Analysis and Discussion of the Heat Treatment Process to Resolve the Failure of Conventional Lathe Carriage

FENG Xiofei,ZHENG Weigng ,JIANG Lito

a.School of Energy And Power Engineering;b.Mechanical Engineering Training Center,Wuhan University of Technology,Wuhan 430063,China

Lathe,an important part of the machining,plays an important role in the development of industrial.The CNC lathe is in production for many years and with great success,but compared traditional lathe is still irreplaceable,is important equipment in turner production.Lathe square turret is the important factor to determine the accuracy of turner,but there is an emergence of the fault in use which seriously affects the accuracy,leads to a direct result of the decrease in efficiency.CA6140 lathe square turret failure to solve the fault square turret,analyzed,and to discuss several modern heat treatment process,comparative analysis,looking for the best way to solve the fault.

1.Failure analysis

Before conducting failure analysis to understand the structure and working principle of the CA6140 lathe square turret[1]as follows:

1.1.The diagram of square turret structure and working principle

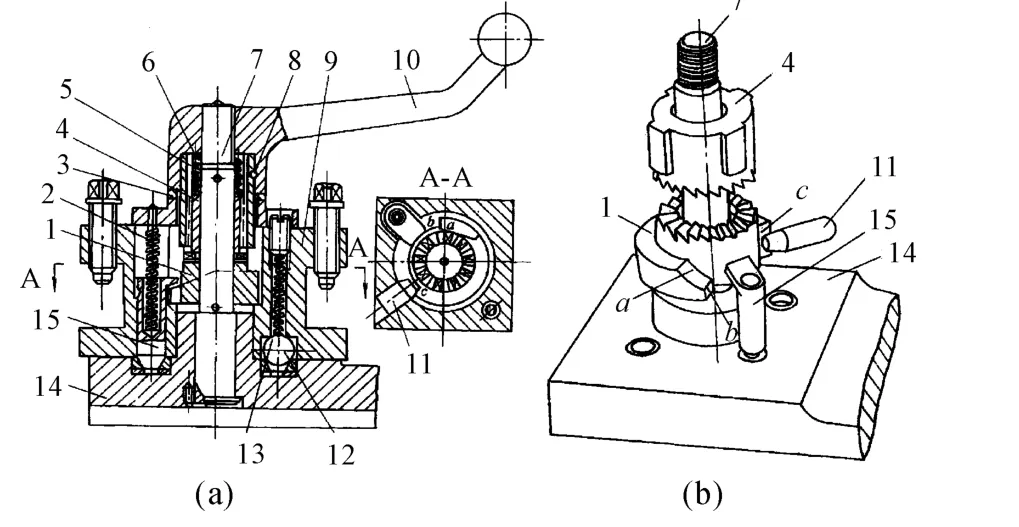

The diagram of structure is Fig.1:

Fig.1 The diagram of CA6140 lathe square turret structure

The working principle of square turret:Counterclockwise rotation of the handle 10,to release the turret body 9,by a pin connecting turning the inner splined sleeve,and drive the rotation of the outer splined sleeve,through which the lower end of the jaw so that the cam rotation,and through the inclined surface of the camapull out the positioning pin 15,the side of the gapbtouch turret body 9 of the positioning pin 15,so that the turret body is rotated,the steel ball 12 slipping out of the hand to another posi-tioning hole of the turret body early positioning,and then clockwise rotation of the handle 10,pin alignment and clamping sequentially.

1.2.The cause of the malfunction

Lathes often need change tool in long-term use,and the traditional lathe tool change is achieved by the rotation of the handle on the turret.Due to frequent rotation of the handle portion of the tool holder,result of repeated exposure to the friction between pin hole sleeve on small skateboard and locating pin head and steel ball in square turret caused by sleeve excessive wear and its cross-section can easily become oval.The direct impact resulting often occurs a certain amount of offset when locking square turret,if not noticed this offset,directly on a workpiece turner,its accuracy will be greatly affected,easily causing the workpiece to waste.if staffs observe this offset,they need to manually correct,no doubt greatly extend the processing time,affecting the efficiency.

Manifested on a traditional lathe CA6140 wear is shown in Fig.2.From Fig.1,the pin holes sleeve its cross-section is circular before excessive wear,but in Fig.2 the pin hole sleeve has severe wear whose sectional has almost oval.

Fig.2 The wear of pin hole sleeve on the small skateboard of CA6140 lathe

2.Solutions and Discussion

The wear is one of the main failure modes of the mechanical parts.The wear resistance of steel is the ability to resist wear on certain working conditions[2].So far,the scientific community does not have a concise and reliable wear law.For certain wear conditions,there are many factors that affect the steel abrasion resistance,including the operating conditions(load,speed,sport,etc.),lubrication state,environmental factors(temperature,humidity,and the surrounding medium,etc.),material factors(component,microstructure,mechanical properties,etc.),the quality of the surface of the part and the physical chemical characteristics[3].Traditional lathe,a small slide pin hole sleeve material is usually 45 steel.In order to improve its surface hardness and wearresistance,the traditionalpractice is the quenching and tempering approach[4].Through the pin hole sleeve wear analysis,ordinary heat treatment obviously does not satisfy the requirements for longterm use.According to wear mechanism discuss this two heat treatment to improve the hardness and wear resistance of 45 steel,as to improve the performance of pin hole sleeve on the small skateboard,and improve production efficiency.

2.1.Subcritical quenched

It is well known that the wearresistance of the steel has much to do with the hardness,strength and toughness of the steel.Steel organization,all factors that can increase the hardness,strength and toughness of the steel can improve the wear resistance of the steel[5].Subcritical quenched due to the quenching temperature range is below in the Ac3 twophase region(austenite+ferrite phase region),because the presence of the ferrite phase,so that the workpiece has good toughness and ductility after quenching, the quench cracking tend to be greatly reduced to[6];the quenching temperature is lower,the austenite formed in the heating of high carbon content,the hardness of the martensite after quenching is higher than the martensite formed by the traditional quenching.Subcritical quenched usually require preheating,and quenching and high temperature tempering preheating is stronger than the traditional annealing or normalizing[7].Therefore,it can guarantee to improve the strength and toughness of the steel in the hardness of the same case if taking appropriate preheating+subcritical quenched process,so as to improve the wear resistance.

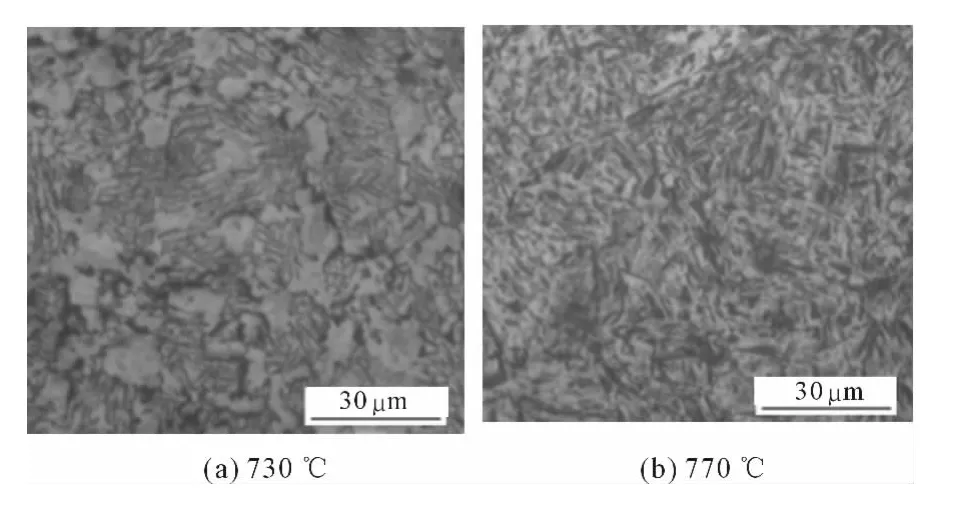

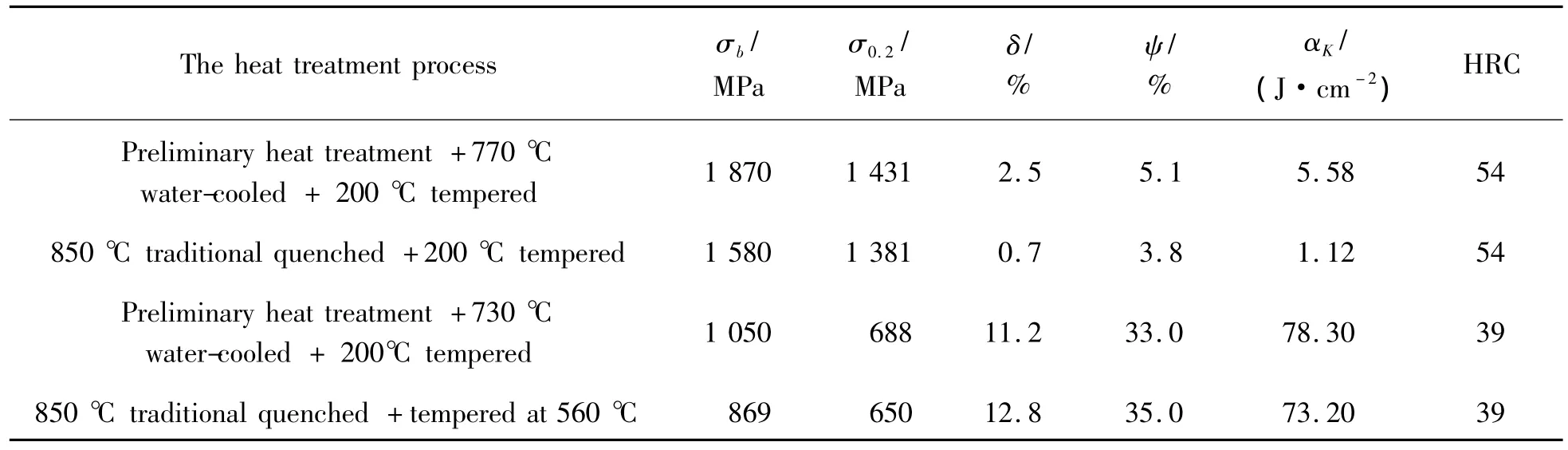

the comparison of the mechanical properties of 45 steel subcritical quenched process with traditional quenching process is shown in Table 1[7].Figure 3[7]gives XJL-02 Vertical metallurgical microscope observation using the 730 ℃ subcritical quenched,770℃after 45 subcritical quenched process handling steel microstructure.Different subcritical quenched temperatures have same preheating conditions(850℃ quenched +550℃ tempered).Table 1 shows that the strength,ductility and toughness of 45 steel by sub-temperature quenched,770℃ +200℃tempered is much higher than at 850℃ traditional quenched+200℃ tempered;in addition the strength and toughness of 45 steel by 730℃subcritical quenched+200℃tempered is higher than at 850℃traditional quenched+tempered at 560℃.This shows the strength and toughness of the 45 steel obtained by the appropriate sub-temperature quenched superior to traditional quenched strength and toughness,and its application to the pin hole sleeve can significantly improve the wear resistance.

Fig.3 Microstructure of 45 steel subcritical quenched(Pre-heat treatment:quenched at 850℃+tempered at 550℃)

Tab.1 Comparison of mechanical properties of 45 steel after subcritical quenching and conventional quenching

2.2.Surface treatment

The part surface quality is one of important factors to affect its wear resistance.Surface treatment can be a good solution to the problem of wear of pin hole sleeve.The surface treatment technique by heating or mechanical processing method does not change the chemical composition of the material surface,but the structure is changed,as well as its properties.Surface treatment enables parts to obtain the surfacehardened layer of a certain depth,and its central portion to maintain good toughness,and thereby improve the wear resistance[3].

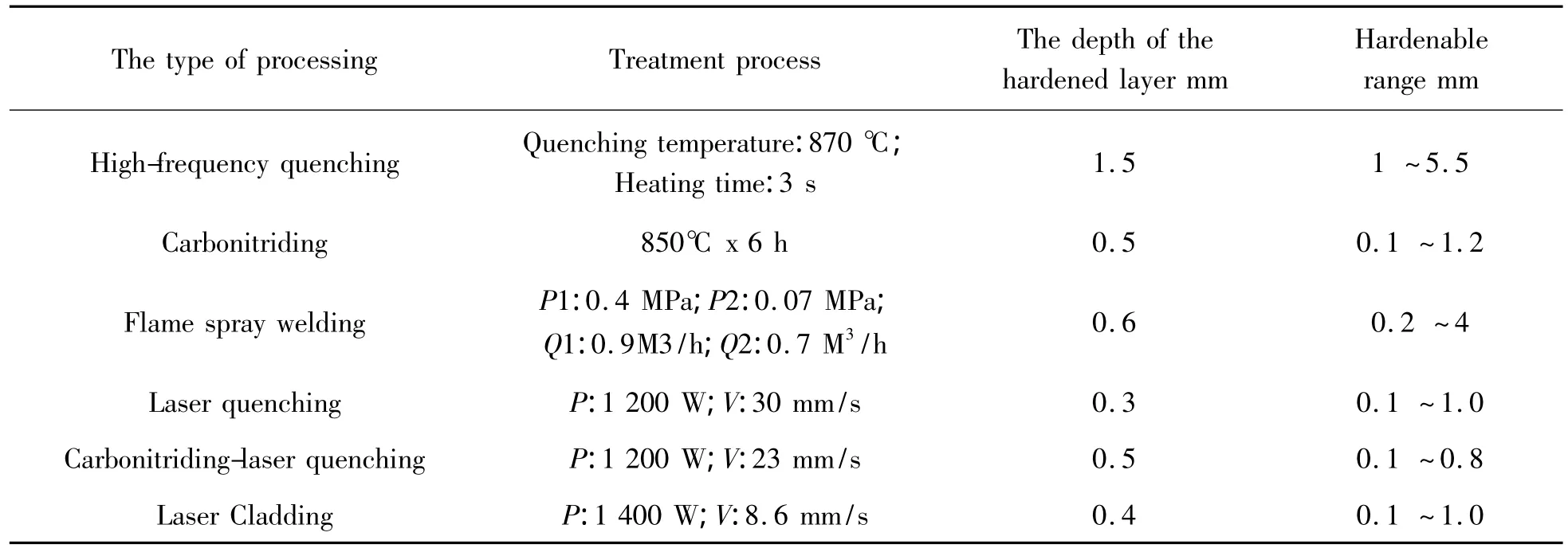

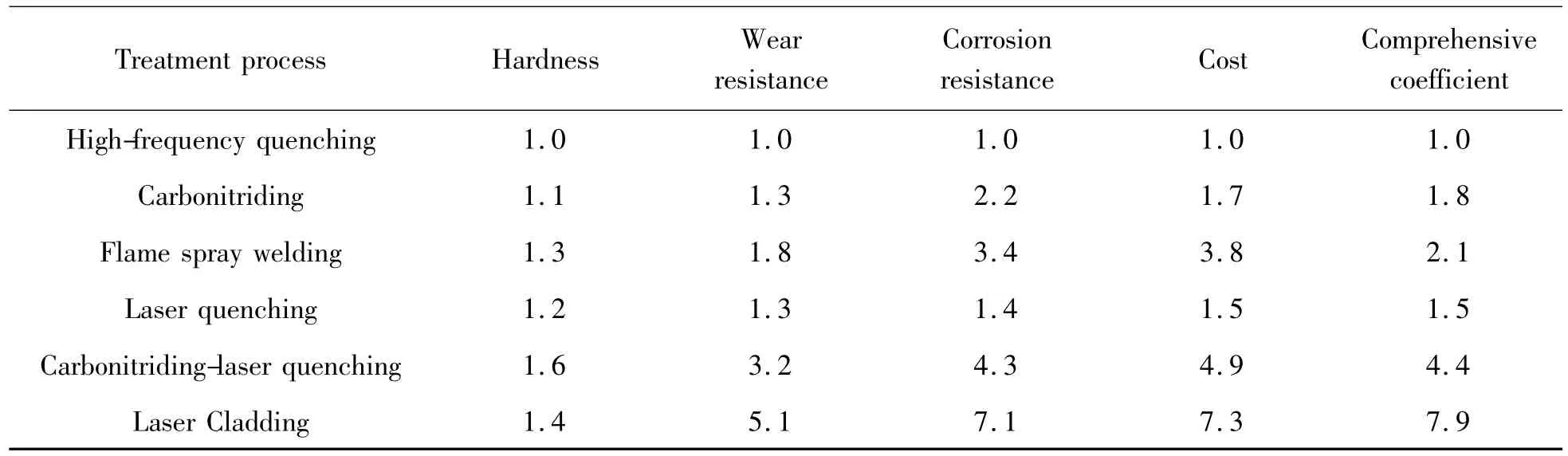

According to Gu’s abrasion resistance studies of 45 steel using several surface treatment[8],it can be drawn the difference in performance of 45 steel under different surface treatment conditions.Use the experimental conditions of the different surface treatment work to 45 steel sample(quenched and tempered state),such as shown in Table 2.For ease of comparison,the datas were normalized,and gives a comparison between the sample performance of several enhanced process,as shown in Table 3.Including carbonitriding in RRJJ25-9T pit gas carburizing furnace,kerosene decomposition gas as a carburizing agent,liquid ammonia(after gasification,drying)as a nitriding agent,direct quenched after carbonitriding.Laser as GJ-1 transverse flow lasers,the output power of 500~2 000 W,continuously adjustable,and a spot diameter of 3 mm.Phosphating processing of the sample surface before the laser hardening.In Tab.2,PandVare the laser power and the scanning speed;P1 andP2,respectively,are the pressure of the oxygen and acetylene gas;Q1 andQ2 are oxygen and acetylene gas flow.Comprehensive coefficient in Tab.3 is multiplied by the three values??of hardness,wear resistance,corrosion resistance divided by the cost values obtained.

From Tab.2 can be seen by the hardened layer depth and hardened rang for 45 steel under the respective surface treatment process,using the surface treatment improve the depth of the hardened layer of the sample.

From Tab.3,it greatly improved the properties of the s to have used surface treatment,and improved the hardness and wear resistance of the samples.The improvements are different by different surface heat treatment process.Laser cladding improves the wear resistance of the sample largest,but also with the highest cost;High-frequency quenching improves the wear resistance of the sample smallest,but the cost is lowest compared to the other processes.To the pin hole sleeve of small skateboard for conventional lathe,the applications of these several surface treatment processes theoretically could improve the abrasion resistance of the sleeve,thereby extending the life,overcoming the malfunction in the production.

Tab.2 The test conditions of the surface treatment process

Tab.3 The performance of sample through several enhanced process and contrast

3.Conclusions

1)After a tool change,the conventional lathe carriage often appears a certain amount of offset caused by excessive wear of pin hole sleeve of the small skateboard.The material of the pin hole sleeve for the 45 steel after traditional quenched and tempered,whose wear resistance do not reach production requirements.

2)Compared with the traditional quenched,subcritical quenched can significantly improve the 45 steel strength,hardness,toughness,so it can improve the wear resistance of the 45 steel,and greatly improve its life cycle if apply this to the pin hole sleeve heat treatment.

3)Using surface heat treatment can improve the wear resistance of 45 steel,in addition the improvement and the cost are different by different surface heat treatment process,so manufacturers can choose appropriate surface treatment process to produce the pin hole sleeve of small skateboard according to the specific needs.

[1]ZHANG Ensheng,XIA Derong,ZHANG Mingchi,et al.The Practical Technical Manual of Turner[M].Nanjing:Phoenix Science Press,1999.

[2]DAI Qixun.Science of Metallic Materials[M].Beijing:Chemical Industry Press,2011.

[3]ZHANG Jiuyuan.Surface Engineering and Failure Analysis[M].Hangzhou:Zhejiang University Press,2005.

[4]SUN Zhi,NI Hongxin,PENG zhuqin.Modern Iron and Steel Materials and Their Engineering Applications[M].Beijing:China Machine Press,2006.

[5]The Editorial Committee of Anti-Wear and Erosion Resistance and Surface Technology of materials.Introduction of Material Corrosion Resistant and Surface Technology[M].Beijing:China Machine Press,1986.

[6]LI Anming,WANG Xiangjie,HUANG Lijuan.Study on Subcritical Quenching Technique for 45 Steel[J].Heat Treatment of Metals,2007,32(10):56-58.

[7]GU Xiaohui,LIU Jun,SHI Jihong.Influence of subcritical quenching process on microstructure and mechanical properties of 45 steel[J].Heat Treatment of Metals,2011,36(11):70-72.

[8]GU Hongwu.The Effect of Some Surface Modification Processes on Wear and Corrosion Resistance of Steel[J].Materials for Mechanical Engineering,1994,18(3):12-14.

- 机床与液压的其它文章

- Strength Analysis and Optimization of a Torsion Beam Rear Suspension

- Development of Vibration Signal Acquisition and Analysis System for Machine Tools Based on LabVIEW

- Numerical Analysis and Experimental Research on Micro Milling Process with Cycloidal Tool Path

- Analysis of the Optimization of Gear Pump Pulsation Based on Matlab

- Simulation Evaluation and Performance Analysis of a Double Coil Magnetorheological Valve

- Remote Condition-based Maintenance Approach to Hydraulic System of Construction Machinery