Synthesisand Applicationof thePolyether Modified Organic Silicone

TONG Dong-feng LIU Jie ZHAO Chuan-jun

(College of Chemical and Environmental Engineering,Qingdao University,Qingdao Shandong 266071,China)

0 Introduction

The application of silicone softeners turns hard and rough fabric into a soft pleasant textile with which the buyer can expect a high degree of wearing comfort.Silicone have wide spread application in the textile industry from fiber,yarn and fabric production to final product finishing.[1]Polysiloxanes bearing polyether,used for textile finishing,can offer textiles good softness,wettability and antistatic ability,and show great application prospect in natural simulation finishing of synthetic fabrics and blended fabrics.But polyether modified polysiloxane synthesized before should not endow textile with better softness,wettability and washability[2]This papar synthesize a kind of novelpolyether polysiloxane.The experiment employed Eight methyl siloxane,tetramethyl dihydro two siloxane and UPEO.

1 Materials and Methods

1.1 Materials

Eight methyl siloxane(D4),tetramethyl dihydro two siloxane and UPEO,H2SO4.All of the reagents used in this study were analytical grade.

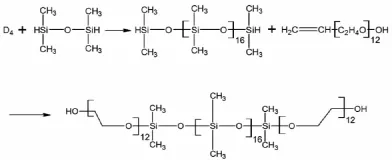

1.2 Synthesis of the Polyurethane modified organic silicone

First of all,Eight methyl siloxane was charged into a four-necked round bottom flask equipped with a mechanical stirrer,a thermometer,a reflux condenser,heating oil bath and a nitrogen gas inlet system.The temperature of the oil bath was increased to a certain temperature.Then some tetramethyl dihydro two siloxane were added to the reaction vessel.When the reaction temperature reached 60-70℃incubated at the beginning after 6 hours at reflux,cooled to normal temperature,the catalyst is neutralized by adding sodium carbonate and allowed to stand stratification,the lower layer discarded consideration of the upper distillation under reduced pressure was raised to 85-100℃removal of low molecular weight.Stop heating is completed,cooling to room temperature,the product was obtained as a colorless transparent.Then based on a molar ratio of allyl polyethers and chloroplatinic acid catalyst solution was added to four-neck flask,connected to a nitrogen,stirred open to the condenser,water bath heating,when the reaction temperature reached 85℃beginning incubated 3 hours at reflux after down to room temperature and filtered to give the product as a colorless and transparent.

Fig.1

1.3 Characterization of the polymer

The Polyether modified organic silicone was determined by the FTIR spectra.

Physical parameters such as emulsion stability,emulsion appearance and PH value of the polyurethane modified organic silicone were shown.Emulsion stability was evaluated by storage time.The emulsion state remains the same under the certain storage time.

1.4 Testing methods

The wettability properties of the fabrics were tested through AATCC-2000 standard methods.

The softness was evaluated by hands feel method,which needs at least 3 people subjective assessment.

2 Results and Discussions

2.1 Molecular structural characterization

Fig.2 T he FT-IR spectra polyether modified organic silicone

Fig.2 showed the FT-IR spectra of the polyether modified organic silicone.The bands at 2900 cm-1and 3475 cm-1were assigned to C-H and O–H bonds which appear on polyether modified silicone.The strong absorption at 1250 cm-1was due to Si-CH.The bands in a range of 1150-1100cm-1were due to C-O-Cand Si-O-Si.The peak at 835 cm-1was assigned to Si-CH3 bond.These showed that the polyether modified organic silicone has been modified successfully.

2.2 Physical characterization

Tab.1 Physical characterization of the polyether modified organic silicone

Tab.1 showed physical parameters such as solid contents(%),emulsion stability,emulsion appearance and PH value of the polyurethane modified organic silicone.It can be seen that PH value was 6-7 and emulsion appearance was yellowish.At the same times,it clearly indicated that emulsion stability 3 months.

2.3 SEM images of the polymer

Fig.3 T he scanning electron microscope of cotton fabric

Fig.3 showed the scanning electron microscope analyses of surface changes of cotton fabric with the polyether modified organic silicone.Fig.2(a)showed the rough surface of cotton fabric.There were many tiny grooves.When SEM images in Figs.2(a)and(b)were compared,it was clear that the cotton fiber of Fig.2(b)were covered with the polyether modified organic.It was considered that the polyether modified organic silicone had been attached to the fiber surface.

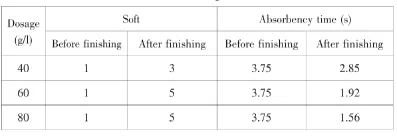

2.4 Effect of fabric wet rubbing fastness

Table2 Rubbing fastness properties of cotton fabric after finishing

Tab.2 showed the effect of fabric treated with polyether modified organic silicone.It was revealed that the softness of the cotton fabrics was improved from rating 1 to rating 5.After the polyether modified silicone finishing fabric has good wettability.The reason of the phenomenon may be that the polyether segment has good wettability and the fiber orientation in the surface film.So a silicone bonded to or adsorbed on the fiber surface.Then the hydrophilic polyether segment outwardly and toward the air.

3 Conclusions

In summary,we have successfully synthesized polyether modified silicone polymers with Eight methyl siloxane,tetramethyl dihydro two siloxane and UPEO as raw material.Polyether modified organic silicone polymer emulsion which is a kind of very good agent for hygroscopicity,can make the absorbency time of the fabric keep 1.56s.In addition,the softness of treated cotton fabrics was excellent.S

[1]Naghash Hamid Javaherian,Abili Baharak.Synthesis of a Silicone Containing Allylic Monomer and its Uses in the Waterborne Polyurethane/Vinyl acetate-Acrylic Hybrid Emulsion Copolymers[J].Progress in Organic Coatings,2010,69:486-494.

[2]Li ge,An qiufeng.The new polysiloxane polyether-based synthesis,characterization and application of basic research[D].Shanxi University of Science and Technology,2009.