畜禽粪污堆肥品质的提升策略

袁伟涛 张婷 马翠柳 王凯英 刘晗璐

摘要:好氧堆肥是有机固体废弃物无害化、资源化和减量化的重要技术,是废弃物与土壤碳库间的桥梁。堆肥将废弃物低耗快速的自然降解并转化为肥料,肥料中腐殖质等养分是良好的土壤修复剂和调理剂,可抵消农业活动造成的有机质损失、提升碳的固存并维持土壤功能。然而,堆肥原料的复杂性和可变性是实现有机质快速腐殖化和维持有机肥质量所面对的巨大挑战。总结堆肥有机质的转化原理,综述工艺参数优化的关键环节、多类型添加剂在生产中的应用效果以及新型堆肥技术前景,进而提出以下几点建议:(1)对辅料进行破壁前处理或添加具有高效木质素分解能力的生物制剂,提高纤维类成分的分解,减少堆肥初期有机质快速矿化损失。(2)降低pH值可提高体系中NH+4/NH3的值,减少氨气挥发;提高氧含量和氨氧化细菌生物量,促进氨氧化和硝化作用,避免反硝化和不完全硝化导致的氮损失。(3)添加氧化剂提供充足的氧化还原电位,有效减少含硫有机质降解矿化后VSCs的释放。可为有机物高效腐殖化、资源化,减轻环境压力促进农业可持续发展提供参考和依据。

关键词:畜禽粪污;堆肥;物质转化;工艺优化;添加剂

中图分类号:S141.4文献标志码:A

文章编号:1002-1302(2024)06-0025-11

收稿日期:2023-08-23

基金项目:河北省科学技术项目(编号:21327308D);吉林省科技发展计划(编号:20200301019RQ)。

作者简介:袁伟涛(1998—),男,河南周口人,硕士研究生,从事特种经济动物微生态营养与调控研究。E-mail:2627783817@qq.com。

通信作者:刘晗璐,博士,研究员,从事特种经济动物微生态营养与调控研究。E-mail:liuhanlu@caas.cn。

随着集约化养殖的发展,畜禽粪污产量急剧增加,已成为农业面的首要污染源。据统计,2020年畜牧业粪污量已达到38亿t[1]。周海宾等认为,我国89.44%的规模化养殖场普遍采用堆肥处理固体粪便,其中采用简易堆沤处理的高达 85.90%[2]。畜禽粪便中的营养物质、病原体、重金属以及药物残留,若不能妥善处理,则会造成严重的环境污染,甚至还会引发公共安全事故[3]。粪便作为碳氮资源库,在堆肥过程中释放的大量CH4、CO2、N2O等温室气体,既会造成环境污染,又會降低堆肥品质[4-5]。粪便中含有多种致病菌和寄生虫虫卵,具有引发疫病传播的风险[6-7]。好氧堆肥能有效杀死粪便中的致病菌,提高土壤中腐生菌的比例[8]。堆肥在氨氧化细菌、硝化细菌等需氧微生物合成代谢作用下,将纤维素、蛋白质等大分子有机质转化为结构更稳定的可溶性腐殖质,如真菌在木质纤维素的降解中发挥关键作用、厚壁菌门参与可溶性有机质的形成[8-10]。粪便中含有的氮、磷、钾等元素能为作物生长提供必要的营养,腐熟后通常被用作土壤改良剂,可以提高土壤肥力,增加土壤碳氮含量,中和土壤酸度,并将草地和土地退化的风险降至最低[11-13]。更为重要的是,堆肥是有效的碳和氮保存手段,可显著减轻温室效应[14]。然而,堆肥过程释放大量CH4、CO2、N2O等温室气体以及氮、硫恶臭气体的排放是限制好氧堆肥技术发展的重要因素,造成有机肥品质下降和严重的环境污染。本研究旨在讨论提升堆肥品质即碳氮保存和除臭的现有策略,主要探讨堆肥工艺优化、添加剂选择和新型堆肥等在提升有机质转化、减少有害气体的排放以及提高有机肥营养水平方面发挥的作用。

1 堆肥过程物质转化规律

从源头、过程和最终产物等角度深入了解堆肥体系物质转化和原理,以及各元素的转移路径有助于解释不同处理策略的作用机理。

1.1 碳在堆肥中的转移和转化

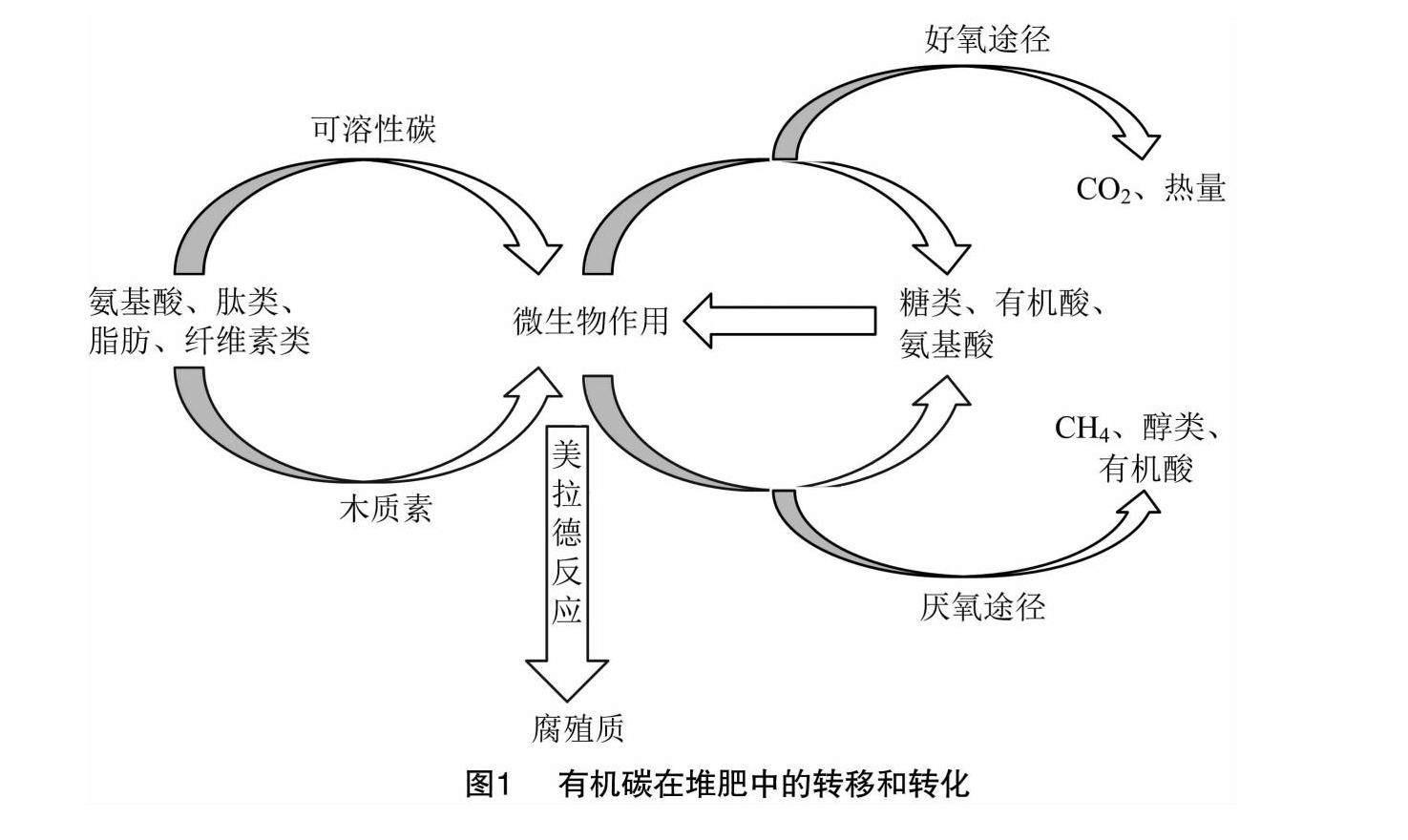

碳元素主要以有机碳的形式存在于新鲜粪便和堆肥辅料中。堆肥过程有机质的转化分为活化和固化2个阶段[15-17]。第一阶段微生物活性提升,快速分解大多数易降解有机质,如蛋白质、氨基酸、脂肪和部分纤维、半纤维等,产生的糖类、有机酸等可溶性非结构化有机碳最先渗入到微生物细胞质内,可溶性有机碳以碳源和能源的形式促进微生物的代谢活动,被完全氧化代谢[18];第二阶段随着可溶性碳进一步消耗,使相关微生物生物量及活性下降,微生物分泌水解酶会促进大分子有机碳,如木质素、纤维素、半纤维素等纤维成分降解转化为多糖、芳香类化合物和一些单体物质,同时通过合成代谢以及生物凋亡转化为堆体内可溶性有机碳,最后通过美拉德反应固定到腐殖质中(图1)[17,19-20]。Ye等认为,堆肥过程中碳的损失占初始碳含量的44.2%,其中以CO2-C、CH4-C形式的碳损失分别占堆肥总碳损失的73.00%、1.58%[21]。CO2因呼吸作用而被释放,包括微生物对小分子有机碳的持续消耗和纤维素表面胞外酶的水解作用两大途径[22]。小分子物质的代谢对碳的保存十分不利,通过调节微生物代谢以限制CO2的释放可能是促进碳保存的潜在措施。Jones等认为,借助腺嘌呤核苷三磷酸(ATP)、还原型烟酰胺腺嘌呤二核苷酸(NADH)抑制剂,可通过限制细胞内氨基酸脱羧、脂肪酸α氧化、丙酮酸转化为乙酰辅酶A和三羧酸循环(TCA)限制呼吸作用,减少CO2释放[23]。ATP抑制剂的加入会加速腐殖质形成,NADH可能促进纤维素降解为可溶性糖和有机质[24]。但TCA作为呼吸作用的基本途径,代谢受阻影响微生物的活性。Cotrufo等认为,微生物代谢产物和坏死性物质难以被微生物再利用[25]。因此,通过提高堆肥可降解纤维物质微生物的生物量以及代谢产物,也是增强碳保留的有效途径。

1.2 氮在堆肥中的转移和转化

氮元素主要以蛋白质、氨基酸、核酸等形式存在于堆肥体系中。堆肥氮循环涵盖多个途径的相互作用,包括氮同化、氨化、硝化、反硝化、厌氧氨氧化和固氮作用(图2)[14]。氨化发生于堆肥高温期,原料中含氮有机质被好氧细菌、真菌分解礦化,转化为可溶态NH3,并通过得失1个质子在NH+4/NH3可溶态与气态之间转化[26-27]。微生物同化作用使部分NH+4/NH3被吸收转化为有机氮成分。堆肥过程中氨水平受温度、pH值、氨化剂密度等因素影响,不同堆肥体系往往差异很大[28]。硝化作用在氨氧化细菌(AOB)、氨氧化古菌(AOA)、亚硝酸盐氧化细菌(NOB)作用下将NH+4/NH3转化成NO-3,这是有机氮转化的重要途径[29]。N2O是堆肥过程中释放的最普遍的气体,其产生与NO-3转化时氧气供应不足有关[30]。堆肥初期耗氧量高,加之基质的沉降使局部供氧不足,不可避免地发生不完全硝化和反硝化而生成N2O[31]。同时,自养型氨氧化细菌(AOB)在缺氧条件下,以氨为电子受体和亚硝酸盐为电子受体生成N2,该过程中N2O是中间产物[32]。Guo等认为,在堆肥高温阶段,与产气相关的微生物活性下降,反硝化作用产生的N2O与N2主要发生在降温期与腐熟期[33]。堆肥氮损失主要发生于嗜热期的NH3大量释放,该阶段氮损失占初始总有机氮的40%~70%[34]。因此,通过维持堆肥过程好氧条件,增强前期氨化作用并减少由此带来的高pH值、NH+4/NH3低可溶性问题,从而达到增强硝化作用并减弱反硝化作用的效果。

1.3 硫在堆肥中的转移和转化

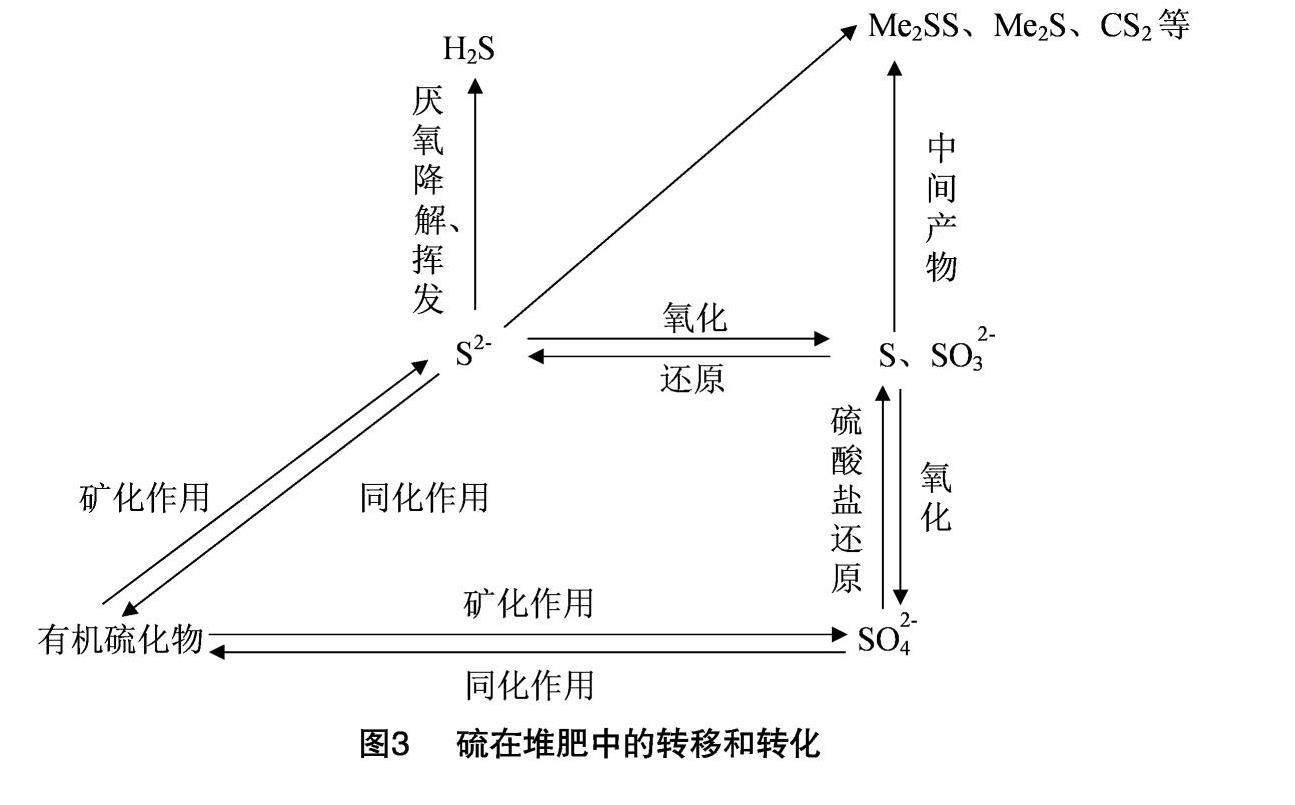

硫元素主要存在于含硫蛋白、硫氨基酸、硫胺酸、磺酸盐等有机质内,在堆肥中的转化与氮元素相似。堆体内有机硫化物在硫氧化菌(SOB)和氧化还原酶(如芳基硫酸酯酶)的作用下发生矿化,氧化的最终产物是硫酸盐(SO2-4),S和SO2-3是硫氧化反应的关键中间体(图3)[35-36]。硫代谢过程由SOB基因编码产物完成。sqr基因参与硫化物氧化成硫单质,而后在pdo基因编码的过硫酸盐双加氧酶作用下进一步氧化为亚硫酸盐,氧化亚硫酸盐的蛋白酶由sor和sox基因编码在细菌胞质内合成。然而,堆肥厌氧区域内含硫蛋白、氨基酸的甲基化和异化还原硫酸盐产生挥发性含硫有机物(VSCs),包括硫化氢(H2S)、二硫化碳(CS2)、甲硫醇(MeSH)、甲硫醚(Me2S)和二甲基二硫醚(Me2SS)等[37-38]。VSCs是堆肥主要的致臭因子,具有较低的气味阈值。H2S气体主要释放于堆肥前期,由于硫氧化过程电子受体不足而产生。Zhang等认为,餐厨垃圾堆肥过程释放的VSCs中的99.8%是H2S气体[39]。Me2S和Me2SS是堆肥过程中硫损失的主要形式,分别占VSCs的33.21%、63.96%[40]。值得注意的是,二甲基硫化物和二甲基二硫物的去甲基化促进H2S释放,而H2S是厌氧条件下甲基化生成甲基硫醇(MeSH)的关键原料[41-42]。可见,控制H2S排放是减少堆肥VSCs释放以及提高硫转化效率的关键。

2 堆肥品质调控策略

2.1 堆肥工艺优化

堆肥受多种因素影响,如C/N、含水率、通气量、pH值、温度,条件改变决定堆肥物质转化效率、堆肥周期以及有机肥养分水平。堆肥温度的变化是微生物代谢水平的重要体现,堆肥嗜热期是有机物转化和实现无害化的关键阶段。高温会导致NH3、H2S等气体的释放增加,但降低温度又会降低堆肥质量和腐熟度。因此,在实践生产中堆肥往往不直接对温度进行调节。

2.1.1 C/N

C和N是微生物代谢所需的关键元素,C为能量来源,N则用于构建细胞结构[43]。C/N在调节有机物降解中至关重要,不仅可以影响有机质的转化效率,还可以反映物质降解程度。Ye等经

过系统分析发现,不同类型堆肥体系中有机碳与总氮含量变化趋势相同,且两者呈正相关[21]。当氮含量过低时,微生物代谢缓慢,影响有机物的降解;氮含量过高,多余的氮将以氨气等形式释放[44]。此外,堆肥C/N的值上升,与CO2损失呈正相关[45]。当堆肥初始C/N的值从23 ∶1上升到29 ∶1时,造成的总碳(TC)损失由43.9%提高到53.0%[44]。Huang等认为,堆肥C/N在(25~30) ∶1间具有良好的堆肥效果[46-48]。不同材料堆肥的C/N差异较大,通常以各种植物性填充剂如稻壳、锯末、秸秆等为辅料,添加到高氮原料堆肥中,如鸡粪和肉食性动物粪便,兼具吸附剂和膨胀剂的作用[49-50]。反刍动物、草食动物粪便中氮含量较低,尿素往往被作为其调节 C/N 的首选原料[51-52]。

2.1.2 pH值

堆肥pH值的变化是有机物代谢的结果。堆肥初期,蛋白、脂肪、糖类等物质降解生成有机酸、含硫有机物矿化产生H2S、氨化作用使NH+4/NH3持续积累,构成一个复杂的酸碱体系[53]。堆肥全程维持在弱碱性的环境中,氨化作用导致pH值上升,硝化作用又使氨发生转化,pH值再次降低[54]。pH值是影响气体挥发的重要因素[55]。低pH值能提高NH+4/NH3比例,有效减少NH3的挥发,但会造成VSCs排放增加[56]。大多数研究认为,堆肥最佳pH值为7~8[53,57]。在调节堆肥酸碱度方面,厨余垃圾基质酸化程度高,过低的pH值会抑制微生物生长,导致甲烷生成,CO2的排放增加[58]。堆肥时添加质量分数为0.1%的醋酸钠(NaAc)、缓冲剂K2HPO4/MgSO4或KH2PO4/MgSO4、CaCO3以及草木灰,可以缓解酸化带来的不利影响,但可能会增加氨的排放[59-62]。堆肥过程中NH3和VSCs等易挥发性气体对pH值敏感性相互对立,难以通过调节pH值缓解。pH值作为堆肥的重要因素,适宜条件下可提升堆肥效益。

2.1.3 曝气率(含氧量)

曝气与温度是评估微生物活性的关键参数[63]。氧气供应在控制堆肥温室气体和挥发性气体排放中具有关键作用。氧气水平影响微生物活性和堆体升温速率,而温度变化与堆体微生物动态分布的耦合作用决定了堆肥的速率和质量。Zheng等研究发现,堆肥堆氧气浓度为20.9%时,温度峰值为70 ℃;氧气浓度为3.16%时,温度可达60 ℃[64]。氧气不足时,微生物活性减弱,升温速率变慢,高温持续时间变短,无害化效果变低,厌氧降解作用增强导致碳、氮元素损耗。另外,曝气量若超过微生物的需求水平,会加速热量流失,增强吹脱效应,导致气体排放增加[65]。按堆肥通气方式分为静态堆肥、抛翻堆体和强制曝气堆肥。与静态堆肥(氧浓度<1%)相比,强制曝气堆肥(氧浓度<5%)拥有更高含量的可溶性有机碳,且能显著降低温室气体的排放[8,66]。其中,曝气率为0.05 m3/min的间歇式曝气(每30~50 min通气7 min)可保持氧浓度>15%,与连续曝气相比,可降低堆肥系统NH3的损失[67]。Chen等认为,缩短曝气时间或曝气间隔,维持氧浓度>14%可有效降低H2S排放[68]。抛翻堆体和强制曝气都能改善堆肥氧含量,选择何种曝气都无法忽略经济效益。

2.1.4 含水量

含水量是维持有效堆肥的重要参数,直接影响微生物的生长速率、氧气扩散能力,以及作为物质交换媒介影响生物降解动力[69]。一般认为,堆肥最佳含水量为50%~70%[70-72]。含水量过高,膜增厚效应使基质填充物间隙变小,空气循环受限造成堆肥局部缺氧,且增加比热容,导致堆肥失败[73]。含水量过低时,堆肥基质转移能力下降,严重影响细菌的新陈代谢并减慢发酵速度[74]。适宜的含水量对于可溶性营养物质的转化与沉积至关重要。Higgins等在家禽垫料堆肥研究中发现,含水量对有效磷、硝化作用的水平有很大的影响,与含水量为50%的植物有效磷沉积(2.7~3.0 mg/g)相比,含水量为70%的植物有效磷含量(4.2~4.8 mg/g)提高41%~78%[75]。

2.2 添加剂

基于堆肥条件调整的可操作性十分有限,在大规模生产中的经济效益不容忽视。在该过程中宜使用添加剂,常用的添加剂包括物理添加剂、化学添加剂、微生物制剂等。

2.2.1 物理添加剂

物理添加剂具有多空隙的蓬松结构,别称膨胀剂、吸附剂,包括有机物理添加剂和无机物理添加剂[76]。

有机物理添加剂常指一些纯天然或人工合成的生物炭,包括秸秆、稻壳、木屑、竹子、蘑菇糠等,因具有较大的比表面积和低成本特性被广泛用于堆肥[77]。这些天然生物炭具有很强的膨胀性和吸附性,不仅能用于调节堆肥基质的含水量和C/N,还能提高堆肥的透气性,利用吸附作用减少氮、硫元素的挥发[29]。Mao等研究发现,20%苹果渣加入到堆肥后可减少57%、24%的NH3、N2O排放量[78]。玉米秸秆是一种常见的农业废弃物,用于堆肥能减少总氮损失,但对NH3排放抑制效果不明显[79]。玉米秸秆可以提升堆体pH值,相对于pH值较低的蘑菇糠,其对NH3的抑制效果(玉米秸秆为30%,蘑菇糠为50%)较差,对VSCs的减排效果(玉米秸秆为80%,蘑菇糠为72%)较好[80-81]。当前一些合成的生物炭如在500 ℃下制备的玉米秸秆生物炭具有微孔结构和极高的表面积,使其气体吸附和离子交换能力表现突出[82]。将竹子生物炭用于堆肥時,温室气体排放量减少93.61%,NH3排放量减少51.42%[83]。其结构特性会促进气体流通,也可作微生物群落繁衍生态位,加速有机物分解,进而促进易挥发性氨态氮的固定[84]。

无机物理添加剂即矿物添加剂,包括沸石、褐煤、黏土、膨润土等[83]。天然沸石是一种多孔的铝硅酸盐矿石,在堆肥中利用沸石的吸附能力和阴阳离子交换作用捕获NH3/NH+4[85]。在淤泥与麦秸共堆肥中添加30%的沸石和1%的石灰,可有效减少50.43%的氮素损失[86];在城市垃圾中加入天然沸石(15%)、镁改性沸石(15%)堆肥后,NH+4固存分别提高64.5%、19.7%[87];堆肥中施用硅藻土会加速有机质降解和腐殖化,减少N2O (58.70%~76.00%)、CH4(17.20%~29.20%)和NH3(6.38%~13.40%)的排放[88]。无机物理添加剂分布广泛,价格低廉,有机物理添加剂随着堆肥被降解,其结构变得稳定,能重复利用。

2.2.2 化学添加剂

堆肥化学添加剂在减少NH3、N2O排放方面表现突出,其种类很多,包括盐类、酸性物质、硝化抑制剂和鸟粪石结晶[85,89]。

铁盐(FeCl3)常用于废水中NH3的处理和厌氧消化VSCs的预处理[90],Yuan等也已证实铁盐在堆肥中消除异味的可行性[91]。FeCl3在堆肥中起到与污水处理时类似的絮凝剂作用,能与气体分子相凝结。另外,铁盐在有机硫化物分解后,将溶解态硫转化为硫单质和硫酸盐,可以降低溶解态硫浓度而减少H2S气体释放[92]。此外,氧化铁(Fe2O3)加入猪粪堆肥时,可能通过促进硫化铁(Fe2S3)和硫化亚铁(FeS)的沉淀或催化VSCs转化加强硫固定,并有效降低46.7%~80.9%VSCs的排放[93]。堆肥中添加强氧化剂,能促进氧化还原反应,将氮、硫固定在硝酸盐和硫酸盐中。

堆肥时添加酸性物质如磷酸钙、乳酸、明矾、硫酸铜、镁盐、磷酸盐等,可抑制NH3挥发,并与NH+4结合成稳定的盐[85]。过磷酸钙是一种有效的堆肥保氮剂,在猪粪和麦秸共堆肥中添加过磷酸钙能有效降低NH3挥发,使堆肥中的总氮损失减少24.0%,同时提高有机肥中氮和磷的含量[94]。Cao等研究发现,将酸化添加剂施用于堆肥中,不仅能显著提高氮固存,还能有效减少CH4的排放[95-96]。通过酸化粪肥控制某一类气体排放的管理方式,往往会增加同一阶段其他气体或下游同一类气体的排放[97]。一方面,NH+4的增加同时为硝化作用和N2O的生成提供底物;另一方面,低pH值和NO-3又会抑制N2O的还原途径[98]。使用含金属离子的酸性剂时要注意用量,避免过量添加导致盐分含量过高。

鸟粪石(MgNH4PO4·6H2O)是一类由等摩尔浓度的镁盐、铵盐和磷酸盐组成的矿物晶体[26]。Jeong等首次在厨余垃圾堆肥中利用鸟粪石沉淀法固定氮元素,堆肥后NH+4含量达到1.4%,是普通堆肥含量的3~5倍[99]。Fukumoto等认为,堆肥时添加H3PO4、MgCl2或Mg(OH)2,能减少NH3、N2O等氮类气体排放[100]。Li等在对几种镁盐、磷酸盐组合的比较中发现K2HPO4/MgSO4为最佳组合,添加后氮损失降至23.3%,有机质分解率达64%,HPO2-4发挥了pH值缓冲剂的作用[101]。镁盐与过磷酸钙的组合能发挥一样的效果,并加速堆肥腐熟[102]。研究证实,利用鸟粪石沉淀法不仅能提高氮固存能力,还能抑制CH4的产生。这可能与鸟粪石晶体形成提高供氧能力或SO2-4有关,从而增强了硝化作用,抑制了甲烷菌的繁殖[95,103-104]。一些原料初始氮含量很高,无法仅靠镁盐和磷酸盐沉淀法全部保存,避免添加水平过高影响有机物降解。

双氰胺(DCD)可抑制氨氧化细菌的代谢、减缓硝化作用、阻止铵态氮(NH+4-N)向亚硝酸盐转化而减少N2O的产生[95,105]。在豬粪和玉米秸秆共堆肥中添加2.5%双氰胺,可显著降低N2O排放78.57%,但对NH3排放无影响[106]。双氰胺在堆肥调控中存在“短板”,常需要与其他添加剂联合使用。

2.2.3 微生物添加剂

堆肥添加微生物制剂能加速物质循环,弥补传统堆肥发酵周期长、养分损失大、温室气体排放量大等缺点。近年来,关于堆肥微生物种属演替规律、外源添加微生物的作用,特别是在有机碳和氮转化方面的研究有很大进展。

在粪便与植物共堆肥体系中,纤维素降解是一直以来的重要难题,所提供的氮的比值远低于总碳与氮的比值比,堆肥接种纤维素降解菌能有效提升对有机碳的利用率。Lu等研究发现,在羊粪堆肥中加入由枯草芽孢杆菌、地衣芽孢杆菌、绿色木霉、黑曲霉和酵母制备的菌制剂,能显著提高有机碳和腐植酸碳含量[107]。在猪粪与蘑菇基质堆肥中接种木质纤维素降解菌,不仅可以提升有机碳的利用率,還能抑制氮功能基因以及反硝化细菌群落[108]。嗜热期是氮转化的主要阶段,接种、氨氧化细菌(AOB)、氨氧化古菌(AOA)、硝化细菌和固氮杆菌可增强氮固定,减少氨气、N2O的排放[109-112]。实验室筛选分离的功能性耐热菌在粪污处理中的应用取得了突出效果。Yu等认为,在家禽粪便堆肥中接种嗜热硬脂芽孢杆菌可以促进糖转化为有机酸,降低pH值,从而显著降低NH3的排放,并提高NH+4-N含量[108]。堆肥添加嗜热亚硝酸盐氧化菌可缓解嗜热期强烈氨化作用下铵和亚硝酸的积累,减少反硝化和不完全硝化导致的N2O排放。将分离出的耐热硝化细菌接种于堆肥中,推动硝化反应,加速铵态氮向硝酸盐转化,NH3排放量减少了29.7%[111]。Chen等发现,污泥堆肥接种耐热硫氧化细菌,可以参与还原性硫的氧化,H2S气体排放量降低了48.9%[113]。

2.2.4 复合添加

仅靠改变堆肥条件或采用某一种添加剂对堆肥效率的提升是有限的,也是有缺陷的。研究人员对多种添加剂复合使用研究日益加深,复合添加的方式弥补了单一添加剂的不足,并减少了其用量。Lei等认为,在猪粪堆肥中,与单独添加10%磷石膏和麦饭石使NH3排放量分别降低59.74%和25.78%、N2O排放量分别降低8.15%和19.00%相比,复合添加5%麦饭石和磷石膏的NH3、N2O的累积排放量可以分别降低68.37%、42.86%[114]。Wang等认为,在猪粪与麦秆共堆肥中,联合添加生物炭和沸石的氮固定效果更好,可以分别减少63.40%、78.13%的NH3、N2O排放[115]。化学添加剂会增加有机肥的盐浓度,影响作物生长,而物理添加剂的吸附作用可缓解高盐离子浓度。将10%沸石于补充镁盐和磷盐的鸟粪石沉淀堆肥中,堆肥电导率降低到2.82 mS/cm,并增加了对NH+4的吸附,氨损失减少到18%[53]。生物炭和微生物制剂也是一种很好的组合。污泥堆肥添加需氧微生物菌剂与竹炭后,可以有效降低CO2、CH4、N2O等温室气体的排放,并提高嗜热期微生物的多样性[84]。实践证明,复合添加是提高堆肥效率更经济有效的策略。

2.3 新型堆肥

近年来,一些创新的堆肥系统如电场辅助、半透膜覆盖和蚯蚓堆肥为提高堆肥品质提供新的思路。

电场辅助堆肥通过提高电子转移效率、增强高氧气利用效率,加速了有机质的分解,提高了腐殖质含量[116-117]。电场辅助下的堆肥过程中CH4、N2O的排放量分别减少97.2%、72.7%,但出现了更大的碳损失,CO2排放增加28.9%[116]。Tan等研究发现,氧化还原能力可用电子转移容量(ETC)来量化,包括电子接受能力(EAC)和电子供体容量(EDC),堆肥中可溶性有机质的组成是氧化还原能力的关键,如腐殖质是EDC和ETC的主要功能组分[118-119]。这些研究增强了对堆肥机理的理解,有助于电场辅助在堆肥中的应用。

半透膜覆盖堆肥采用一种由聚四氟乙烯(PTFE)材料制成的,膜上排布0.2 μm的微孔,能隔离灰尘、气溶胶的疏水性分子筛选膜[120]。膜覆盖堆肥结合送风系统,可保持堆内均匀的氧气浓度,加速升温和有机质的降解。在牛粪与麦秆的共堆肥中,膜覆盖后提高腐殖酸含量和聚合度,可以增加与腐殖质合成相关优势属的丰度[121]。半透膜覆盖奶牛粪堆肥的碳转化率增高,CO2和CH4排放的碳损失仅为非膜覆盖的1/7[8]。

原生动物堆肥在微生物和原生动物协同下完成,包括蚯蚓和黑水虻幼虫堆肥[122-124]。蚯蚓处理污泥有大规模应用的先例,其对污泥的降解能力是自然分解的3倍[125]。蚯蚓引入生物炭与污泥的共堆肥后,抗生素水平显著降低,抗生素抗性基因ermF和tetX水平显著降低[126]。黑水虻幼虫堆肥能有效地将粪便转化为优质肥料,还可用作畜牧业替代性饲料成分[127-128]。

3 总结与展望

堆肥可实现有机废弃物资源化利用和畜牧业健康发展。结合堆肥物质转化、迁移规律,对提升堆肥质量、减少物质损耗、降低对环境负面效应提出以下几点调控建议:(1)对辅料进行前处理或添加具有木质素降解效力的生物制剂,提升纤维类有机质的分解,促进糖-胺缩合反应和木质素-蛋白聚合反应,减少堆肥前期可溶性有机质快速矿化消耗,从而提高堆肥腐殖质含量。(2)降低pH值可提高体系NH+4/NH3,减少NH+4的积累致使氨气挥发;提高氧含量和氨氧化细菌生物量,促进氨氧化为硝酸盐,减少发生反硝化和不完全硝化导致N2O、N2等气体释放。(3)添加氧化剂提供充足的氧化还原电位,有效减少含硫有机质降解矿化后VSCs的释放,提高pH值减少H2S气体产生。根据畜禽养殖不同粪肥特性和作物养分需求特点开展堆肥生产,提高粪污的综合利用率,减轻环境压力,促进农业和畜牧业的可持续发展。

参考文献:

[1]杨开宇,林常枫. 畜禽粪污厌氧发酵预处理技术研究进展[J]. 能源环境保护,2021,35(6):42-48.

[2]周海宾,丁京涛,孟海波,等. 中国畜禽粪污资源化利用技术应用调研与发展分析[J]. 农业工程学报,2022,38(9):237-246.

[3]Yao Q F,Borjihan Q,Qu H H,et al. Cow dung-derived biochars engineered as antibacterial agents for bacterial decontamination[J]. Journal of Environmental Sciences,2021,105:33-43.

[4]王丽丽,孙东升,许 雷,等. 秸秆过滤猪场废水及滤料与猪粪好氧堆肥研究[J]. 农业工程学报,2022,38(19):180-189.

[5]Jawad J,Khalil M J,Sengar A K,et al. Experimental analysis and modeling of the methane degradation in a three stage biofilter using composted sawdust as packing media[J]. Journal of Environmental Management,2021,286:112214.

[6]Black Z,Balta I,Black L,et al. The fate of foodborne pathogens in manure treated soil[J]. Frontiers in Microbiology,2021,12:781357.

[7]Tran D T Q,Bradbury M I,Ogtrop F F V A N,et al. Environmental drivers for persistence of Escherichia coli and Salmonella in manure-amended soils:a meta-analysis[J]. Journal of Food Protection,2020,83(7):1268-1277.

[8]Fang C,Yuan X R,Liao K K,et al. Micro-aerobic conditions based on membrane-covered improves the quality of compost products:insights into fungal community evolution and dissolved organic matter characteristics[J]. Bioresource Technology,2022,362:127849.

[9]Jiang Z W,Lu Y Y,Xu J Q,et al. Exploring the characteristics of dissolved organic matter and succession of bacterial community during composting[J]. Bioresource Technology,2019,292:121942.

[10]Wu J Q,Wei Z M,Zhu Z C,et al. Humus formation driven by ammonia-oxidizing bacteria during mixed materials composting[J]. Bioresource Technology,2020,311:123500

[11]Jennifer E,Adam G,Mark B,et al. Persistence of human pathogens in manure-amended Australian soils used for production of leafy vegetables[J]. Agriculture,2020,11(1):14.

[12]Loss A,Couto R,Brunetto G,et al. Animal manure as fertilizer:changes in soil attributes,productivity and food composition[J]. International Journal of Research-GRANTHAALAYAH,2019,7(9):307-331.

[13]陳文旭,刘逸飞,蒋思楠,等. 微生物菌剂对厨余垃圾堆肥温室气体减排的影响[J]. 农业工程学报,2022,38(23):181-187.

[14]Huang D L,Gao L,Cheng M,et al. Carbon and N conservation during composting:a review[J]. Science of the Total Environment,2022,840:156355.

[15]李文圣. 不同组群奶牛粪便堆积过程中温室气体排放及碳氮转化规律[D]. 杨凌:西北农林科技大学,2015.

[16]Voběrková S,Vaverková M D,Adamcová D. Enzyme production during composting of aliphatic–aromatic copolyesters in organic wastes[J]. Environmental Engineering Science,2017,34(3):177-184.

[17]Liang C,Schimel J P,Jastrow J D. The importance of anabolism in microbial control over soil carbon storage[J]. Nature Microbiology,2017,2(8):1-6.

[18]Ma S S,Sun X X,Fang C,et al. Exploring the mechanisms of decreased methane during pig manure and wheat straw aerobic composting covered with a semi-permeable membrane[J]. Waste Management,2018,78:393-400.

[19]Zhao Y,Zhao Y,Zhang Z C,et al. Effect of thermo-tolerant actinomycetes inoculation on cellulose degradation and the formation of humic substances during composting[J]. Waste Management,2017,68:64-73.

[20]聶晓瑀,于春静,卢 倩,等. 微生物在农作物秸秆好氧堆肥过程中的研究进展[J]. 中国农学通报,2022,38(26):76-81.

[21]Ye P P,Fang L F,Song D,et al. Insights into carbon loss reduction during aerobic composting of organic solid waste:a meta-analysis and comprehensive literature review[J]. Science of the Total Environment,2023,862:160787.

[22]Wei Z M,Ahmed M T,Zhao L,et al. Microhabitat drive microbial anabolism to promote carbon sequestration during composting[J]. Bioresource Technology,2022,346:126577.

[23]Jones S W,Fast A G,Carlson E D,et al. CO2fixation by anaerobic non-photosynthetic mixotrophy for improved carbon conversion[J]. Nature Communications,2016,7:12800.

[24]Yu C J,Lu Q,Fu C,et al. Exploring the internal driving mechanism underlying bacterial community-induced organic component conversion and humus formation during rice straw composting with tricarboxylic acid cycle regulator addition[J]. Bioresource Technology,2022,365:128149.

[25]Cotrufo M F,Soong J L,Horton A J,et al. Formation of soil organic matter via biochemical and physical pathways of litter mass loss[J]. Nature Geoscience,2015,8(10):776-779.

[26]Wang S G,Zeng Y. Ammonia emission mitigation in food waste composting:a review[J]. Bioresource Technology,2018,248:13-19.

[27]Wang R X,Zhao Y,Xie X Y,et al. Role of NH3recycling on nitrogen fractions during sludge composting[J]. Bioresource Technology,2020,295:122175.

[28]Chowdhury M A,de Neergaard A,Jensen L S. Composting of solids separated from anaerobically digested animal manure:effect of different bulking agents and mixing ratios on emissions of greenhouse gases and ammonia[J]. Biosystems Engineering,2014,124:63-77.

[29]Cáceres R,Malińska K,Marfà O. Nitrification within composting:a review[J]. Waste Management,2018,72:119-137.

[30]Yang Y J,Kumar A M,Wu L L,et al. Microbial driving mechanism of biochar and bean dregs on NH3and N2O emissions during composting[J]. Bioresource Technology,2020,315:123829.

[31]Chen H Y,Awasthi M K,Liu T,et al. Influence of clay as additive on greenhouse gases emission and maturity evaluation during chicken manure composting[J]. Bioresource Technology,2018,266:82-88.

[32]Zheng J X,Liu J B,Han S H,et al. N2O emission factors of full-scale animal manure windrow composting in cold and warm seasons[J]. Bioresource Technology,2020,316:123905.

[33]Guo H H,Gu J,Wang X J,et al. Microbial driven reduction of N2O and NH3emissions during composting:effects of bamboo charcoal and bamboo vinegar[J]. Journal of Hazardous Materials,2020,390:121292.

[34]Nigussie A,Kuyper T W,Bruun S,et al. Vermicomposting as a technology for reducing nitrogen losses and greenhouse gas emissions from small-scale composting[J]. Journal of Cleaner Production,2016,139:429-439.

[35]Tang K,Baskaran V,Nemati M. Bacteria of the sulphur cycle:an overview of microbiology,biokinetics and their role in petroleum and mining industries[J]. Biochemical Engineering Journal,2009,44(1):73-94.

[36]Chen L X,Ren Y L,Lin J Q,et al. Acidithiobacillus caldus sulfur oxidation model based on transcriptome analysis between the wild type and sulfur oxygenase reductase defective mutant[J]. PLoS One,2012,7(9):e39470.

[37]Schiavon M,Martini L M,Corrà C,et al. Characterisation of volatile organic compounds (VOCs) released by the composting of different waste matrices[J]. Environmental Pollution,2017,231:845-853.

[38]Drennan M F,DiStefano T D. Characterization of the curing process from high-solids anaerobic digestion[J]. Bioresource Technology,2010,101(2):537-544.

[39]Zhang H Y,Li G X,Gu J,et al. Influence of aeration on volatile sulfur compounds (VSCs) and NH3emissions during aerobic composting of kitchen waste[J]. Waste Management,2016,58:369-375.

[40]Ma R N,Liu Y,Wang J N,et al. Effects of oxygen levels on maturity,humification,and odor emissions during chicken manure composting[J]. Journal of Cleaner Production,2022,369:133326.

[41]Fisher R M,Le-Minh N,Alvarez-Gaitan J P,et al. Emissions of volatile sulfur compounds (VSCs) throughout wastewater biosolids processing[J]. Science of the Total Environment,2018,616/617:622-631.

[42]Wang J,Chu Y X,Tian G M,et al. Estimation of sulfur fate and contribution to VSC emissions from lakes during algae decay[J]. Science of the Total Environment,2023,856:159193.

[43]Iqbal M K,Nadeem A,Sherazi F,et al. Optimization of process parameters for kitchen waste composting by response surface methodology[J]. International Journal of Environmental Science and Technology,2015,12(5):1759-1768.

[44]Li D Y,Yuan J,Ding J T,et al. Effects of carbon/nitrogen ratio and aeration rate on the sheep manure composting process and associated gaseous emissions[J]. Journal of Environmental Management,2022,323:116093.

[45]Zhang L,Zhao T T,Shi E H,et al. The non-negligibility of greenhouse gas emission from a combined pre-composting and vermicomposting system with maize stover and cow dung[J]. Environmental Science and Pollution Research,2021,28(15):19412-19423.

[46]Huang G F,Wong J W C,Wu Q T,et al. Effect of C/N on composting of pig manure with sawdust[J]. Waste Management,2004,24(8):805-813.

[47]Yu K,Li S Y,Sun X Y,et al. Maintaining the ratio of hydrosoluble carbon and hydrosoluble nitrogen within the optimal range to accelerate green waste composting[J]. Waste Management,2020,105:405-413.

[48]Ogunwande G A,Osunade J A,Adekalu K O,et al. Nitrogen loss in chicken litter compost as affected by carbon to nitrogen ratio and turning frequency[J]. Bioresource Technology,2008,99(16):7495-7503.

[49]Zhang L,Sun X Y. Influence of bulking agents on physical,chemical,and microbiological properties during the two-stage composting of green waste[J]. Waste Management,2016,48:115-126.

[50]Zhang L,Sun X Y. Improving green waste composting by addition of sugarcane bagasse and exhausted grape marc[J]. Bioresource Technology,2016,218:335-343.

[51]Lazcano C,Gómez-Brandón M,Domínguez J. Comparison of the effectiveness of composting and vermicomposting for the biological stabilization of cattle manure[J]. Chemosphere,2008,72(7):1013-1019.

[52]Zhao B,Wang Y Y,Ma L T,et al. Adding an appropriate proportion of phosphogypsum ensured rice husk and urea composting to promote the compost as substrate utilization[J]. Bioresource Technology,2022,344:126301.

[53]Chan M T,Selvam A,Wong J W C. Reducing nitrogen loss and salinity during ‘struvite food waste composting by zeolite amendment[J]. Bioresource Technology,2016,200:838-844.

[54]Wang Y J,Pang L,Liu X Y,et al. Using thermal balance model to determine optimal reactor volume and insulation material needed in a laboratory-scale composting reactor[J]. Bioresource Technology,2016,206:164-172.

[55]Wang Y,Liu S J,Xue W T,et al. The characteristics of carbon,nitrogen and sulfur transformation during cattle manure composting:based on different aeration strategies[J]. International Journal of Environmental Research and Public Health,2019,16(20):3930.

[56]Gu W J,Sun W,Lu Y S,et al. Effect of Thiobacillus thioparus 1904 and sulphur addition on odour emission during aerobic composting[J]. Bioresource Technology,2018,249:254-260.

[57]Keng Z X,Chong S,Ng C G,et al. Community-scale composting for food waste:a life-cycle assessment-supported case study[J]. Journal of Cleaner Production,2020,261:121220.

[58]Oertel C,Matschullat J,Zurba K,et al. Greenhouse gas emissions from soils:a review[J]. Geochemistry,2016,76(3):327-352.

[59]Komilis D P,Tziouvaras I S. A statistical analysis to assess the maturity and stability of six composts[J]. Waste Management,2009,29(5):1504-1513.

[60]Li S,Huang G H,An C J,et al. Effect of different buffer agents on in-vessel composting of food waste:performance analysis and comparative study[J]. Journal of Environmental Science and Health(Part A),2013,48(7):772-780.

[61]Paradelo R,Moldes A B,Barral M T. Evolution of organic matter during the mesophilic composting of lignocellulosic winery wastes[J]. Journal of Environmental Management,2013,116:18-26.

[62]Yu H,Huang G H. Effects of sodium acetate as a pH control amendment on the composting of food waste[J]. Bioresource Technology,2009,100(6):2005-2011.

[63]Puyuelo B,Gea T,Sánchez A. A new control strategy for the composting process based on the oxygen uptake rate[J]. Chemical Engineering Journal,2010,165(1):161-169.

[64]Zheng G D,Wang Y W,Wang X K,et al. Oxygen monitoring equipment for sewage-sludge composting and its application to aeration optimization[J]. Sensors,2018,18(11):4017.

[65]Zhao S,Yang X F,Zhang W J,et al. Volatile sulfide compounds (VSCs) and ammonia emission characteristics and odor contribution in the process of municipal sludge composting[J]. Journal of the Air & Waste Management Association,2019,69(11):1368-1376.

[66]Fang C,Yin H J,Han L J,et al. Effects of semi-permeable membrane covering coupled with intermittent aeration on gas emissions during aerobic composting from the solid fraction of dairy manure at industrial scale[J]. Waste Management,2021,131:1-9.

[67]Wang K,Li W G,Guo J H,et al. Spatial distribution of dynamics characteristic in the intermittent aeration static composting of sewage sludge[J]. Bioresource Technology,2011,102(9):5528-5532.

[68]Chen J,Chen T B,Gao D,et al. Reducing H2S production by O2feedback control during large-scale sewage sludge composting[J]. Waste Management,2011,31(1):65-70.

[69]Petric I,Helic' A,Avdic' E A. Evolution of process parameters and determination of kinetics for co-composting of organic fraction of municipal solid waste with poultry manure[J]. Bioresource Technology,2012,117:107-116.

[70]Barthod J,Rumpel C,Dignac M F.Composting with additives to improve organic amendments:a review[J]. Agronomy for Sustainable Development,2018,38(2):17.

[71]Petric I,Mustafic' N. Dynamic modeling the composting process of the mixture of poultry manure and wheat straw[J]. Journal of Environmental Management,2015,161:392-401.

[72]Luangwilai T,Sidhu H S,Nelson M I. One-dimensional spatial model for self-heating in compost piles:investigating effects of moisture and air flow[J]. Food and Bioproducts Processing,2018,108:18-26.

[73]Makan A,Assobhei O,Mountadar M. Effect of initial moisture content on the in-vessel composting under air pressure of organic fraction of municipal solid waste in Morocco[J]. Iranian Journal of Environmental Health Science & Engineering,2013,10(1):3.

[74]Guo R,Li G X,Jiang T,et al. Effect of aeration rate,C/N ratio and moisture content on the stability and maturity of compost[J]. Bioresource Technology,2012,112:171-178.

[75]Higgins B T,Chaump K,Wang Q C,et al. Moisture content and aeration control mineral nutrient solubility in poultry litter[J]. Journal of Environmental Management,2021,300:113787.

[76]Liu X Y,Zhang L.Effects of additives on the co-composting of forest residues with cattle manure[J]. Bioresource Technology,2023,368:128384.

[77]Zhu P,Shen Y L,Pan X S,et al. Reducing odor emissions from feces aerobic composting:additives[J]. RSC Advances,2021,11(26):15977-15988.

[78]Mao H,Zhang T,Li R H,et al. Apple pomace improves the quality of pig manure aerobic compost by reducing emissions of NH3and N2O[J]. Scientific Reports,2017,7(1):1-8.

[79]Yuan J,Zhang D F,Du L L,et al. Effect of woody peat as an additive on maturity and gaseous emissions during pig manure composting[J]. Compost Science & Utilization,2019,27(2):69-80.

[80]張红玉,李国学,袁 京,等. 固氮添加剂降低厨余垃圾堆肥中NH3和H2S排放[J]. 农业工程学报,2013,29(23):173-178.

[81]李 赟,袁 京,李国学,等. 辅料添加对厨余垃圾快速堆肥腐熟度和臭气排放的影响[J]. 中国环境科学,2017,37(3):1031-1039.

[82]Li R H,Wang Q,Zhang Z Q,et al. Nutrient transformation during aerobic composting of pig manure with biochar prepared at different temperatures[J]. Environmental Technology,2015,36(7):815-826.

[83]Zhang B X,Xu Z C,Jiang T,et al. Gaseous emission and maturity in composting of livestock manure and tobacco wastes:effects of aeration intensities and mitigation by physiochemical additives[J]. Environmental Technology & Innovation,2020,19:100899.

[84]Yin Y N,Yang C,Li M T,et al. Research progress and prospects for using biochar to mitigate greenhouse gas emissions during composting:a review[J]. Science of the Total Environment,2021,798:149294.

[85]Shan G C,Li W G,Gao Y J,et al. Additives for reducing nitrogen loss during composting:a review[J]. Journal of Cleaner Production,2021,307:127308.

[86]Awasthi M K,Wang Q,Huang H,et al. Influence of zeolite and lime as additives on greenhouse gas emissions and maturity evolution during sewage sludge composting[J]. Bioresource Technology,2016,216:172-181.

[87]Taheri-Soudejani H,Heidarpour M,Shayannejad M,et al. Composts containing natural and Mg-modified zeolite:the effect on nitrate leaching,drainage water,and yield[J]. Clean,2019,47(8):1800257.1-1800257.9.

[88]Ren X N,Wang Q,Chen X,et al. Elucidating the optimum added dosage of diatomite during co-composting of pig manure and sawdust:carbon dynamics and microbial community[J]. Science of the Total Environment,2021,777:146058.

[89]Li M H,Li S Y,Chen S G,et al. Measures for controlling gaseous emissions during composting:a review[J]. International Journal of Environmental Research and Public Health,2023,20(4):3587.

[90]Wilson C A,Tanneru C T,Banjade S,et al. Anaerobic digestion of raw and thermally hydrolyzed wastewater solids under various operational conditions[J]. Water Environment Research,2011,83(9):815-825.

[91]Yuan J,Yang Q Y,Zhang Z Y,et al. Use of additive and pretreatment to control odors in municipal kitchen waste during aerobic composting[J]. Journal of Environmental Sciences,2015,37:83-90.

[92]Dhar B R,Elbeshbishy E,Hafez H,et al. Thermo-oxidative pretreatment of municipal waste activated sludge for volatile sulfur compounds removal and enhanced anaerobic digestion[J]. Chemical Engineering Journal,2011,174(1):166-174.

[93]Gao X Z,Yang F Y,Cheng J W,et al. Emission of volatile sulphur compounds during swine manure composting:source identification,odour mitigation and assessment[J]. Waste Management,2022,153:129-137.

[94]Jiang J S,Huang Y M,Liu X L,et al. The effects of apple pomace,bentonite and calcium superphosphate on swine manure aerobic composting[J]. Waste Management,2014,34(9):1595-1602.

[95]Cao Y B,Wang X,Liu L,et al. Acidification of manure reduces gaseous emissions and nutrient losses from subsequent composting process[J]. Journal of Environmental Management,2020,264:110454.

[96]Li Y B,Liu T T,Song J L,et al. Effects of chemical additives on emissions of ammonia and greenhouse gas during sewage sludge composting[J]. Process Safety and Environmental Protection,2020,143:129-137.

[97]Pan J T,Cai H Z,Zhang Z Q,et al. Comparative evaluation of the use of acidic additives on sewage sludge composting quality improvement,nitrogen conservation,and greenhouse gas reduction[J]. Bioresource Technology,2018,270:467-475.

[98]Liu B B,Morkved P T,Frostegard A,et al. Denitrification gene pools,transcription and kinetics of NO,N2O and N2production as affected by soil pH[J]. FEMS Microbiology Ecology,2010,72(3):407-417.

[99]Jeong Y K,Kim J S.A new method for conservation of nitrogen in aerobic composting processes[J]. Bioresource Technology,2001,79(2):129-133.

[100]Fukumoto Y,Suzuki K,Kuroda K,et al. Effects of struvite formation and nitratation promotion on nitrogenous emissions such as NH3,N2O and NO during swine manure composting[J]. Bioresource Technology,2011,102(2):1468-1474.

[101]Li Y,Su B S,Liu J L,et al. Nitrogen conservation in simulated food waste aerobic composting process with different Mg and P salt mixtures[J]. Journal of the Air & Waste Management Association,2011,61(7):771-777.

[102]Jiang T,Ma X G,Yang J,et al. Effect of different struvite crystallization methods on gaseous emission and the comprehensive comparison during the composting[J]. Bioresource Technology,2016,217:219-226.

[103]Wang Q,Awasthi M K,Ren X N,et al. Combining biochar,zeolite and wood vinegar for composting of pig manure:the effect on greenhouse gas emission and nitrogen conservation[J]. Waste Management,2018,74:221-230.

[104]Zhang D F,Luo W H,Yuan J,et al. Effects of woody peat and superphosphate on compost maturity and gaseous emissions during pig manure composting[J]. Waste Management,2017,68:56-63.

[105]Dai Y,Di H J,Cameron K C,et al. Effects of nitrogen application rate and a nitrification inhibitor dicyandiamide on ammonia oxidizers and N2O emissions in a grazed pasture soil[J]. Science of the Total Environment,2013,465:125-135.

[106]Yuan J,Li Y,Chen S L,et al. Effects of phosphogypsum,superphosphate,and dicyandiamide on gaseous emission and compost quality during sewage sludge composting[J]. Bioresource Technology,2018,270:368-376.

[107]Lu J W,Wang J G,Gao Q,et al. Effect of microbial inoculation on carbon preservation during goat manure aerobic composting[J]. Molecules,2021,26(15):4441.

[108]Yu J,Gu J,Wang X J,et al. Effects of inoculation with lignocellulose-degrading microorganisms on nitrogen conversion and denitrifying bacterial community during aerobic composting[J]. Bioresource Technology,2020,313:123664.

[109]Kuroda K,Waki M,Yasuda T,et al. Utilization of Bacillus sp. strain TAT105 as a biological additive to reduce ammonia emissions during composting of swine feces[J]. Bioscience,Biotechnology,and Biochemistry,2015,79(10):1702-1711.

[110]Lu Y S,Gu W J,Xu P Z,et al. Effects of sulphur and Thiobacillus thioparus 1904 on nitrogen cycle genes during chicken manure aerobic composting[J]. Waste Management,2018,80:10-16.

[111]Zhao Y,Li W G,Chen L,et al. Effect of enriched thermotolerant nitrifying bacteria inoculation on reducing nitrogen loss during sewage sludge composting[J]. Bioresource Technology,2020,311:123461.

[112]趙欧亚,侯利敏,孙世友,等. 不同商品发酵菌剂对牛粪堆肥微生物群落的影响[J]. 江苏农业科学,2022,50(14):239-244.

[113]Chen L,Li W G,Zhao Y,et al. Effects of compound bacterial agent on gaseous emissions and compost maturity during sewage sludge composting[J]. Journal of Cleaner Production,2022,366:133015.

[114]Lei L S,Gu J,Wang X J,et al. Effects of phosphogypsum and medical stone on nitrogen transformation,nitrogen functional genes,and bacterial community during aerobic composting[J]. Science of the Total Environment,2021,753:141746.

[115]Wang Q,Awasthi M K,Ren X N,et al. Comparison of biochar,zeolite and their mixture amendment for aiding organic matter transformation and nitrogen conservation during pig manure composting[J]. Bioresource Technology,2017,245:300-308.

[116]Tang J H,Li X,Zhao W Q,et al. Electric field induces electron flow to simultaneously enhance the maturity of aerobic composting and mitigate greenhouse gas emissions[J]. Bioresource Technology,2019,279:234-242.

[117]Fu T,Shangguan H Y,Wu J X,et al. Insight into the synergistic effects of conductive biochar for accelerating maturation during electric field-assisted aerobic composting[J]. Bioresource Technology,2021,337:125359.

[118]Tan Z H,Dong B,Xing M Y,et al. Electric field applications enhance the electron transfer capacity of dissolved organic matter in sludge compost[J]. Environmental Technology,2024,45(2):283-293.

[119]Yuan Y,Xi B D,He X S,et al. Insights into the redox components of dissolved organic matters during stabilization process[J]. Environmental Science and Pollution Research,2018,25(13):13026-13034.

[120]楊丽楠,李 昂,袁春燕,等. 半透膜覆盖好氧堆肥技术应用现状综述[J]. 环境科学学报,2020,40(10):3559-3564.

[121]Song Y J,Li R Y,Wang Y X,et al. Co-composting of cattle manure and wheat straw covered with a semipermeable membrane:organic matter humification and bacterial community succession[J]. Environmental Science and Pollution Research,2023,30(12):32776-32789.

[122]段自豪,夏 慧,黄 魁,等. 蚯蚓对污泥堆肥过程中活性真核微生物的影响[J]. 环境科学学报,2023,43(4):408-416.

[123]Liu T,Awasthi M,Chen H Y,et al. Performance of black soldier fly larvae (Diptera:Stratiomyidae) for manure composting and production of cleaner compost[J]. J Environ Manage,2019,109593.

[124]Aira M,Olcina J,Pérez-Losada M,et al. Characterization of the bacterial communities of casts from Eisenia andrei fed with different substrates[J]. Applied Soil Ecology,2016,98:103-111.

[125]Liew C S,Yunus N M,Chidi B S,et al. A review on recent disposal of hazardous sewage sludge via anaerobic digestion and novel composting[J]. Journal of Hazardous Materials,2022,423(Pt A):126995.

[126]Huang K,Chen J Y,Guan M X,et al. Effects of biochars on the fate of antibiotics and their resistance genes during vermicomposting of dewatered sludge[J]. Journal of Hazardous Materials,2020,397:122767.

[127]Siddiqui S A,Ristow B,Rahayu T,et al. Black soldier fly larvae (BSFL) and their affinity for organic waste processing[J]. Waste Management,2022,140:1-13.

[128]Liu T,Awasthi S K,Qin S Y,et al. Conversion food waste and sawdust into compost employing black soldier fly larvae (Diptera:Stratiomyidae) under the optimized condition[J]. Chemosphere,2021,272:129931.