Molten Carbonate Fuel Cell Combined Heat, Hydrogen and Power System: Feedstock Analysis

Yousif M. Hamad; Tarek A. Hamad; Abdulhakim A. Agll; Kevin B. Martin; Mathew Thomas; Sushrut G. Bapat;

Highlights

Biogas can be produced from wastewater, organic, agricultural and industrial waste.

Biogas produced from these feedstocks is a potential source of renewable energy.

Methane present in biogas can be used to fuel a Molten Carbonate Fuel Cell (MCFC).

The MCFC can be used for a combined heat, hydrogen and power (CHHP) system.

The CHHP system reduces fossil fuel usage and greenhouse gas emissions.

Abstract

Biogas is an untapped potential in regards to an alternative energy source. This immediately available resource will allow countries to reduce their greenhouse gas emissions, energy consumption, and reliance on fossil fuels. This energy source is created by anaerobic digestion of feedstock. Sources for feedstock include organic and inorganic waste, agricultural waste, animal by-products, and industrial waste. All of these sources of biogas are a renewable energy source. Specifically a fuel cell can utilize the methane present in biogas using integrated heat, power, and hydrogen systems. A study was performed concerning energy flow and resource availability to ascertain the type and source of feedstock to run a fuel cell system unceasingly while maintaining maximum capacity. After completion of this study and an estimation of locally available fuel, the FuelCell Energy 1500 unit (a molten carbonate fuel cell) was chosen to be used on campus. This particular fuel cell will provide electric power, thermal energy to heat the anaerobic digester, hydrogen for transportation, auxiliary power to the campus, and myriad possibilities for more applications. In conclusion, from the resource assessment study, a FuelCell Energy DFC1500TM unit was selected for which the local resources can provide 91% of the fuel requirements. Key words: Molten carbonate; Tri-generation; Feedstock; Hydrogen; Fuel cell

INTRODUCTION

Biogas is a potentially enormous source of renewable energy. It is produced by the anaerobic digestion of wastewater, organic and inorganic waste, agricultural waste, industrial waste, and lastly animal by-products. Biogas can be treated to produce Hydrogen, Power and Heat (CHHP) by utilizing a molten carbonate fuel cell. This paper will examine the development of a CHHP system at the Missouri University of Science and Technology (Missouri S&T;) campus located in Rolla, Missouri, USA. The CHHP system is capable of producing enough power for the campus so that air pollution will decrease; in turn, making the community healthier(Hamad, et al., 2013; Agll, et al., 2013; Yu, et al., 2013). The electric power purchased by campus will consequently reduce. An additional benefit of the CHHP system is the higher efficiency at which it operates compared to other distribution plants of similar dimensions. The hydrogen produced can be a power source for diverse purposes on the university campus. These can include but are not limited to personal transportation, reserve power supplies, portable power, and mobility/utility applications. Within the vicinity of the Missouri S&T; campus are a variety of feedstock that can be utilized for consumption to produce biogas were ascertained. A study on energy flow and resource availability was executed to pinpoint the type and source of feedstock necessitated to continuously run the CHHP at maximum capacity to produce electricity, heat recovery, and hydrogen (Pecha, et al., 2013; Braun, 2010; Ghezel-Ayagh, McInerney, Venkataraman, Farooque, & Sanderson, 2011).

1 BACKGROUND

The Missouri S&T; campus is one of four universities within the University of Missouri system, which includes UM Columbia, UMSL, and UMKC. The campus is comparatively smaller than the other three with only 284 acres (1.15 km2). Roughly 6,760 students attend Missouri S&T; in Rolla, Missouri, which has a population of 20,000. This is a diminutive city in a rural area located on Interstate 44 between Springfield and St. Louis, Missouri. One of the largest purchasers of electricity from the city of Rolla is Missouri S&T.; The yearly consumption of power is approximately 2.6 GWh/yr. The greatest demand for electricity is expressed as 6.4 MWe. Presently the electrical power consumed at the university is acquired from Rolla Municipal Utilities (RMU). This power is then allocated from the substation and switchgear situated at the campus power plant. The university also produces electricity using a thermal power plant that employs a backpressure steam turbine, which accounts for a supplementary 10% of electricity. The university power plant was constructed in 1945 and is fueled by coal and woodchips. This fuel delivers steam to the University for space heating, chilled water via absorption chillers, and backpressure steam turbines. The research exhibited in this paper was implemented as a piece of the 2011-2012 Hydrogen Student Design Contest. The contest regulations stipulate the use of FuelCell Energy fuel cell and biogas with 60% methane and 40% carbon dioxide (Hamad et al., 2013; Agll, et al., 2013).

2. RESOURCE ASSESSMENT

2.1 Feedstock Source Identification During the assessment, “locally available feedstock”was defined as one which is within 20 km of Rolla. The largest source of feedstock is Municipal Solid Waste(MSW) averaging 60 tons/day. Of this, approximately 33% is organic waste including 17% food waste. The campus plans to partner with the City of Rolla and will start an ‘Organic Waste Collection Program to collect organic waste. Currently, the city offers residential curbside collection of recyclable materials at no extra cost. The second largest resource is the rejects and waste resulting from change over at the Royal Canin dog and cat nutrition company located in Rolla. The Royal Canin waste is currently disposed at a landfill facility 40 km from the company.

Potential feedstock from the campus includes food

waste, sanitary sewer, and woodchips. Food waste collected daily is mixed with the trash and the sanitary sewer is connected to the citys main sewer lines. Another potential feedstock source from the campus is unused woodchips that the campus will have available when the existing power plant is decommissioned as planned. Other feedstock considered in the analysis include waste from the local winery and brewery, timber from Mark Twain National Forest (MTNF), and wastewater from the city treatment plant.

Based on the location of the feedstock two facilities

were allocated. Facility A can be used for organic wastes. This feedstock will then undergo anaerobic digestion. Collection and anaerobic digestion of waste water will be off-campus at the treatment plant (Facility B).

2.2 Energy Conversions

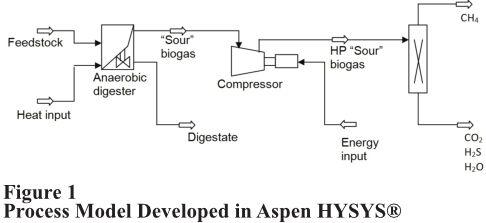

After identifying the amount of feedstock, the amount of fuel that can be generated using anaerobic digestion was estimated (Salminen, & Rintala, 2002). Figure 1 illustrates the production of methane from the feedstock using an anaerobic digester (AD). This process utilizes a new technology which combines the separation of acid gases into a single pressure swing adsorption (PSA) unit. By combing these steps, this technology reduces capital and operating costs. The quantity of locally available feedstock and the estimated fuel production at each facility is tabulated in Table 1.

Based on the equipment datasheet for DFC1500?(Pecha, et al., 2013; Spencer, et al., 2013) 307 m3/h of fuel is required with a heat content of 156 MJ/m3. From Table 1, we can see that the available feedstock can readily supply this entire amount of fuel. However, because wood chips and timber have a slow digestion rate, the use of these may not be considered prudent. From the rest of the available feedstock 260 m3/h of methane may be obtained at a heat content of 37 MJ/m3, which is equivalent to 91% of the fuel cell requirement. Therefore, based on these calculations only one DFC1500? can be installed in the Facility A. Also because of the low methane production at Facility B an investment of CHHP plant does not seem practical and therefore was avoided.

3. COMBINED HEAT, HYDROGEN, AND POWER SYSTEM TECHNICAL DESIGN

The design presented in this paper consists of an anaerobic digestion system, a combined heat, hydrogen and power unit and hydrogen post-processing system(Hamad, et al., 2013). These systems were designed based on the results from the feedstock assessment and the expected biogas production from local resources(Hamad, et al., 2013). Consequently, a DFC1500TM unit was selected for the CHHP system for which local resources can provide 91% of the fuel requirements. The daily unmet fuel need will be supplied by natural gas purchased from the local utility company.

3.1 Site Plan and Location

The selected location to install the system is adjacent to the existing ‘Alternative Fuels Station and future ‘Green Hotel and Convention Center in the Campus Master Plan developed in 2009. By doing so, the design is compliant with the Universitys Master Plan and maximized the chances for implementation. Currently, Missouri S&T; has a 350 bar hydrogen fueling station, an electric vehicle charging station, a hydrogen research and development garage, and a renewable energy transit depot in the alternative fuels station area.

The amount of feedstock and generate methane has a direct impact on the design and selection of the anaerobic digestion and combined heat, hydrogen, and power systems. The hydrogen post-processing system is designed considering the on campus demand, while, using a fuel utilization factor of 65% (Hamad, et al., 2013). The following section describes the major components of the AD and CHHP system.

3.2 Feedstock Delivery System and Storage Section 2 provides the feedstock collection and transportation strategies. A steel building, Figure 2, will be used for storage of this feedstock. The building is designed for avoiding any damage from external elements (Miao, et al., 2011). The storage facility contains a macerator to reduce the size of feedstock to be of diameter less than 0.05 m. This process helps in increasing the methane production. The macerator uses a 15 kWe Taskmaster? 1600 shedder from Franklin Miller Inc.(Iacovidou, Ohandja, Gronow, & Voulvoulis, 2012).

3.3 Feedstock-to-Fuel Conversion System

The process flow of the feedstock-to-fuel conversion can be seen in Figure 2. Initially the feedstock is kept in a storage silo, made of cement, and later is transferred to the hygienisation unit. This transfer is performed using a screw feeder. The temperature of the feedstock is raised to 70 0C in this process, while, being cured for one hour. The elevated temperature curing allows for the elimination of the pathogens (Hamad, et al., 2013; Agll, et al., 2013). The feedstock is then sent to an equalization tank wherein this biomass is mixed to create a homogenous mixture. This homogenous mixture is then fed to the AD, a complete-mix type from Siemens (Refer Table 2 for its details). The digester is jacketed at 40 0C. The digester contains a reliable JetMix? Vortex Mixing system. This system performs intermittent mixing while suspending the organic and inorganic wastes. The mixing system is not affected by the tank level and also reduces dead spots. The system also has the capability to mix multiple tanks using central pumping facility. This reduces the total equipment cost of the digester system.

Using the above procedure, we get biogas, digestate and water (Holm-Nielsen, Al Seadi, & Oleskowicz-Popiel, 2009). The digestate is then sent back to the storage tank, later collected and transported to the facility. This storage tank is also an insulated concrete tank which can also hold biogas in case the allocated biogas storage tank is full.

Energy Science and Technology2013年4期

Energy Science and Technology2013年4期

- Energy Science and Technology的其它文章

- Nitrogen Foam Profile Control for Heavy Oil Reservoir

- Applications and Study on Organophosphate Acids (Salts) for Oil Well Cement Retarder

- Role of Hydrogen in Variation of Electrical, Optical and Magnetic Properties of ZnSe-Fe Bilayer Thin Films Structure

- Development of a Model Wind and Solar Power Installation Comprising High Temperature Superconductors

- Feasibility of Recharging Electric Vehicles With Photovoltaic Solar Panels

- Energy Analysis of a Concentrating Photovoltaic Thermal (CPV/T) System