Research on the inference of CNC machine fault based on Bayes and FTA

Bin SHEN,Yi-shun SU,Shu-yu ZHAO

The Sino-German School for Postgraduate Studies,Tongji University,Shanghai201804,China

Research on the inference of CNC machine fault based on Bayes and FTA

Bin SHEN,Yi-shun SU†,Shu-yu ZHAO

The Sino-German School for Postgraduate Studies,Tongji University,Shanghai201804,China

Due to the complexity of the fault tree,the fault tree will firstly be decomposed to obtain sub-modules with similar modular structure,and also the module library will be built to store the sub-modules.This paper will introduce the basic processes and principles of feature-retrieval based on module library.In order to avoid repetition retrieval and NP problem,the concept of valid module will be introduced,that is to not only consider the hierarchy relationship of the event in fault tree,but also consider the affiliation between each event when traversing module library.Finally,this paper studies an optimal sorting method of importance based on Bayesian theory and also makes the importance correction.The core component of this paper is to build the module library based on the basic modular structure,and also introduce the concept of valid module as well as optimal sorting of importance based on Bayesian theory on the minimum cut sets.The present study result indicates that this method can effectively reduce the solving size,accelerate the speed of diagnosis,and improve the credibility of importance sorting as well.

Modularization,Effective modular,Fault tree,Minimal cut sets,Traversal search

The application of CNC machine in modern manufacturing has become widespread.In practical production,if we can make right judgment timely of the CNC machine fault,ascertain the fault part,find out the reason and remedy with lower maintenance costs and in a short period,then it could greatly reduce the maintenance blindness and also improve the production economy and security[1].In the early 1960s,Bell-Labs in American firstly used the FTA method,and random failures of the militia missile launch control system were successfully predicted. Subsequently,Boeing developed computer program based on the FTA to improve aircraft.The study of FTA used in CNC machine fault diagnosis started in the past few years.The CNC machine fault diagnosis is mainly based on the rules and case-based,but methods have their disadvantages,i.e.,the existed cases are few,and rule-based is always stored in redundant and non-logical,which makes the application of FTA become a trend.Fault tree analysis is a good method to make security and reliability analysis of complex systems,it can obtain good result in running and maintaining CNC machine by using the fault tree analysis to predict and diagnose fault[2].

1.The key elements of fault tree diagnosis inference

1.1.Modular decomposition of fault tree

CNC machine system is very complex,and the fault tree it generated is very large.Thus,fault tree for making relatively qualitative and quantitative analysis of fault tree seems very difficult[3].In order to make better analysis of fault tree,it is usually necessary to simplify the fault tree.At present,modular analysis of fault tree is a very effective simplified method for fault tree.The modular decomposition algorithm generally uses DFLM twice.

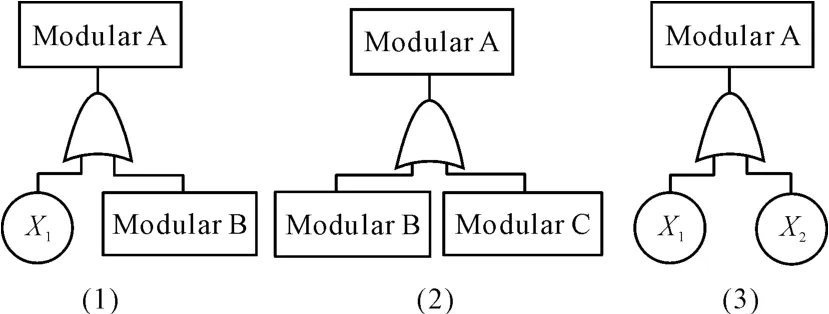

1.2.Basic structure of fault tree modular

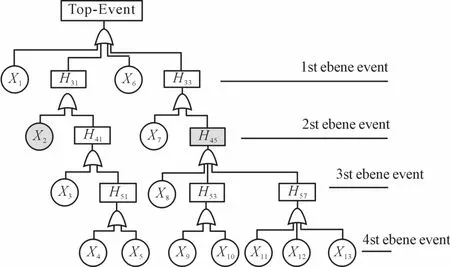

Through the modular analysis of fault tree,one could get three basic modular structures as shown in Figure 1.The basic modularization structure of fault tree is a binary tree,which is composed of two layers.The first layer mainly is“modular Top-event”,and the second layer is random combination of“submodule events(i.e.intermediate events)”and“module end events”.The two layers are connected by logical symbols“and”or“or”.Since there is little redundancy protection of CNC machine,this paper doesn’t put“and”into consideration.

Figure 1.The basic modular structure

1.3.Fuzzy search of fault tree modular library

When traversing the modular library,one should firstly obtain the feature information which is needed to be retrieved.Judging from the instruction form of fault,CNC machine fault includes fault with alarm display and fault without alarm display[4].Thus,the basic information obtained from fault diagnosis includes not only the alarm display from CNC machine itself,but also the alarm display from pilot lamp. This information has to be described by maintenance staff.Of course,one could not exclude that the fault description from maintenance staff is same to the fault reason of alarm.Therefore,after obtaining the information of these two respects,the inference engine should transfer the alarm into fault description,and also remove duplicate with the fault description from maintenance staff.After removing duplicate of phenomenon description,the inference engine can regard every independent phenomenon as feature to go into successively retrieval phase.The retrieval object is the fault tree modular library.Before retrieval,one will firstly introduce the significance of the introduction of valid modular.

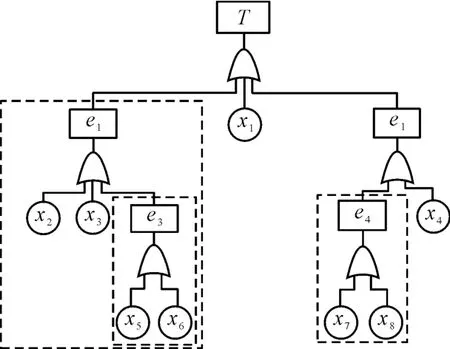

2.The introduction of valid modular and its meaning

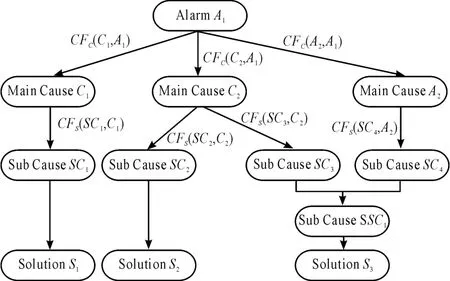

Generally,once the basic feature of fault is certained,one could start to locate every feature in fault tree,and find out the corresponding modular name in fault tree.In order to obtain the prime reason of fault(i.e.,the traversal of bottom event),one just needs to treat every feature modular name as Top-event,and then Downward-searching.However,there exists a problem of this method,i.e.,if there is one feature modular name which is below the sub-fault tree another modular name corresponded to,then it will lead to repeat retrieval when making bottom event traversal of sub-fault tree.Besides,if there are a lot of fault features,then it will lead to a substantial increase in retrieval workload,and that is so-called“NP”problem.For example,as shown in Figure 2,there are three fault features,e1,e3and e4,and e1includes e3,while e4is from an independent sub-fault tree.When one traverses e1and e3,respectively,it will generate repeat traversal in fact.Therefore,the aim of introducing the valid fault tree is to avoid repeat traversal of fault tree.Thus,the design of event library should not only consider the hierarchy relationship of the event in fault tree,but also consider the affiliation between each event(parent-child relationship).

Figure 2.Multi-Ebene Fehlerkennfeld

3.The process of inference based on module library

3.1.Basic process and principle of feature-retrieval

3.1.1.Basic process of retrieval

1)Firstly,traversing every fault feature in framework library and locating every feature in fault tree(i.e.,corresponding event).Reading the hierarchy and subordinate frame name that the feature-event corresponded to from event library,and as to fault feature which is subject to a sub-fault tree,treating the highest level of fault features hierarchy as the Top-event of this sub-fault tree.

2)Secondly,traversing every sub-fault treewhose fault feature is treated as Top-event,i.e.,to retrieve the sub-frame and embody the notch(modular bottom event).After the sub-frame expanding,retrieving other units of the second layer level of this frame.And if it retrieves and discovers that the sub-frame exists,then it should continue to retrieve the frame this sub-frame corresponded to.Before start to retrieve the next frame,the inference will automatically embody this frame as valid frame and also embody all the notches existing in this frame at the meantime.Continuously downward-searching the sub-frame,until the sub-frame does not appear any more.

3)As to the fault tree system which only have“or”logical connection,the final minimum cut sets of the modular are usually the set of bottom events,i. e.,the bottom event can be regarded as the prerequisites of the deriving rules.

3.1.2.Two prior principles

1)If the fault node exists in the bottom event,then embody it and regard it as the top priority of importance.

2)Through traversal searching,it will generate new bottom events,and their importance could get the sub-priority.

3.2.The composite fault frame based on valid fault modular

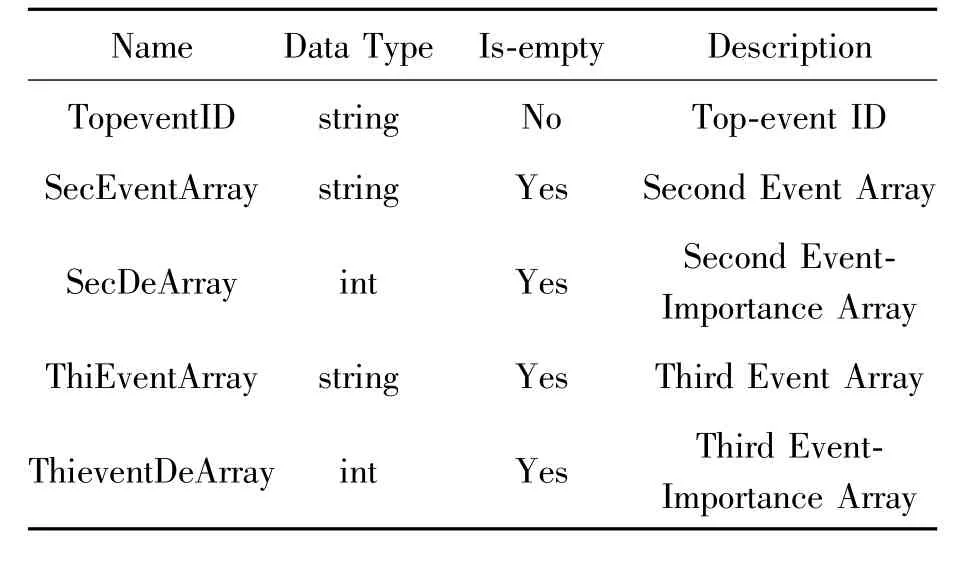

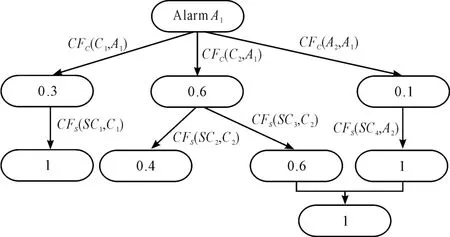

Through fuzzy retrieving of fault tree modular library and obtaining the valid modular,one could arrange these modular according to the fault modular synthetic table as shown in Table 1,and then one could get the fault frame figure as shown in Figure 3. Thus,one can just solve the minimal cut sets according to this valid synthetic fault frame.This method greatly simplifies the calculation process,and makes the final minimum cut sets obtained much more effective simultaneously.

Table 1.The com posited frame of fault-modular

Figure 3.The fault tree for the composited frame of fault-modular

4.Bayesian calculation of importance based on the whole valid fault modular

4.1.Bayesian theoretical basis and method

The basic point of Bayesian method is that every unknown variable X could be regarded as a random variable,and its unknown can be described by a probability distribution.This probability distribution is a probability description of the existing prior information of variable X before sampling.This probability distribution is called prior distribution or prior in short.Either unknown variable has uncertainty,probability and probability distribution are the best way to describe the uncertainty degree.As a new method to process the uncertainty knowledge,Bayesian method has a certain theoretical basis of probability theory and could well express knowledge structure.Thus,it aroused extensive attention,and it has been adopted in many areas to obtain satisfactory results.Especially in fault diagnosis field,there still has big development room besides the previous study. Therefore,it has a significant study value and good development prospect.At present,Bayesian method has been successfully applied into many areas,such as aerospace fault diagnosis,defense systems,industrial fault diagnosis and pattern recognition.And the most successful application is the application of fault diagnosis area.

Bayesian method is used to elaborate system and solve statistical problem based on Bayesian theorem. By using Bayesian method,the possibility of every cause could be back-inferenced through the phenomena of events[5].Because of its outstanding ability of dealing with the uncertain information from events with complex causality,Bayesian network is applied into fault diagnosis.

4.2.Bayes’theorem

The substance of total probability formula is to integrate the various causes of events to infer the possibility of events[6].But in reality,one usually needs to analyze the causes of events if the known events already have taken place.For example,under the above hypothesis of total probability,known event A occurred,then how to get the occurring possibility of event B,PSolution of this question leads to the Bayes’theorem.

Bayes’theorem:suppose the sample space of experiment E is S.A is an event of E.B1,B2,B3…are a division of S,and P(A)>0,P(Bi)>0,i=1,2,…,n,theni=1,2,…,n.This formular[7]provides a method to calculate the posterior probability through the prior probability.

Figure 4.The composited frame of faults

Figure 5.Event importance distribution

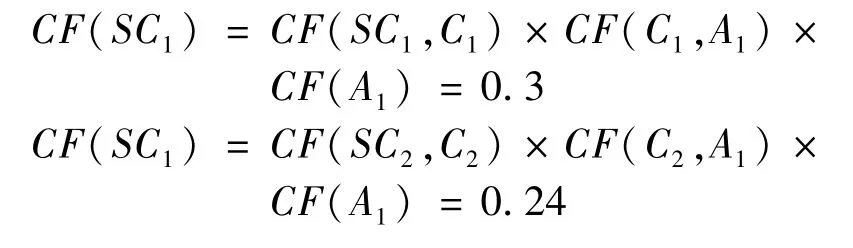

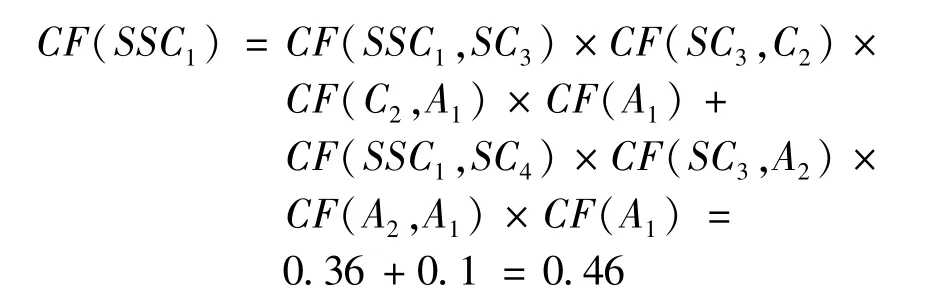

Through CF(A)=CF(A/B)×CF(B),we can get that:

Thus,the importance sorting of these three bottom events are:SSC1>SC1>SC2

5.Importance correction

When making importance calculation,the occurring importance of every event in modular is given by the experts in field who will combine knowledge and experience to make professional assessment and then give the result.Therefore,it has an important reference value.However,the“phenomenon descriptions”on fault diagnosis interface inputs are usually given by operators who intuitively get the suspected failure point based on the actual failure site,and it is the easiest to be excluded by operators,especially when“phenomenon descriptions”are modular bottom events,they will have a high importance. Therefore,the aim of importance correction is to treat the known phenomenon descriptions in inputs as prior investigation objects.

6.Conclusion

This paper build the modular library based on the basic modular structure,and introduced the concept of valid modular and also optimal sorting of importance for minimal cut sets based on Bayesian theory.The introduction of valid modular effectively reduces the workload of traversal search on fault tree,which will greatly improve the solving speed and the efficiency.Besides,optimal sorting of importance on minimal cut sets based on Bayesian theory couls well enhance the credibility and accuracy of troubleshooting,and the diagnostic capabilities and speed are also satisfied.

[1] Bo-sheng YE,Zeng-shuang HUANG,Bin LI.Study on fault diagnosis system for CNC machine tools based on fault tree analysis[J].Machinery Design&Manufacture,2006(8):135-137.

[2] Xun SUN.The study of fault diagnosis algorithm based on FTA[D].Dalian:dalian university of technology,2009.

[3] Wen-bin LIU.Research on dynamic fault tree analysis method based on modularization[D].Nanjing:Nanjing University of Science&Technology,2009.

[4] Na YANG.Research on no-alarm display to fault diagnosis and repair for CNC machine[J].Mechanical and E-lectrical Information,2013(12):41-42.

[5] Jian-chuan LI,Niao-qing HU,Guo-jun QIN,et al. Bayesian network theory and its application in machine fault diagnosis[J].China mechanical engineering,2003,14(10):896-900.

[6] Ning FAN.Research on inference algorithm in Bayesian network for fault diagnosis[J].Information technology,2011(3):158-161.

[7] Zhou SHENG.Probability theory and mathematical statistics[M].Beijing:Higher Education Press,2008.

Weihai HHH Mach.&Elec.Group

Weihai HHH Mach.&Elec.Group is the most technical company focusing on Power transmission and Hydra-controlling.HHH has the ability of developing and testing of complete sets of transmission system with relevant technical training.HHH provide efficient,excellent cost-effective power transmission system and intelligent electric fluid transmission and control system to OEM customers,who are was dedicated to the industry of off-highway machinery,agricultural/forestry machinery,petroleum machinery,metallurgical/mining machinery,shipbuilding,airport and firework vehicles.

As the only authorized maintenance center of the of SAUERDANFOSS-DAIKIN in Asia,and maintenance center of SAMPO,FAIRFIELD in China,HHH has a professional repair team and a repair network over the country.At the HHH maintenance center,there a 250KW test bench for the testing of hydraulic and electric unit before delivery.

Address:No.71 Yihaiyuan,WenHuaXiRoad,Weihai ShanDong,P.R.China

Post code:264209 Tel:0631-5626907 Fax:0631-5620300

Toll-free hotline:400-6612-699 E-mail:info@hhh-fec.com http://www.hhh-fec.com

基于Bayes和FTA的机床故障推理研究

沈 斌,苏依顺†,赵淑玉

同济大学中德学院,上海 201804

由于机床故障树的复杂性,通过对故障树进行模块化分解得到具有相似模块结构的子模块,并建立模块库进行存储。介绍了基于模块库的对故障特征进行检索的基本流程和原则,同时为了避免重复检索以及NP问题的产生,引入了有效模块的概念,即在遍历模块库时,不仅要考虑事件在故障树中上下层级关系,也要考虑各事件之间的从属关系。最后研究了一种基于贝叶斯理论的重要度最优排序方法并进行重要度校正。核心是引入了有效模块的概念和对最小割集进行基于贝叶斯理论的重要度最优排序。结果表明:该方法能有效缩短求解规模,诊断速度快,重要度排序可信度高。

模块化;有效模块;故障树;最小割集;遍历检索

TH327

10.3969/j.issn.1001-3881.2014.18.002

2014-05-15

Bin SHEN,Professor.†Yi-shun SU,E-mail:su_yishun@163.com

- 机床与液压的其它文章

- Electro-mechanical power coup ling system for PHEV with high price-performance ratio*

- Design of 20 t forging manipulator clam p rotation hydraulic control system*

- Particle removal by an oscillating bubble in the pipe*

- Design and application of attitude measuring device for DC power output filter circuit

- Simulation of automobile ESP system based on fuzzy control*

- Research on multi-axial multi-excitations road simulation test method for AMT actuator*