Review on the Methods for the Ground Improvement

ZHANG Lizhou ,DENG Xiangbo,XIE Yuxia,WANG Kun

1.Department of Civil Engineering,The University of Hong Kong,Hong Kong,China;

2.Chongqing Survey Institute,Chongqing 400020,China;

3.School of Civil Engineering,Central South University,Changsha 410004,China;

4.Chongqing Changshou Economic & Technological Development Area-Development Investment Group Co.,Ltd,Chongqing 401221,China;

5.East China Investigation and Design Institute under CHECC,Hangzhou 310014,China

Many large cities,such as Shanghai,Guangzhou,Hong Kong,Macau and Bangkok,are located at or around the estuary of big rivers,which means the construction in those places may encounter with the problem of soft clay or silt.It is well known that the soft soil(i.e.,soft clay,silt or highly organic soil)is not suitable for the structures with high compressible characteristics.However,due to the dense development of those cities,engineers have to take measures to address those problematic soils on site.More specifically,the objectives of those soil modifications are to increase the volume stability,enhance the strength,decrease the hydraulic conductivity and promote the durability of soil before the construction.Owning to the serious problems experienced by those cities,these cities have a more advanced technology and experience in ground improvement.

1.Introduction

It is clear that most civil engineering projects are built on,in or with soil.Generally speaking,the structures will experience settlement if built on or in the soil,particularly for the problematic soil,and the excessive settlement(especially differential settlement)will affect the serviceability of the structures or even the safety of those structures(Burland &Wroth,1975).As to address such problem,effective measures should be taken before the construction of such structures.Taken the new Hong Kong international airport for example,the new site of the airport was chosen on the site of Chek Lap Kok island(Plant,1999).The huge reclamation works was required there for the space of the run-way.The material below the sea water is meters of Hong Kong marine clay,which is very compressible with high liquid index.Because of the environmental consideration,dredging was not allowed.Thus the reclamation had to be built on the marine clay and the reclamation material was also from the soft soil nearby such site.In respect to the methods for the ground improvement project,the vertical drains,combined with preloading were applied as to achieve a suitable ground condition for the construction purpose.Due to the appropriate selection of such methods and well test programs before the airport construction(Lo & Mesri,1994;Lo & Premchitt,1999),the Chek Lap Kok airport performs well in service and set a good example for the conduction of ground improvement in Hong Kong and around the world.

Fig.1 New Hong Kong international airport

Currently,it should be pointed out that the major methodologies for ground improvement are compaction,pre-compression,cementation,earth reinforcement,drying and heating which can make the soil particles more closely or increase inter-locking bonding.Therefore,the soil can perform less deformable and the settlement of structures will be decreased.

The recent methodologies for ground improvement:

1)Compaction,also including dynamic compaction,vibro-compact as well as blasting.Most of these methods are better applied for the cohesionless soils,but some still available for cohesive soils;

2)Pre-compression mainly focuses on the acceleration of the soil consolidation by vertical drains and preloading(surcharging);

3)Soil in-situ stabilization and in-situ fixation,which means the soil is mixed on site with cement or chemical reagents to improve the engineering properties of soils;

4)Thermal stabilization that enhances the engineering properties of soils by the control of compressibility and the increase of the soil particle size.

5)Reinforcement of soil by the application of reinforcement element;

In the following,these methodologies will be illustrated in details and the considerations for the selection of such methods will also be discussed.

2.Ground investigation

The objective of the ground investigation for ground improvement is to obtain reliable information,including the properties of soil,extent of problematic ground,surrounding circumstance and so on,which set a solid foundation for economic and safe design of ground treatment.During this process,high-quality sample is required for the oedometer or triaxial tests for the mechanical properties of soil.Besides,the disturbed soil can be used to characterize the classification of soil,determination of water content,plasticity,liquid limit,grain size distribution et al.

In order to obtain the parameters of soil,the instrumentation for the ground investigation include standard penetration test(SPT),cone penetration test(CPT),vane shear test,pressuremeter,piezometer to recognize the site characteristics of the site and roughly estimate the soil properties.On the other hand,the oedometer test,triaxial,permeability test and other laboratory tests can be applied to recognize the engineering properties of problematic soil more accurately on the basis of less disturbing of samples.

Acting as an important factor for the design of ground improvement,the ground investigation should be carefully considered at the beginning stage of the ground improvement planning.Otherwise,the extra cost of re-work of the project may appear in the future.

3.Compaction

The basic concept of compaction is to make the soil particles more closely as to reduce compressibility and increase strength of soils,which can be sub-divided into surface compaction and deep densification.

Surface compaction is the process of packing soil particles more closely together by rolling or mechanical means,thus it increases the dry density of the soil.Although this method can not be very effective in deep for deep site,it is very easy for conduction and cost saving if it is used in a proper way.Meanwhile,the effectiveness of this method depends on the method of compaction,compactive effort,water content of compaction,and volume and water content changes subsequent to compaction.The dry density is a scalar to measure the effectiveness of compaction,and different soil has their different optimum moisture content corresponding to the maximum dry density of the soil(Fig.2).In the field compaction work,tampers and rollers are applied to improve the engineering properties of soil,based on the soil properties and the scale of the work.

Fig.2 Compaction curve for some typical soils

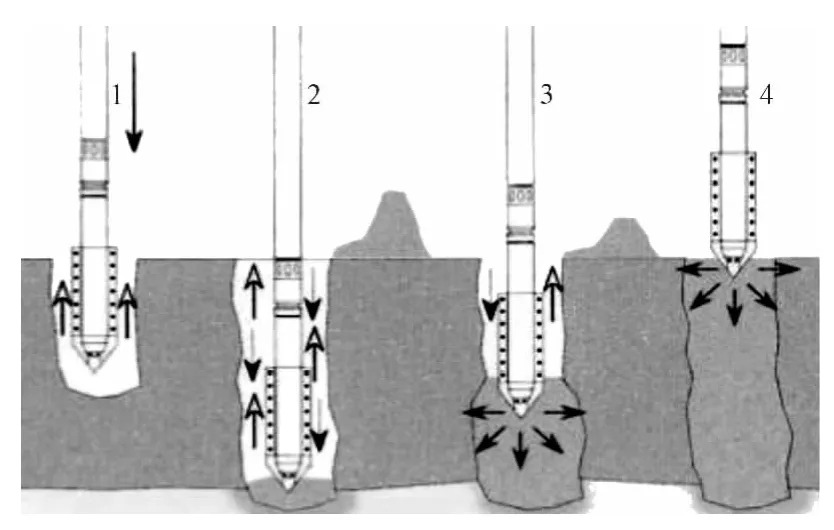

Except for surface compaction,deep densification is another method of compaction.The basic concept is slightly different from the surface compaction,which breaks down the initial structures of soils by dynamic pounders,vibration or blasting.Thus the soil particles of the ground will move to a new and more stable arrangement.So the excessive settlement and liquefaction potential will be eliminated because of the stable status of soil particles.Generally,the deep densification method can be more suitable for the cohesionless soils.But for the cohesive soil(such as clay or silt),the stone column(Chummar,2000)can be applied which can not only squeeze the soils around the column,but also take advantage of the confining pressures of the soil around to improve the bearing capacity of the stone column.On top of that,the stone column can play as a vertical drain channels,accelerate the consolidation process of the cohesive soil which increases the engineering properties of soil in return.

Fig.3 Installation of stone column

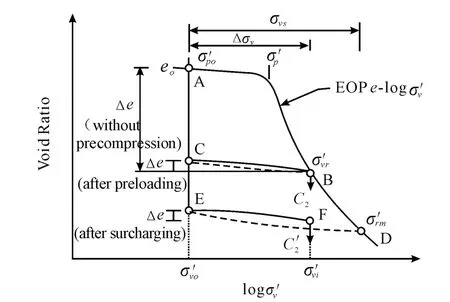

4.Pre-compression

Pre-compression is a process by compressing the soil under an applied stress prior to placing or completing the structures,as to increase the shear strength and subsequently bearing foundation and reduce the post construction settlement to a tolerable value.The principle of pre-compression is to enhance the effective stress within the soil by the increase of loading or reducing the pore water pressure.In this process,the consolidation will speed up,along with settlement.But due to the irrecoverable characteristics of the consolidation settlement,the rebound phenomenon of soil is very small after the removal of the pre-loading.Thus the primary consolidation settlement will be reduced after the completion of the construction(Stamatopoulos,1983).Besides,the surcharging(preloading in excessive of final load)can be applied to reduce the primary consolidation.But more importantly,the secondary consolidation settlement can be also reduced by surcharging and can not be decreased by pre-compression.

Fig.4 Working principles of pre-loading and surcharging

In particular,the vertical drain can be provided in the pre-compression process.Combining with the vertical drain,the rate of consolidation can be further speeded up and time required for the consolidation can be decreased because the drainage distance becomes much smaller than that of the previous condition by the horizontal drainage effect(Zaleski-Zamenhof,1983).

5.Reinforced fill structures

The application of reinforced fill structures is commonly applied to the embankments,bridge abutments as well as retaining wall.Due to the limited stability of big dimensional cutting slope,The placement of reinforcements within the reinforced fill structures can play a very significant role for the improvement of shear resistance of the structures which comes from the direct resistance of the reinforcements and the mobilized frictional resistance due to the increase of normal force around the reinforcements(Guangqing et al,2003).With the help of this technique,the stability of the slope or embankments will increase dramatically.Besides,the advantages for the application of reinforced fill structure are technical and economical.Especially in the rugged terrains,the reinforced fill structure can be used to replace the need of pile foundation,making it simple to construct and cost saving.On top of that,the reinforced fill structure also is very adaptable seismic zone(Sadri,1997,Eliahu & Watt,1991).

Fig.5 Reinforced fill retaining wall

As to the design of such structure,design procedure is much more complicated as compared with the design methodology for retaining wall.Geoguide 6(GEO 2002)carried out the design procedure for the reinforced fill slope design based on the Hong Kong experience:

1)Design geometry of reinforced block,fill properties and reinforcement.

2)External stability check.

3)Determination tensile force to be resisted by individual layers of reinforcement.

4)Checking rupture and pullout of individual layers of reinforcement.

5)Compound stability check.

6)Serviceability check.

7)Spacing of reinforcement.

8)Design of connections and facing.

9)Drainage provisions.

10)Details/Drawing.

After having a blueprint for the reinforced fill structure,the implementation of the project should be carried out by construction.The construction of reinforced fill structures is a technically task for the contractors.High level of rework cost and difficulties of remedial work would appear if it is under bad construction control.In addition,a great number of problems could be triggered,including rupture of reinforcement,rupture of facing element,face bulging if it is not constructed under careful supervision.Thus the GEOGUIDE 6(GEO,2002)put forward the areas required to be supervised under the construction control:

1)Assumptions critical to the design(foundation or ground water levels)should be reviewed during construction by the designer.

2)Construction supervision:Pre-construction review ,Method and sequence ,Preparation of the foundation,

Temporary drainage ,Storage of materials ,Installation of reinforcing elements ,Compaction of backfill ,Compliance testing of materials.

Fig.6 Failure case of reinforced fill structure

6.Deep mixing method

The appearance of clay,silt,highly organic soil at the site of construction may lead to high rate of foundation failure,intolerable settlement because the soil used for construction with the characteristics of low strength,high compressibility and low conductivity.As a result of such adverse soil condition,the difficulty and cost for the remedial work are quite considerable.Thus,a method is required to treat the problematic soil in situ,increasing the engineering properties of soil for construction.In general,the typical methods for deep mixing include:

Chemical Deep Mixing(CDM):Wet Method,Stabilisers/hardening agents are in a slurry form.

Dry Jet Mixing Method(DJM):Dry Method,Stabilisers/hardening agents are pneumatically conveyed using compressed air.

The working principle of this method is pretty simple which includes in-situ stabilization and in-situ fixation.As a soil modification technical in which the soil is mixed on site,making use of the cement or chemical addictives to improve engineering and environmental properties of soft ground(Terashi,1997).The objectives of deep mixing method are settlement control,strength increase,slope stability control,reduction of hydraulic conductivity and so on.

It should be highly noted that the research on the DMM still keeps going by the use of cement,and cement-lime and other reagents.The major focus is to place effect of soil types,reagents types,properties of reagents,mount of reagents to the triaxial shear strength of soil,compressibility as well as permeability of problematic soil.During this process,both the filed tests and laboratory tests are conducted(Consoli,2007)as to further increase the understanding of DMM.

Fig.7 Deep mixing process

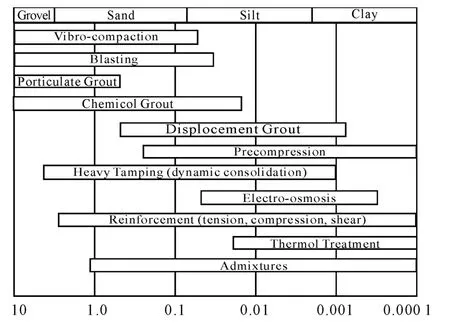

7.Selection criteria

The major methods of ground improvement have been presented.But the selection of the methodologies for ground treatment is a big challenge for designers.The appropriate selection of the method should be based on the evaluation factors of ground.Here,some considerations needed to be considered during the design process are list out,but not the least(Mitchell,1981).

1)The purpose of the ground improvement,such as settlement control,conductivity control and increase strength.

2)The area,depth,total volume of the treated ground.

3)Soil properties and types of soil.

4)Material availability.

5)Equipment and technique availability.

6)Environmental consideration;.

7)Engineering experience and custom.

8)Budget.

9)Time availability.

Fig.8 The selection of ground treatment methods based on the particle size distribution(Mitchell,1981)

7.Conclusions

Numerous methods for ground improvement have been presented in this paper.There is no doubt that the advantages and limitations coexist for each of these methods.None of these methods can be suitable for all types of soils,thus the selection of the method for ground treatment is extremely important and difficult.In term of this condition,the factors should be considered listed above,but the actual conditions and engineers’experience of the treated ground should also be taken into account as to achieve the best method for ground improvement.

The shortage of land space and dense development of urban area make the intensive requirement for the treated ground for construction and activity.Thus the ground improvement may develop more in technical,and economical as to satisfy the need of the market.

[1]Burland J B,Wroth C P.Settlement of buildings and associated damage[R].1975.

[2]Consoli N C,Foppa D,Festugato L,et al.Key parameters for strength control of artificially cemented soils[J].Journal of geotechnical and geo-environmental engineering,2007,133(2):197-205.

[3]Chummar A V.Ground improvement using stone columns:problems encountered[C]//An International Conference on Geotechnical and Geological Engineering.Geo Eng.Melbourne,Australia,2000.

[4]Eliahu U,Watt S.Geogrid-reinforced wall withstands earthquake[J].Geotechnical Fabrics Report,1991,9(2).

[5]Guide to Reinforced Fill Structure and Slope Design(Geoguide 6)[M].Hong Kong:Geotechnical Engineering Office.

[6]Guangqing Y,Ying C,Qian S.Testing study on deformation and stress of reinforced earth retaining wall for high embankment[J].Chinese Journal of Rock Mechanics and Engineering,2003,22(2):321-326.

[7]Lo D O K,Mesri G.Settlement of test fills for Chek Lap Kok airport[C]//Vertical and Horizontal Deformations of Foundations and Embankments(GSP 40).ASCE.1994:1082-1099.

[8]Lo D O K,Premchitt J.Long-Term Consolidation Tests on Solis from the Chek Lap Kok Formation[J].HKIE Transactions,1999,6(3):8-14.

[9]Mitchell J K.State-of-the-art report on soil improvement[J].Journal of the Soil Mechanics and Foundations Division,ASCE,1981:96.

[10]Plant G W.HONG KONG INTERNATIONAL AIRPORT[C]//Twelfth European Conference on Soil Mechanics and Geotechnical Engineering(Proceedings).1999.

[11]Sandri D.A performance summary of reinforced soil structures in the Greater Los Angeles area after the Northridge earthquake[J].Geotextiles and Geomembranes,1997,15(4):235-253.

[12]Stamatopoulos A C,Kotzias P C.Settlement-time predictions in preloading[J].Journal of Geotechnical Engineering,1983,109(6):807-820.

[13]Terashi M.Theme lecture:deep mixing method–brief state of the art[C]//Proceedings of the fourteenth International Conference on Soil Mechanics and Foundation Engineering.Hamburg:[s.n.]:1999:2475.