Lubricant Oil Condition Assessment Based on AHP and Fuzzy Comprehensive Evaluation

DU Chuanin,WANG Juxiang

a.Graduate Students’Brigade;b.Department of Airborne Vehicle Engineering,Naval Aeronautical Engineering Institute,Yantai 264001,China

1.Introduction

Engines rely highly on lubricant oil to operate properly.The film of lubricant oil between engine components can reduce friction and provide an additional pathway for heat transfer,thereby assisting the engine in maintaining its mechanical efficiency,prolonging its life,and guaranteeing its normal operation[1-2].Engines can not work without lubricant oil,and lubricant oil quality determines the work condition of engine.At the same time,many wear particles,which are the products of engine components friction,suspend in lubricant oil.On the basis of wear metal elements types and concentrations,the condition of component that contains these elements,can be determined.Apparently,acquiring real time oil quality and wear metal elements information,and taking in time measures,can guarantee that the engine is in good state.

According to the above analysis,Lubricant oil condition assessment is a multi-index evaluation problem,and it is very hard to assess oil condition by considering single index.Therefore,it should be solved by considering indexes comprehensively that characterizing oil condition.

In this paper,lubricant oil of a missile launching vehicle and guarantee vehicle is investigated.Through physical and chemical analysis,FTIR analysis,and AES analysis,oil physical and chemical indexes,oil property deteriorating indexes,and wear metal elements indexes can be acquired.These indexes characterize oil condition from different respects.By using AHP[3-4](Analytic Hierarchy Process)and fuzzy comprehensive evaluation[5],these indexes are considered comprehensively to assess lubricant oil condition.

2.Analysis of lubricant oil condition assessment process based on AHP

In 1980,AHP was proposed by T.L.Satty to organize and synthesize people subjective judgment,which can also transform qualitative problem to quantitative problem,and make complex problem systematical and hierarchical.There are four steps to assess lubricant oil condition process using AHP.①Analyze relationship between factors ofassessment process,and build hierarchy.② Compare every two factors of every layer,and construct judgment matrix.③ According to the judgment matrix,compute relative weight of factors.④Check consistency of the judgment matrix.

2.1.Hierarchy of lubricant oil condition assessment

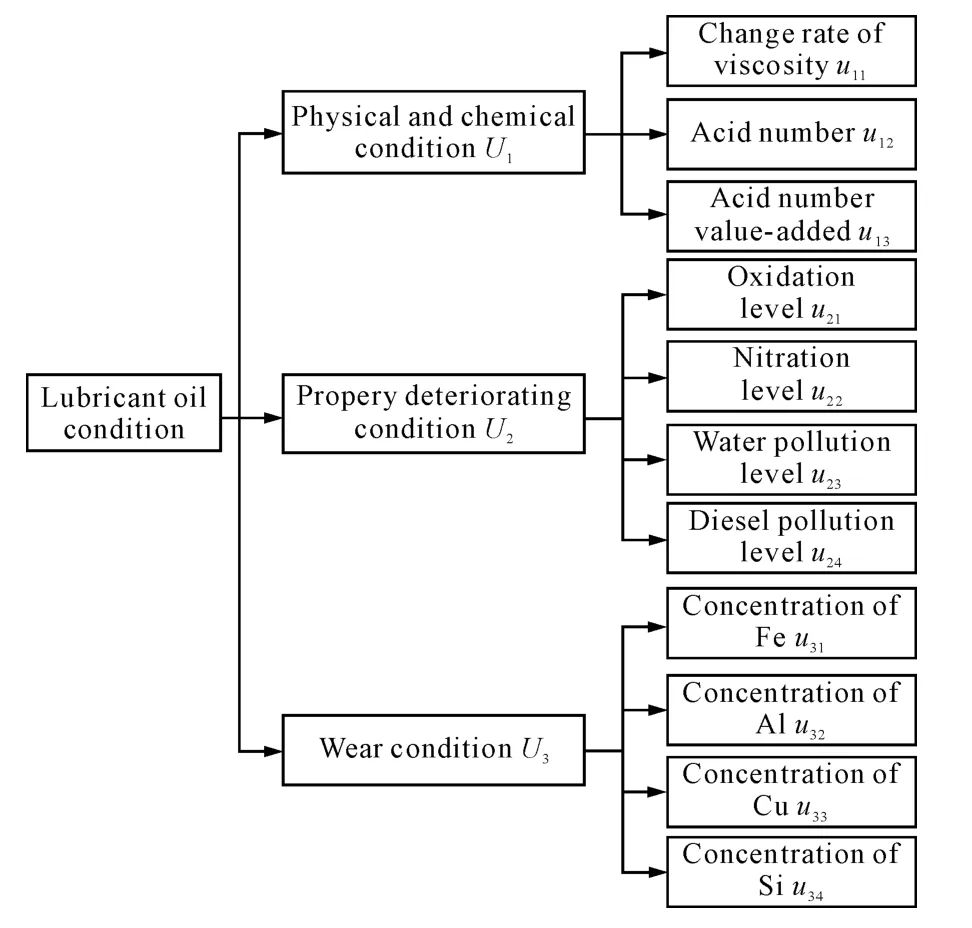

In the process of lubricant oil condition assessment,firstly,three testings are conducted,and eleven indexes that characterize oil condition are acquired;secondly,on the basis of some indexes,oil physical and chemical condition,oil property deteriorating condition,and wear condition can be determined;lastly,according to these conditions,lubricant oil condition can be assessed comprehensively.So the hierarchy of oil condition assessment can be constructed,and illustrated with Fig.1.

Fig.1 Hierarchy of lubricant oil condition assessment

2.2.Establish of judgment matrix of factors

After construction of hierarchy,comparison of every two factors is taken to determine relative importance of every factor,and quantify the relative importance with 1-9 scales proposed by Satty to establish judgment matrix.For example,judgment matrixA=(aij)n×nof layerBrelative to layerAis established,andaijis the quantified scale between theith factor and thejth factor of layerBaccording to their relative importance to layerA.

2.3.Computation of factor weight

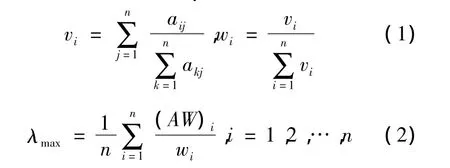

According to judgment matrixA,preferential weight of factors can be determined by computing the maximum eigenvalue of matrixAand its corresponding eigenvector.The eigenvectorW=(w1,w2,…,wn)represents the ratio of weight distribution.Eigenvector can be obtained by root method as follows:

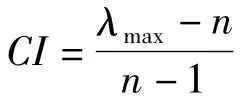

2.4.Consistency check

Tab.1 Average random consistency indicator RI

3.Fuzzy comprehensive evaluation

According to the hierarchy of lubricant oil condition assessment,the assessment process is divided into three layers.Evaluation starts from the bottom-layer sub-factors,and then on the basis of this layer evaluation,further evaluation is conducted.Thus,multi-fuzzy comprehensive evaluation model is needed.

Multi-fuzzy comprehensive evaluation model is according to the features of objects,to set up index system,to divide all the factors with special features.In accordance with the lower to higher,firstly do the comprehensive evaluation for everysection,and next,do the senior comprehensive evaluation for every lower result,and finally get the realistic results.Concrete steps are shown as follows:

3.1.Setting element set and comment set

2)Setting up comment setV= {V1,V2,…,Vp}.

3.2.Determining the weight of every element

3.3.Determining single element fuzzy matrix

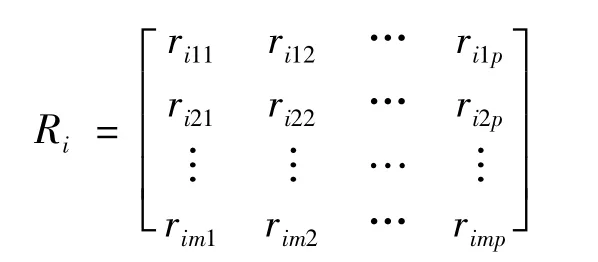

According to fuzzy theory,every element’s membership ofUiis calculated with formula.The appraisal ofjth single factor isrij=(rij1,rij2,…,rijp),whererijkis the fuzzy membership degree of factoruijto gradevk.The overall fuzzy evaluation matrix of allmfactors is

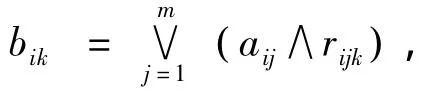

3.4.Multi-fuzzy comprehensive evaluation

Since the hierarchy of lubricant oil condition assessment is divided into three layers,a model of secondary fuzzy comprehensive evaluation can be built.Firstly,do the comprehensive evaluation for every element in the bottom layer,and then do it for the higher layer.

1)First-grade fuzzy comprehensive evaluation

2)Second-grade fuzzy comprehensive evaluation

After the first-grade comprehensive evaluation,the evaluation results of all the subset ofUare got,the second-grade fuzzy evaluation matrix can be determined by

Supposing the weight vector of elements inUisA= {a1,a2,…,an},the result of second-grade comprehensive evaluation is

where

Finally,according to maximum membership degree method,evaluation result is the comment elementvicorresponding to the maximum ofbi(i=1,2,…,p).

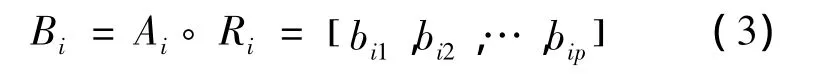

4.Lubricant oil condition assessment

Samples investigated are CD-15W/40 lubricant oil,and collected from one launching vehicle and one guarantee vehicle.Through physical and chemical analysis[6,7],FTIR analysis[8,9],and AES analysis[10],oil physical and chemical indexes,oil property deteriorating indexes,and wear metal elements indexes are acquired.The results are listed in Tab.2.

Tab.2 Lubricant oil testing results

Based on theory analyzed in section 2 and 3,lubricant oil condition is assessed in this section.The assessment takes physical and chemical condition,oil property deteriorating condition,and wear condition into account comprehensively,as illustrated with Fig.1.

4.1.Establish of element set and comment set

According to the hierarchy of lubricant oil condition assessment,element set of oil condition assessment isU={U1,U2,U3}.In our research,the final oil condition assessment result is divided into three levels,which are“normal”,“abnormal”,and“oil change”.So the corresponding comment set is defined asV={normal,abnormal,oilchange}.

The element set has three subsets:U1,U2,U3,whereU1={U11,U12,U13},U2={U21,U22,U23,U24},andU3={U31,U32,U33,U34}.Theirs corresponding comment sets areV1={normal,attention,alarm},V2={normal,attention,alarm},V3={normalwear,abnormalwear,severewear}.

4.2.Determining fuzzy evaluation matrix

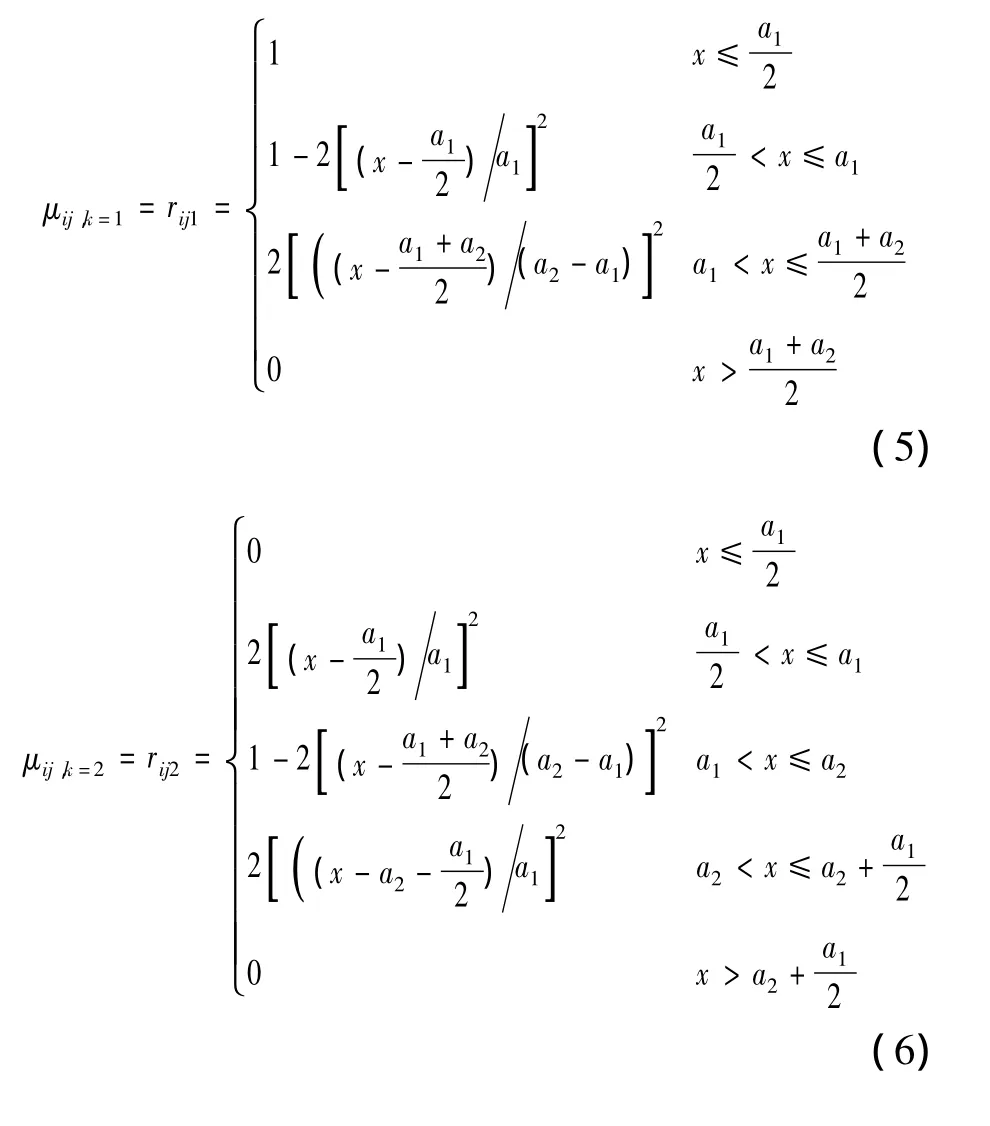

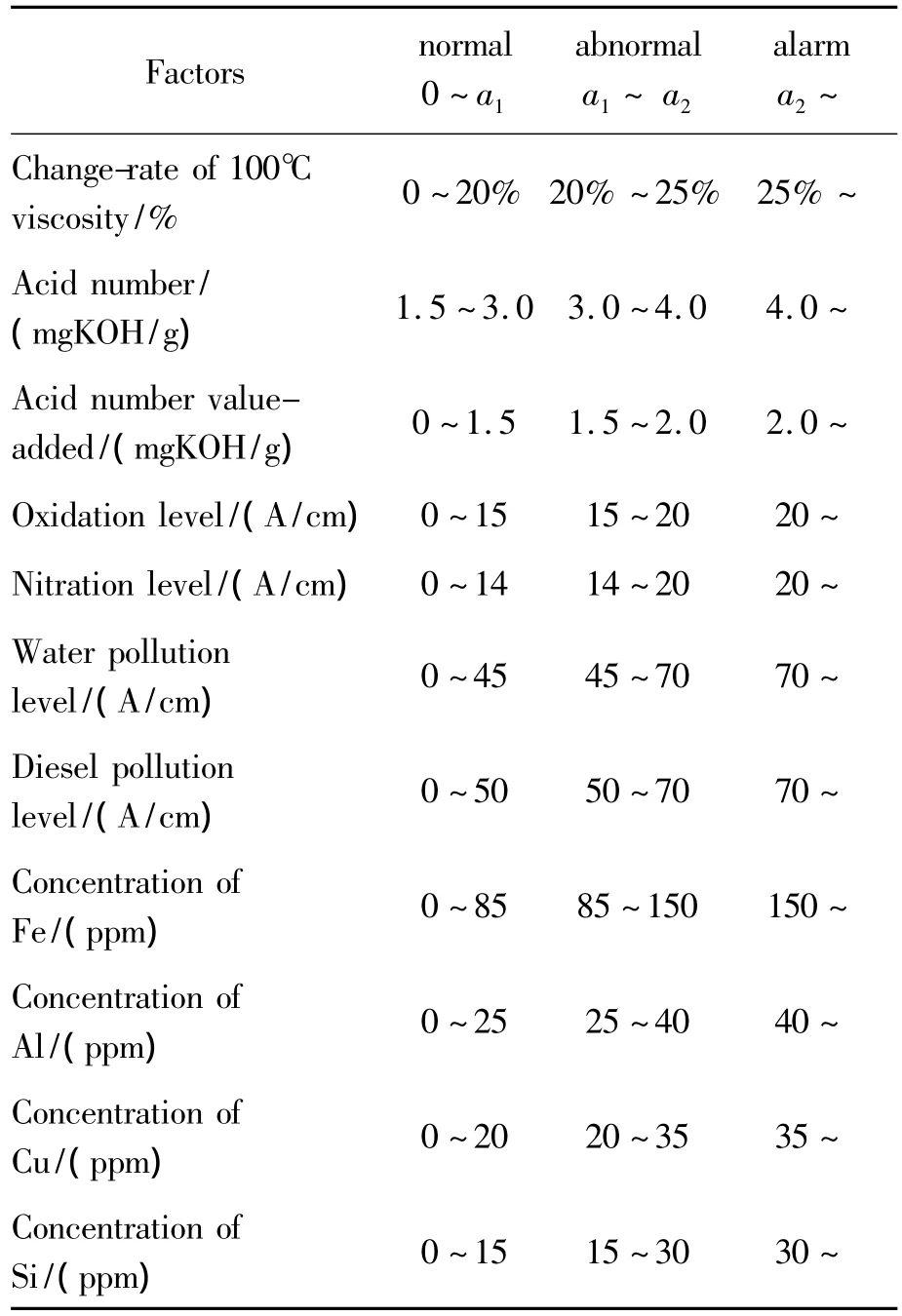

The first-grade fuzzy evaluation matrixRiis determined by calculating every element’s membership ofUiwith formula.The membership used in this paper is defined as follows:

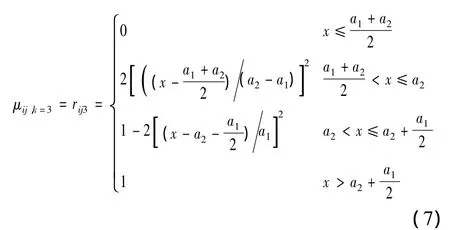

Where,imeansith subsetUi,jmeans thejth elementUij,kmeanskth comment level,a1anda2are constant number that divide factors into grade.On basis of lots of experiments,a1anda2for each factor can be found in Tab.3.

Tab.3 Grade divisions of factors

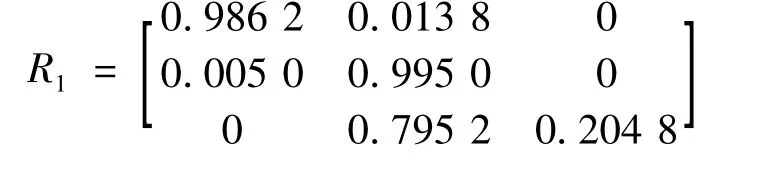

According to formula(5)~(7)and grade division table,first-grade fuzzy evaluation matrix can be determined as follows.

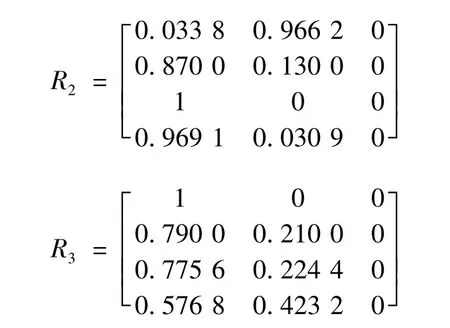

First-grade fuzzy evaluation matrixes for launching vehicle lubricant oil condition are:

First-grade fuzzy evaluation matrixes for guarantee vehicle lubricant oil condition are:

4.3.Determining weight vector

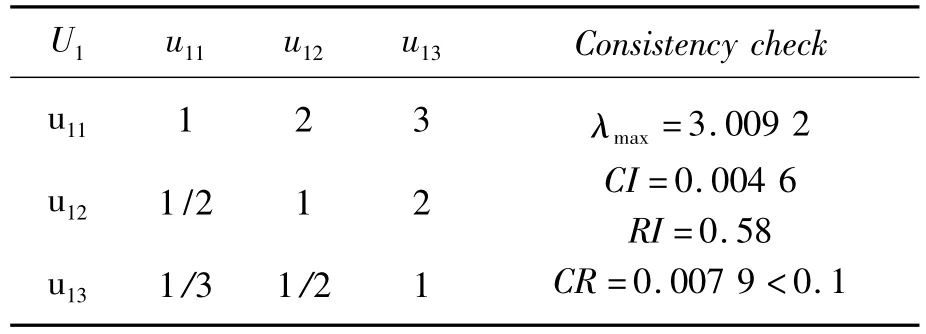

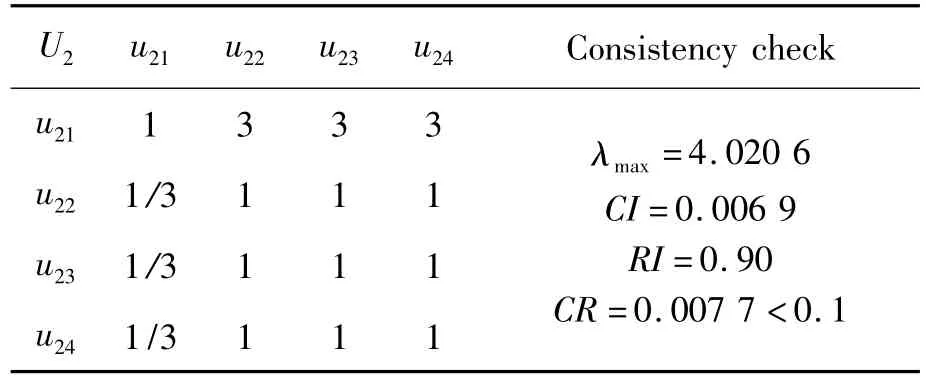

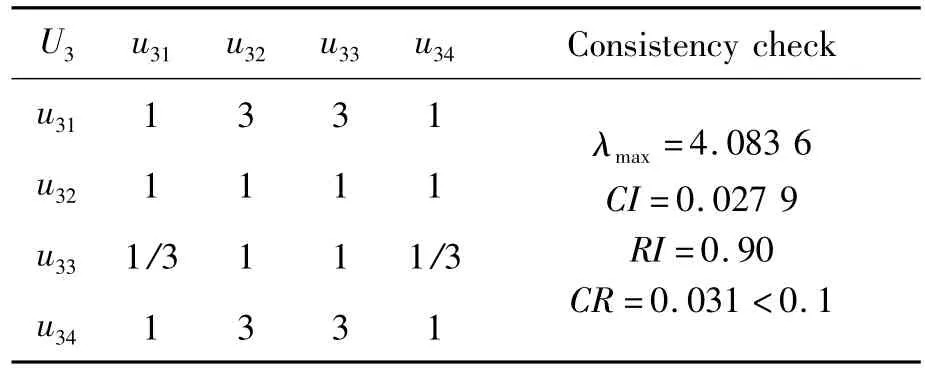

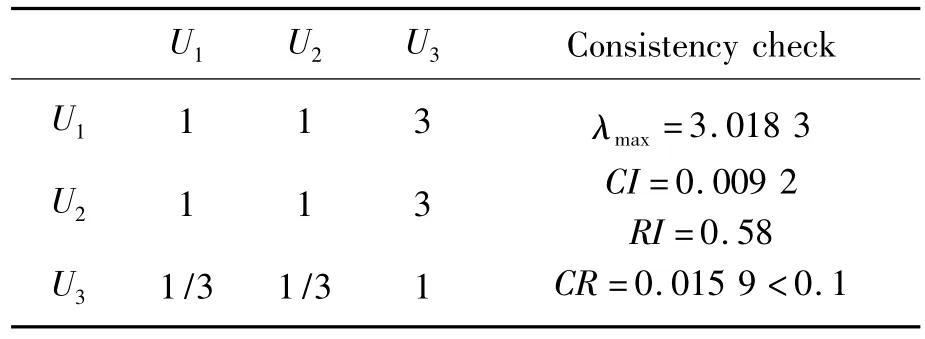

Weight vectors are calculated from judgment matrix generated from AHP.Based on the results of testing,relationship between indexes,and theirs influence on lubricant oil condition,judgment matrixes are determined is Tab.4~7.

Tab.4 Judgment matrix of physical and chemical properties indexes

Tab.5 Judgment matrix of property deteriorating indexes

Tab.6 Judgment matrix of wearing element indexes

Tab.7 Judgment matrix of factors

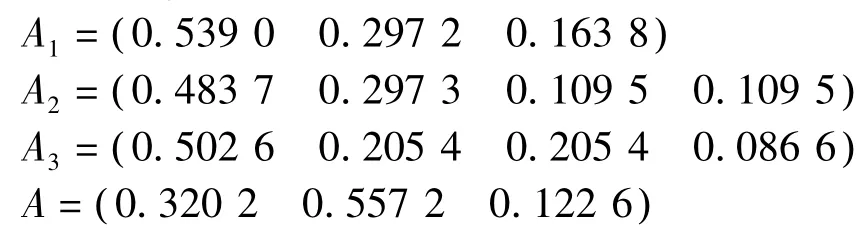

The weight vectors are:

4.4.First-grade fuzzy evaluation

Taking first-grade fuzzy evaluation matrix and weight vector to formula(3),and according to the maximum membership degree method,the first-grade fuzzy evaluation result can be determined.

First-grade fuzzy evaluation result of launching vehicle lubricant oil condition is:

B1= (0.539 0 0.297 2 0.163 8),physical and chemical property condition is“normal”;

B2= (0.297 3 0.483 7 0.000 0),property deteriorating condition is“attention”;

B3= (0 .502 6 0.205 4 0.000 0),wear condition is“normal wear”.

First-grade fuzzy evaluation result of guarantee vehicle lubricant oil condition is:

B1= (0 .539 0 0.297 2 0.000 0),physical and chemical property condition is“normal”;

B2= (0 .483 7 0.358 4 0.000 0),property deteriorating condition is“normal”;

B3= (0 .502 6 0.088 6 0.000 0),wear condition is“normal wear”.

4.5.Second-grade fuzzy evaluation

Second-grade fuzzy evaluation result of launching vehicle lubricant oil condition is:

B = (0.320 2 0.483 7 0.163 8)

Second-grade fuzzy evaluation result of guarantee vehicle lubricant oil condition is

B = ( 0.483 7 0.358 4 0.000 0)

According to the maximum membership degree method,lubricant oil condition of launching vehicle and guarantee vehicle is“attention”and “normal”respectively.The first-grade fuzzy evaluation result of launching vehicle shows that property deteriorating condition is“attention”,and so it can be concluded that lubricant oil“attention”condition is mainly caused by oil property deteriorating.It has been surveyed that the launching vehicle engine bears more load than guarantee vehicle engine,and its working environment is worse,therefore its antioxidant additive and antiwear additive are consumed more quickly.In the future,the lubricant oil of launching vehicle should be given more attention,especially its property deteriorating condition,and the time interval of oil monitoring should be reduced.

5.Conclusions

Lubricant oil experiences a lot of change in use,and many indexes that characterizing its property may show different change trend,so it is very hard to assess oil condition by considering single index.Therefore,lubricant oil condition assessment is a multi-index evaluation problem,and it should be solved by comprehensive evaluation.In our research,oil physical and chemical property indexes,oil property deteriorating indexes,and wear indexes are considered comprehensively,AHP and fuzzy comprehensive evaluation methods are used to assess oil condition.The example shows that the methods give the reasonable results that according with actual oil condition.According to the assessment,engine lubrication state is acquired,and engine maintenance support decision-making can be provided.

[1]MAO Meijuan,ZHU Zi xin,WANG Feng.Technologies and Application of Equipment Oil Monitoring[M].Beijing:National Defense Industry Press,2006.

[2]REN Guo quan,ZHANG Peilin, ZHANG Yingtang.Theory of Equipment Oil Intelligent Monitoring[M].Beijing:National Defense Industry Press,2006.

[3]Saaty.Thomas L.The Analytic Hierarchy Process[M].New York:McGraw-Hill,1980.

[4]Saaty T L.A Scaling Method for Priorities in Hierarchical Structures[J].Journal of Math Psychology,1997,15:234-281.

[5]HU Baoqing.Foundation of Fuzzy Theory[M].Hubei:Wuhan University Press,2004.

[6]National Standard Agency. GB 265—88, Petroleum Products—Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity[S].Beijing:National Standard Agency,1988.

[7]National Standard Agency. GB 264—83, Petroleum Products—Determination of Acid Number[S].Beijing:National Standard Agency,1983.

[8]ASTM E2412-04 Standard Practice for Condition Monitoring of Used Lubricants by Trend Analysis Using Fourier Transform Infrared(FT-IR)Spectrometry[S].United States:ASTM Committee,2004.

[9]ASTM E168-06 Standard Practices for General Techniques of Infrared Quantitative Analysis[S].United States:ASTM Committee,2006.

[10]ASTM D6595-05 Test Method for Determination of Wear Metals and Contaminants in Used Lubricanting Oils or Used Hydraulic Fluids by Rotating Disc Electrode Atomic Emission Spectrometry[S].United States:ASTM Committee,2005.

- 机床与液压的其它文章

- Strength Analysis and Optimization of a Torsion Beam Rear Suspension

- Development of Vibration Signal Acquisition and Analysis System for Machine Tools Based on LabVIEW

- Numerical Analysis and Experimental Research on Micro Milling Process with Cycloidal Tool Path

- Analysis of the Optimization of Gear Pump Pulsation Based on Matlab

- Simulation Evaluation and Performance Analysis of a Double Coil Magnetorheological Valve

- Remote Condition-based Maintenance Approach to Hydraulic System of Construction Machinery