Hydraulic Hybrid Technology and Its Research Progress

LUO Nianning,ZHNAG Jian,JIANG Jihai,ZHANG Qingrun

1.School of Automotive Engineering,Harbin Institute of Technology,Weihai 264209,China;

2.School of Mechatronics Engineering,Harbin Institute of Technology,Harbin 150001,China

Hydraulic Hybrid Technology and Its Research Progress

LUO Nianning1*,ZHNAG Jian2,JIANG Jihai2,ZHANG Qingrun2

1.School of Automotive Engineering,Harbin Institute of Technology,Weihai 264209,China;

2.School of Mechatronics Engineering,Harbin Institute of Technology,Harbin 150001,China

Hydraulic hybrid technology and its technical characteristics are briefly introduced in this paper.Its research progress as well as the existing problems and shortages are discussed.The key technologies that constrain the commercialization of the technology are pointed out in this paper.

hydraulic hybrid,secondary regulation,hydrostatic transmission

National Natural Science Foundation(51275123)

*LUO Nianning,Senior Engineer.E-mail:luo@hit.edu.cn

1.Introduction

Continuous deterioration of the energy and environment problem over the world has become a critical factor that restricts the sustainable development of the society.Before finding a safe,stable,and cheap new energy,hybrid technology that reduces energy consumption and emissions is the most realistic choice based on the current level of technology.

Hydraulic hybrid technology is a significant branch of hybrid technology.Hydraulic hybrid technology combines main power unit(internal combustion engine,MPU for short)with high energy density and hydraulic assistant power unit(APU for short) with high power density,which can achieve braking energy regeneration and improving output characteristics of the engine.Hydraulic hybrid technology’s advantages stand out in urban public service domain such as urban bus,garbage collection,and express delivery,which exist in many complex cyclic operating conditions like frequently start-stop.As the research moves along,hydraulic hybrid vehicle(HHV for short)has drawn more and more attention with its superior economic efficiency,dynamic property,and security to hybrid electric vehicle(HEV for short).

2.The advantages of hydraulic hybrid technology

Hydraulic hybrid technology integrates secondary regulation hydrostatic transmission technology,hydraulic energy storage technology and traditional automobile technology.Hydraulic hybrid technology takes advantages of the high power density of hydrostatic transmission and fast charge-discharge performance of hydraulic accumulator that can recover the braking energy of vehicle efficiently,and coordinate the internal consumption engine and hydraulic assistant unit to separately or simultaneously drive the vehicle in subsequent driving under the control of computer.This is essentially the process of making use of hydraulic accumulator and hydraulic pump/motor to realize braking energy conversion and temporary storage;therefore,the performance of energy conversion component and energy storage element decides the total efficiency of hybrid vehicle to a great extent,directly affecting the effect of energy saving and emission reduction.There is no significant difference between the efficiencies of hydraulic pump-motor and motor-generator,which are about 89%~93%[1].

However,when comes to the efficiency of energy storage element,differences become obvious:limited by its charge acceptance of maximum charging current and power.Storage battery can only absorb approximately 20%braking energy[2],and several fires caught by storage battery have triggered people’s worry for its safety.Hydraulic accumulator applies molecular potential energy stored principle which belongs to the mechanical storage mode,has neither the effect of multiple different property energy conversions efficiency or time effects,nor the limitation of recharge cycles.Years of application in construction machinery fields also shows that hydrostatic transmission technology possesses not only mature technology,simple system strategy,stability and reliability,but also no pollution during production running or after rejection.Though some properties of ultra-capacitor exceed hydraulic accumulator,but its overall technology is not as mature as hydraulic energy storage system.

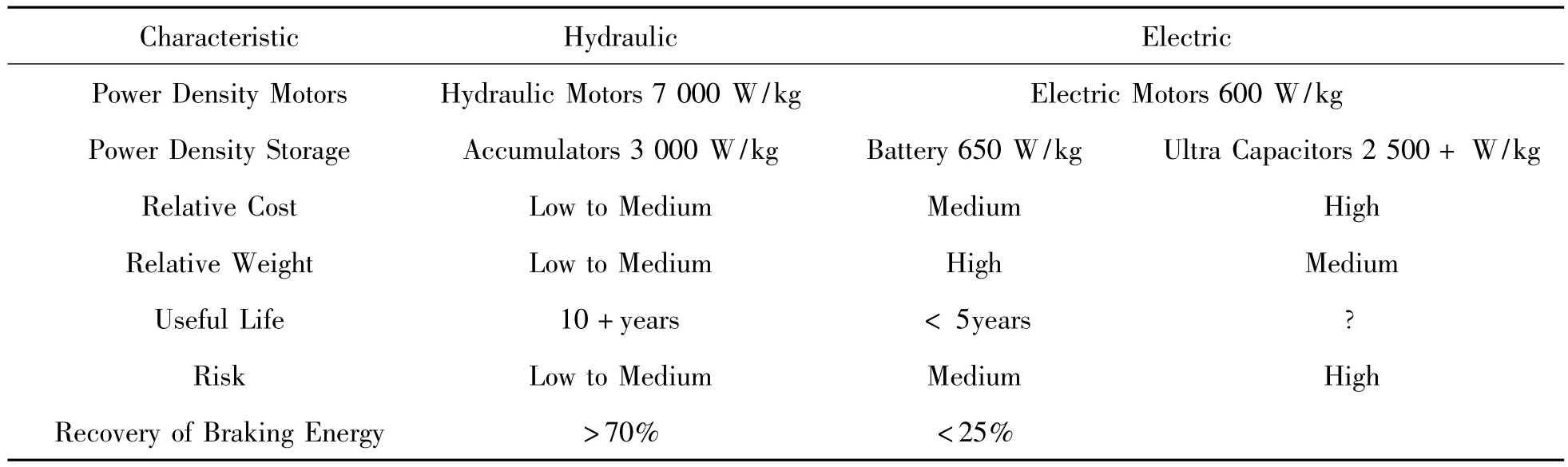

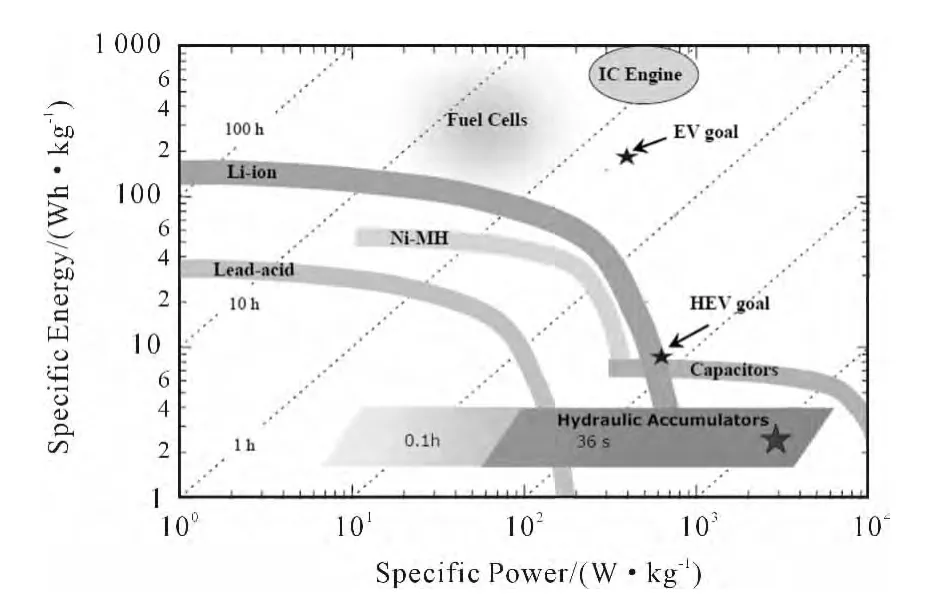

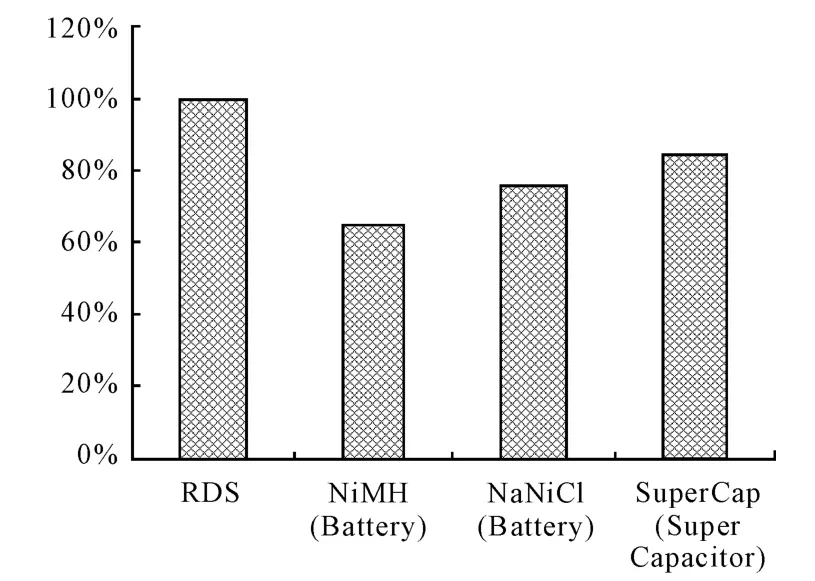

Tab.1[5-6]and Figs.1~3[7-8]compare the two types of hybrid technology from different views,and Fig.4 shows the main units’efficiency of hydraulic braking energy regeneration system.Obviously hydraulic hybrid technology has the better energy efficiency.The same conclusion was also reached by Ricardo Corp.,American Eaton Corp.and Parker Corp.[3-4].

Tab.1 Electric vs.Hydraulic technology

Fig.1 Energy density and power density of different energy storage elements

Fig.2 Braking energy regeneration rate of parallel hybrid power system

Fig.3 Energy efficient of different hybrid vehicles from EPA

Fig.4 Main units’efficiency of hydraulic braking energy regeneration system

3.Working principle of hydraulic hybrid system

APU of HHV consists of hydraulic pump/motor,hydraulic accumulator and control valve block,and makes use of the characteristic of hydraulic pump/ motor that is capable of working in four-quadrant and temporary storage of hydraulic accumulator to optimize the operating point of engine,improve the output characteristic of engine and achieve braking energy regeneration.The hydraulic APU can automatically regulate the engine to operate in high fuel efficiency area and drive the vehicle alone,or together with the engine while the vehicle is running.Hydraulic pump/motor converts braking energy of the vehicle into hydraulic energy and stores it in hydraulic accumulator when the vehicle brakes and decelerates.During subsequent start,acceleration,or in a normal driving condition,hydraulic energy will released by hydraulic motor to assist the engine or separately drive the vehicle[11-12].The topological structure of HHV is similar to that of HEV,which can be classified into series,parallel and parallel-series,as shown in Fig.5(dash and green dotted lines denote hydraulic energy,full lines denote mechanical energy,read dotted lines denote chemical energy).

Fig.5 Typical topological structure of hybrid system

Series type has simple structure,its arrangement of engine does not bound to the drive train,and operating point can be selected in high efficiency area without the constraint of the driving condition of the vehicle.But series type’s driving power all comes from hydraulic pump/motor;therefore,the system efficiency gets low after several times of conversion.Parallel type has compact structure,but its engine is rigid connected to the axle;thus,the engine speed is restricted by the vehicle speed and consequently cannot be stabilized at ideal condition.Parallel-series type combines advantages of the two above,which generally adopts planetary gear train transmission to decompose,modulate,and then converges the output power of engine so as to realize the decoupling of the engine and vehicle.The main structure modes at present are input coupled type and output coupled type shown in Fig.6.Although their structure and control are more complex,step-less speed regulations of the vehicle can be achieved by regulating the distribution ratio of hydraulic power;hence,speed change mechanism can be removed.

Fig.6 Two types of parallel-series structure mode[14-15]

4.Domestic and overseas research status of hydraulic hybrid technology

4.1.Overseas research status

Since German professor Nikolaus first put forward the concept of hydrostatic transmission with secondary regulation in 1977[12],Backé,Murrenhoff,Metzner and Kodak had conducted many studies on its control and energy saving principle.P.Buchwald and G.Christensen had studied the theory of braking energy regeneration in 1979.In 1985,German produced the first hybrid vehicle named MAN Hydrobus.After that,many research institutes like Athens Volvo Car Corp.,Australia Permo-drive Corp.,the United Kingdom Artemis Intelligent Power Corp.,Netherlands Innas Corp.,Korea University of Ulsan,and Poland University of Lodz had carried out their own hydraulic hybrid test cars and they all obtained good energy efficient[1,11-13].Mitsubishi,ISUZU and Nissan had also developed several CPS(Constant Pressure System)buses based on series structure in the mid 1990’s,which are operated in three cities including Tokyo.Tests indicated that the exhaust emission and fuel consumption can be reduced by 25%,the emission of NOxcan be reduced by 39%,and the black smoke can be reduced by 60%[13,16].

U.S.Environmental Protection Agency(EPA) is the most active affiliation on hydraulic hybrid technology.it organized a huge cooperative research group since 1980’s,and its members including US army,Ford Motor Company,Eaton Corp.,Parker-Hannifin Corp.,UPS Corp.,FEV,University of Michigan,University of Wisconsin,etc..More than 165 million dollars had been invested from 1994 to 2006,and many hydraulic hybrid systems based on mild hybrid(parallel)type or full hybrid(series) type had been developed.Vehicle type includes urban mini-bus,pickup,SUV,package car,refuse trucks,etc.,as shown in Fig.7[16].The data released shows that the braking energy regeneration rate of hydraulic hybrid system exceeds 71%,thus economic efficiency is raised by at least 20%,and emissions can be reduced effectively.Eaton Corp.formulated a research goal of 70% energy saving(as shown in Fig.8)and announced that they would start to develop commercial hydraulic hybrid refused trucks named CNG since 2012[17].The same year Parker-Hannifin Corp.declared that after actual running for over a year,their refused trucks that apply series RunWise technology can save 43%fuel consumption every year[18].

4.2.Research status in China

The research on hydraulic hybrid technology within China is relatively later compared with other nations,and research scope is relatively narrower: the research mainly concentrated on some universities and some small technology companies sensitive to new technology.In 1989,Professor Liu from Harbin Institute of Technology first studied the speed regulation characteristics of hydrostatic transmission with secondary regulation system[19].Urban Bus Company of Beijing conducted experiments on hydraulic energy saving device of bus.Between 2004 and 2010,Beijing Jiajiehengxin Energy Technology Corporation,Beijing Chuangshiqi Technology Corporation,Harbin Institute of Technology and Shenzhou Vehicle Company of Shanghai Jiaotong University successively developed their own test vehicles,whose energy efficient rate all went beyond 20%when driving in urban conditions[1,11-13].

Fig.7 EPA’s hydraulic hybrid program

Fig.8 Eaton’s hybrid hydraulic development roadmap

Other major institutions engaged in researching hydraulic hybrid technology are Jilin University,Tsinghua University,Beijing Institute of Technology,Nanjing University of Science and Technology,Zhejiang University,Shanghai Jiaotong University,Taiwan Da-Yeh University,etc..Due to the shortage of funding investment,progress of this technology is rather slow,mostly remaining in theoretical research stage.Companies who promoted this technology in the early stage are at a standstill.However,the literatures published these years show that research on hydraulic hybrid technology has gained increasing attention.

4.3.Status analyses

Most hydraulic hybrid test vehicles released so far apply the series or parallel type structure and aim at urban public service domain,such as urban bus,garbage collection and express delivery.In the 2009 Shanghai PTC exhibition,Rexroth Corp.displayed a hydraulic hybrid refuse truck with parallel type structure HRB(Hydrostatic Regenerative Braking)system for the first time[20],which marked the beginning of commercialization process of hydraulic hybrid technology.Then,US Eaton Corp.brought out the HLA (Hydraulic Launch Assist)system in 2010,and Australia HHT Corp.brought the HDA(Hydraulic Drive Assist)in 2012[21].Parker Corp.also announced that its series type structure RunWise system would be brought to market at the end of this year[18],which is applied in non-passenger vehicles,like the former three parallel type structure systems.This indicates that,although hydraulic hybrid technology overseas is far ahead,its security,comfort or ride cannot reach the requirement of passenger car.

In China,the corresponding researches are relatively few and are remained in theoretical exploration.Those test vehicles are also staying in the process of principle or functionality verification,and the existing problems are large noise,large impaction and power shortage at the early stage of braking energy regeneration process,and the brake wheel is easy to lock at the later stage of the process.Some even cause backlash and motoring at the end of braking energy regeneration process,which will seriously endanger the safety of vehicle or driver.Those are the reasons why most researchers follow or inherit the research approach of HEV,and focus on the improvement of energy efficiency,but never really organically combine the secondary regulation hydrostatic transmission technology,hydraulic hybrid technology and traditional automobile technology.

After comprehensively analyzing the research status at home and abroad,the main problems are summarized so far as follows:

1)Influence mechanisms on the vehicle of hydraulic pump/motor’s creep characteristic,hysteretic characteristic and hydraulic system’s fluid-noiseheat multi-field coupling characteristic in specific system topological structure and actual operating condition are still unclear.

2)During the process of hydraulic accumulator releasing energy todrive,impaction mechanism caused by the condition of MPU and APU simultaneously driving or its transition is still unclear.

3)Contradiction between regulation characteristic of combining braking energy regeneration and progressive control of total braking torque hasn’t been studied in-depth yet.

4)Conflict between improving braking energy regeneration rate and ensuring safely braking(the ECE automobile regulations)hasn’t been studied indepth yet.

These are key technologies that constrain the commercialization of hydraulic hybrid technology.Before making these problems clear in theory,it’s impossible to fundamentally solve them by merely optimizing the present control strategies.

5.Key technologies of hydraulic hybrid technology

1)Topological structure of hydraulic hybrid system and optimization method to match the key parameters

The greatest advantage of hybrid vehicle is that it can achieve braking energy regeneration,so how to safely and conveniently recover braking energy and cooperate with engine to drive the vehicle safely and reliably according to requirement of the driver are the cruxes of hydraulic hybrid technology.Topological structure of hydraulic hybrid system decides not only the travel path of system power,the way of braking energy regeneration and power synthesis,and the control strategy and energy saving performance,but also the controllability and security of the total vehicle.Thus,choosing the proper topological structure and method of parameters matching according to the characteristics of secondaryregulation hydrostatic transmission technology and hydraulic energy storage technology is the basis of optimizing braking regeneration to meet the demand of safely driving,and taking advantages of respective characteristics of the engine and hydrostatic transmission technology.

2)Improving braking energy regeneration rate and security control of braking regeneration process

Improving braking energy regeneration rate is the main method to improve economic efficiency of the total vehicle,and meeting the requirement of the ECE automobile regulations is the basic standard of a vehicle.Recently,research shows that braking energy regeneration rate maximization will certainly sacrifice some security of the vehicle,because the braking of HHV is related to the hydraulic braking energy regeneration system and mechanical friction braking system;inherent parameter perturbations of hydraulic system and uncertainty of the pavement adhesive condition are great changelings to realize progressive control of total braking torque of the vehicle,which, however,is the unavoidable key problem for applying hydraulic braking energy regeneration technology.

3)Control strategy on hybrid system working mode and total vehicle synergy driving

Driving resistance and speed can vary widely during the vehicle running.It is the uncertainty of actual traffic environment,randomness of the driver’s request,and flexible working mode of the parallelseries type topological structure that result in the complexity of total vehicle control system.Especially during the process of hydraulic accumulator releasing energy to drive,totally different output characteristics between the MPU and APU will cause some impactions as the APU intervenes and quits.Hence how to guarantee the ride and progressive controllable is the crux to realize driving control.

4)Macroscopic planning strategy on total vehicle energy management

Power system that automatically adapts to the driving condition of vehicle is the key element to achieve energy conservation and emission reduction.It’s generally known that different drivers drive the same vehicle in the same traffic environment will have different fuel consumption,and similarly the same driver drives the same vehicle in different traffic environment will have different fuel consumption.This shows that,despite road conditions and load conditions,the energy efficiency of total vehicle is also affected by traffic environment and the driver’s experiences.So how to recognize the driver’s intention and the vehicle’s driving condition,and then choose the proper working mode so as to adapt to the high frequency extremely severe conditions like low speed creeping,accelerating at low-speed and heavyload status and hard intensive braking of urban bus,is the aim to macroscopically plan the total vehicle energy management strategy.

6.Conclusions

Developing urban bus and improving its overall performance is one of the best measures to solve the current urban traffic congestion and realize the target of energy conservation and emission reduction.Hydraulic hybrid technology with its special advantages will certainly become the main technological meaning to upgrade and update the traditional energy saving technology of urban buses of our country.Domestic and overseas researches show that:hydraulic hybrid system with good technology compatibility and great

performance can recover its investment within two or three years.Prophase research of our project team also indicates that the hydraulic hybrid bus applying comprehensive structure can achieve at least energy saving by 35%,dynamic property increasing by 60%,and further reduce emission of PM 2.5,directly reduce energy consumption and noises of transportation,and enhance the traffic capacity of urban load section,which is suitable to China’s national condition.There are approximately 30 million urban buses at present,hence promoting the application of hydraulic hybrid technology is of great significance for achieving the goals of energy conservation and emission reduction put forward by the 12th Five-Year Plan of our country,reducing dependence on foreign petroleum,promoting sustainable economic development and building environment-friendly society.

[1] WANG Xin.Research on energy saving and control performances of wheel drive hydraulic hybrid vehicle[D].Harbin:Harbin Institute of Technology,2010.

[2] Gray C L.Hydraulic hybrids-EPA hybrid truck initiative[EB/OL].[2012-05-18].http://files.harc.edu/ Projects/Transportation/HydraulicHybridsGray.pdf.

[3] De Coster T.Parker.Hydraulic hybrids technology[R].Parker-Hannifin Corporation,2012.

[4] Kargul J J.Hydraulic hybrids 101-affordable hybrids for a petroleum and carbon constrained world[C]//2012 Green Transportation Summit,Seattle,Washington,2012:6-27.

[5] Ogando J A.Different kind of hybrid[J].DESIGN NEWS,2007(7):75-78.

[6] Rydberg K.Energy efficient hydraulic hybrid drives: SICFP’09[C]//Link ping,Sweden,2009.

[7] Kargul J J.Hydraulic hybrid vehicle 101-delivering efficiency to commercial vehicles[R].U.S.Environmental Protection Agency,2007.

[8] Permo-drive.Hybrid Comparisons-Competitive Advantages of the RDS Technology[EB/OL].[2013-04-30].http://www.permo-drive.com/compare/index.htm.

[9] Kargul J J.Hydraulic hybrid vehicle 101-A cost-Effective solution for a petroleum and carbon constrained world[R].U.S.Environmental Protection Agency,2010.

[10]Read D.The National Vehicle and Fuel Emissions Laboratory Technology TransferEfforts[R].USEPA/ NVFEL,2006.

[11]SUN Hui.Research and optimization on the key technologies of secondary regulation hydrostatic transmission vehicles[D].Harbin: Harbin Institute ofTechnology,2009.

[12]LIU Tao.Research on the parameters optimization and control strategy of hydraulic hybrid vehicle[D].Har-bin:Harbin Institute of Technology,2010.

[13]LUO Nianning,ZHANG Jian,JIANG Jihai.Hydraulic hybrid technology[J].HYDRLICS PNEUMATICS&SEALS,2012,32(2):81-85.

[14]DU Jiuyu,WANG Hewu,HUANG Haiyan.Research on performance of power split hydraulic hybrid powertrain for vehicle[J].Journal of Mechanical Transmission,2011(6):15-18.

[15]Optimal design of power-split transmissions for hydraulic hybrid passenger vehicles[Z].

[16]ZHANG Jian,LUO Nianning,JIANG Jihai.Hydraulic hybrid vechicle[J].MACHINE TOOL&HYDRAULICS,2012(6):67-79.

[17]Bohlmann B.Hydraulic hybrid systems for commercial vehicles[R].Eaton Corporation,2007.

[18]Gray C.RunWise advanced series hybrid[R].Parker-Hannifin Corporation,2011.

[19]LIU Qinghe,XIE Zhuowei,FU Gongling.Analysis of speed regulation of of HST of secondry rotative velocity regulation system[J].HYDRLICS&PNEUMATICS,1989(3).

[20] Bosch R.Carries environmental protection product to PTC Asia[J].Logistics Technology and Application,2009(11).

[21]Hall C.Australia Hydraulic Hybrid Assist[EB/OL].[2013-04-30].http://www.itshybrid.com/products.htm.

液压混合动力技术及其研究现状分析

罗念宁1*,张 健2,姜继海2,张清润2

1.哈尔滨工业大学汽车工程学院,山东威海 264209;

2.哈尔滨工业大学机电工程学院,哈尔滨 150001

介绍了液压混合动力技术及其技术特点,分析了国内外研究现状和当前研究中存在的问题与不足,指出了制约液压混合动力技术商业化应用的关键技术。

液压混合动力;二次调节;静液传动

TK05

10.3969/j.issn.1001-3881.2013.24.004

2013-04-30

- 机床与液压的其它文章

- On-line Condition Monitoring Based on Empirical Mode Decomposition and Neural Network

- Control Method on Adaptive Abrasive Belt Grinding of Pipe Socket Weld

- Research on Pneumatically Actuated 6-DOF Parallel Robot Based on SimMechanics

- Application of Machine Vision in Auto-registration of Machine Parts Assembly