on target for Posterity yang Fuxi upholds China’s Bow and Arrow-making legacy

By JIAO FENG

THE bow and arrow craftsmanship of the Ju Yuan Hao workshop in Beijing was recognized as one of Chinas National Intangible Cultural Heritages in 2006. It was among the first cultural traditions to be given the title.

At the time, 48-year-old Yang Fuxi was one of the few master craftsmen remaining adept at traditional Chinese bow and arrow construction. Yangs workshop, called “Ju Yuan Hao” for generations, produces some of the more complex bow and arrow designs of ancient China. Creating them today still requires many hours of handiwork by the most skilled technicians. The art is a true treasure of Chinese traditional culture.

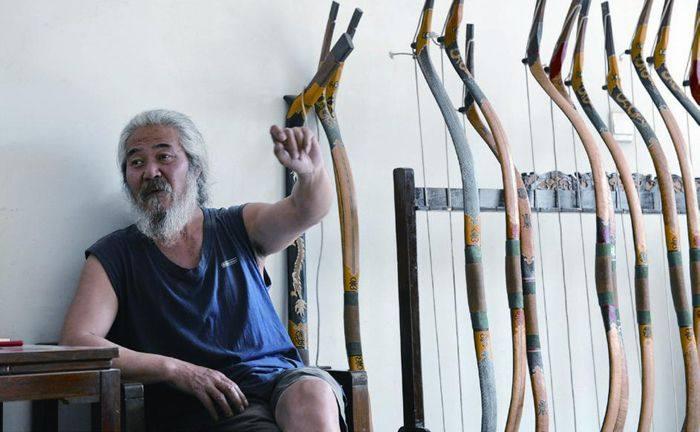

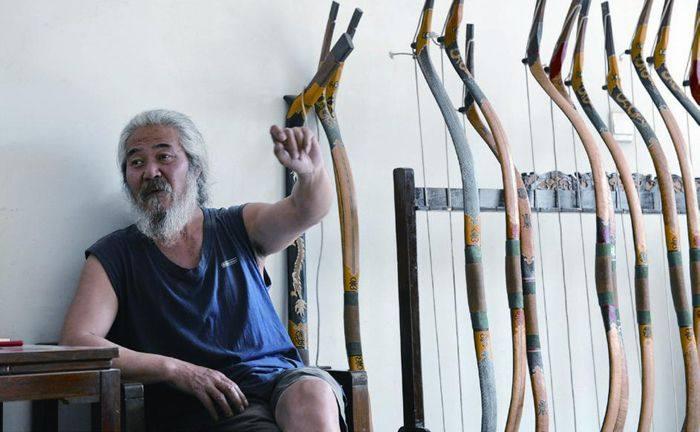

Ju Yuan Hao, located in Beijings eastern suburbs, is a two-story house that serves as both Yang Fuxis home and studio. The reception room on the first floor features a horizontal plaque inscribed with the Chinese characters, “Ju Yuan Hao,” a name of which Yang is proud. Beside the plaque is a row of bows. The tools Yang uses to fashion his exquisite pieces are scattered throughout his house, along with half-finished bows and in-progress arrows.

The bow and arrow has been around for thousands of years in China and was the decisive weapon in many a battle. According to Yang, the Ju Yuan Hao workshop was opened in 1720 by an ironmonger under the patronage of the royal house of the Qing Dynasty (1644-1911).

With the proliferation of firearms in China, bows and arrows gradually disappeared from battlefields, and craftsmen went out of business. At the beginning of the 20th century, Yang Fuxis grandfather, Yang Ruilin, bought the current premises, when the previous owner was set to close down.

Yang Ruilin was infatuated with bow and arrow making. He not only absorbed all the techniques for making all kinds of conventional bows and arrows, but also experimented with derivatives such as crossbows and sleeve arrows. With his considerable efforts, the workshops business prospered and became one of the few bow and arrow manufacturers to survive until the founding of New China in 1949.

Yang Fuxis father and uncle learned the techniques for bow and arrow making from an early age. In the early 1950s, Ju Yuan Haos products began to be exported to the U.K. In all likelihood, had the “cultural revolution” (1966 – 1976) not taken place, Yang Fuxi too would have been given a traditional training in his ancestral craft.

Late Inheritance

Yang Fuxi was born in 1958. The billows of political movements had put an end to the family business, and their shop was converted into a woodwork studio. Although in his early years Yang Fuxi was deprived of an education in armaments, he did learn how to work with wood, and this gave him a solid foundation when he came to take up bow and arrow construction many years later.

“Although I didnt personally see my father and uncle make bow and arrow sets, I often heard them talking about the process. Also, I often played with the bows and arrows at my home when I was a kid. All this served to make me interested in making them myself,” said Yang.

As an adult, Yang Fuxi took jobs as a carpenter, a chemical plant worker and a taxi driver, but he never forgot his family craft. He dreamed of promoting the bow and arrow business by opening recreational archery ranges.

He proposed to authorities opening archery ranges at tourist sites such as the Forbidden City and the Great Wall for visitors to experience the culture of traditional Chinese archery, but was rejected.“Nobody was interested: they said that such ranges would be dangerous to patrons and could damage the cultural sites themselves,” said Yang.

Later, he brought bow and arrow sets made by his father to film studios in the hope that they would appear in films. He had some success here – producers said they would think of using his products when there was the need. After returning home from studios, Yang told his father:“We should start over with bow and arrow making. Its anything but a waste of time.”Yangs father was nearly 70-year-old and the craft faced the danger of becoming extinct. In 1998, when Yang Fuxi turned 40 years old, he quit his job driving taxis and embarked upon a traditional trade education under his aging father.

Mastering techniques

“After quitting my job I had my back to the ropes. It was a very hard time for me – at the beginning, I had no income at all,” Yang said.

Making a bow is a process made up of over 200 individual steps. It is extremely difficult to master all the techniques required in a few years. In order to learn faster, Yang made the most of his time, working day and night on perfecting his handiwork. Thanks to his foundation in woodwork and the support of his father, Yang learned the techniques quickly. But it still took years: “It was after my father passed away in 2006 that I really mastered all the steps,” Yang said.

Yang admits he had relied heavily on his father before his passing. Whenever he encountered a difficult procedure that he couldnt do well himself, his father would step in. “My father was like a walking stick: If youve been walking with assistance for a long time, you feel no desire to walk on your own.”

Yang shows us a bow hanging on a wall, saying: “For example, I had never single-handedly constructed the release trigger for this kind of bow without my fathers help. Hed explained to me on many occasions how to do it, and although I got the theory, I just couldnt do it. After he passed away, I had no choice but to try and try again, always remembering what he said, and I finally mastered it,” said Yang.

The manufacture of a good bow and arrow demands extremely high quality raw materials that are difficult to find nowadays, such as silk, bamboo, buffalo horn, sinew, special woods and glue, lacquer and animal hide. Strips of horn are glued onto the belly of the bow, which is made of bamboo, to enhance its flexibility, and the core of the bow itself is wrapped in birch bark to ensure its resistance to water. The arrow shaft is made of a special wood called Liu Dao Mu (abelia), which is tough and of a suitable width. Glue must be made from either fish maw or pigskin. Yang Fuxi always makes this glue himself to ensure quality.

The horn used for making the bow needs to be at least 60 centimeters long, and horns of such length are difficult to come across – there are no buffalos in northern China. Yang has tried hard to build contacts with reputable, legal horn dealers whom he can trust to find the right horns and ensure the safety of animals. After the long process of collecting all the raw materials, Yang can finally go about putting together his bows and arrows. But there are other difficulties once the pieces are finally assembled.

Aiming for the Market

“We started making bows and arrows, but couldnt sell them and didnt even know where to look to find buyers. By 2002 we only sold one bow and the money from the sale barely covered the cost of the materials. We didnt have any other stable income so we really struggled,”Yang recalled, saying that was the most difficult time in the life of the business. The good news was that later, Yang met Xu Kaicai, former coach of Chinas national archery team. Xu became a backer of Yangs business and introduced him to a customer, Stephen R. Selby, the former director of the Intellectual Property Department of Hong Kong Special Administrative Region. “Mr. Selby was very knowledgeable about traditional bow and arrow construction. When we met for the first time he just sat there, listening. He double-checked what I had said about the materials we used, and after receiving confirmation about the authenticity and quality of all the different parts and components, he bought over 20 sets. He then went on to introduce us to other customers as well.”

Yang brims with confidence when talking about the quality of his work. “Through word of mouth, I gradually built up a customer base, and the same customers come back again and again.”

The person who discovered and helped promote the cultural worth of Yangs bows and arrows was Yi Degang, a professor at Inner Mongolia Normal University and a scholar in traditional Chinese archery. In 2003, Yi Degang was studying in the School of Scientific History and Archaeometry at the University of Science and Technology of China for his doctoral degree, and got to know about Ju Yuan Haosbows and arrows while collecting materials for his thesis. He made a visit to Yang Fuxis father and asked about the intricate procedures involved in his craftsmanship. For a period he came to Yangs workshop every day to watch the whole process as it unfolded. His PhD thesis, A Study on Traditional Chinese Bow and Arrow Making and Related Mechanical Knowledge, and a later paper, An Investigation into the Bow and Arrow-making of the Ju Yuan Hao Workshop in Beijing, attracted a lot of attention at the Ministry of Culture. His efforts helped increase recognition of Ju Yuan Hao, and under his recommendation, the workshops work was selected to be in the first batch of Chinas National Intangible Cultural Heritages in 2006.

Although Ju Yuan Hao gained fame from its official recognition and Yang attracted some more customers, he is still worried about his business – because its technically illegal. A bow and arrow set is considered to be a dangerous item in China, just like guns and knives. According to regulation, Yang isnt allowed to register at the department of industry and commerce and to produce or sell bows and arrows without the permission of provincial-level police departments.

“I tried many times but still couldnt get a business permit. Now my bows and arrows are considered as artistic works for collection purposes,” admitted Yang. Another problem that worries him is who will pass on the craft after hes gone. He used to have some apprentices, but many gave up due to the heavy demands of the training. Yang also worries that if he has too many apprentices, they will end up competing against him for customers.“There really arent that many traditional bow and arrow lovers out there; the market is limited,” said Yang, frankly. Profits from selling bows and arrows remain his familys sole source of income to this day.

Discussing the future, Yang says that in order to keep the craft alive, he plans to write a book about bow and arrow making. In addition, he still dreams of opening a traditional archery range one day. He says he heard that in South Korea, children often go to practice archery after school, and believes such a thing could work in Beijing as well. If children become proficient in the culture of traditional archery as well as gain hands-on experience in archery, the market will steadily expand, he said. “If I can get more people interested in the traditional Chinese bow and arrow and fall in love with archery, Ill be happy. Plus, it would be good to sell a few more bows.”