Intelligent-fusion Control Strategy for Complex Uncertainty System

HUANG Lichao,LI Lei

1.School of Mechanical Engineering,Chongqing Industry Polytechnic College,Chongqing 401120,China;2.College of Automation,Chongqing University,Chongqing 400044,China

1.Introduction

Before the rolling of steel bar billet,the steel bar billet must be gradually heated to the value of stipulated temperature,and then maintain the constant temperature in the heating furnace until all the inner temperature of steel bar billet is reached to the stipulated temperature.Generally the fuel is taken by the nature-gas,or mixture of blest furnace gas and revolving furnace gas and cake oven gas,or the mixture of the above both.The process is very complex,and it is depended on the heat calorie of fuel,and different gas is different in heat calorie.Therefore it is the key that how to assort or arrange the different gas so as to get steady heat calorie and of course,also a reasonable ratio of the air-fuel is very important.If the air is surplus or shortage then it will be resulted in heat efficiency low or insufficiency combustion.In order to ensure effectively running of the heating furnace,all the subsystem of control system must be harmonically operated.The control of industrial heat furnace belongs to a complex system control problem.The heating furnace system is a large-scale complex system,it means that it is large in scale,complicated in structure, intricate in information interaction,strong coupling in variables,and difficult in mathematic description.So,it is very troublesome for mathematic modeling.In fact,it always applies generalized control model based on knowledge description to control or manage the whole system.It deals with lots of puzzles lied in the industrial control fields.The paper mainly discussed the control strategy of intelligence fusion based on characteristic analysis of controlled object.

2.Cybernetics characteristic of industrial heat furnace

There are special kinds of complexities in control process of industrial heat furnace.There are always nonlinearity,uncertainty,infinite dimension,distributed and multi-hierarchy control.For information to handle,it is uncertain,random and incomplete,and also the image information and symbolic information mixed,etc.So it is difficult to establish precise mathematic model by analytic method.From the angle of cybernetics characteristic,the characteristic of this kind of complex system can be summarized up as the following[1]. ① Some of system parameters being unknown,time-varying,random and decentralized.②System delay being unknown and time-varying.③Model being obvious non-linearity in the system.④System parameters being cross-correlated.⑤ Environment disturbance being unknown,timevarying and random.For the above mentioned characteristic,the conventional control approach(such as PID)is unsuitable.

The puzzles mainly are shown as follows[2-3].

①Uncertainty puzzle.The conventional PID control is based on the mathematical model,of which the math model of controlled process and environment disturbance must be known or acquirable by means of system identification.However it is very difficult to establish mathematical model for the control puzzles such as”unknown”,”uncertainty”or”littleknown”,so it is also impossible to be controlled by PID method effectively.

②Strong non-linearity.For strong nonlinear controlled process,although there are some nonlinear control theories for use,as a whole,nonlinear system theory is farther from maturing application than the linear system theory,and its approach is too complex to apply.

③Semi-structured and non-structured puzzle.Conventional control theories apply differential equation,state equation and all kinds of mathematic transformation as the research tool.They are numerical computing approaches essentially.Therefore it is strictly subjected to the structured control described by mathematic model.However the problems of nonstructured control are difficult to be described by math method.

④System complexity.In the industrial heating furnace,there are some factors such as being strong in coupling and being across-constrained and etc,the conventional control can’t solve these problems effectively.

⑤Problems of reliability.There are contradictory phenomena between robustness and sensitivity in system.It is necessary to explore more effective control strategies and algorithms.For such a large scale complex system,surely it always adopts the decomposition coordination principle to divide the complex system into a lot of small subsystems even until a physical unit.

3.Control strategy of complex sub-system

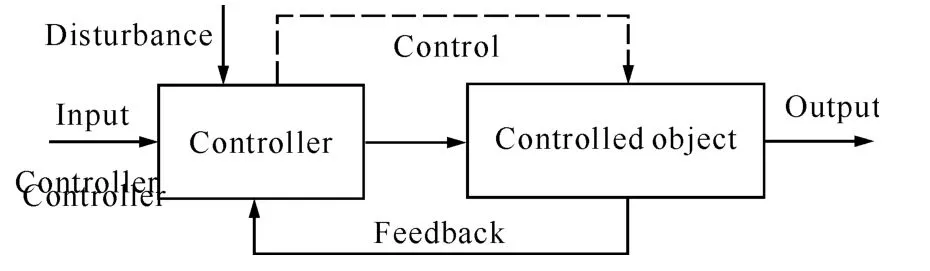

For complex control process,it is very suitable for adopting non-mathematic generalized control model based on knowledge representation.It can break complex process into a lot of subsystem,and the model of generalized control subsystem is shown as in Fig.1.

Fig.1 Generalized control model of subsystem

In a practical control project,relying on knowledge and experience of control experts or operators,the system can be controlled effectively,and the effect can be satisfactory.It means that the controller can complete the desired control tasks by means of human intelligence, knowledge, experience and skill.Therefore,it is a kind of control model combined human with machine,i.e.a combination of controller(human)model and controlled object(machine)model,such as generalized control model of combined human knowledge model and controlled object theory model.For a controlled object with the above characteristic,there are some strategies to be selected,such as artificial neural network,fuzzy logic control,expert system control and human simulated intelligent control(HSIC),and so on.They don’t need any controlled-object or process mathematic model.In the above control strategies,the strategy of HSIC is closer to engineering practice than other control method.It mainly summarizes human control experience,imitates human control experience and behavior,and applies the production rule to describe its heuristic and instinctive reasoning behavior in control field.Nowadays,the most excellent controller is still human’s brain.Since the basic properties of HSIC is to simulate expert control behavior,therefore its control algorithm is an interaction of the multi-modal control to coordinate all kinds of incompatible control demands in a complex control system,such as robustness and accuracy,rapidness and smoothness,and so on[4].

4.Fusion control strategy of control unit based on HSIC

Due to being lack of strict mathematic model,it is difficult to control complex system by classical control method(such as PID)or modern control theory method(such as MIMO).The best choice is to apply intelligent control strategy such as artificial neural network,fuzzy logic control,expert system control and HSIC[5]and so on.In which,the HSIC has the following properties,adopting the strategy of combined open-loop control with closed-loop control,and multi-modal control of combined quantitative and qualitative control,and adopting stability monitoring.It is more flexible in constructing algorithm,and better in control performance.

4.1.Control unit model

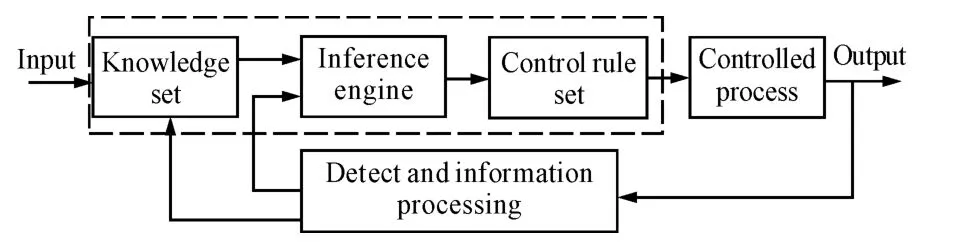

Based on the HSIC,the thought of expert control system can easily be introduced into the controller.Then the structure of expert system can be simplified,and the knowledge base and control rule of reasoning organization could be fused into the human simulated intelligent controller.It can flexibly apply the multi-modal control,and strengthen the ability of judging and reasoning.The structure of controller based on HSIC is shown as in Fig.2.

Fig.2 Model of fusion controller based on HSIC

The knowledge set is established by production rule,its basic structure is IF(condition)THEN(action),and its outstanding advantages are that it is better in module,each piece of rule can be added,deleted,and modified independently.There is nonrelation among each piece of rule,and therefore it is very suitable for the application of control function module of complex unit.

4.2.Fusion control algorithm

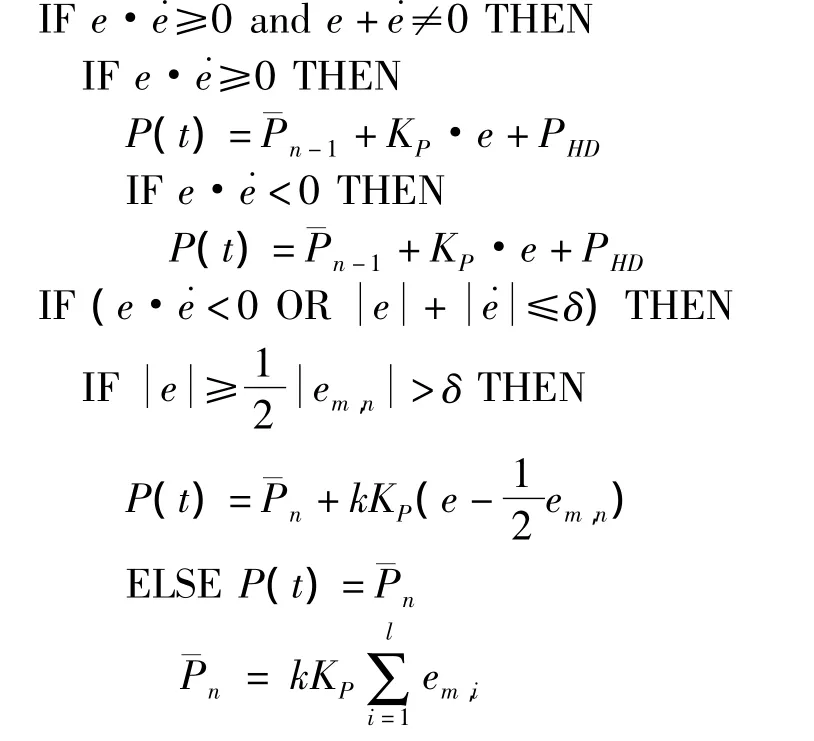

A sort of improved basic control algorithm can summarized as follow.The control rule set can be deduced from engineering control algorithm.That is based on the prototype algorithm of HSIC,and the control rule set of summarized the control experience is a suit of control rule to be matched for different characteristic state.The detailed control rules are as the following,there are two sorts of control pattern.

①ife·≥0 ande+≠0 then P-HD control pattern(Proportion and Half Derivation).

②ife·≤0 ore==0 then HO control pattern(Half Open-loop).

The algorithm after fused expert control knowledge can be summarized up the following by structured English description method.

In which,Pis the output of controller(to controlled process),eis the input of controller(system error signal),˙eis first-order derivative of error,em,iis theithextremum of errore,Kpis the proportion gain,k is a constraint coefficient,PHDis component of half derivation,˙em,iis theithextremum ofin PHD pattern,andis thelthneeded holding constant of half derivation component in P-HD pattern.Define=0(differential extremum memory),i,l,nis nature number,and δ is the sensitivity of controller input.

5.Simulation experiment of fusion algorithm

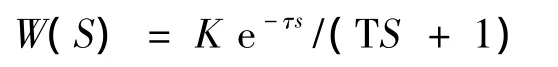

For convenience,here it only takes simplified control algorithm to make the simulation.Ignoring the influence of various factors such as nonlinearity,time varying,uncertainty and so on,the robust controller itself can ensure the control quality,and therefore the simulated math model is not so important.If the controlled system is considered as first-order process with time lag in industrial heat furnace in machining operation,then its control process can adopt the model of inertia node with pure time lag to be described approximately.

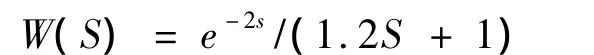

In which,τ,T,Kis respectively the pure lag time,time constant of rolling process,gain coefficient.Generally three parameters in the formula can be determined by means of unit step response method.For convenience,here it takes τ=2,T=1.2,K=1,and therefore the model is

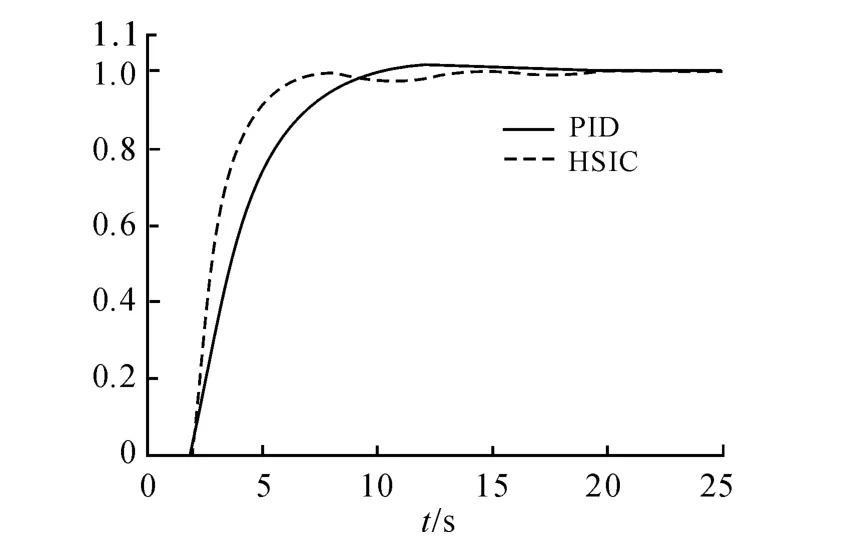

Under the condition of Matlab environment,adopting unit step input signal,by means of Simulink tool box it can build system simulation model to make the simulation of control process.The simulation adopts respectively the PID and intelligence fusion based control algorithm(simplified as HSIC in the following figure)to be in charge of controlling the same process,and the simulation curve is shown as in Fig.3.

Fig.3 Process response

In the Fig.3,the curve 1 and curve 2 is respectively the response curve by PID and HSIC,and from Fig.4,it can be seen that both PID and HSIC can not be in overshoot,but for the former the rising and regulating time is lower than the later,therefore the later owns better control effect.

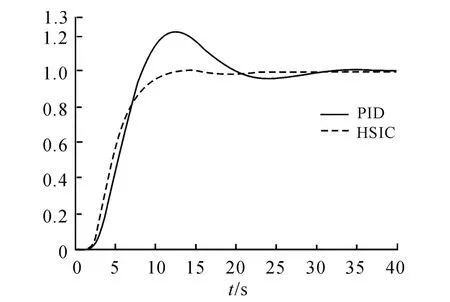

In order to validate the advantages of fusion control strategy,here it gives a comparison of robustness for parameter changing.the parameter of controller consists ofK,Tand τ,and for simplification,here it would add an inertia node 1/(2S+1)in controlled object,namely when the transfer function of controlled object changes fromW(S)=e-2s/(1.2S+1)toW1(S)=e-2s/(1.2S+1)(2s+1)the response curve is shown as in Fig.4.From the Fig.4,it can be seen that it hardly changes in system response for HSIC control,and there is not any overshoot,but it has seriously overshoot for PID control.

When the system parameter changes the HSIC has very strong robustness than PID.In the controlled process of industrial heat furnace,the PID control produces very obvious overshoot,and the rising as well as regulating time get slow,but the HSIC is hardly changing.The simulation mentioned above shows that control algorithm of HSIC is better in control quality than PID.

Fig.4 Response of two-order process with pure lag

6.Conclusions

In the control of complex uncertainty system for large-scale industrial heating furnace,it is always decomposed into lots of subsystem.The upper coordination decision unit coordinates the performance index of each subsystem to ensure the whole system balance among performance index.Each subsystem can be controlled by intelligent fusion strategy,and the practices show that it is stronger in robustness,more accurate in control precision,better in steady or dynamic control quality by intelligent-fusion control strategy.

[1]Taifu L,Guoliang F.Analysis on Control Strategy for a Kind of Uncertain Complexity System[J].Journal of Chongqing University:Natural Science Edition,2003,26(1):4-7.

[2]Zhi Y,Taifu L.Complex Correlation System Control Based on Human Simulation Intelligence[J].Journal of Chongqing University:Natural Science Edition,2002,25(7):9-11.

[3]Zhi Y,Taifu L.Analysis on Correlation Problem with Control of Uncertain Systems[J].Journal of Chongqing University:Natural Science Edition,2002,25(2):19-23.

[4]Taifu L,Zhi Y,Renming D.Implementation on Control and Management Integration for a Kind of System with Uncertainty Complex Systems[C]//Proceedings of 2002 International Fieldbus/Control and Exhibition.Shanghai:Tongji University Press,2002:303-307.

[5]Zhusu L,Yaqing T.Human Simulated Intelligent Controller[M]. Beijing: National Defense Industry Press,2003.

- 机床与液压的其它文章

- Strength Analysis and Optimization of a Torsion Beam Rear Suspension

- Development of Vibration Signal Acquisition and Analysis System for Machine Tools Based on LabVIEW

- Numerical Analysis and Experimental Research on Micro Milling Process with Cycloidal Tool Path

- Analysis of the Optimization of Gear Pump Pulsation Based on Matlab

- Simulation Evaluation and Performance Analysis of a Double Coil Magnetorheological Valve

- Remote Condition-based Maintenance Approach to Hydraulic System of Construction Machinery