马加丹冻土特征和基础类型选择

Vladimir P.Vlasov

(1.俄罗斯科学院西伯利亚分院,麦尔尼科夫冻土研究所 东北冻土站,马加丹685000,俄罗斯;2.俄罗斯东北州立大学,马加丹685000,俄罗斯)

0 General description

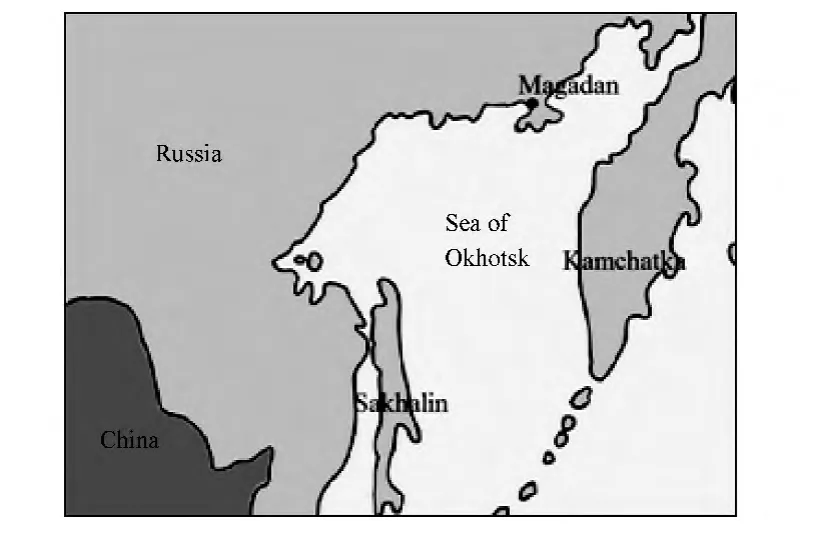

The city of Magadan is situated in the southern permafrost zone of Russia's Far Northeast[1].It lies on the coast of the Gulf of Taui in the Sea of Okhotsk where the StaritskyPeninsula joinsthe mainland (Fig.1).Magadan is bounded by Nagaev Bay on the west and by Gaertner Bay on the east.The mountain ranges to the north and south have elevations of 200 m to 700 m above sea level.The city is crossed by Magadanka Creek with a wide,swampy valley.Most part of the city is located south-west of Magadanka Creek,on the Magadanka-Nagaev watershed.Surface and subsurface waters of the watershed drain into Magadanka Creek to the north-east and into Nagaev Bay to the west.The watershed has a maximum elevation of 120 m above sea level.Its northeastern slope is gentle(3° to 5°),while the western slope is steep and abrupt.

Fig.1 Location of Magadan

Magadan is located in an area of high earthquake activity[2].Earthquakes of magnitude 8~9 are possible in the area[3].

The climate is monsoonal.The annual mean air temperature is-3.6℃,with daily means above 0℃from mid-May to mid-October.Mean annual precipitation is 550 mm,of which about half falls as rain.Winds are generally from the west and southwest in summer and from the northeast and east in winter.The mean annual wind speed is 5.6 m/s.The number of days with snow storms is about 50.Snow cover is up to 0.3 m deep and characterized by with redistribution[4].

1 Geology and permafrost

The geological structure of the area is determined by its location within the Magadan Intrusion[5].The upper 10~15 m of the geological section consist of Quaternary deposits underlain by rocks of Neogene age more than 100 m in thickness.

The Neogene rocks include the marine pebbles with sand and the lagoon and continental materials represented by sandy clays,gravels and pebbles,and granodiorite weathered and solid rocks.The former comprise the southeastern slope of the Magadanka-Nagaev watershed,while the latter make up the remaining part of the city area.The Quaternary sediments that blanket the Neogene rocks are in turn subdivided into alluvial,colluvial,and residual.

The alluvial deposits occur in the valley of Magadanka Creek and comprise its floodplain and terraces.Lithologically,they consist of sand,gravel and cobble in widely varying proportions.Sands have varying compositions from silty to gravelly.The alluvium 10 m or more in thickness often contains beds and layers of gravelly sandy and clayey silts.

The colluvial deposits occur everywhere on the slopes.They consist largely of silty sands,sandy silts,and clayey silts with varying amounts of boulders,cobbles and pebbles of granodiorite.At depth,the colluvial deposits gradually merge with the Neogene rocks of similar composition.The thickness of this layer is a few meters,but increases up to 10 m along the slope bases.

The residual soils derived from the weathering of the underlying rocks lie at greater depths.These soils together with the bedrock occur near the surface only on the steep slopes.The thickness of the residuum is up to 10-15 m.

The geocryological conditions in the Magadan area are highly variable and complicated.Permafrost occurs as isolated lenses and patches in thawed ground.The permafrost bodies vary in size from 100 to 10 000 m2.Their thickness varies from 2 to 30 m,depending on size.The depth to the permafrost table generally is 3 to 5 m,but may be deeper in places.Two-layer permafrost is occasionally encountered,in which the layers of frozen ground are separated by thawed ground.

The local permafrost is characteristically warm,with temperatures at the depth of zero annual amplitude close to 0℃,normally about-0.1 to-0.2℃.Exceptions to this are the permafrost bodies in wet low-lying and high areas of the city,where ground temperatures are-0.5 to-1℃.Presently,however,the size and thickness of permafrost bodies can only be judged for the time of a geotechnical site investigation,because any disturbance of the heat exchange at the ground surface by construction activities causes immediate changes to the thermal state of the warm permafrost.Observations indicate that the permafrost at Magadan is gradually degrading,with global climatic change contributing to the trend.

The frozen gravels and sands generally have a massive cryostructure,while silts and silty sands have a layered or reticulate cryostructure.Ice contents are highest in the upper permafrost layers.Total moisture contents down to 8~10 m depths,in some cases to lower depths,are 0.08~0.12 for the frozen gravels,0.18~0.22 for the sands and sandy silts,and 0.3~0.35 for the clayey silts.The layers with moisture contents of 0.4~0.6 are encountered.At these moisture (ice)contents,the frozen soils are often thaw-unstable and may produce settlements of 3 to 18 cm/m.

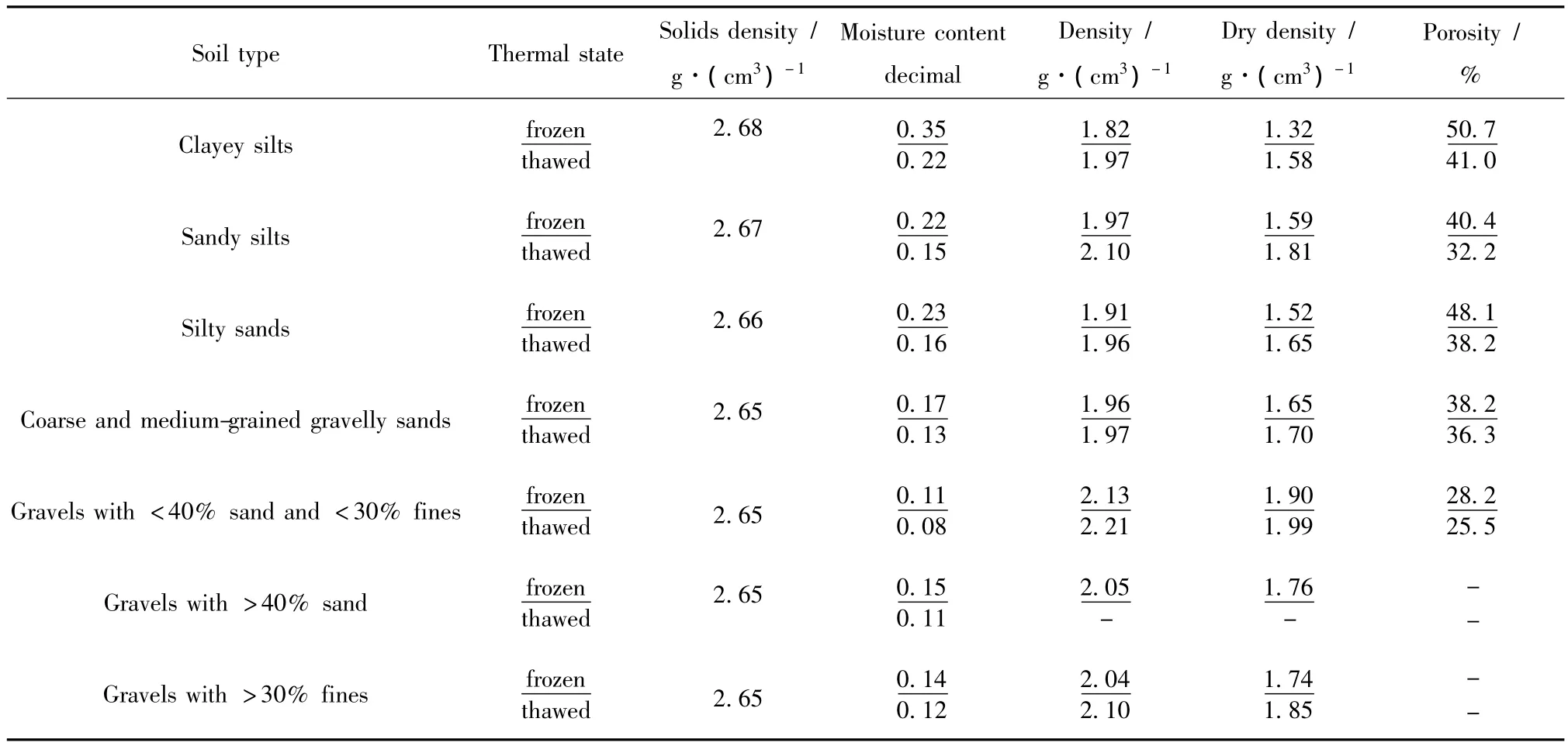

The thawed soils surrounding the permafrost bodies are not inferior in engineering properties to normal unfrozen soils,and may even be superior in some parameters[6].This is because the thawed soils were in a perennially frozen state in the geological past,but gradually warmed due to climatic and anthropogenic impacts.The post-cryogenic structure characteristic of thawed soils has been completely destructed.The action of the soil weight accompanied by aggregate breakup of the mineral framework in the saturated medium caused repacking of the solid particles,expulsion of the excess pore water,and filling of the pores with fines.These processes resulted in increased soil density and improved physical properties.The former frozen state of the soils is evidenced by geotechnical investigation data(Table 1).

Table 1 Averaged physical characteristics of frozen and thawed soils in Magadan(depth interval from 3 to 30 m)

The frost-related processes active in the Magadan area include only frost heaving in oversaturated finegrained soils and silty sands dominant in the upper part of the geological section,especially in the active layer,as well as icing formation at the foot of steep hillslopes and in the Magadanka Creek valley.

Groundwater is encountered in most of the construction sites.Its occurrence is due to the rough terrain,deep seasonal thaw(down to 3.5 m),and abundant precipitation.Porous and fractured granodiorite aquifers are present.Most common are the so-called seasonal perched water bodies in thawed sands and gravels.Due to the high variability in soil facies,they occur as isolated lenses with limited water flow.Although yields are low,serious difficulties for earthwork can be created during snowmelt in the spring and incessant rains in the summer and autumn.

Yields of the Neogene sediments are generally low.Supra-,intra-and subpermafrost waters are encountered occasionally in sands and gravels in the depth interval from 1 to 12 m.They are recharged by infiltrating precipitation and by water flowing from fractured aquifers at the foot of steep hillslopes.As a result,the Neogene aquifers at these locations may have heads of up to 5 m.The layer of alluvial gravel,6 to 7 m in thickness,in the Magadanka valley(within the floodplain and partially in the low terrace)has highest yields.Gravel aquifers here are 200 to 300 m or more in width.In summer,the steady water level rises to the ground surface.In winter,the head may increase to 1~2 m,resulting in the formation of icings throughout the winter.Protective dikes are constructed along the river bank to eliminate the icing problems on engineering structures.

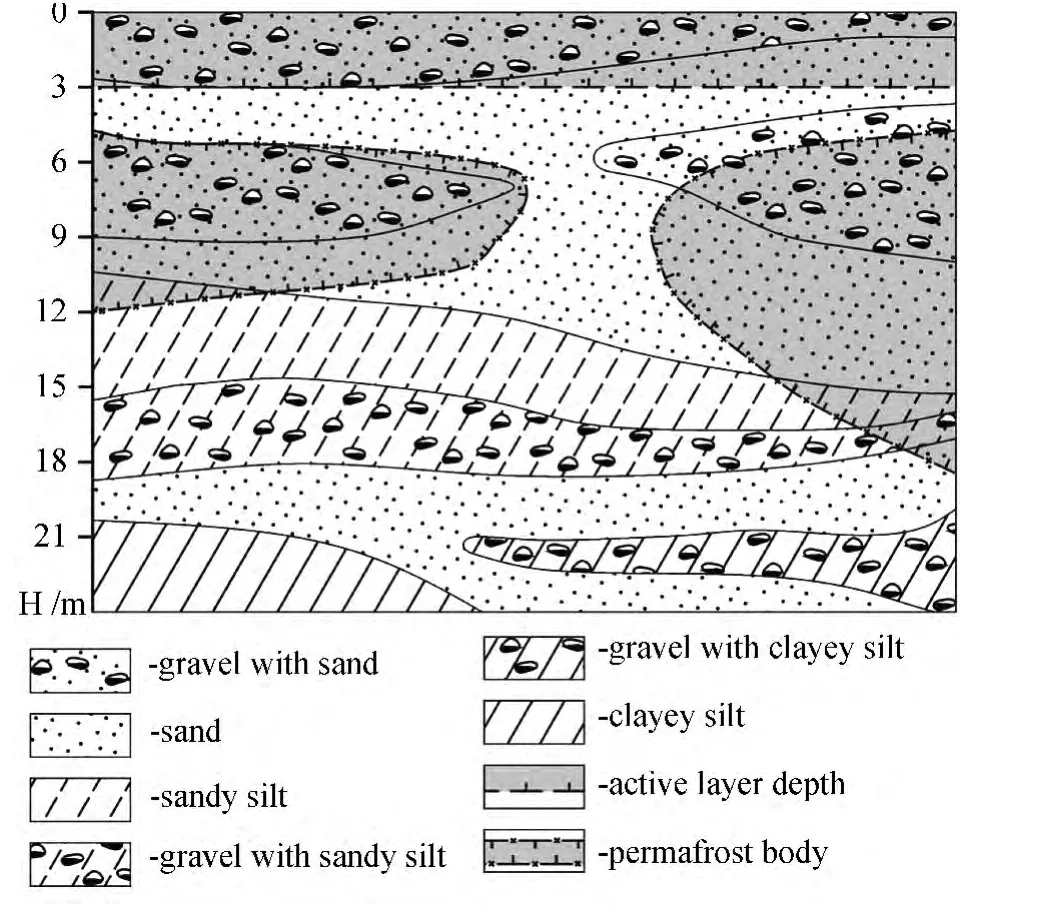

2 Selection of pile placement method

The co-existence of frozen and thawed ground (Fig.2)within a construction site dictates the selection of foundation designs.Geocryological considerations include:1)warm permafrost;2)variable depths to the top of permafrost,often far below the active layer,and occasional two-layered permafrost with thick thawed interlayers;3)strong spatial and temporal variability of the permafrost bodies in response to shortterm climatic variations and construction activities;4) occurrence of ice-rich and hence thaw unstable soils; 5)seasonal soil freezing to depths of 1 to 3.5 m;during very cold winters with low snowfall soil freezing may be as deep as 4~5 m,resulting in frozen layers which remain unthawed for one or two summers or in newly formed permafrost;6)great depths(8~20 m or more)to the firm strata with sufficient strength and stability to safely support the buildings and structures.

Fig.2 An example of the geotechnical cross-section for a construction site

For such geocryological conditions,the Russian building code[7]stipulates for the use of Principle II,or the active method of constructing in permafrost.This method is best suited for sites underlain by bedrock or consolidated soils,including thawed and frozen soils whose deformation and strength properties are not changed on thawing.However,these materials are often overlain by unconsolidated sediments.Principle II therefore requires that measures be undertaken to minimize deformation of the foundation materials(e.g.,pre-thawing of frozen ground,replacement of frozen ground with thawed coarse materials,use of piles extending below a thaw-unstable stratum)and the superstructures be designed to accommodate differential settlements.The latter involves the use of structural elements that prevent additional stresses or the structure of a building must be of sufficiently rigid construction to resist these stresses.In general,these structural measures in combination with techniques to mitigate differential settlements are incorporated into the seismic de-sign requirements for the seismically active southern permafrost zone.

If follows from above that the viability,stability and serviceability of buildings and structures in Magadan must be provided by selection of a proper design for the foundation and superstructure,engineering preparation of the site,and control of the interaction of the foundation with the ground.A set of all or part of the listed measures is termed techniques for ensuring building stability[8].

The goal of the designer is to select the foundation type and design best suited,from technical and economic considerations and past experience,for the local soil and permafrost conditions.

3 Pile foundations in Magadan

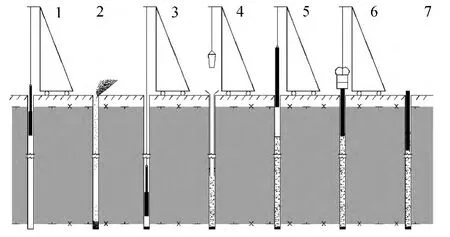

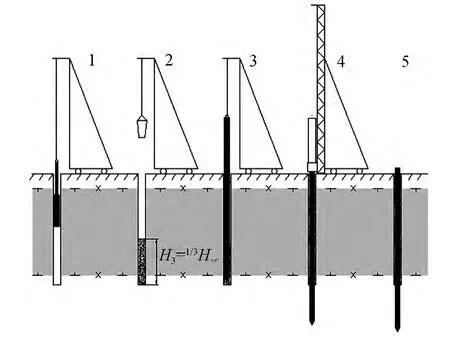

Piles are the main foundation type for Magadan.They create the opportunity to reduce subsoil deformations to safe values for structural competences due to slotting of thaw unstable layers with the deepening of their bottom ends in bearing layers of thawed soils.For this purpose the very specific technologies:composite drilled-and-slurried piles(Fig.3)and drilled-anddriven piles(Fig.4)are used here.

Fig.3 Structure diagram of composite drilled and slurried piles:1-drilling;2-road metal driving in the slurry on the drill hole;3-rubbly pad driving by the way of tamping;4-concreting of the tamped pile part;5-reinforced concrete member driving in the hole;6-vibratory pole driving into the pile monolithic concrete;7-performed composite drilled and slurried pile

Fig.4 Structure diagram of drilled-and-driven piles1-pile hole drilling;2-hole grouting for slurry;3-drill holes;4-pile driving from the hole bottom;5-pile driven at the project reference

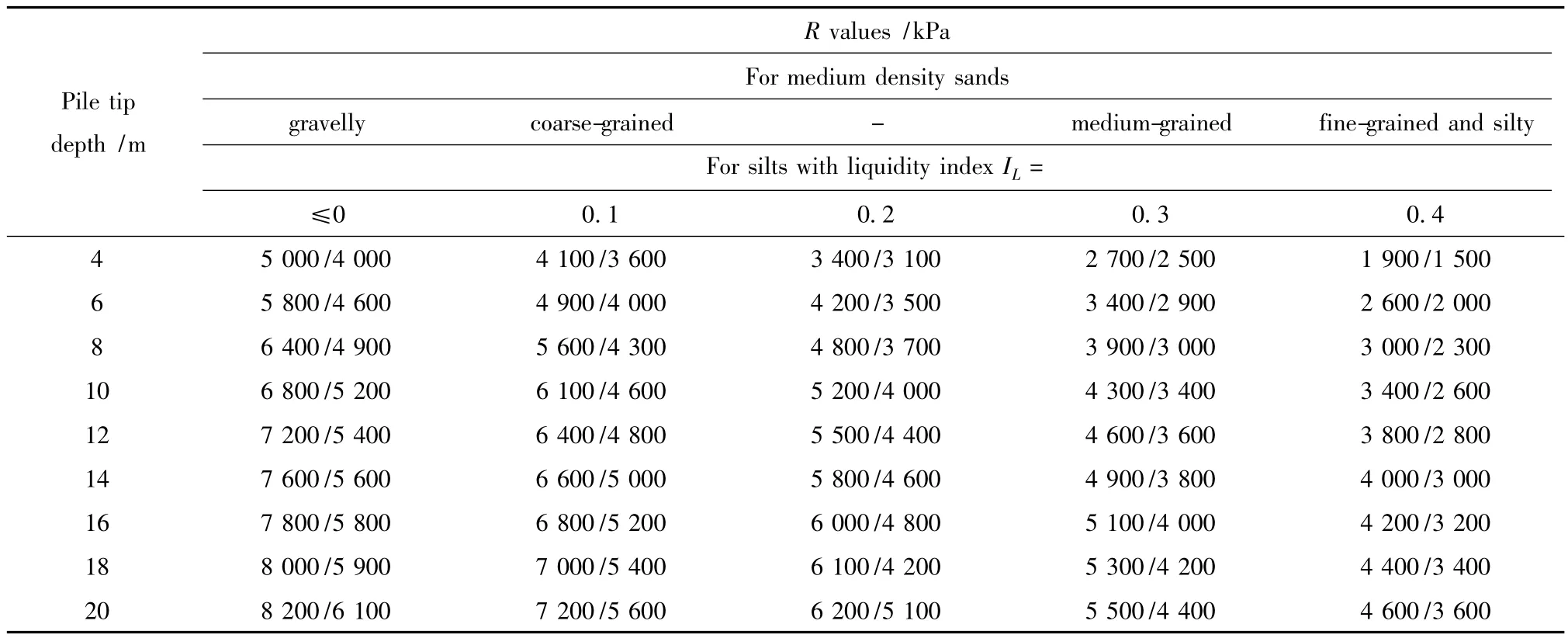

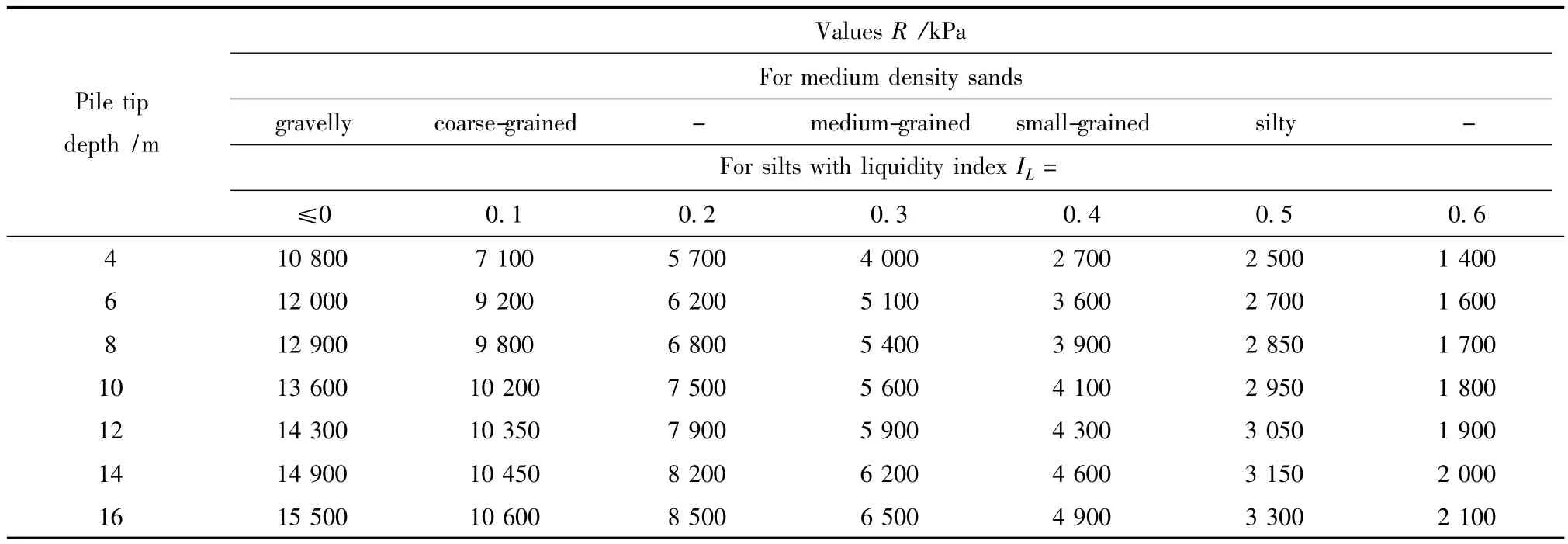

Permafrost reasoning of pile placement technologies relating to the local construction conditions is given in Konash and Vlasov.The results of the accomplished studies are reflected in the regional building regulations[9-10].In view of new data and requirements,these regulations were updated and published as Guidelines for Design and Construction of Pile Foundations in Thawing and Thawed Ground in the Magadan Oblast[11].This document amends and develops the mandatory provisions of the Russian construction codes forfoundation engineering in the permafrostregion[7,12].For practical project development and foundations the regional resistivity amount of thawed soils under the pile tips(Tables 2 and 3)and on the side surface(Table 4),specific values of the negative friction force(Fig.5)as well as the correction factors dependent on the accepted practice of pile placement (composite drilled-and-slurried pile or drilled-anddriven pile)are described.All data necessary for design analyses have been obtained from field tests[6,13-19].Their certainty is controlled by many experimental and check tests of different constructions and pile standard size in the most various permafrostgeological conditions as well as long-term project and construction practice of pile foundation on the thawing and thawed soils of the Magadan region[6,15,20-21].

For pile foundation design in the Magadan area,in the capacity of calculating bearing course thawed soils for composite drilled-and-slurried piles and drilled-and-driven piles underlying under the permafrost thickness and in the absence thereof under the layer of seasonal frost-thawing which within the bounds of the compressible thickness depths give summary compression not exceeding the tolerated one by the standards for constructing class of buildings and constructions[22]are used.At determining the bearing course of pile foundation soils it is taking into account that the construction region is in the seismically active zone.In this respect the pile embedment depth from the ground surface or from the foundation pit bottom must be no less than 4 m and where there are water saturated silt sands in the foundation-no less than 8 m[11].

The selection of pile type and pile arrangement (e.g.pile clusters,fields,rows)is made on the basis of concrete conditions of construction site characterized by the materials of engineering permafrost investigations which are performed according to SP 47.13330.2012(Federal Agency for Construction,Housing and Utilities(Gosstroy),2012)and SP 11-105-97[23]and construction and technological peculiarities of future building or construction taking into account the dimensions and intention of their underground facilities as well as the design loads on the foundation.Where thick permafrost is present with its base located at a depth of 10 m or more from the foundation pit bottom,piles are penetrated placed into the thawed soil barred by permafrost,by composite drilledand-slurry method(see Fig.3).At smaller depths to the permafrost base,drilled-and-driven piles(see Fig.4)are used.If permafrost is absent,spread footings,strip footings or mat foundations are used.

Table 2 Design resistance of thawed soils R under composite drilled-and-slurried piles tips

Table 3 Design resistance of thawed soils R under drilled-and-driven piles tips

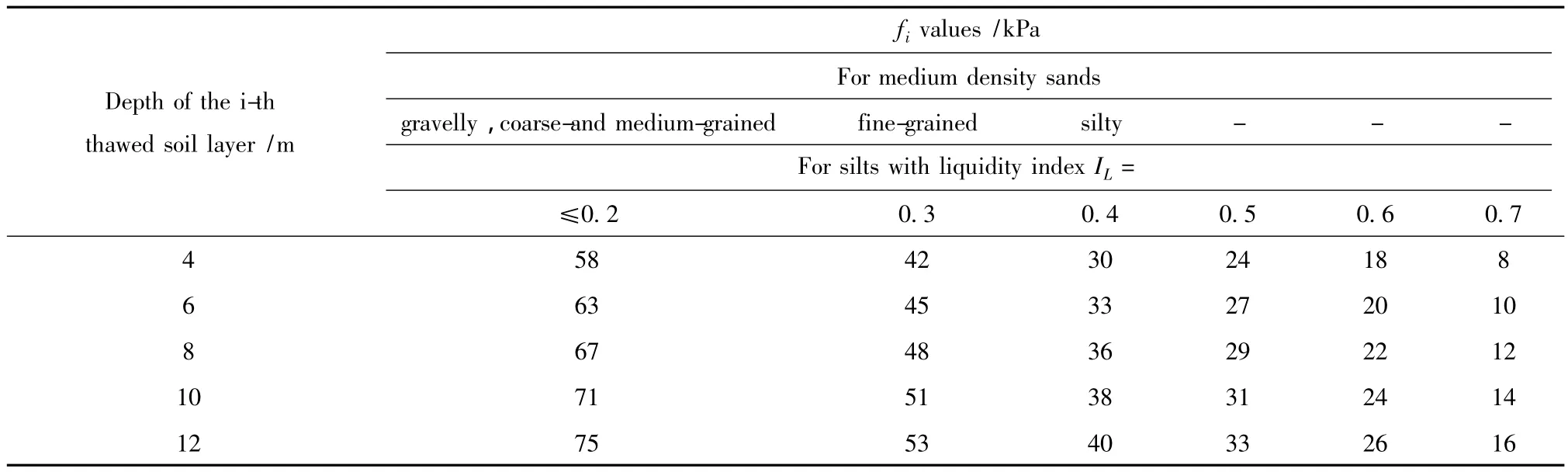

Table 4 Design resistance of thawed soils fialong the pile skin

Drilling for pile placement is made by drilling machines with cable tool percussion effect.This drilling method is used in the soils of any type and structure (with heavy percentage of coarse material,boulders etc)as well as thermal state-without restriction[24].The usage of other hole boring method for the purposes of pile foundation on the territory of Magadan turned out to be difficult because of dreadful garishness of frozen soiled and hydrogeological conditions of construction sites[5].

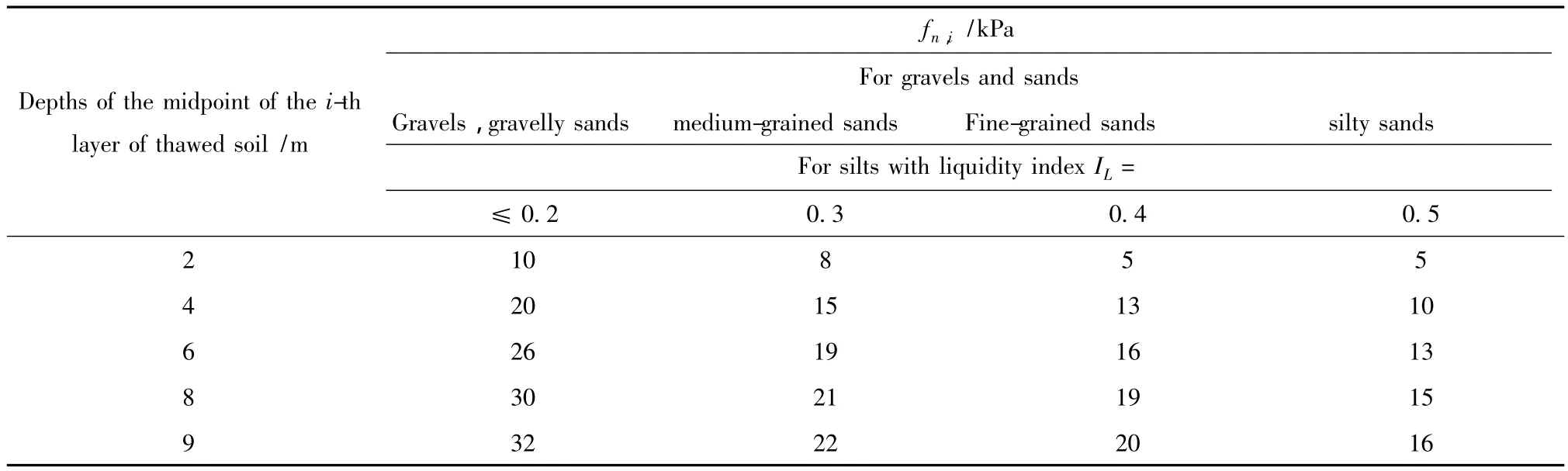

Table 5 Design values of negative friction fn,iof thawing soils

Cable tool percussion drilling is that the rock drill dropping at a height(about 1 m)damages mine rock by its chisel nose.The water periodically pouring in the deepening hole mixes with finely crushed soil and makes it into liquid-like saturated soil-drilling slurry taking out of the hole by the sludge after every drilling run.The disadvantage of the method is an incomplete cleanup.As a rule,on the hole bottom the layer of slurry at a height from 10 to 30 cm or frequently more leaves unselected.Besides the soil at some though small depths lower than the hole bottom can be in a few loosened state.

Usually the drilling consists of the borehole wall lining by casing metal pipes.Depending on the complexity of frozen ground and hydrogeological conditions of the construction site the well casing can be effected in two ways.In the former case the hole is drilled at once at all the depths settled by the project and only then it is cased by metal pipe of corresponding diameter.This method is used when soil hole walls have sufficient temporal stability and can retain their entirety for more period of time after the drilling termination.The second way is used in the case of unstable hole walls which start already to ruin while drilling.It consists of the well casing by separate passover offsets driving in them one after one in proportion to driving in unstable soil.Usually the passover offsets are joined by electro-welding.

Pipe swaging(entirely or partly)is made by rock drill and its removing by instrumental rope winch of drilling machine[20,24].

Composite drilled and-slurried piles are composite constructions placed into the deep holes:on the bottom they consist of the tamped concrete pole resting on the reinforced road metal of the drill hole with slurry vestiges and an upper reinforced drop concrete member embedded in the tamped part of the pile monolithic pole to a depth equal to at least three times in the diameter of the hole;though the biggest diameter of the pile crosssection must be 15 cm less than pile diameter where composite pile is made.

The main criterion defining the quality of this technology of the foundation installation and consequently the formation of bearing sand core in the pile bottom is firm contact of a tamped concrete pole with the drill hole.The problem of quality of this contact can be aggravated by the presence of slurry vestiges and loosened rock between the elements named above.The matter is that the density of this slurry will be always lower than the natural density soil of undisturbed structure.The way out is that the coarse rock is tamped in the slurry vestiges and loosened pile bottom[6].

As tamper it is used the rock drill of drilling machine.For this purpose the rock drill is provided with the interchangeable nose in the form of the round metal plate with thickness of 30~50 mm the diameter of which must be 1 cm less than the hole diameter.In the process of road metal tamper preliminary buried at the hole bottom by the layer exceeding the height of slurry vestiges no less than twofold,the consolidation deformations of road metal interpenetration into the slurry and than in the soil of the hole bottom and its walls are taken place.

The consolidation of the road metal surface is performed up to the getting of the magnitude of the‘refusal'not exceeding 2 cm for the latest five tamper blows.Though the total amount of the refusal magnitudes must be no less than the height of slurry vestiges layer measured before the beginning of tamping.As the result densely packed structure of road metal-and-slurry pad is created.Along with the compacted sand core under the bottom of the drill hole it creates the pile structural bearing by the means of which the vertical impulse is transmitted from the service loading though the composite construction(tamped pit and reinforcedconcrete pole)on the underlying soils of building or construction foundations.

At the end of road metal-and-slurry pad installation the tamped concrete pole which is the intermediate element of the composite pile is performed.It has very important practical value for future foundation because varying the height of the tamped part where the reinforced concrete pile element is embedded the necessary foundation depth settled by the project is provided.

The supratamped pile element is made of the concrete mixture of the class not lower than B-20 with the water-cement ratio WC 0.45~0.55 and the cone slump 5~10 cm.As the anti-freezing agent-the accelerator of the concrete strength development sodium chloride in a rate of 2.5% ~3.5% of the cement weight in the concrete mixture is applied.

In the holes the concrete mixture is put by the method of vertically movable pipes(VMP)with the diameter of 250~325 mm.The concrete mixture settled on the projected height is tightened by the vibrating pile driver while lowering the reinforced concrete pole into the tamped pile shaft.The last one is embedded in the concrete mixture of the tamped shaft.The abutment joint between these elements must be no less than three hole diameter.

Composite drilled-and-slurried piles can be settled in the holes with extracted and non extracted casing pipe.The last one is used when there is no the possibility of qualitative pile production in the holes with the extracted protecting cover.Usually there are such conditions on the slump and thermostatic lots as well as on the sites with ice-rich embedded permafrost with the interlayer of well filtering thawed coarse and sandy soils where under the pressure of the permafrost ground waters heavily refillable due to the ice melt-out from the permafrost the composite pile shaft on the separate hole sites can be damaged during the concrete mixture con-solidation of its tamped part.

The advantage of composite drilled-and-slurried piles driving in the soil is the possibility to produce them in any lengths and diameter and place accurately enough on the project references either at the bottom or at the top of the piles,minimizing the building vestiges.This type of piles turned out to be very popular during the building of the city urban districts,the construction area of which is situated on the development sites of intermediate discontinuous permafrost with a capacity of more than 10 m[17,21].At the presence in the structure base ice lenses of smaller dimensions the foundations have been already installed from drilled and-driven piles[6].

Drilled-and-driven piles are solid reinforced concrete piles designed to take account of the pile-driving impact loads driven into the bottom of pilot holes in the bearing layer of thawed soils.Pilot holes must be drilled on 0.5~1 mm lower than the permafrost base and have the diameter larger than the diagonal of the cross-section of the pile in 2~5 cm.In Magadan on the building sites for driving it is used the standards reinforced concrete piles with the lengths of 5~12 m and the cross-section of 30 cm×30 cm.Their placement in the piles is performed by the autocrane of the appropriate bearing capacity and the driving into the soil-by the tubular diesel hammer with the weight of the striking part in 1.8,2.5 and 3.5 ton-force.

Before the placement piles are cleaned of the slurry.The thickness of its vestiges shouldn't exceed 30 cm.The existence of frozen slurry on the hole bottom is not admitted.For the exception of the last one the holes are drilled with the borehole wall lining by casing pipes.However in the frozen soils where the hole walls can retain temporal stability it is not obligatory to effect their casing on condition that the drill hole for further driving into the thawed soil will be performed instantly after the finishing of drilling but no later than 4 hours after the hole clearing.It is to be noted that the casing pipes must be taken out of the holes before the beginning of pile driving as after that this procedure will be extremely difficult or even impossible.

Piles settled in the holes are driven lower than their bottom in the thawed soil at depths settled by the project whereby the base load-bearing capacity will provide the perception of calculated load from the future construction including the additional load when the permafrost thaws and consolidates around the pile.The control pile refusal(magnitude of its diving in the soil for one hammer blow)allocated by the project organization serves as the criterion of driving termination[11].

The measurement of the refusals is performed in the end of driving when the depths diving in the soil riches the project references or the magnitudes of the actual refusals come close to the calculating values.The driving is ceased if the average refusal value in three consecutive blow counts,10 hammer blows in each doesn't exceed the magnitude of control refusal pointed in the piling project.

Piles embedded lower than the hole bottom less than one meter(if it is not required by the project) and given pile refusal during three consecutive blow counts are subjected to the inspection for the causation that complicates pile driving.In this case on the basis of studying the materials of engineering and geological research and the capacity of utilizable diesel pile hammer it is decided the question about the measuring of the piles lengths,drilling depth and the replacement of pile-driving equipment.The piles given the refusal that is much more than the pile refusal are subjected to the check-out(dynamic and static)after the‘rest’,time limits of which for different types of the thawed soils taking into account their thixotropic properties are contained in the guidelines[11].As the results of such check-out the character of the future pile usage in the foundation structure(with the redundancy of specific piles or without their redundancy)is settled.

4 Conclusions

Project development and foundation installation with the usage of composite drilled-and-slurried piles and drilled-and-driven piles on the territory of Magadan is performed in accordance with the requirements of the local building code[11],drafted in the development of mandatory provisions of national standards and rules and regulations concerning the regional building peculiarities under the conditions of isolated patches expansion of permafrost during their simultaneous existence with the thawed soils.

The importance of the placement methods of these pile types on the territory of the city with very specific permafrost conditions is that due to them the construction sites with most diverse diving of lenses and permafrost regions underlying by the thawed soils which are reliable base for future foundations of buildings and constructions here.Complete slotting of thaw unstable layers and piles diving in the thawed soils provide required operational stability of construction objects.Besides high bearing pile capacity embedded on the thawed soil foundation it should be noted their adaptation for negative skin friction when the permafrost thaws and consolidates around the pile.Since the drill holes are larger in diameter than the cross-section of the piles,the annular space between the pile and the hole can be filled with any type of slurry.In Magadan the common practice is to use drilling slurry produced in large quantities during cable tool percussion drilling for placement of these pile types.It was established that in the result of this action it is managed to reduce the effect of the negative skin friction influence on the piles no less than 40%[6].

Practically all the city buildings and constructions raised on the piles are used without any essential deformation characteristics.The exception is five civilian objects,the foundations of which were erroneously damaged in the thaw unstable permafrost.Three of them almost at once after placing in operation went on the bum,two others managed to avoid the deformations-the preventive consolidation of pile foundations were made[20].

If it is necessary to reconstruct old construction objects,further operational suitability of their foundations can be always checked by static pile check-out being directly a part of the foundations of the existing buildings by the procedure represented in the work[25,28].In case of the deficiency revealed by the check-out of bearing ability of these piles,all foundation or its part can be strengthened by hydraulic jack cave-in of specific piles in supporting layers of the thawed soils[26].

[1] Ershov E D(ed.).Geocryology of the USSR[M].Moscow:East Siberia and Far East.Nedra,1989.

[2] Strakhov V N,Ulomov V M(eds).Seismic Zonation of the Russian Federation,4-sheet Map[M].Moscow:Tekart,2000.

[3] Malinovskiy S B,et al.On seismic hazard in the Magadan Oblast[M].Kolyma,2005,1:27-32.

[4] Velli Y Y,Dokuchaev V I,Fedorov N F.Building on Permafrost Reference Manual[M].Leningrad:Stroyizdat,1977.

[5] Chapovskiy E G(ed.).Engineering Geology of the USSR,Far East[M].Moscow:Moscow State University Press,1977.

[6] Vlasov V P.Construction of Pile Foundations in Unfrozen and Thawing Ground of the Magadan Region[M].Yakutsk:Permafrost Institute Press,1992.

[7] Ministry of Regional Development of the Russian Federationa[M].Moscow:Updated Edition of SNiP,2012.

[8] Ershov E D,Khrustalev L N,Dubikov G I,et al.Engineering Geocryology[M]:Moscow:A Reference Book.Nedra,1991.

[9] Instruction for Design and Construction of Pile Foundations in Magadan[M].Magadan:USSR Minvostokstroy,1979.

[10] Instruction for Design and Construction of Pile Foundations in Thawed and Thawing Soils in the Magadan Oblast[M].Magadan: USSR Minvostokstroy,1988.

[11]Melnikov Permafrost Institute.Guidelines for Design and Construction of Pile Foundations in Thawing and Thawed Ground in the Magadan Oblast[M].Yakutsk:Melnikov Permafrost Institute Press,2012.

[12]Ministry of Regional Development of the Russian Federationb[M].Moscow:Updated Edition of SNiP,2012.

[13]Vlasov V P,Konash V E.Results of static pile testing data analysis in Magadan.In:Building in East Siberia and Far North[J].Krasnoyarsk:Krasnoyarsk Promstroyniiproekt,1974,29:68-72.

[14]Vlasov V P.On the effect of“rest”on the bearing capacity of piles embedded in Magadan fine soils.In:Building in East Siberia and Far North[J].Krasnoyarsk Promstroyniiproekt,Krasnoyarsk,1974,29:84-91.

[15]Vlasov V P.Experience with pile foundation construction in Magadan[J].Osnovaniya,Fundamenty i Mekhanika Gruntov,1988,4:2-4.

[16]Vlasov V P.Consideration of loading friction in static pile testing in thawing soils.In:Transactions of the Magadan Promstroyniiproekt[J].Magadan Promstroyniiproekt,Magadan,1991:29-36.

[17]Vlasov V P.Introduction of composite slurried piles in Magadan.In:Transactions of the Magadan Promstroyniiproekt.Magadan Promstroyniiproekt[J].Magadan,1991:37-45.

[18]Vlasov V P.Engineering-geocryological studies in support of pile foundation engineering practice in areas of sporadic permafrost[J].Kolyma,1994,7-8:16-21.

[19]Vlasov V P.Rational method for pre-construction pile tests in thawing soils.In:Proceedings of Interregional Scientific Practical Conference“Russian Building Industry[C]//Problems,Prospects and Human Resources”,East Siberian State Technological University,Ulan-Ude,1999,2:3-12.

[20]Konash V E.Pile Foundations in Sporadic Permafrost Areas(An Example of Magadan)[M].Stroyizdat,Leningrad,1977.

[21]Vlasov V P,Zeeva A N.A new composite pile placement method for permafrost condition in Magadan[C]//In:Proceedings of the 7th InternationalSymposium on Cold Region Development (ISCORD– 2004).Hokkaido Organizing Committee,Japan, 2004.

[22]Ministry of Regional Development of the Russian Federation[M].SP 22.13330.2011,Soil Bases of Buildings and Structures,Moscow:Updated Edition of SNIP 2.02.01-83*.2011.

[23] Russian Federation Committee on Construction.SP 11-105-97,Geotechnical Site Investigations[M].Moscow:Guidelines for Permafrost Areas,2003.

[24]Rastegaev I K.Excavation of Frozen Ground in Northern Building[M].Novosibirsk:Nauka,1992.

[25]Vlasov V P.Management of stability of pile foundation in service.In:Proceedings of the Sixth International Symposium on Permafrost Engineering[J].Journal of Glaciology and Geocryology,2004a,189-193.

[26]Vlasov V P.Problems of bed and foundation stability in the Magadan Oblast[J].Soil Mechanics and Foundation Engineering,2004b,41(2):65-70.

- 黑龙江大学工程学报的其它文章

- The harm of perennial frozen soil to the pipeline exporting the crude oil from Mohe county to Daqing city

- Overview of research methods of frozen soil hydrology in Heilongjiang Province

- Environmental geochemistry of urban areas in Yakutia

- A permafrost factor in the development of deformations on the Amur Highway

- The problem of project statement of construction principles of buildings and facilities in permafrost

- The forecast of a temperature regime of soils containing the pile foundation of a pithead on diamond-mining mines of cryolithic zone