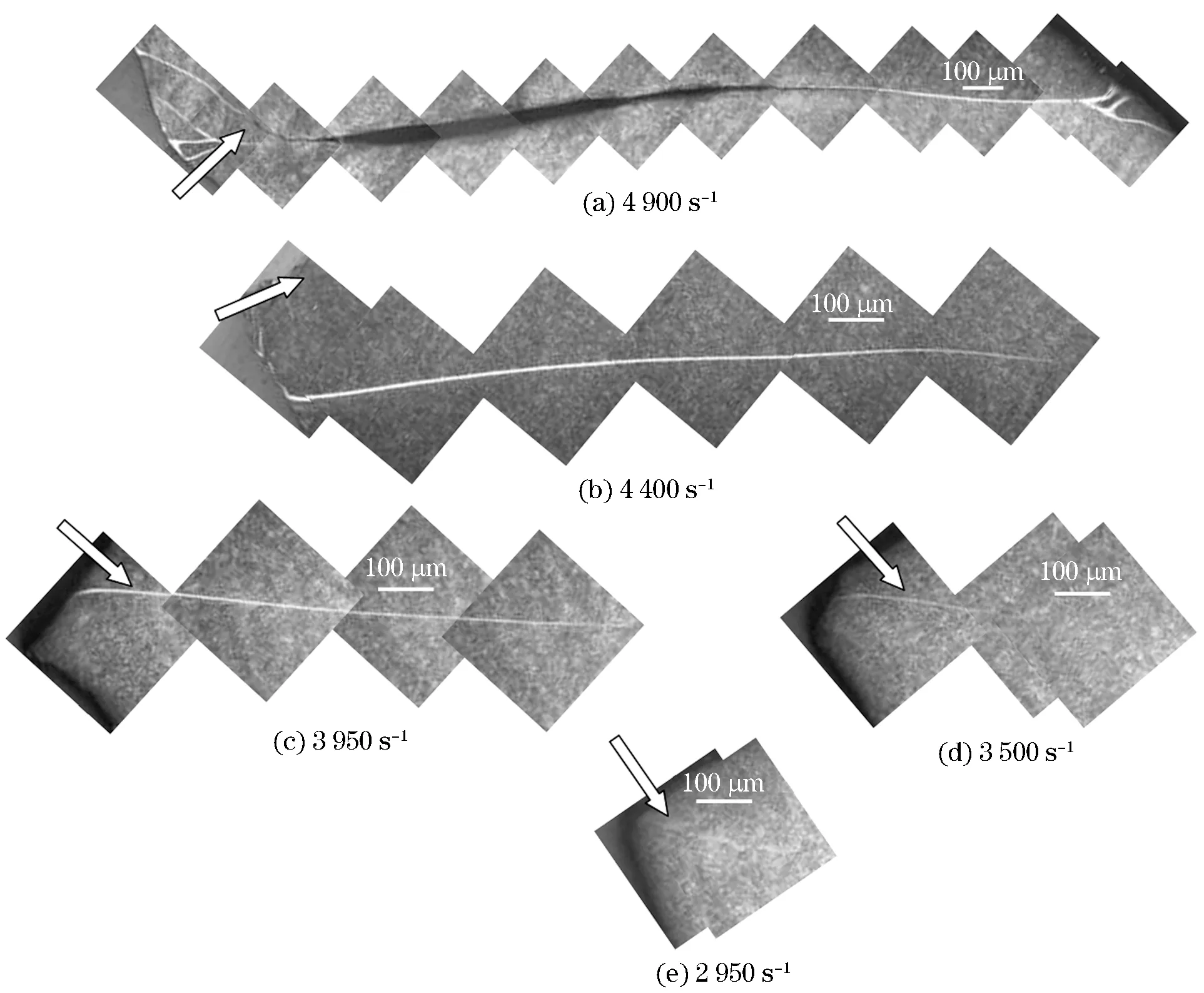

The microstructure evolutions of two steels are shown as Fig. 3 and Fig. 4. It should be noted that the direction of the arrow is the compression direction. Adiabatic shear localization begins from a wide and short deformed band, then evolve into narrow and white transformed band, and the white band further develop into micro crack and macro crack. Both two steels exhibit similar deformation development processes.

Fig.3 ASB observation of 30CrMnSi under different strain rates

Fig.4 ASB of 35CrWMo steel under different strain rates

At strain rate of 2 600 s-1, deformed adiabatic shear band occur at the true strain of 0.24 in the 30CrMnSi steel. ASB occur in the 35CrWMo steel at 2 950 s-1. Therefore, the two materials exhibit different anti-shear localization nucleation or adiabatic shear sensitivities. Hence, the 30CrMnSi steel exhibits more tendency to adiabatic shear localization than the 35CrWMo steel.

Adiabatic shear localization develops into crack at 3 800 s-1in the 30CrMnSi steel and at 4 900 s-1in the 35CrWMo steel. The fracture and the failure stress are also much higher in the 35CrWMo steel than in the 30CrMnSi steel. Therefore, not only the two materials exhibit different adiabatic shear sensitivities, but also the occurrence of ASB and the critical strain rate from ASB developing into fracture are different. The 30CrMnSi steel prefer more easily to the occurence of adiabatic shear localization and fracture than the 35CrWMo steel. The possible reason for the different adiabatic shear sensitivity behaviors is the different compositions of the steels. For the 35CrWMo steel, the composition design purpose is to improve the anti-adiabatic shear sensitivity of the steel served under high strain rate, similar with the steel used in high speed cutting. Although the element content is not high, W and Mo elements are appropriate to be used in high temperature condition. Under high strain rate loading, about 90% of plastic deformation transfer into heat, and the compounds containing W and Mo elements resist to the heating. The designation of the 35CrWMo steel is prone to postpone the development process of ASB to macro crack. Therefore, under high strain rate loading, adiabatic shear band is not easy to occur in the 35CrWMo steel. For the 35CrMnSi steel, the material is more sensitive to adiabatic shear banding.

Another reason is that the adiabatic shear sensitivity is closely related with both dynamic strength and dynamic ductility. The dynamic strengths of the two steels are similar, but the ductility of the 35CrWMo steel under high strain rate is much higher than that of the 30CrMnSi steel. Therefore, the 35CrWMo steel exhibits more anti-adiabatic shear banding sensitivity.

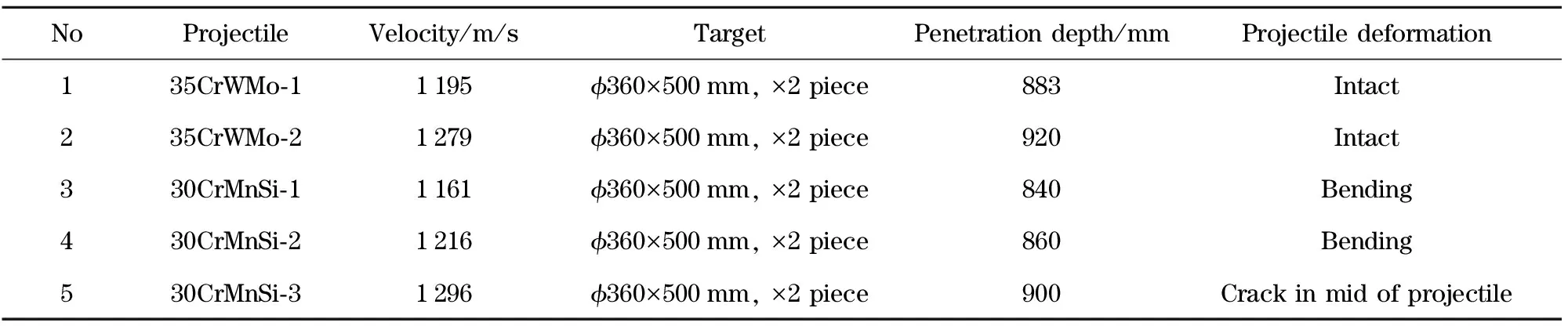

2.3 Ballistic experimental results

The ballistic experiments were carried out with different velocities for two steel projectiles. Selected results are given in Tab.2. It can be seen that at similar high impact velocities, the 35CrWMo projectiles penetrate more than the 30CrMnSi projectiles. At similar high impact velocities, the 30CrMnSi projectiles deform and fracture at the transmission region from the head to the cylinder. This can be concluded that the 35CrWMo projectile has better penetration capability than the 30CrMnSi projectile. The microstructure observation shows that there are no adiabatic shear localization occur in the 35CrWMo and the 30CrMnSi steel projectiles at two relatively low velocities. But at the impact velocity of 1296 m/s, there is an ASB occurring at the side of the crack in the 30CrMnSi steel projectile, while the 35CrWMo keep intact. Therefore, the different penetration performances of two steel projectiles are closely related with their adiabatic shear sensitivities. If the steel is more sensitive to adiabatic shear banding under high strain rate loading, the projectile will deform and fracture much easily compared with other steel projectile which is less sensitive to ASB.

Tab. 2 Selected penetration experiment results of two steel projectiles

Similar with the dynamic behavior of the steels under high strain rate loading using SHPB, the penetration performance is also closely related with dynamic strength and ductility. During penetration process, the projectile will experience dynamic compression stage, then dynamic tensile. For ASB occurring, it usually occurs in dynamic compression stage. However, if the projectile has better ductility, during penetration process, the projectile will accommodate more deformation and postpone the occurrence of adiabatic shear band. Therefore, if the steel projectile has high ductility, its penetration capacity is better compared with the counterpart with relatively lower ductility, even though with similar strength.

3 Conclusions

The following conclusions can be obtained from the above SHPB and penetration experimental research:

① The dynamic plastic deformation in the 35CrWMo steel is much higher than that of the 30CrMnSi steel, although they exhibit similar static strength.

② Combining true stress-time curves with the microstructure observation from SHPB experiments, the 30CrMnSi steel exhibits more adiabatic shear sensitivity than the 35CrWMo steel, which indicates that the adiabatic shear sensitivity is closely related with both dynamic strength and dynamic ductility.

③ The 35CrWMo steel projectile has better penetration performance than the 30CrMnSi projectile due to different adiabatic shear sensitivity. For the designations and selections of projectile materials, the material’s sensitivity to adiabatic shear localization should be considered besides the high strength and high toughness characteristics.

[1] Meyers M A. Dynamic behavior of materials[M]. New York: John Wiley & Sons Inc, 1994: 448-486.

[2] Bai Y L. Adiabatic shear banding [J]. Res Mechanics, 1990, 31:133-203.

[3] Shockey D A, Erlich D C, Meyers M A. Shock waves and high-strain-rate phenomena in metals: concepts and applications[M]. New York: Plenum Press, 1981: 249.

[4] Odeshi A G, Bassim M N, Al-Ameeri S, et al. Dynamic shear band propagation and failure in AISI 4340 steel [J].Journal of Materials Processing Technology, 2005,169:150-155.

[5] Xu Y B, Bai Y L, Shen L T. Formation, microstructure and development of the localized shear deformation in low-carbon steels[J]. Acta Materialia,1996, 44: 1917-1919.

[6] Woei S L, Chen Y L, Chen T H. Adiabatic shearing behavior of different steels under extreme high shear loading[J]. Journal of Nuclear Materials, 2008, 374:313-319.

[7] Odeshi A G, Bassim M N, Ameeri S A. Effect of heat treatment on adiabatic shear bands in a high-strength low alloy steel [J]. Materials Science and Engineering, 2006, 419:69-75.

[8] Marchand A, Duffy J. An experimental study of the formation process of adiabatic shear bands in structural steel [J]. Journal Mech Phys Solids, 1988, 36: 251-258.

(Edited by Cai Jianying)

10.15918/j.jbit1004-0579.201524.0422

TG 142.1 Document code: A Article ID: 1004- 0579(2015)04- 0573- 06

Received 2014- 01- 03

E-mail: linwang@bit.edu.cn

Journal of Beijing Institute of Technology2015年4期

Journal of Beijing Institute of Technology2015年4期

- Journal of Beijing Institute of Technology的其它文章

- Generalized ionospheric dispersion simulation method for wideband satellite-ground-link radio systems

- Multi-subpulse process of large time-bandwidth product chirp signal

- Factor-graph-based iterative channel estimation and signal detection algorithm over time-varying frequency-selective fading channels

- Nano-silica particles enhanced adsorption and recognition of lysozyme on imprinted polymers gels

- Similarity matrix-based K-means algorithm for text clustering

- Optimizing control of a two-span rotor system with magnetorheological fluid dampers