Research on hydraulic wind turbine semi-physical simulation platform①

Ai Chao (艾 超), Chen Lijuan, Kong Xiangdong

(*Hebei Provincial Key Laboratory of Heavy Machinery Fluid Power Transmission and Control,Yanshan University, Qinhuangdao 066004, P.R.China)(**Key Laboratory of Advanced Forging & Forming Technology and Science (Yanshan University),Ministry of Education, Qinhuangdao 066004, P.R.China)(***School of Mechanical Engineering, Yanshan University, Qinhuangdao 066004, P.R.China)

Research on hydraulic wind turbine semi-physical simulation platform①

Ai Chao (艾 超)***, Chen Lijuan***, Kong Xiangdong②

(*Hebei Provincial Key Laboratory of Heavy Machinery Fluid Power Transmission and Control,Yanshan University, Qinhuangdao 066004, P.R.China)(**Key Laboratory of Advanced Forging & Forming Technology and Science (Yanshan University),Ministry of Education, Qinhuangdao 066004, P.R.China)(***School of Mechanical Engineering, Yanshan University, Qinhuangdao 066004, P.R.China)

According to a research on the 30kVA simulation experimental platform of hydraulic wind turbine, its basic structure, composition and operation principle are expounded in this paper. An inverter motor is used to simulate the wind turbine, while a similarity calculation method is applied between the small and large wind turbine. A fixed displacement pump-variable motor closed loop is used as the main transmission system, and a self-excited synchronous generator generates electricity through the grid connection. The experiment and simulation study on the speed and power control of the hydraulic wind turbine is conducted, based on the experimental platform, thus correctness and progressiveness of the experiment platform is further verified. The experimental platform study lays a foundation for further research on the characteristics of hydraulic wind turbine.

wind power generation, hydraulic transmission, simulation of experimental platform

0 Introduction

With the deterioration of global climate and serious energy shortage, wind power as a kind of new green energy generation, gets the widespread attention, research and application at home and abroad in recent years, and it is mainly concentrated in doubly fed induction generator and direct-drive permanent magnet wind power generation system. But the two models have shortages such as large weight, high cost and so on[1].

Hydraulic wind turbine as a new type of wind generator, compared with the above two kinds of traditional models, uses hydraulic flexible transmission to replace rigid transmission, so that it solves the problems of high fault rate and large weight in the gear box transmission and the large volume and weight of the direct drive generator. At the same time, the transmission ratio can be adjusted from time to time, thus it not only eliminates the need for large power electronic device of rectifier inverter, but also realizes the application of synchronous generator in the wind power field, which can improve the quality of electric energy.

Domestic and foreign scholars and companies have carried out a series of researches on hydraulic wind power technology in recent years. Norway ChapDrive company has studied 225kW and 900kW floor type hydraulic wind turbine since 2004, and applied for a patent in China and a more efficient 5MW model is also in research[2]; in the support of the British carbon fund, Scotland Edinburgh Artemis Intelligent Power company completed the prototype development of 1.5MW hydraulic wind turbine in 2009[3]; The hydraulic wind turbine experimental platform was established in the IFSA Laboratory of German Rheinisch-Westfaelische Technische Hochschule in 2010, and the university studied the principle feasibility of the hydraulic wind turbine and the control characteristics of the system, and test the efficiency of hydraulic wind turbine through the experimental platform[4]; the Japanese Mitsubishi Heavy Industries (MHI) started to use large-scale wind power system which adopted hydraulic transmission in Yokohama in December 2012, and it planned to install and run 7MW offshore wind power generation system in the Hunterston of UK[5]; many American and British companies study key hydraulic components and the maximum power point tracking control of transmission system in the hydraulic wind turbine, but at present they are all at laboratory research stage, not industrialized.

In China,Kong, et al.[6-9]in Yanshan University carried out a series of researches on hydraulic wind turbine, such as the wind turbine characteristics, the main hydraulic transmission system control characteristics, the maximum power point tracking, the grid impact and the low voltage ride through technology etc.; Li[10]in Zhejiang University carried out researches on hydraulic transmission systems for tidal current turbine; Dalian Spark New Energy Developments Limited Company introduced the technology of hydraulic wind turbine main transmission from Norway ChapDrive company in 2010, but without successful related report.

To master the key technology of hydraulic wind turbine generator system, it is necessary to establish a simulation experimental platform for the deep research on hydraulic wind turbine. This paper introduces the 30kVA hydraulic wind turbine simulation experimental platform which was set up in the research process by the team of professor Kong Xiangdong in Yanshan University.

1 Composition of the 30kVA hydraulic wind turbine simulation experimental platform

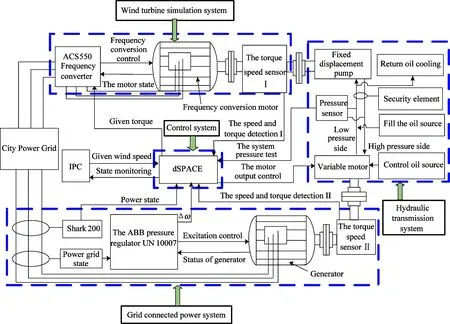

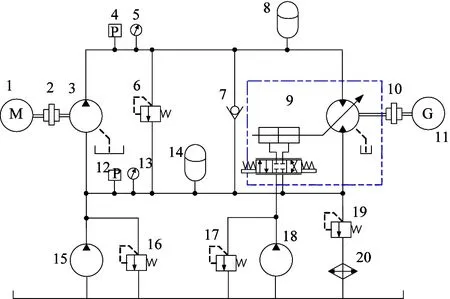

The 30kVA hydraulic wind turbine simulation experimental platform is mainly composed of a wind turbine simulation system, a hydraulic transmission system, a grid generation system and a control system. The overall structures are shown in Fig.1, and the physical map is shown in Fig.2. The working principle is as follows: the inverter controls variable frequency motor to simulate the wind turbine; frequency conversion motor drives the fixed displacement pump turn, and the output high pressure oil through the pipeline into a variable motor to drive variable motor turn; generator, which is rigidly connected with the motor output shaft, operates at synchronous speed driven by the motor to realize grid connection power; in the process of operation, variable motor swash plate swing angle is controlled by the main controller to realize the motor speed control and the generator power control.

Fig.1 The structure diagram of 30kVA hydraulic wind turbine simulation platform

Fig.2 The experimental hydraulic system

2 The wind turbine simulation part of 30kVA hydraulic wind turbine

The wind turbine simulation system consists of frequency converter, variable frequency motor and speed torque sensor. And it can realize the wind turbine output power simulation and the torque characteristics simulation under different wind speed.

(1) The wind turbine characteristics of the 30kVA hydraulic wind turbine

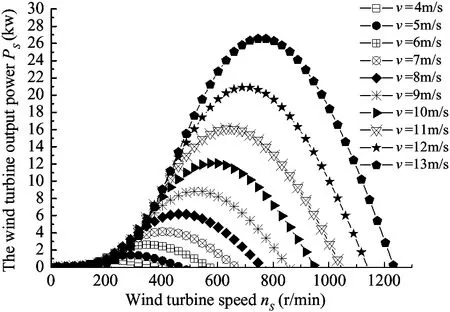

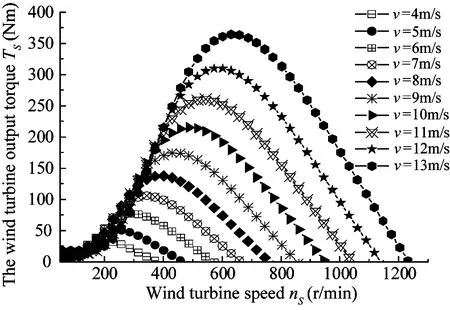

The wind turbine inherent characteristics are shown in Fig.3, Fig.4 and Fig.5. This experiment uses the wind turbine characteristic module to realize the wind turbine characteristic simulation.

(2) The wind turbine similarity simulation principle

If the wind turbine simulation experimental platform achieves the wind energy capture ability similar to real wind turbine, it needs to meet the following 3 similar conditions: ① similar power; ② the same wind energy utilization coefficient; ③ similar moment of inertia.

Fig.3 The equivalent wind energy utilization coefficient

Fig.4 The output power curve of turbine

Fig.5 The output torque curve of turbine

The process of similarity calculation is as follows:

Definition of similarity coefficient: KPGis power coefficient, Kωis speed coefficient, KRis radius coefficient, and Kλis tip speed ratio coefficient. They are the ratio of corresponding real quantity and analog quantity. The subscript of the similarity simulation experiment physical parameters is the letter “S”, but the real physical parameters don’t have subscript. Based on the above definition, the equations are got:

Calculation formula of wind energy utilization coefficient CP(λ,β) given in Ref.[11] is as follows:

(1)

According to the similar simulation conditions ① and ②, the equivalent wind utilization coefficient CPSof similarity simulation experiment can be got and expressed by Eq.(1). Its change rule is similar to Fig.3. The variation trend and the value of the wind energy coefficient utilization remain unchanged, but the similar experimental tip speed ratio is used to represent the corresponding tip speed ratio.

(2)

(3)

(4)

(5)

Eq.(3) is put into the output power expression Eqs (4) and (5). The output power and torque of the similar simulation wind turbine can be got and respectively represented by Eqs(6) and (7), and the change rules are shown in Fig.4 and Fig.5. As you can see from Fig.4, in the partial load area, the wind turbine simulation has the same optimal power curve with the real shape wind machine.

(6)

(7)

When the wind turbine rotational inertia is equivalently simulated, wind turbine is regarded as a disc. Then according to similar simulation condition ③, the wind turbine simulation rotational inertia is as

(8)

Motion differential equations of the system is as follows:

(9)

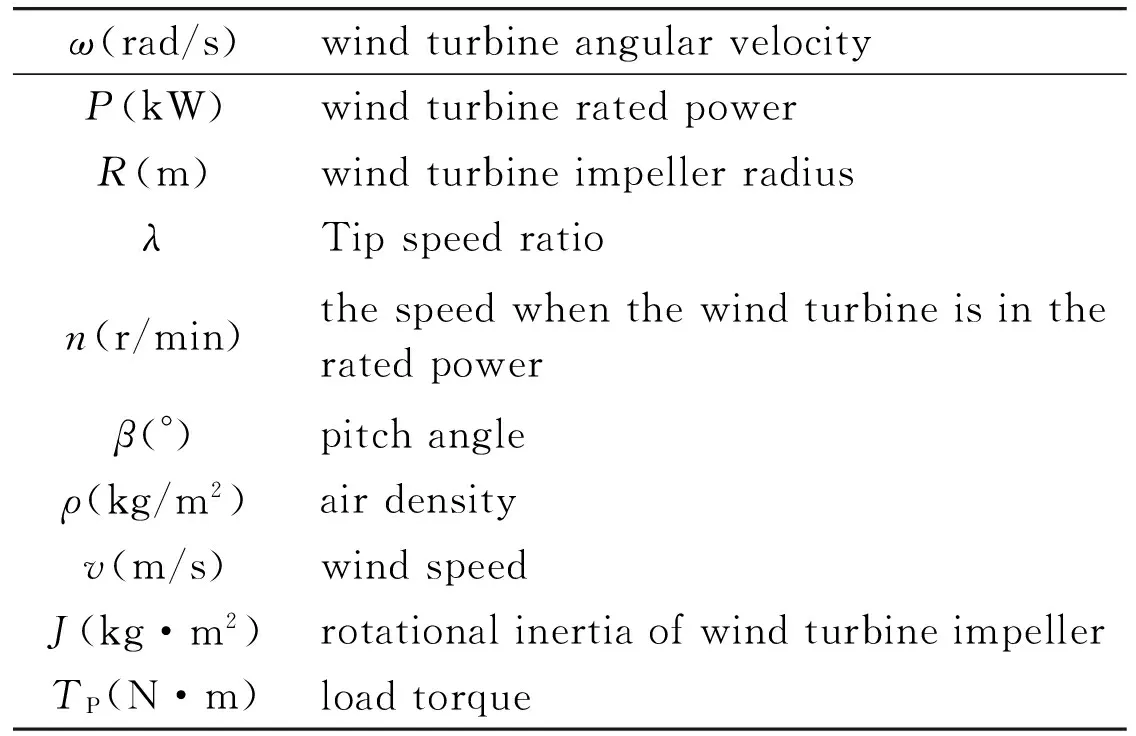

Among them, the significance of each physical quantity is shown in Table 1. The subscript for “S” symbol is the relevant physical quantity of the simulation wind turbine.

Table 1 Significance of each physical parameters

3 The hydraulic transmission part of the 30kVA hydraulic wind turbine

The main transmission system of the hydraulic wind turbine is a fixed displacement pump -variable motor closed system. Transmission process from the output power of the wind turbine simulation system to the power of the grid connection power system can be realized. Its physical map is shown in Fig.2, and the hydraulic principle is shown in Fig.6.

In the loop of fixed displacement pump - variable motor volume speed, the displacement VPof fixed-displacement pump is invariant, speed ωpis variable and the displacement Vmof variable motor is changed. When the system pressure Phis invariant, it has the following characteristics:

(10)

Pm=pωpVp

(11)

where nm——motor speed, r/min ωp——pump speed, r/min Vp——pump delivery, ml/r Vm——the motor's displacement, ml/r Pm——the motor power, kW

1-the motor; 2- the shaft coupling; 3- the fixed displacement pump; 4,12- the pressure sensor; 5,13- the pressure gauge; 6-the high pressure relief valve; 7-the check valve; 8,14- the accumulator; 9-the variable motor; 10- coupling; 11- the generator; 15- the oil supply pump; 16- the oil supplement relief valve; 17-the control overflow valve; 18- the control pump; 19- the back pressure valve; 20- the cooler

Fig.6 The hydraulic system scheme of 30kVA hydraulic transmission wind energy conversion system

The fixed displacement pump - variable motor system of hydraulic wind turbine can realize the control of speed and power through changing the swing angle of variable motor directly or indirectly.

4 The wind turbine grid connection power generation part of 30kVA hydraulic wind turbine

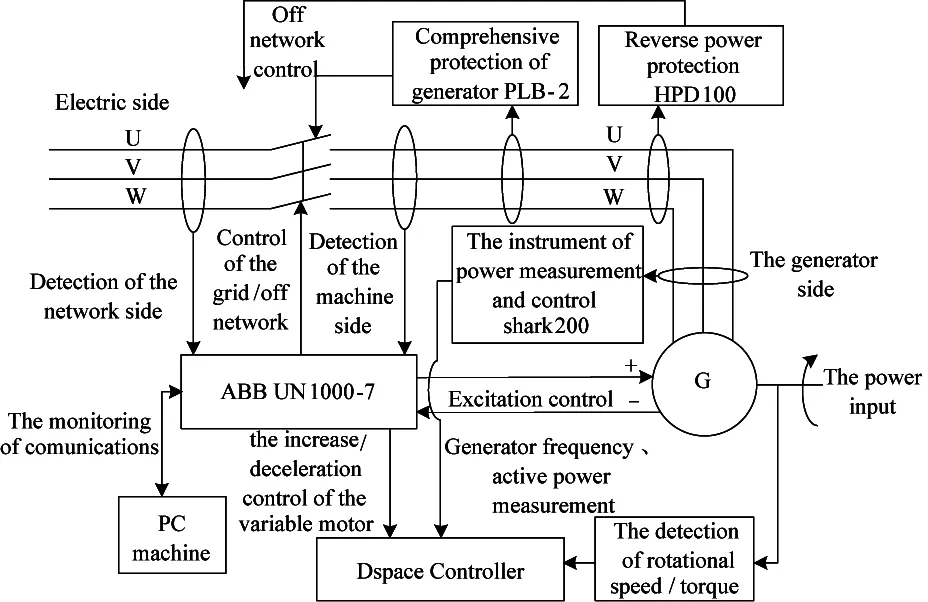

The grid connection power system principle is shown in Fig.7. It mainly realizes the function of single machine synchronization grid connection power.

Fig.7 The grid connection system schematic

Among them, the main switch is alternating current contactor of Siemens TF50 series. Electric quantity detection module Shark200 collects voltage, active power, frequency and the active power current ,and they are converted into analog signals back to the controller system. The generator integrated protection device PLB-2 tests the operation parameters of the generator in real time, and its functions include: over-voltage protection, over-current protection, over-frequency protection, over load protection etc.

Variable motor and excitation synchronous generator are connected rigidly by rotational speed and torque sensor, and the speed is stable in the 1500r/min. Before grid connection, voltage controller UN 1000-7 tests whether the frequency, amplitude and phase of the generator end meet the condition of grid connection. At the same time UN 1000-7 also has other functions such as closing cast net, tripping off network, realizing the frequency regulation through feeding back the frequency signal to the control system etc. Multi-function electric power monitoring and controlling device Shark200 feeds back power signal to the control system to realize power regulation of the cast net.

5 The controller dSPACE part of the 30kVA hydraulic wind turbine

The hydraulic wind turbine control system mainly consists of an industrial control computer and a dSPACE controller. The Matlab/Simulink software is installed in the industrial control computer. After programming, the programs are downloaded to dSPACE controller to execute control function. The industrial control computer shows monitoring interface, and the experimental data is collected and displayed through it. The dSPACE main controller of the experimental platform can debug and collect the data in real time. The main control cabinet of the 30kVA hydraulic wind turbine experimental platform is shown in Fig.8, and the dSPACE controller is shown in Fig.9.

Fig.8 The main control cabinet of the experimental desk

Fig.9 The dSPACE controller of the experimental platform

6 Simulation and experimental research on the control characteristics of the simulation experimental platform

When the simulation and experimental analysis of the control system characteristics is carried out on the 30kVA hydraulic wind turbine simulation experiment platform, the inverter control mode is set to speed control mode. That is, under the condition of constant flow, the research on systematic control characteristic is realized.

6.1 The control of generator speed

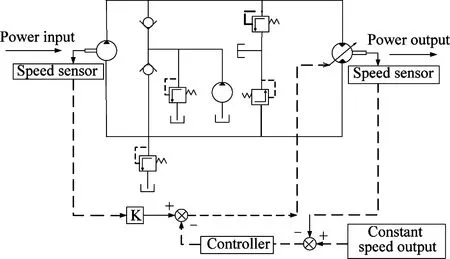

In order to realize the hydraulic wind turbine synchronization, the control of the speed must be carried out. The wind wheel spindle is connected with fixed displacement pump rigidly, and the variable motor is connected with the generator shaft rigidly. Therefore, when the rotating speed of the wind wheel changes, the control of the generator rotational speed equals to the variable motor speed control when the speed of the fixed displacement pump changes.

The speed signal of the fixed displacement pump is detected, then the control signal from controller to the variable motor can compensate the changes of the fixed displacement pump speed. That is, the combined control method is used to realize constant speed control of the system, based on indirect flow feedback and direct speed closed loop control. The control block diagram is shown in Fig.10.

Under the different fixed displacement pump speed, simulation and experimental researches on output speed of the main drive system are carried out on the experimental platform. the specific results are shown in Fig.11.

Fig.10 The constant speed control diagram of fixed displacement pump to variable displacement motor based on flow feedback

As shown in the experiment and simulation curves, when the speed of fixed displacement pump is large, dynamic response of the motor speed is relatively faster, and overshoot is smaller. The reason is that the natural frequency of transfer function about variable motor speed and pendulum angle is proportional to the change of swing angle.

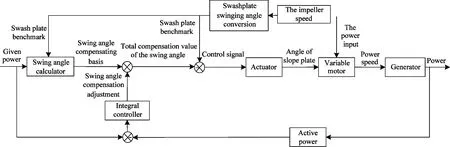

6.2 The control of generator power

For the use of wind energy to the maximum extent, the power of the unit must be controlled. The method is used to control the transmission power of the system, based on the direct control of motor angle compensation value. The specific control block diagram is shown in Fig.12.

Fig.11 The simulation and experiment result of variable motor speed

Under different wind speed, the step signal is given to the variable motor, and simulation and experimental researches on the output power are carried out on the experiment platform. The specific results are shown in Fig.13.

As shown in the experiment and the simulation curves, it is feasible to adopt the direct yaw angle given value method to control transmission power of the system, and ensure the precision of power control.

Fig.12 The power control block diagram of motor swivel angle directly given

7 Conclusion

The structure, composition and working principle of the 30kVA hydraulic wind turbine simulation experimental platform are introduced in this paper. And the wind turbine simulation part, hydraulic transmission part, grid connection power part and controller dSPACE of the hydraulic wind turbine are elaborated in detail. Based on the experimental platform, the experimental and simulation researches on the speed and power control are conducted, and the obtained conclusions are as follows. Simulation and experimental results of rotating speed and power have the same motion trend,and finally the simulation curve and experimental curve coincide, which indicates that the speed and power of the generator can be controlled by the simulation platform under the wind speed change, thus the accuracy and progressiveness of the experimental platform is verified.

Fig.13 The simulation and experimental result of output power

Reference

[ 1] Musial W. Butterfield S. McNiff B. Improving Wind Turbine Gearbox Reliability. In: Proceedings of the 2007 European Wind Energy Conference, Milan, Italy, 2007. 1-10

[ 2] Mortensen K A, Henriksen K H. Efficiency analysis of a radial piston pump applied in a 5MW wind turbine with hydraulic transmission: [Master dissertation]. Denmark: Aalborg University, 2011. 2-3

[ 3] Hamzehlouia S,Izadian A. Modeling of hydraulic wind power transfers. In: IEEE Power and Energy Conference at Illinois (PECI) 2012, Champaign, USA, 2012. 1-6

[ 4] Schmitz J, Vatheuer N, Murrenhoff H. Development of a hydrostatic transmission for wind turbines. In: The 7th International Fluid Power Conference, Aachen,Germany, 2010. 1-12

[ 5] Wu X X. The new trends of wind power equipment. http://www.nea.gov.cn/2012-02/17/c_131416746.htm: National Energy Administration, 2012

[ 6] Ai C, Kong X D, Li H. Simulation study on constant speed output control of fixed displacement pump-variable displacement motor hydraulic system. In: Proceedings of 2011 International Conference on Fluid Power and Mechatronics, Beijing, China,2011. 276-281

[ 7] Ai C. Research on speed control and power control of hydraulic type wind turbine: [Ph. D dissertation]. Qinhuangdao: Yanshan University, 2012. 115-150

[ 8] Kong X D, Ai C, Wang J. A summary on the control system of hydrostatic drive Train for wind turbines. Chinese Hydraulics & Pneumatics, 2013, (1): 1-7 (In Chinese)

[ 9] Kong X D, Ai C, Lou X X. Impact of grid-connecting simulation research of hydraulic wind turbine. Journal of System Simulation, 2012, 24 (9): 2012-2018

[10] Shi M S, Liu H W, Li W, et al. Design of hydraulic transmission system for tidal current turbines and its simulation validation. Automation of Electric Power Systems, 2014, 38(3): 118-122

[11] Siegfried H. Grid integration of wind energy convertion systems. Second Edition. UK: Member of the Institute of Translation and Interpreting, 2002. 43-44

Ai Chao, born in 1982,he received his Ph.D in College of Mechanical Engineering of Yanshan University in 2013.He works in Yanshan University as a lecture and a graduate student tutor, his research interests include fluid power transmission and control, wind power generation and optimization design of hydraulic components.

10.3772/j.issn.1006-6748.2015.03.004

①Supported by the National Key Basic Research Development Program of China (No. 2014CB046405), the National Natural Science Foundation of China (No. 51475406, 51405423) and the Hebei Youth Fund (No. QN20132017).

②To whom correspondence should be addressed. E-mail: xdkong@ysu.edu.cn Received on Nov. 3, 2014***, Liao Lihui***, Chen Wenting***

High Technology Letters2015年3期

High Technology Letters2015年3期

- High Technology Letters的其它文章

- Probability density analysis of SINR in massive MIMO systems with matched filter beamformer①

- An energy-saving scheduling scheme for streaming media storage systems①

- Design and analysis on four stage SiGe HBT low noise amplifier①

- Diversity-multiplexing tradeoff of half-duplex multi-input multi-output two-way relay channel with decode-and-forward protocol①

- Edge detection of magnetic tile cracks based on wavelet①

- Probabilistic data association algorithm based on ensemble Kalman filter with observation iterated update①