Design of a State Monitoring and Alarm Device for Escalator

LIU Yingjie ,WANG Weixiong,XIE Chao,WANG Xinhua,LIN Chuanglu,LI Zhongxing,SONG Yuechao,HUANG Daimin,CHEN Min,GUO Yigang,FENG Shuan,LIN Hongyang

1.Guangzhou Academy of Special Equipment Inspection& Testing,Guangzhou 510180,China;2.Guangzhou Institute of Measuring and Testing Technology,Guangzhou 510030,China;3.Guangzhou CAV Co,Guangzhou 511434,China

1.Background

Escalator as one of vertical transportation vehicles are widely used in our daily life.They bring us good convenience because of their high speed and large carrying capacity characteristic.However due to their configure complexity,components degradation as well as harsh implementation environment,escalator may sometimes break down and result in injuries to their users.To keep escalator in good condition,regular maintenance as well as inspection are required,the work not only involves of lots of technical staffs,but also some potent ional risks may not be detectable.Researchers are seeking for intelligent way to handle this big problem.Some Original Machine Manufacturers like OTIS,MITSUBISHI,HITACHI have built some state monitoring devices such as MOTISIBA in escalators which can monitor the state of escalator and give warning signals when there are some malfunctions in escalators,those devices enhance the safety level of escalator,but most devices are self own and simple function device which receive orders and signals from the main controller of running escalator,when there is a failure occurs in the main controller,the monitoring device will not work properly.This paper addresses to develop an new remote monitoring device which is independent of main controller of escalator,the remote monitoring device can send warning signals to technical staff to deal with the emergency problem.

2.Implementation system and schematic for monitoring device for escalator

2.1.Remote monitor device system for escalator

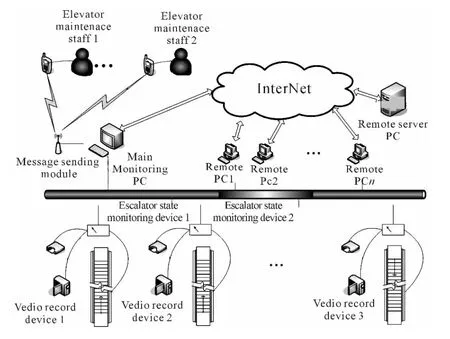

Implementation System for escalator monitoring device is shown in Fig.1,the monitoring device diagnoses the actual states of escalator such as normal running,malfunction running,inspection running,power failure state,then the obtained analysis results are transmitted through internet or GPRS to the remote monitoring PC and the service workers as well as technical staffs.Once the malfunctions of escalator are recorded and transmitted,the technical staffs will respond to emergency events as soon as possible.

Fig.1 System structure of remote monitoring devices

2.2.Schematic of monitoring device for escalator

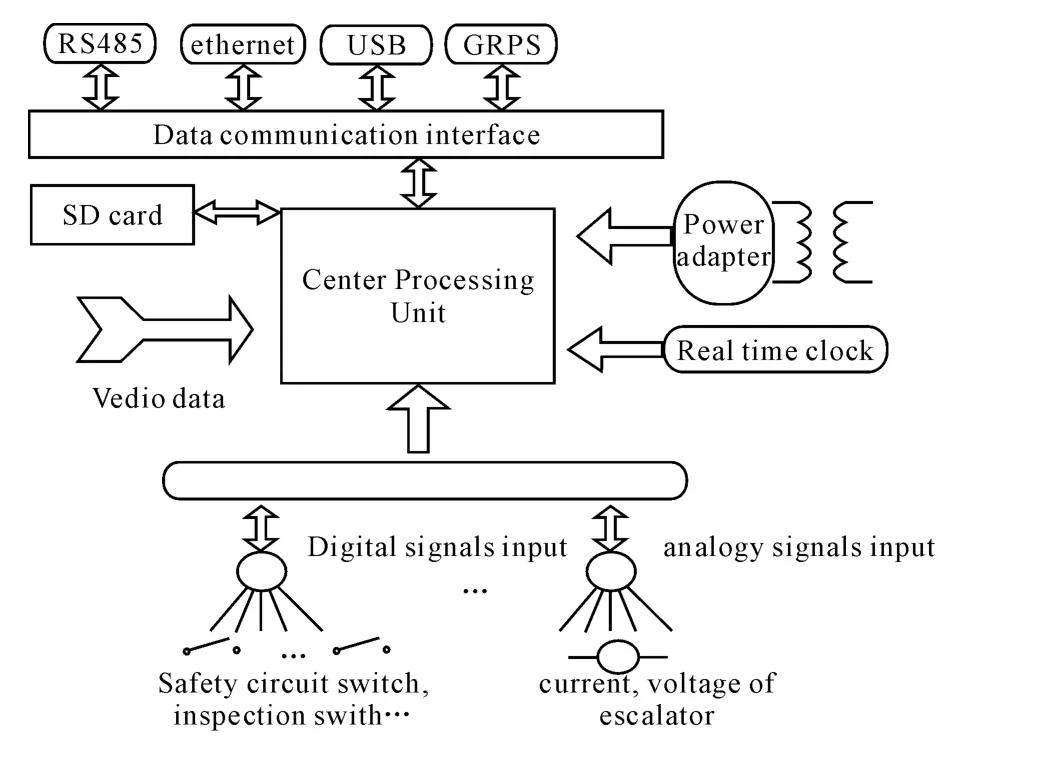

The schematic of active monitoring device is shown in Fig.2.It composes of sensor units which collects the input current and voltage of the frequency converter and on off state of contacts,an data process unit for calculation of the collected data,an data store unit for storing the collecting date,a signal transmit unit for sending the analyzing results to the remote PC as well as the technical staff of the escalator,an center processing unit for diagnosing the state of escalator.

Fig.2 Schematic of the remote monitoring device for escalator

3.Hardware and software design of the active monitoring device for escalator

The design of the monitoring device for escalator is composed of hardware and software design.The hardware includes the power unit,the center processing unit,the data process unit,the sensor and the data transmission unit,which are described as follow.

3.1.Components of monitoring device for escalator

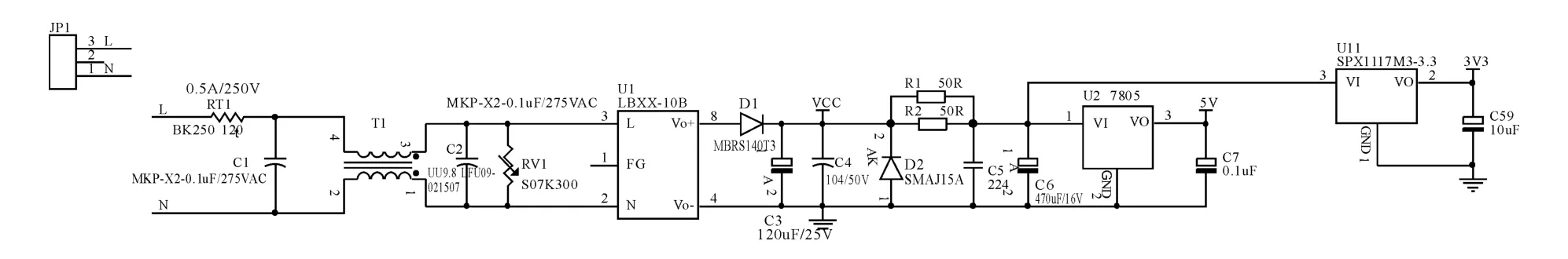

The power unit is shown in Fig.3.The power unit is designed for supplying the 3.3V DC voltage for the center processing unit and date acquisition IC.

Fig.3 Power unit of monitoring device

The center processing unit is selected for diagnose the state of escalator;whose type is STM32 produced by ST INC.

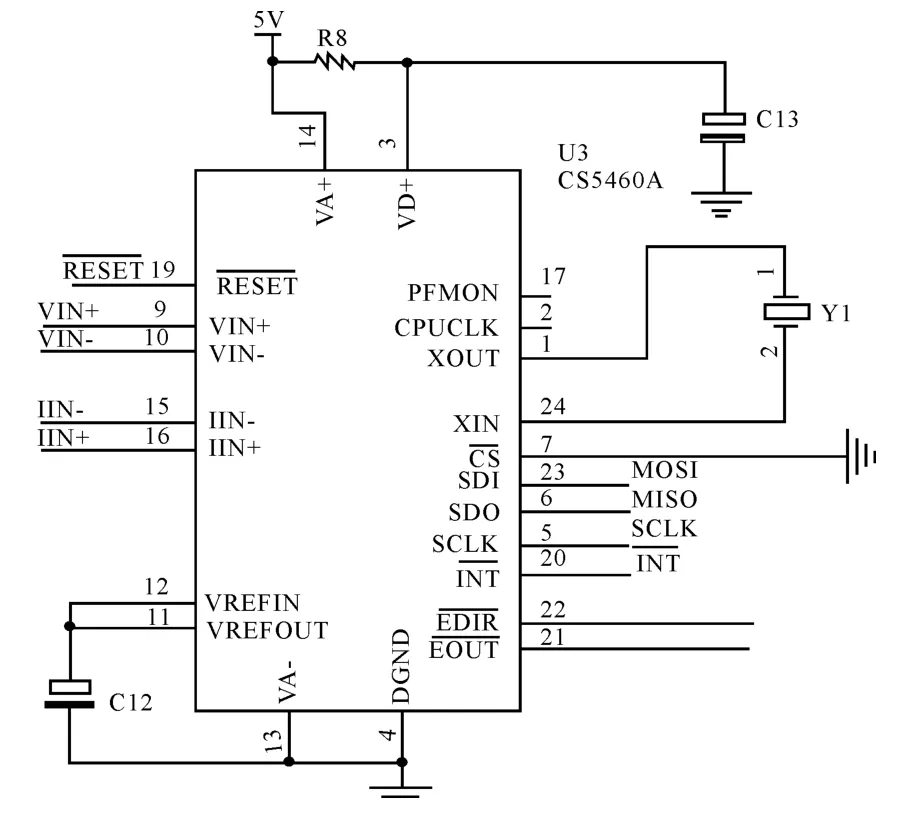

The data process unit is given in Fig.4,which takes advantage of a specific current and voltage acquisition IC typed as CS5490 for processing the measured data obtained by the sensor unit,the RMS of current and voltage can be obtained easily by executing orders given by the core controller IC through I2C communication bus.

The analyzing results are sent to the remote PC and repairmen as well as technique staff by the DTU.Which communicate with the core controller through USART.

The prototype of monitoring device for escalator is given in Fig.5.

Fig.4 current and voltage data process unit

Fig.5 The developed monitoring device for escalator

3.2.Fault diagnosis strategy

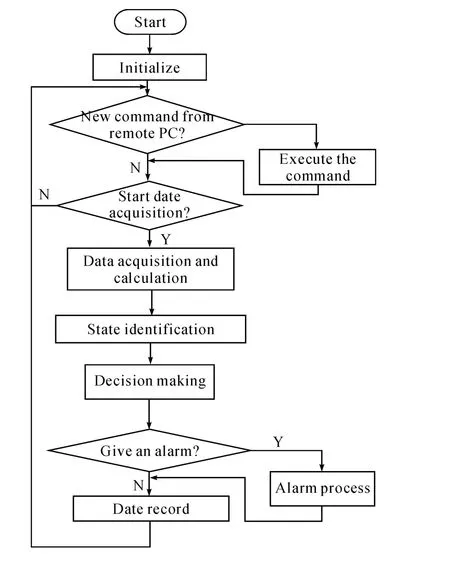

Fault diagnosis procedure of the monitoring device is shown in Fig.6.The monitoring device received orders from the remote PC,if there is no new order to be given,the monitoring device executes the on line monitoring routine,first the signals are measured,the center process unit executes the routine of the abnormal state identification,an sophisticated logic calculation strategy is used to diagnose the state of the escalator,when the analyze is over,the center process unit enters the phase of decision making,the core controller determines whether or not to give alarm signals.

3.3.User interface of monitoring system

The user interface for monitoring device is used for on line monitoring the state of the escalator as well as for data analysis.The monitoring user interface should contain the basic information of the monitoring escalator such as the type and the specification of the escalator,more importantly, the information that when the escalator is in state of malfunction,as well as the rate of the malfunction during a period of statically time should be recorded.

Fig.6 Fault diagnosis procedure of monitoring device

4.Experiment and date analysis

Experiments have been done to verify the performance of the developed monitoring device.The monitoring device is installed for an escalator typed as Green max 200 in our laboratory in Guangzhou.

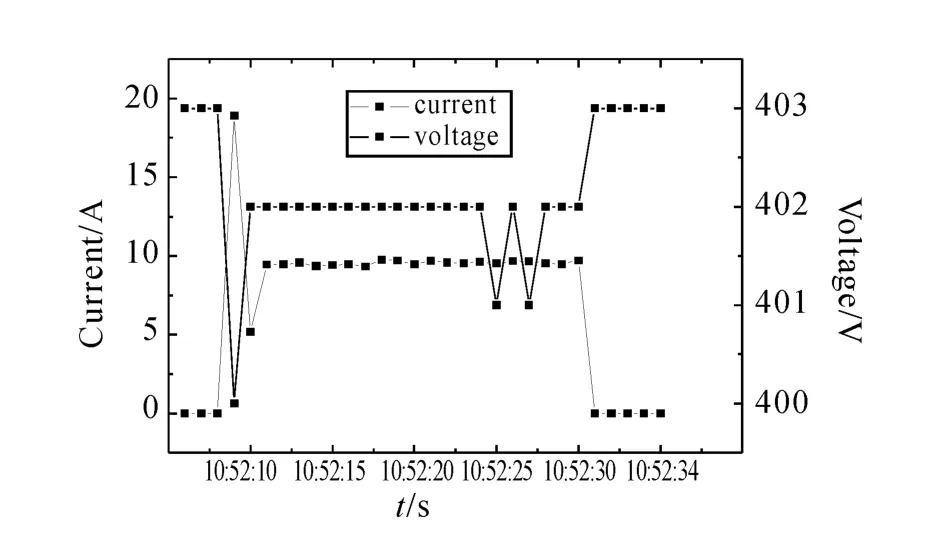

To test the monitoring function,it has to trigger the malfunction of escalator on purpose,and then see whether or not the active monitoring devices can detect the malfunction through analyzing the collection dates.the test results show that the active monitoring device are able to collect runing current and some on off signal of contacts,the power failure the inspection state elevator malfunction can be detected,the alarm signal can be given out when emergency event happens.The monitoring state is shown in Fig.7.It is showed that the inspection state has been captured by the monitoring device.

The collected upward and downward current and voltage of escalator are shown in Fig.7 and Fig 8.It can be seen that the start current is about two time larger than the normal current of running state for escalator,the develop remote monitoring system can work well to record those signals.

Fig.7 Escalator move upward(no load)

Fig.8 Escalator move downward(no load)

5.Conclusions

The developed monitoring device monitors on line the escalator state and diagnoses the malfunctions such as current abnormal and inspection check state as well as power failure,which helps the technical staff to find the cause of failure in escalator and save the rescue time by immediately sending the alarm signals to rescue team when some accidents happens in escalator.With the developed device it can to some extent avoid some losses caused by escalator malfunctions through detecting the key parameters all the time which characterized the possibility of malfunction.Another advantage of the developed devices is that the developed monitoring device is active and independent of the main controller in escalator,when the escalator main controller goes wrong,it can work properly.The experiment result verifies the claimed characteristic of the device.

[1]WANG Jun.On state monitoring of escalator through internet[J].Trans Argriculture,2002,34(1):23-45.

[2]ZHAO Shuo,LI Changrong.Designing Strategies on Elevator Control System[J].Journal of Qiqihar University,2005,21(1):2005.

[3]LI Bing.Fault diagnose of escalator[J].Elevavtor World,2005,18(1):122-128.

[4]LI Xiaogang,LIU Jian,MENG Bin.The Actuality and Research Direction of Remote Elevator Monitoring System[J],China Elevator,2006,17(17):35-38.

[5]ZHANG Wenya,CAI Li,LIANG Ziyi,The Application of CDMA Wireless Communication in Remote Monitoring System[J].Control & Automation,2007,23(13):95-97.

- 机床与液压的其它文章

- Detection of Bearing Fault Signal Based on the Wavelet and Chaos Theory

- Development of Vibration Signal Acquisition and Analysis System for Machine Tools Based on LabVIEW

- Vibration Analysis of a Large-size Reduction Gearbox Test System Based on Its Dynamic Characteristics

- Fusion Control Strategy Based on I-Fuzzy-Smith Algorithm for Complex Process with Large Lag

- Simulation Analysis of PID Optimization of Hydraulic Pressure System Based on Genetic Algorithm

- The CFD Numerical Simulation on Ventilation of Indoor Transformer Substation