Experimental study on milling tool life for SKD11 steel and optimization of cutting parameters*

Jun-min XIAO

Department of Mechanical and Electrical Engineering,Zhongshan Polytechnic,Zhongshan 528404,China

Experimental study on milling tool life for SKD11 steel and optimization of cutting parameters*

Jun-min XIAO†

Department of Mechanical and Electrical Engineering,Zhongshan Polytechnic,Zhongshan 528404,China

In order to improve tool life for hardened steel SKD11 during the milling process,the related milling experiments are carried out and the influence of cutting parameters on tool life is analyzed based on range method.It is found that the influence of axial cutting depth on tool wear is pretty strong,and the influence of radial cutting width on tool wear is very weak.Based on the milling experiments,the mathematical model of tool wear is established by using of regression analysis method.In order to solve the actual milling problem,the cutting parameters are optimized by using of SQP optimization method based on MATLAB software.During the optimization process,the machining efficiency and the tool wear quantity are set as the objective function.The optimized cutting parameters could greatly improve the machining efficiency in the premise of ensuring smaller tool wear,and it provides the important theory evidence and case reference for NC machining enterprises to reduce com positive production costs.

Tools life,Wear,Machining efficiency,Mathematical model,SKD11

1.Introduction

Tool life is not only an important indicator to evaluate the reliability and performance of cutting tool,but also is the basis for the optimization of cutting parameters and tool design,and makes the strategy of automatic tool change and tool requirement planning. Therefore,it is very necessary to predict and evaluate tool life reliably[1].Many Chinese and foreign scholars have carried out scientific research about cutting tool life from different academic directions. For example,Alauddin studied the influence of cutting speed,feed rate and axial cutting depth on tool life by using the response surface method,and established tool life formulas[2].Tsai et al studied the effect of cutting parameters on tool life based on a new network proposed by Tsai.This network could automatically select the optimal number and node type by applying PSE criterion,and the prediction accuracy is much higher than the neural network[3].LI Xuanqi,et al carried out some related experimental study on tool wear for titanium alloy and analyzed the influence of tool geometry parameters on tool wear,and the conclusion was drawn as follows:the larger spiral angle is helpful to improve the tool life[4].WANG Xiaoqin et al carried out the related research of tool life for Ti6Al4V material and constructed the tool life model.The optimized parameters were obtained by drawing the curves of tool life and machining efficiency in the paper[5].The hardened steel SKD11 has a very high hardness,and its hardness can reach HRC58-62.It is widely used in the field of plastic mold and die due to its good mechanical properties.Since the hardened steel SKD11 has relative high hardness,the cutting tool by using this kind of material is always subjected to high cutting stress and high temperature environment in themilling process,which will directly shorten the service life of milling cutters[6].The rapid wear of milling tool will significantly increase the auxiliary production time and greatly improve the tool cost,so it is very important for milling hardened steel to improve tool life by optimizing cutting parameters.

2.Experimental conditions and results

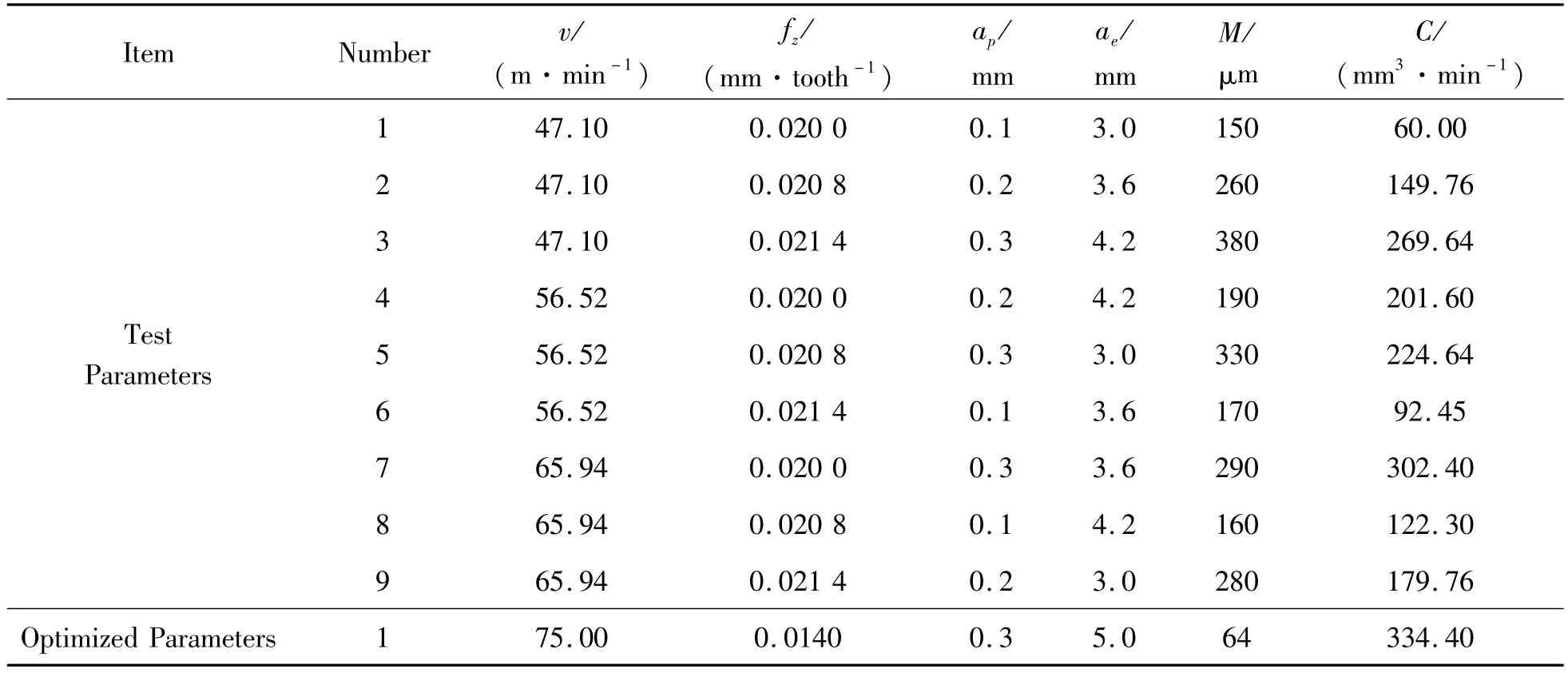

The CNC machining center of VMC650E type is used in milling experiments of tool wear.The workpiece material used in the experiments is the hardened steel SKD11,and the hardness is up to HRC58. The end-mill cutters of solid carbide with TiAlN coating are adopted during the machining process,and the tooth number of milling cutter is 4 and tool diameter is 6 mm.The work-piece blank is the cube and the size is 100×100×30(mm3).The range of cutting parameters is as follows:The spindle speed is 2 500 r/min,the feed is200~300mm/min,the axial cutting depth is 0.1~0.3 mm and the radial cutting width is 3.0~4.2 mm.The ZIG-ZAG reciprocating cutting way is adopted in the milling process. Based on the four parameters of cutting speed,feed rate,axial cutting depth and radial cutting width,the L9(34)orthogonal milling experiments are designed and carried out according Taguchi method,and the experimental data as shown in Table 1 could be obtained[7].

Table 1.The experimental data o f too lwear

3.Analysis of experimental data

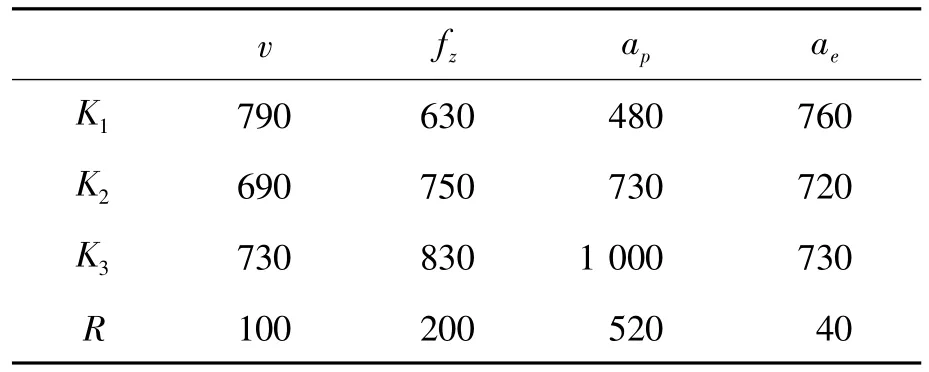

The analysis content about tool wear quantity M as shown in Table 2 could be obtained based on the range method.Ki(i=1,2,3)represents the sum of test results with the same level in each column.R is the range value of factors,and its expression is as follows:R=max(K1,K2,K3)-min(K1,K2,K3).The range value in each column is different according to Table 2,and which means that the influence of different factors on test data is different.The bigger range value of one factor shows that it has greater influence on tool wear.According to the experimental data of Table 2,the conclusions could be drawn:the influence of axial cutting depth on tool wear is the strongest,and the influence of radial cutting width on tool wear is the weakest.

Table 2.The range analysis of tool wear

4.Construction of prediction model

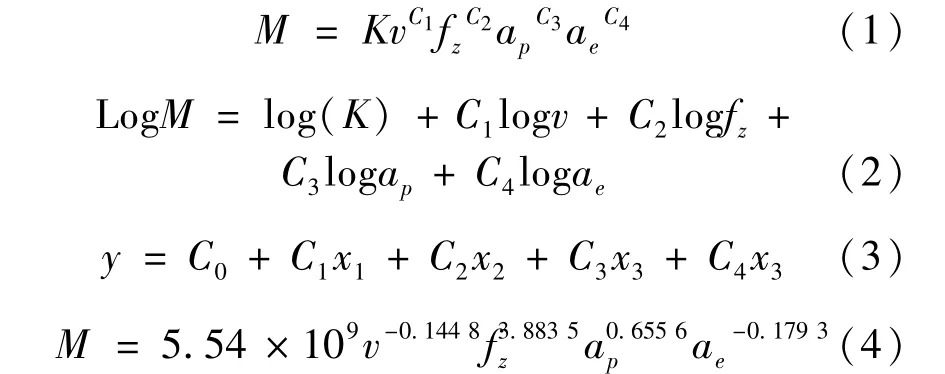

The prediction model of tool wear as shown in Eq.1 could be constructed in the premise of considering the four factors of cutting speed,feed rate,axial cutting depth and radial cutting width.The meaning of parameters in Eq.1 are as follows:M represents the tool wear quantity(Units:μm),K represents comprehensive coefficient of milling conditions,v represents cutting linear velocity(Units:m/min),fzrepresents feed rate per tool-tooth(Units:mm/tooth),aprepresents axial cutting depth(Units:mm),aerepresents radial cutting width(Units:mm).Since the equation as shown in Eq.1 is a typical nonlinear function,it is necessary to convert Eq. 1 into linear function as shown in Eq.2.If y=Log M,C0=log(K),x1=log v,x2=log fz,x3=log apand x4=log ae,then the complex linear equation as shown in Eq.2 could be converted into the equation as shown in Eq.3.Based on the experimental data as shown in Table 1,the corresponding coefficients in Eq.3 could be solved through multiple linear regression,and the value of corresponding coefficients in Eq.3 are as follows:C0=9.743 7,C1=-0.144 8,C2=3.883 5,C3=0.655 6,C4=-0.179 3.Therefore,the model of tool wear for hardened steel SKD11 as shown in Eq.4 could be obtained.

In order to evaluate the fitting degree of the prediction model of tool wear,the significance testing for the regression equation as shown in Eq.4 should be carried out by using of statistic F.The law of significance testing of statistic F is as follows:n represents the number of experiments,m represents the number of variables,the significant level is set as 0.05;if F<F0.05(m,n-m-1),then the regression equation can not be trusted;if F>F0.05(m,n-m-1),then the regression equation can be trusted.In this paper,m is 4 and n is 9,the value of F0.05(4,4)can be obtained by consulting F distribution table,and it is 6.39.Based on the equation as shown in Eq.5,the F value of the prediction model could be obtained according to experiments data,and it is43. 38.Because F>F0.05(4,4),so the prediction model of tool wear in this paper is very significant,and it can predict the tool wear accuracy in the machining process.The meaning of parameters in Eq.5 is as follows:SArepresents regression sum of squares,SErepresents the residual sum of squares.

5.Cutting parameters optimization

5.1.Objective function

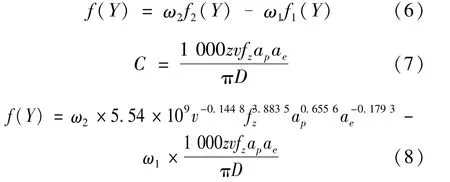

In order to improve the machining efficiency and reduce tool wear in milling process,the material removal rate is set as objective function f1(Y)and the tool wear quantity is set as objective function f2(Y).Based on function f1(Y)and function f2(Y),one new objective function f(Y)could be constructed by using unified objective function method,and multi object function can be converted to a single objective model[8].If the weight coefficient of function f1(Y)isω1and the weight coefficient of function f2(Y)is ω2,then the unified objective function as shown in Eq.6 can be obtained.The material removal rate as shown in Eq.7 can be obtained according to cutting material volume per unit time.The meaning of parameters in Eq.7 is as follows:C represents material removal rate(Units:mm3/min),z represents the number of cutter tooth,D represents tool diameter. The objective function f(Y)as shown in Eq.6 can be converted into a new objective function as shown in Eq.8.On the basis of experience,the value ofω1is set as0.8 and the value ofω2is set as0.2 in Eq.8.

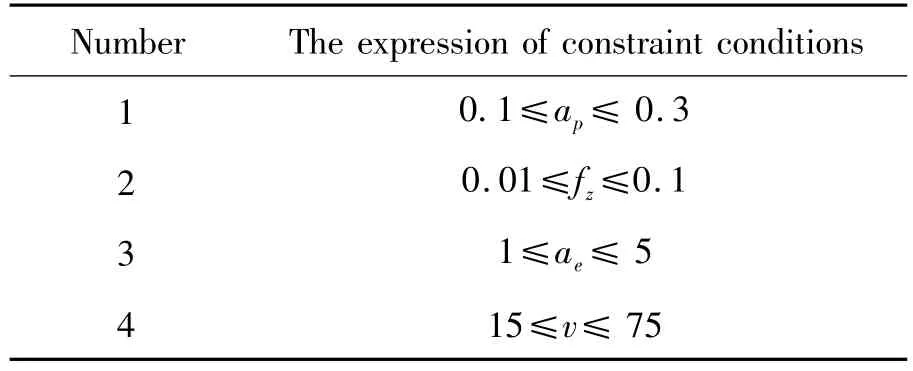

5.2.Constraint conditions

In order to ensure the rigidity of the milling cutters,the axial cutting depth has a certain range;due to the limit of the performance of milling cutters,the feed rate per tool-tooth must has a scope limitation;according to cutting experience,the radial cutting width generally should not exceed 85 percent of tool diameter.On the basis of the above analysis,the constraint conditions as shown in Table 3 could be obtained.

Table 3.The constraint conditions for Eq.8

5.3.Solution of optimized cutting parameters

At present,there are many optimization methods for solving constrained nonlinear minimization problems with multiple variables,such as sequential quadratic programming(SQP),genetic algorithm(GA),particle swarm optimization(PSO),artificial neural nets(ANN)[9-10].Genetic algorithm is a random algorithm,and it can not obtain certain solutions;particle swarm optimization is easy to fall into local solution,and most likely it can not obtain the optimal solution;artificial neural nets algorithm requires a large number of sample data,and its solution is not very reliable.Because the solution results based on SQP are very reliable and the programming of SQP is simpler than other optimization methods[11],the SQP is adopted for solving the optimizedcutting parameters in this paper.The programming of SQP has three steps and they are as follows:(1)update Hessian matrix of Lagrange function,(2)solve quadratic programming problem,(3)search target and calculate objective function.Based on MATLAB software,the computer program for solving the minimization problem is written,and the solution results could obtained as follows:Cutting velocity v=75 m/min;feed rate fz=0.014 mm/tooth;axial cutting depth ap=0.3 mm and radial cutting width ae=5 mm.Based on Eq.4 and Eq.7,the tool wear quantity and machining efficiency could be obtained by using the above optimized cutting parameters,and which are 63.7μm and 334.4mm3/min.In order to better reflect the effect of optimization,comparison of parameters optimization about tool wear quantity and machining efficiency as shown in Table 4 are obtained in this paper.

Table 4.Comparison of parameters optimization

6.Conclusion

Based on the range analysis of experimental data,the conclusions are drawn as follows:the strongest influence on tool wear is axial cutting depth,followed by feed rate,cutting velocity and radial cutting width.Therefore,in order to reduce tool wear,smaller axial cutting depth and feed rate should be adopted in a machining process.Based on cutting experiments,the prediction model of tool wear for SKD11 steel has been constructed by using of regression method.It has been confirmed that the prediction model as shown in Eq.4 has very high credibility through the significance testing of regression equation.A unified objective function could be constructed based on machining efficiency and tool wear quantity,and by which the optimized cutting parameters could be solved based on the SQP optimization method and MATLAB software.Optimized cutting parameters obtained in this paper could greatly improve the machining efficiency in the premise of ensuring smaller tool wear.

[1] PAN Yongzhi,AI Xing,WAN Yi.Development of an Off-line Tool-life Prediction and Management System[J].Journal of Manufacturing Technology&Machine Tool,2008,15(8):114-117.

[2] Alauddin M,Baradie M A.EI.,Hashmi M S J.Prediction of tool life in end milling by response surface methodology[J].Journal of Materials Processing Technology,1997,71:456-465.

[3] Tsai M K,Lee B Y,Yu SF.A predicted modeling of tool life of high-speed milling for SKD61 tool steel[J]. Intermational Journal of Advanced Manufacturing Technology,2005,26:711-717.

[4] LI Xuanqi,FAN Wei,YANG Gang.Experimental study on milling tool wear of titanium alloy[J].Journal of MECHANICAL ENGINEER,2008(5):56-57.

[5] WANG Xiao-qin,AI Xing,ZHAO Jun.Research on Tool Life in Ti6Al4V Milling with Coated Carbides and Cutting Parameter Optimization[J].JOURNAL OFWUHAN UNIVERSITY OF TECHNOLOGYl,2008,30(10):109-112.

[6] Jing Lulu,Shen Zhong,Chen Ming.Experiment on Surface Integrity of Milling Tool for Hardened Steel SKD11[J].Journal of Transactions of Nanjing University of Aeronautics&Astronautics,2007,24(2):157-163.

[7] ZHANG Mianhao.Research on Cutting Parameters Optimization based on Tool Life[J].Journal of NEW TECHNOLOGY&NEW PROCESS,2011(9):70-73.

[8] SHUI Yongbo,DING Weiping,YANG Mingliang.Multiple Objectives Optimization Design of Suspension Parameters of a Certain Car[J].Journal of Machinery Design&Manufacture,2013(7):56-59.

[9] ZHANG Gang,ZHU Mingbo,CHEN Yu.3D Trajectory Optimization of the SAR Imaging Seeker Based on SQP[J].Journal of COMPUTER ENGINEERING&SCIENCE,2012,34(4):145-150.

[10]WU Liang-hong,WANG Yao-nan.Research on Differential Evolution Algorithm for MOPs[J].Journal of Journal of Hunan University:Naturnal Science,2009,36(2):53-57.

[11]MA Li.Mathematical Experiments and Construction[M].Beijing:Tsinghua University Press,2010.

摘要:根据珍珠岩吸音板压制工艺和生产要求,设计了一种双向压制液压机液压系统。基于AMES-im软件,建立了该液压系统的仿真模型,对各工作缸的相关动态特性进行了分析。通过流量-时间关系图和压力-时间关系图可知:该系统的设计可满足生产需要,具有可行性,为实际液压系统的设计和参数优化提供了依据。

关键词:液压成型机;AMESim;仿真研究

中图分类号:TP273

SKD11铣削刀具寿命试验研究及工艺参数优化*

肖军民†

中山职业技术学院机电工程学院,中山 528404

为提高SKD11模具钢铣削刀具的寿命,对SKD11模具钢进行了刀具寿命铣削试验,基于极差方法分析了各工艺参数对刀具寿命的影响规律。基于刀具寿命铣削试验,利用多元线性回归方法,推导并求解出了SKD11模具钢铣削刀具磨损的数学模型。利用最优化设计方法和MATLAB优化工具箱,以加工效率和刀具磨损为目标函数,针对实际的铣削问题优选了工艺参数。优化的工艺参数能兼顾刀具寿命和加工效率,为加工企业降低综合生产成本提供了重要的理论依据和案例参考。

刀具寿命;磨损;加工效率;数学模型;SKD11

TG714;TG54

珍珠岩吸音板成型机液压系统设计与仿真研究

肖艳军†,朱嘉钰,和利虎

河北工业大学,天津 300130

10.3969/j.issn.1001-3881.2014.18.022

2014-05-13

*Project supported by Fostering Plan for Outstanding Young Teachers in Higher Education Institutions of Guangdong Province(Yq2013195)

†Jun-min XIAO,Associate professor.E-mail:xiaojunmin517@

163.com

- 机床与液压的其它文章

- Design and application of attitude measuring device for DC power output filter circuit

- Developing deburring device based on burr formation principles*

- Application research on three-phase inverter with space-vector pulse modulation*

- Glowworm swarm optimization algorithm merging simulated annealing strategy*

- Comprehensive obstacle avoidance system based on the fuzzy control for cleaning robot

- Implementation of wireless communication and real time control for CNC system of embedded CNC turret punch press*