基于热释电探测器的重频脉冲激光诊断

张 磊,邵碧波,杨鹏翎,王振宝,闫 燕

(西北核技术研究所激光与物质相互作用国家重点实验室,陕西西安710024)

1 Introduction

The high-repetition-rate laser has wide foreground applications in the photoelectric confrontment.However,there are still series of technical difficulties in the far-field beam diagnosis of the high-repetitionrate laser.Compared with the photoconductive detector,the pyroelectric detector is characterized by non-wavelength selectivity,material uniformity in large areas and electric circuit simple for process signals,so it has been widely used in the fields of military and civilians[1-2,7].In this paper,the diagnosis method to repetition rate pulse laser based on the pyroelectric material was investigated.

2 Theoretical model of pyroelectric detector

The pyroelectric crystal becomes slice after incision.The electrode is deposited on the two faces of a slice of pyroelectric crystal,which is upright the direction of spontaneous polarization.So the pyroelectric detector is similar to the flat capacitor.Because the free charge produced by spontaneous polarization appears on the interior face of a pyroelectric crystal,the chained charge is neutralized by the free charge on exterior face.

By setting the calorific capacity of the pyroelectric detector asH,and the heat conductivity between detector and environment asG,we assume that the ambient temperature is consistent,and the temperature of the detector ΔTis higher than the ambient temperature,then the heat flux from the detector to the environment ΔQis

In the situation of single pulse radiation,if the temperature distribution of detector is uniformity,we carry on the modeling to the pyroelectric detector,then the pulse power expression is:

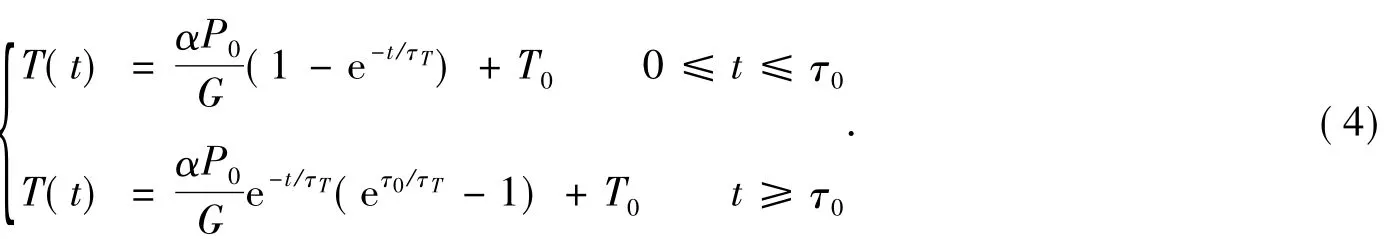

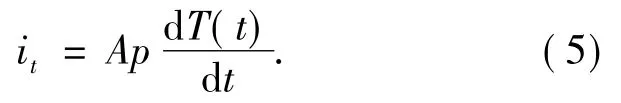

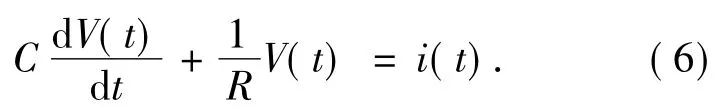

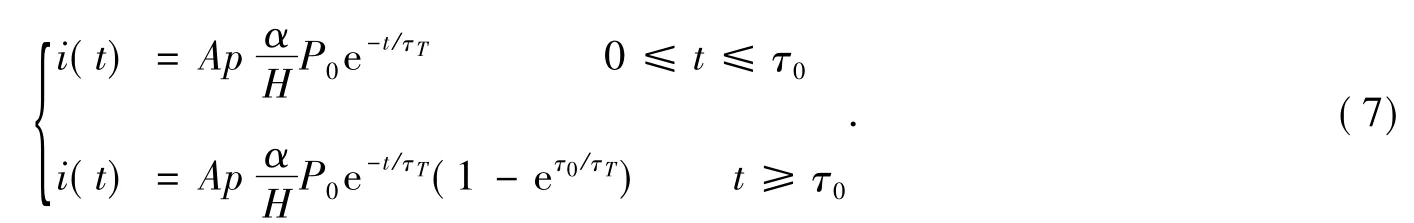

Substituting Eq.(3)into Eq.(2),if the detector is under single pulse radiation,we can obtain the temperature response as follows:

We set τT=H/Gto be the heat time-constant,and the current across detector is:

Where,Ais the active area of the photosensitive unit,pis the pyroelectric coefficient,and the voltage whichi(t)produces on impedanceZis obtained by the following equation:

We set τe=RCto be an electricity time-constant.Substituting Eq.(4)into Eq.(5),the electric current expression can be obtained as follows:

We solve the differential equation to obtain the voltage expression:

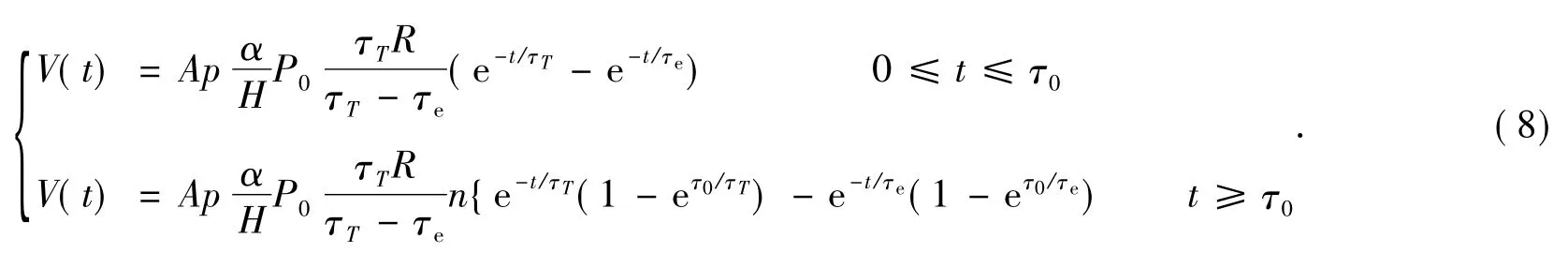

We choose several typical pyroelectric materials to calculate[4],analyse,and contrast their response characteristics.The results are shown in Fig.1.

Fig.1 Response curves of different pyroelectric materials

Fig.1 indicates when the photosensitive units have the same area and thickness,it takes the shortest time for the pyroelectric detector of LiTaO3material to come back to thermal equilibrium,and the speed of response is the quickest.

When the detector receives the pulse radiation,we can see that from temperature rise and the voltage expressions,the most main parameters which affect performance are the pyroelectric detector's heat time-constant τTand the electricity time-constant τe.

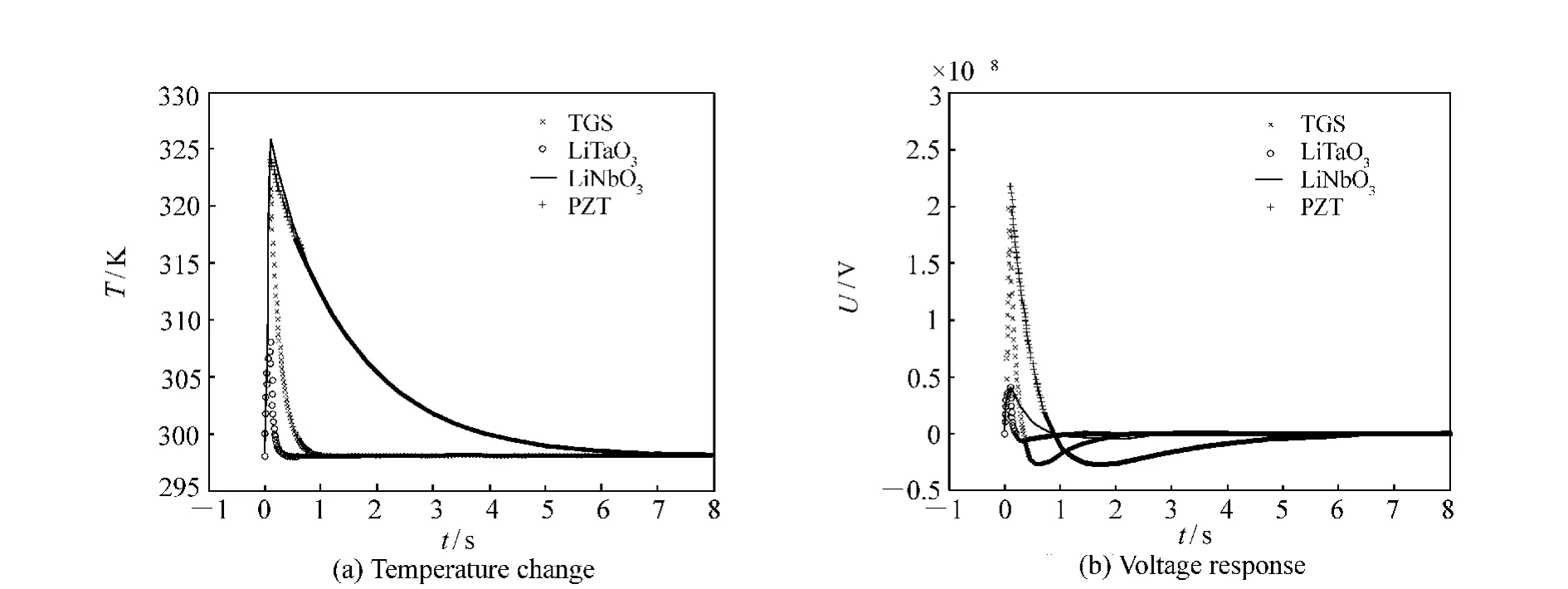

Seen from τT=H/G,the heat time-constant is determined by detector's calorific capacity and the heat conductivity,but calorific capacityH=CvADis determined by the material volume specific heat capacityCv,the area of detector photosurfaceAas well as the detector's thicknessD.Under the situation that the pyroelectric material has been chosen and the detector's area of photosurface is 1 mm2,the temperature rise and voltage response curve of different detector with different thicknesses are shown in Fig.2.

Fig.2 Response curves of different detector thicknesses

In Fig.2(a),it is observed that the reduction of thickness conduce detector's calorific capacity to minish,so the pulse laser radiation of similar power cause the temperature to increase,simultaneously radiation to speed up,and response frequency to improve.However,regarding the small thickness,the calorific capacity which is excessively low causes detector's saturated threshold value to reduce.Fig.2(b)indicates that before the detector is saturated,detector's voltage responsivity increases gradually along with the reduction of thickness,however,the downward overswing also increases,therefore recuperating electric circuit's design should be considered to reduce the overswing.

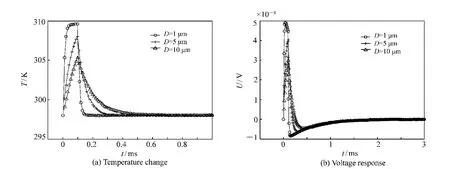

Fig.3 Voltage response curves of different electricity time-constants

Fig.4 One-dimensional thermal analysis

The electricity time-constant is another key parameter that affects the detector performance,and voltage response curves of different electricity timeconstants are shown in Fig.3.

The simulation result indicates that regarding the voltage response characteristic,when the electricity time-constant reduces,the time that signal returns to the baseline may be reduced,and simultaneously the responsivity is increased,but the scope of the overswing will also be increased.In the situation that pyroelectric detector's interface resistance and self-capacitance are certain,the electricity timeconstant may be adjusted by changing pre-amplification electric circuit's input resistance and the input capacity.

3 Heat transfer theory of pyroelectric detector

We take the thin film as the sensitive unit to design the pyroelectric detector,which consists of a silicon substrate,an insulating layer,an electrode below,a pyroelectric level,a electrode up and a absorption film from bottom to top[5,6].

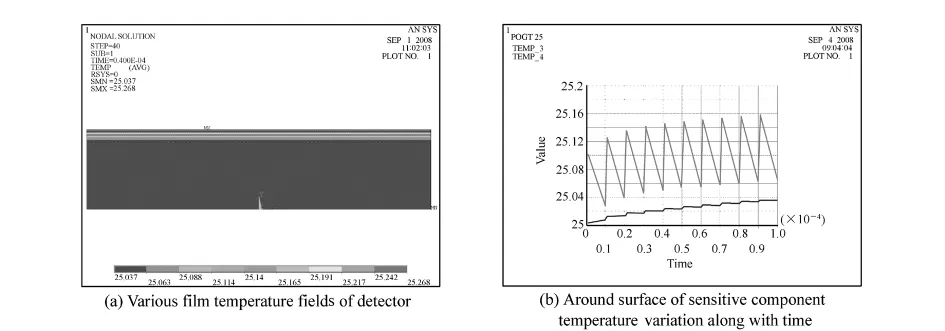

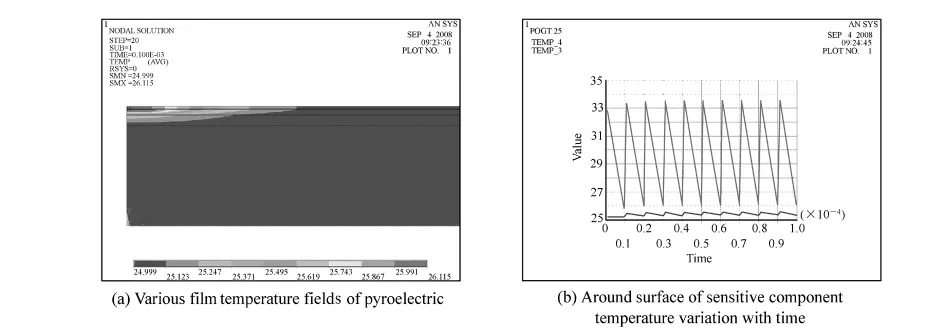

The detector worked under the room temperature of 25℃,and we calculate the temperature field with 10 pulse radiation.Under the radiation by the big area beam and the small one,the temperature field distribution of the detector is shown in Fig.4 and Fig.5.

Fig.5 Two-dimensional thermal analysis

Regarding the former,the sensitive unit temperature is assumed in periodic variation along with the incident pulse light.Because the pulse optical frequency rate is high,the heat of detector can not disperse promptly,therefore the photosensitive unit temperature rise increases along with the pulse number.When the heat change between the detector and external environment reaches the balance,the temperature of detector rise tends to be stable,and this time around the superficial temperature difference really respondes the single pulse energy of incident light.Under the situation of beam incidence,it may regard the surface of detector which receive ray radiation as to be big infinitely,at the same time the thermo diffusion carries on along crosswise and longitudinal.As shown in Fig.5,the thermal equilibrium time is established to reduce.

4 Experimental verification

The pyroelectric detector is a kind of high impedance[8].It must be matched with the preamplifier with a quick speed and a low noise.The performance of the detector is affected by the preamplifier.So it is significant to improve the performance of the amplifier.

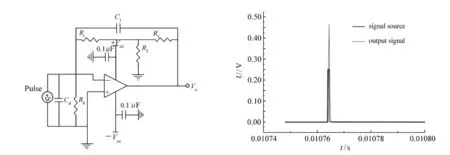

In order to raise the responsivity,we must reduce the speed of response advisably.The current amplifier[9]shown in Fig.6 transforms the electric current produced by the pyroelectric detector into the voltage signal directly,and its merit is that the input resistance is low,even approximate zero,which can satisfy the request of the quick response.

Fig.6 Current amplifying circuit and simulation result

By using the green light pulse laser to radiate the pyroelectric detector with the current amplifier separately,detector's output voltage response is shown as Fig.7.

Fig.7 Output waveform of detector with current amplifying circuit(the repetition frequency is 10 kHz)

As shown in Fig.7,the repetition frequency of the signal measured with the pulse width of 100 μs can reach 10 kHz.

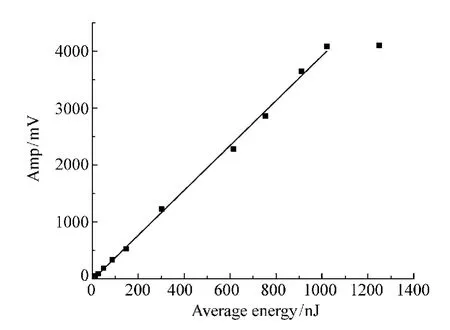

Based on the theory analysis and experiment validation above,the detector unit is demarcated in laboratory.The responsivity measured can reach 2.5 V/nJ.At present,the detector unit can measure the signal with the frequency of 10 kHz.The linear dynamic range of the detector unit is possible to reach 110,which has the linearity of 0.999 27.The imitating curve is shown in Fig.8.

Fig.8 Measurement of linear dynamic range of detector unit

5 Conclusions

A pyroelectric detector unit with a current amplifier to diagnose far-field beams is investigated,which can measure the laser signal with the frequency of 10 kHz.The responsivity measured can reach 2.5 V/nJ.It validates the feasibility to measure the laser energy of high-repetition-frequency pulse laser by adopting the pyroeletric detector.

[1]Pyroelectric,photodiode and RP heads for repetitive energy measurements.[EB/OL].(2010-02-03)[2011-03-21].http://www.ophiropt.com

[2]SEASLER G M.Piezoelectricity in polyvinylidene fluoride[J].Acoust Soc Am,1981,70:1596-1608.

[3]HOSSAIN A,RASHID M H.Pyroelectric detectors and their applications[J].IEEE T.Ind.Appl.,1991,27(5):824-829.

[4]ODEN A.Probe with PVDF sensor for energy measurements of optical radiation[J].Measurement Sci.Rev.,2003,3(3):111-114.

[5]WANG S D,FAN L Z.Laser radiation detector using polyvinylidene fluoride film:US,4906849[P],1990-03-06.

[6]BURLAND D M,MILLER R D,TWIEG R J,et al..Assessment of polymeric materials for second-harmonic generation and electro-optic applications[J].SPIE,1993,1852:186-197.

[7]SAMOILIV V B,YOON Y S.Frequency response of multilayer pyroelectric sensors[J].IEEE T.Ultrason.Ferr.,1998,45(5):1246-1254.

[8]LI J H,YUAN N Y,CHAN H L W.Influences of different substrates on the detectivity of pyroelectric sensors[J].Integrated Ferroelectrics,2002,49(1):255-264.

[9]PHAM L,TIHEN W,YE C,et al..Surface-micromachined pyroelectric infrared imaging array with vertically interated signal processing circuitry[J].IEEE T.Ultrason.Ferr.,1994,41(4):552-555.

——庆祝国防科工局核技术支持中心成立十周年